5 Important Benefits of Procurement Data Management

As an experienced procurement professional, you understand the importance of relying on accurate and real-time information to make decisions.

From selecting suitable suppliers to ensuring timely purchases or navigating turbulent times—investing in tools that collect, analyze, and manage data can help you immensely in all these aspects of procurement.

Moreover, relying on data can bring numerous benefits to your organization, such as cost savings, better operational efficiency, and fewer risks.

We invite you to keep reading as we explore these and other benefits of procurement data management in more detail.

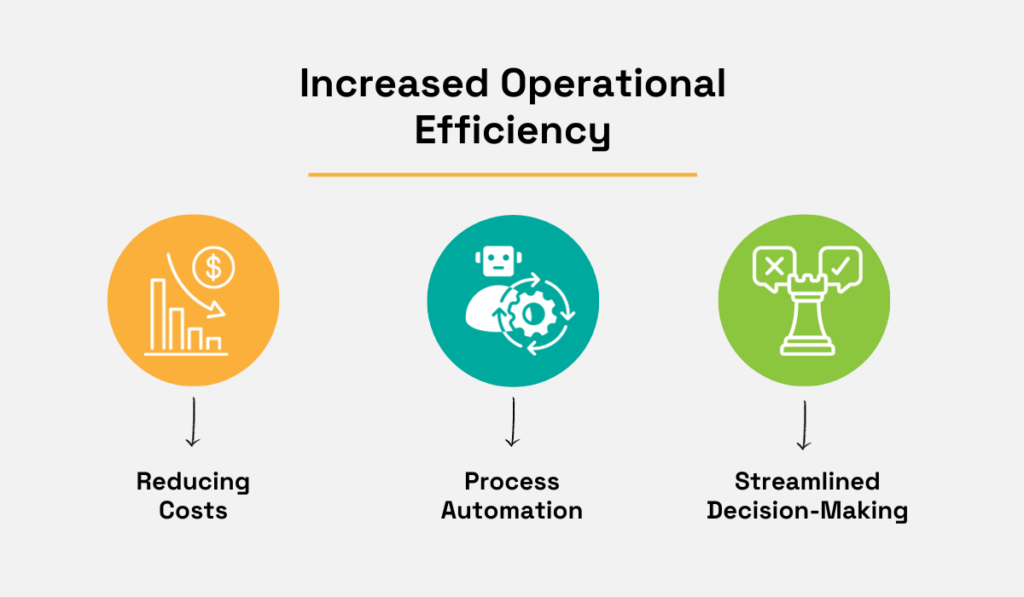

Collecting, analyzing, and managing your procurement data in the right way can significantly increase your operational efficiency.

In other words, you can optimize workflows, minimize waste, and achieve procurement objectives with optimal resource utilization.

Let’s see how in more detail.

First and foremost, data driven procurement requires tools i.e. software to collect and analyze data.

This results in procurement automation that frees up your time for strategic activities by handling routine tasks.

Consider how much time your in-house data analysts would need to manually collect and analyze data about potential suppliers.

However, with a data management system in place, or by using external sources that can automatically retrieve this information, your procurement team can save valuable time, leading to reduced manual work and significant time savings.

Take Apple and its supplier data management system, as an example.

Instead of tedious searching for supplier information, they rely on their secure online database, the Prospective Supplier Portal, to identify suitable suppliers.

Source: Apple

They ask suppliers to register and provide all necessary information in one place.

Apple’s procurement experts can then access this data to analyze and compare it instead of spending countless hours searching through their internal and external sources.

This gives them more time to make better decisions.

By relying on data, you can get real-time insights into your procurement process.

These insights can empower you to make faster, better-informed decisions that can improve your entire procurement.

For example, when you have up-to-the-minute data on inventory levels, you can make timely reorder decisions and avoid stockouts or overstocking, thus preventing delays and waste.

Streamlined decision-making and procurement automation both contribute to cost reduction and savings.

But you can identify even more cost-saving opportunities through efficient data management.

For example, data management enables you to track and analyze waste in your procurement processes, including identifying redundant steps, reducing packaging waste, and optimizing transportation routes.

We will come back to this benefit in the following sections.

In summary, procurement data management can enhance your operational efficiency in more ways than you might imagine.

Source: Veridion

Automating your procurement processes, streamlining your decision-making, and reducing your costs would hardly be possible without proper procurement data management.

Another crucial benefit of procurement data management is the minimization of supplier risks.

Suppliers are arguably the most critical factors in the procurement process.

Whether your procurement will be efficient depends on your supplier selection and continuous relationship with your suppliers.

However, from the moment you consider a supplier to work with, you also have to consider the risks associated with them.

This is underscored by a survey by Deloitte, which has shown that as much as 75% of Chief Procurement Officers (CPOs) use supplier risk scoring as one of the crucial factors in supplier sourcing.

Illustration: Veridion / Data: Deloitte

It’s precisely collecting and analyzing procurement data that can help you in both supplier sourcing and minimizing supplier risks.

Let’s explain how.

If we go back to Apple’s supplier data management system, we can see that they collect information about their potential suppliers through a single portal.

This includes contact information, company location, capabilities, product descriptions, industry classification codes, and certifications.

By leveraging this data, Apple’s procurement team can categorize suppliers into those with specific certifications required to work with Apple and those without.

Or, in other words, suppliers that present more significant risks and those that come with fewer risks.

Of course, that is not enough for risk assessment, but it marks the first step in minimizing supplier risks for them.

In many cases, companies also utilize third-party services, such as big data platforms, for more thorough risk assessment.

The insights these data platforms provide can empower you to make better supplier-sourcing decisions and help you with risk monitoring later in the procurement process.

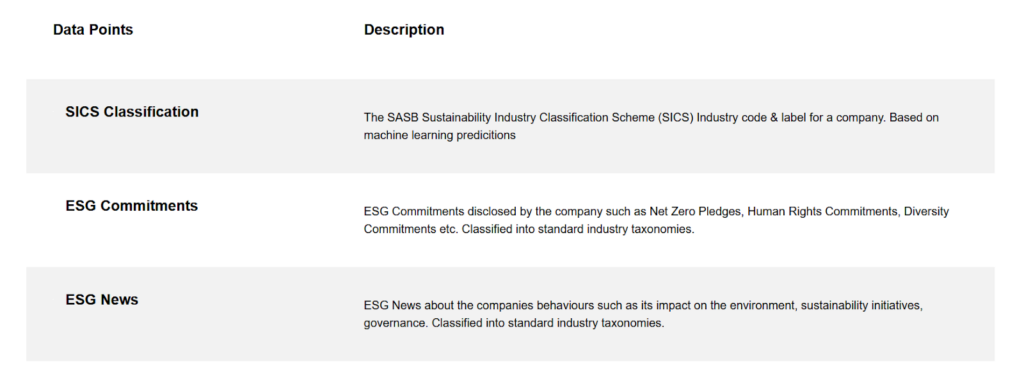

Veridion is one such big data company.

At Veridion, we provide a global database with continuously updated supplier information. Our goal is to provide companies with precise, near-real-time data to mitigate supplier risks.

Source: Veridion

What sets Veridion apart is not only our database of suppliers, which assists in finding the right ones for you but also our ability to track changes in supplier activities in near-real-time.

This capability allows us to alert you when a supplier changes location, loses a certification, or poses another type of risk.

All these insights can significantly reduce supplier risks.

Additionally, with our company search service, you can further minimize risks by searching for suppliers using specific criteria such as sustainability and ESG criteria, as seen below:

Source: Veridion

Prioritizing suppliers with strong ESG credentials is the new norm—and rightfully so, knowing that sustainability practices align with ethical and environmental concerns.

What is more, sourcing suppliers based on this criterion also safeguards against reputation damage and potential legal fines.

Therefore, utilizing a data platform that can give you accurate information to perform ESG risk assessments seems inevitable.

In conclusion, by collecting and analyzing supplier data during the supplier discovery process, you can identify more suitable suppliers with fewer associated risks.

Relying on accurate data on suppliers can help mitigate risks later in the procurement process, too.

Finally, data management can empower you to make more informed and strategic decisions when working with your suppliers.

Effective procurement data management equips your organization with essential tools for gaining deeper insights into supplier performance.

These insights, derived from data on purchase orders, delivery times, product quality assessments, and supplier responsiveness yield numerous advantages, including:

When you have access to this procurement data, you can objectively assess your suppliers’ performance and identify those that are underperforming and causing disruptions in your supply chain.

Take, for example, the persistent challenge of shipping delays—an issue that Deloitte’s 2022 Manufacturing Supply Chain Study revealed could negatively impact profits by up to 13%.

Shipping delays are a major challenge for any organization, as they can lead to manufacturing line stoppages, increased transportation costs, and unhappy customers.

However, this is where data analysis can help.

By continuously monitoring your suppliers’ performance data, you can pinpoint those consistently failing to meet delivery deadlines and take measures to address the issue.

You may choose to work closely with underperforming suppliers to improve their delivery reliability or, where necessary, explore alternative suppliers that can better meet your deadlines.

But the benefits of procurement data analysis continue beyond this.

You can also leverage data to compare the performance of multiple suppliers against one another, allowing you to quickly identify top performers and underperformers.

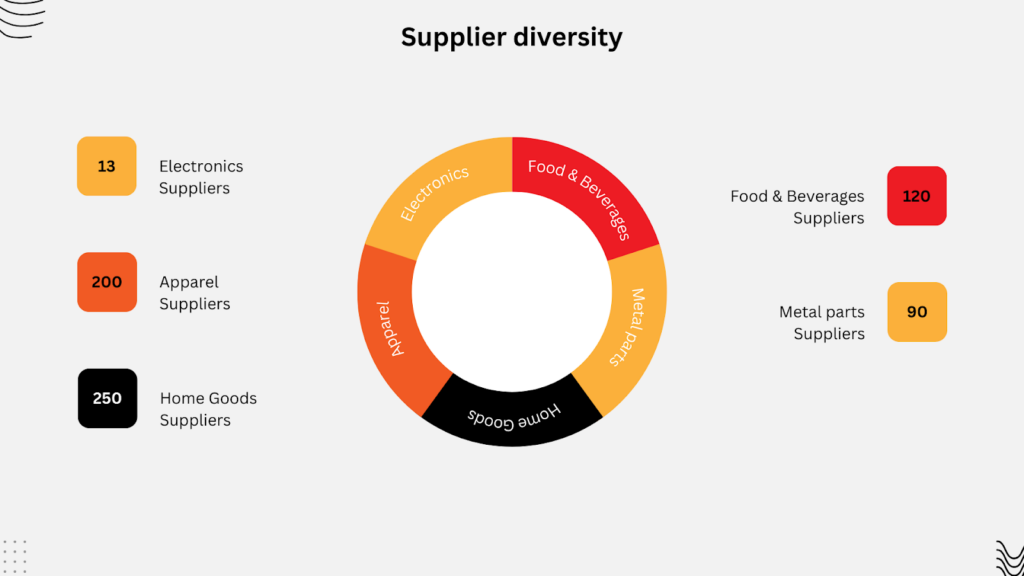

This benchmarking forms the basis for supplier improvement initiatives and diversification strategies, enhancing the reliability and diversity of your supplier base.

Source: Veridion

Lastly, the power of data analysis extends to fostering collaborative relationships with your suppliers. Rather than merely pointing out shortcomings, data-driven discussions can lead to mutually beneficial solutions.

This collaborative approach nurtures better performance and long-term supplier relationships—the number one strategy to deliver the most value to procurement in 2023 for 61% of CPOs.

In summary, scrutinizing supplier data provides a clearer understanding of how their performance affects your procurement process.

This empowers you to make well-informed decisions, ensuring the quality you’ve invested in.

When it comes to procurement data management, one of the standout benefits is the ability to uncover cost-saving opportunities.

One straightforward approach is to analyze your supplier performance data.

By doing so, you can identify underperforming suppliers who might not deliver the expected value for the price you pay, as we explained earlier.

But there is more to this with procurement data management.

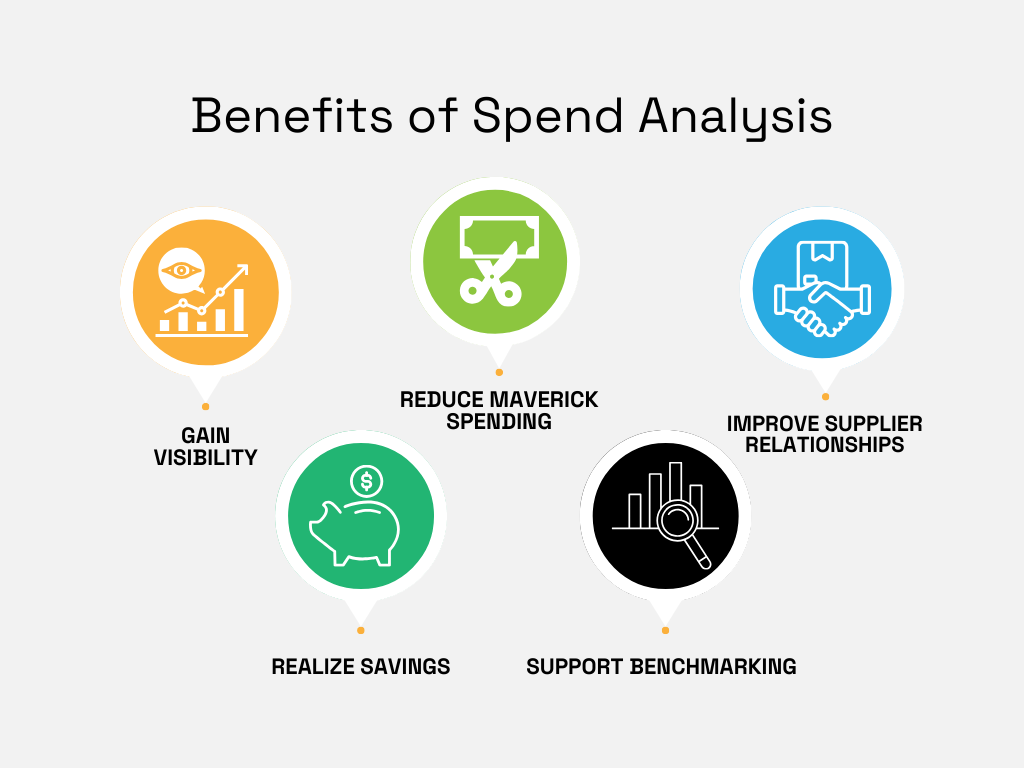

In fact, you can conduct spend analysis across your entire procurement process to get insights into where your organization is spending money and, more importantly, where you can cut costs.

Source: Veridion

One aspect of spend analysis is reducing maverick spending—unauthorized or off-contract purchases that can result in higher costs.

For example, employees in other departments may make purchases outside of negotiated contracts, causing inefficiencies and increased expenses.

Data management helps pinpoint such maverick spending instances so you can take corrective actions.

But there are also other ways in which data management can increase your savings.

For example, you can leverage data to get real-time insights into your inventory levels, which helps you reduce the costs of overstocking or understocking.

But it’s not only you who can have these insights—your suppliers can, too.

Take, for example, Walmart.

Their suppliers also have real-time visibility into Walmart’s inventory levels, simplifying the entire process of managing logistics.

Their suppliers are the ones who directly make sure the in-demand products are promptly restocked.

This—let’s say—automated approach is possible because of real-time data, which enhances visibility across suppliers and makes sure the right decisions are made on time.

But Walmart goes even further in finding ways to increase cost (and time) savings by relying on data.

Having over 100,000 suppliers, negotiating with such a massive base can be challenging. So, they found an innovative solution—automated negotiations using artificial intelligence.

Source: Veridion

This strategy relies on precise supplier data, particularly regarding payment terms and opportunities for improved terms and additional discounts.

Simply put, instead of people negotiating with all these suppliers, they use AI chatbots that rely on accurate and fresh data to make negotiations.

And the results are quite impressive.

Walmart’s chatbot successfully reached agreements with 64% of suppliers, well exceeding the initial 20% target. The negotiations had an average turnaround of just 11 days.

By relying on accurate data, Walmart achieved an average savings of 1.5% on the negotiated spend and extended payment terms to an average of 35 days.

This innovative approach significantly increased their cost savings, eliminating the need for individual negotiations with each supplier.

Walmart’s success story shows a new approach to procurement data management, leading to increased cost savings.

With the ongoing evolution of technology and data analytics, we can expect more companies to adopt similar strategies in pursuit of cost-efficient procurement practices.

After all, increased cost savings represent not only a benefit of procurement data management but also a strategic advantage in a competitive market.

The final but equally essential benefit we’ll explore today is the capacity to gain a competitive edge by analyzing procurement data.

Simply put, by effectively collecting, organizing, and utilizing data, you can outshine your competitors.

But how, you might ask?

The answer lies in using this data to make informed decisions and formulate more robust procurement strategies that we have been mentioning throughout this article.

It all comes down to seizing the advantage of insights gathered from your data.

The table below summarizes the ways to achieve a stronger competitive advantage.

| Increased Cost Savings | When you analyze your procurement data, you uncover opportunities for cost reduction. This includes identifying maverick spending and negotiating better terms with suppliers. These savings can be reinvested in other aspects of your procurement, giving you a financial edge over competitors. |

| Better Risk Management | Effective risk management, whether related to suppliers or supply chain disruptions, provides a competitive advantage. Many competitors struggle in this area because they lack accurate data for effective risk mitigation. |

| Improved Reputation | Managing procurement data helps you identify suppliers that align with your sustainability practices. Collaborating with like-minded suppliers who share ethical and environmental values enhances your reputation. Moreover, it allows you to meet the expectations of customers who demand transparent and ethical sourcing. |

On top of that, by relying on data, you can leverage innovations that can further help you save costs and stand out from the competition, as we saw with Walmart.

These are just a few examples of how procurement data management can set you apart from the competition.

In essence, procurement data management empowers your business to make informed decisions, manage risks effectively, and enhance your reputation.

And it is precisely these advantages that can position you to outperform your competitors in a highly competitive market.

In this article, we’ve explained five important benefits of procurement data management: improved operational efficiency, reduced supplier risks, better insight into supplier performance, cost savings, and a strengthened competitive edge.

We’ve demonstrated these advantages by looking at industry leaders like Apple and Walmart, who use data effectively to boost efficiency, cut costs, and manage risks.

So, if you want to reap these benefits and improve your procurement processes, now is the ideal moment to start managing your procurement data better.