7 Supplier Sourcing Mistakes to Avoid

Key Takeaways:

Supplier sourcing is the backbone of smooth business operations.

Its main role is to find reliable suppliers that will help the company sidestep supply chain risks and keep its operations running smoothly.

But while its impact is huge, sourcing isn’t always easy. Plenty of errors can turn this process into a costly ordeal if you’re not careful.

Here’s the good news, though: in this article, we’re exposing the most common mistakes in supplier sourcing.

We’ll be showing their consequences with real-world examples and expert insights, as well as sharing some tips to help you steer clear of them.

Let’s get started.

Many procurement teams make the mistake of starting the supplier selection process without clearly defining their needs first.

That’s a big problem because skipping this step can easily lead to confusion and misalignment between the vendor and the sourcing department.

And if a supplier doesn’t fully understand what you’re asking for, you’re unlikely to get it.

So, you may end up with a product that doesn’t meet your specifications or isn’t compatible with your company’s processes.

Rivian, the American electric vehicle manufacturer, learned this the hard way.

In their Q3 2024 vehicle forecast and delivery report, Rivian had to adjust its production estimate by as much as 18%, lowering it to between 47,000 and 49,000 vehicles.

Why?

According to Bloomberg, it was because Rivian miscalculated its copper winding requirements, which resulted in a miscommunication with a supplier and a subsequent shortage of this key component.

Source: Bloomberg

By the time the Rivian team realized they didn’t have enough copper windings, the supplier had already allocated resources to other customers.

The carmaker has since found alternative suppliers, but the last-minute nature of the switch has driven costs up.

Therefore, in the end, Rivian had no choice but to lower their production forecast.

This is a clear example of how a lack of planning can quickly spiral into bigger issues—production halts, added expenses, and decreased efficiency.

That’s why it’s so important to spend time upfront developing a detailed specification of exactly what you need from your suppliers.

Linda Tuck Chapman, CEO of Third Party Risk Institute Ltd., a company offering third-party risk management training and certifications, agrees.

Illustration: Veridion / Quote: LinkedIn

And don’t just focus on quantities, either.

Be sure to cover all your bases: technical requirements, performance standards, timelines, and quality benchmarks.

It’s also advisable to involve your internal stakeholders.

They often have insights that could help you better align with the organization’s broader goals, so let’s explore that in more detail.

It’s all too easy to fall into the trap of choosing suppliers who meet only your immediate procurement goals and needs, without considering the bigger picture.

However, this can be a significant strategic error.

Suppliers that don’t align with your organization’s mission or values can steer the company off course, jeopardizing both its goals and reputation.

For instance, if a business claims to prioritize ethical sourcing, but partners with vendors who fall short of those standards, it risks coming across as hypocritical.

Just look at Dior.

Despite their public commitment to sustainability, quality, and craftsmanship, they recently faced backlash after reports revealed some of their suppliers were underpaying workers and enforcing long hours.

Source: Forbes

Exploitative working conditions don’t exactly scream high quality and social responsibility, right?

In a statement to CNN, Dior acknowledged that Italian authorities had informed them of these suppliers’ “illegal practices” and has since pledged to cut ties with them:

“The house of Dior firmly condemns these unworthy acts, which contradict its values and the code of conduct signed by these suppliers… Despite regular audits, these two suppliers had evidently succeeded in hiding these practices.”

Nevertheless, the damage to their brand was already done.

This just goes to show how important it is to thoroughly evaluate suppliers before partnering up with them.

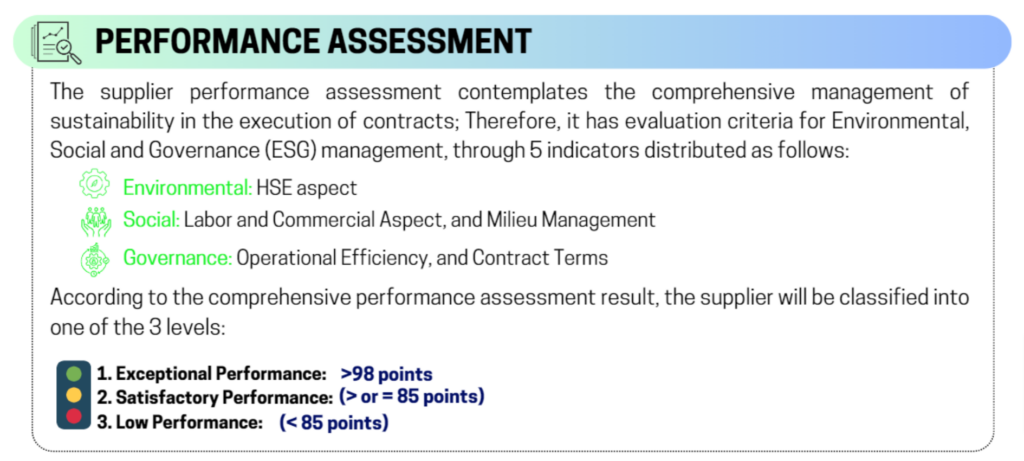

Why not take a page out of Ecopetrol’s book?

This largest and primary petroleum company in Colombia screens its potential partners meticulously.

According to their website, the evaluation process encompasses three key factors: Performance (criteria shown below), Strategic Potential, and Management Concept.

Source: Ecopetrol

This helps them ensure their vendors aren’t only aligned with their core values, but also support their future growth.

So, before you lock in a new supplier, ask yourself: will they bring us closer to our objectives, or lead us further away?

This one question could make all the difference in your supplier sourcing decisions.

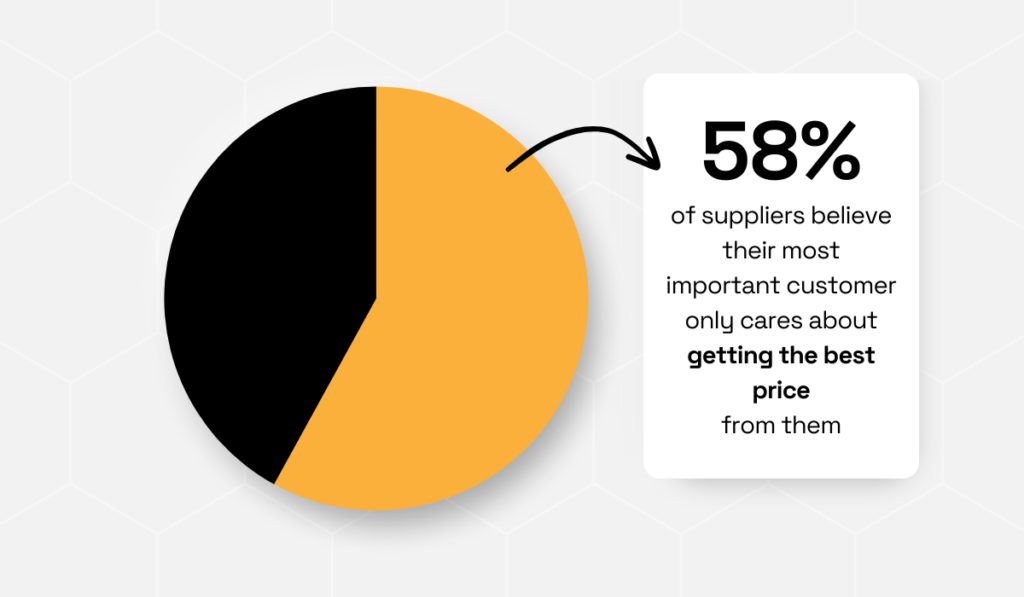

Prioritizing cost savings over quality is a bad idea that can backfire in so many ways, yet sourcing teams still make this mistake.

According to a HICX survey, 58% of suppliers report that getting the lowest price is exactly what their customers care about most.

Illustration: Veridion / Data: HICX

What these buyers don’t realize, however, is that they aren’t doing their companies any favors.

Sure, the initial purchase price might be lower, but the low-cost vendors often compromise on quality, which can then lead to a host of problems.

For example, back in 2007, Mattel had to recall 19 million toys they imported from China because they were covered in lead paint, making this incident the largest recall in their history.

Source: The New York Times

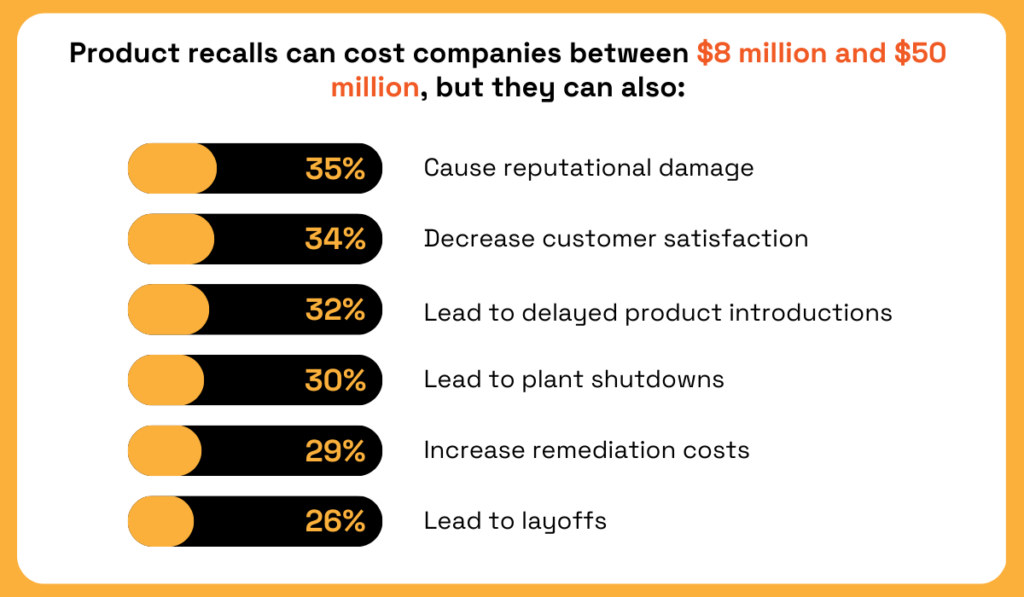

Not to mention the fact that the financial impact of product recalls is enormous.

A 2024 ETQ survey reveals that rectifying product recalls can cost businesses anywhere between $8 million and $50 million.

But the fallout doesn’t stop there. Recalls hit hard in other areas, too.

The survey found that respondents experienced:

Illustration: Veridion / Data: ETQ

The cause of these recalls?

In the majority of cases—61% of them—product recalls could be attributed precisely to supplier issues, the survey respondents claim.

So, does opting for lower-cost suppliers really help save money?

Hardly.

In fact, the hidden expenses and risks of poor quality mean that, in the end, the cheapest option often ends up being the most expensive one.

Even when comparing supplier prices, never focus solely on the initial purchase cost.

Instead, look at the total cost of ownership (TCO) of a product—or you may end up spending far more than expected.

Matthew Miles, DFMA and Value Engineering Manager at Dynisco Instruments, finds that the companies that neglect TCO simply can’t make sound sourcing decisions.

“All too often the people responsible will calculate the easy things like shipping rates, labor and material costs, and say, ‘Oh, wow. It’s cheaper over there.‘ Unfortunately, the things they overlooked—the cost of quality, additional warranty and service expense, travel expenditures, increased inventory, and so on—these all go into corporate overhead, which is then ‘peanut buttered’ across the entire organization.”

And the worst part?

They often fail to realize the broader impact of their choices until it’s too late.

This mistake is especially common in offshoring.

Assuming that cheaper suppliers will boost their profits, organizations switch to low-cost countries without considering the broader financial implications.

This includes both direct costs, like transportation, taxes, and fees, as well as indirect costs, such as inventory, quality, and risk.

So, what initially seems like an easy way to improve the bottom line quickly turns into quality issues, delays, stolen intellectual property, and late-night conference calls with managers in different time zones.

So, what’s the solution?

Easy—establish a comprehensive TCO evaluation framework before making any major sourcing decisions.

Here’s what to include in your TCO analysis:

| Purchase Price | The baseline product cost |

| Acquisition Costs | Transport, packaging, customs, and payment terms |

| Ownership Costs | Stock management, depreciation, and maintenance |

| Usage Costs | Operating costs, use value, and any related services |

| Quality Costs | Compliance, defect management, and rework |

| Disposal Costs | End-of-life costs, like recycling, resale, or disposal |

Assessing all these cost factors will provide a clearer understanding of the financial impact of each purchase and help you avoid costly surprises later on.

It’s much better to be proactive and analyze your decisions from all angles than having to constantly put out fires.

When negotiating with suppliers, being inflexible and focusing solely on your own wants are your biggest enemies.

This kind of behavior not only risks straining your relationship with the vendor—it could even drive them away from working with you in the future.

Sanchita Saxena, a visiting scholar at NYU’s Stern Center for Business, has been studying supplier-buyer relationships for some time now, particularly in the fashion industry.

She found that, unfortunately, many brands rely on an exploitative model, where they pressure suppliers to reduce costs or accept unreasonable terms.

In fact, one supplier told Saxena they felt “blackmailed” by their client, highlighting the toll these practices can take:

“The company was threatening [us] saying, if we don’t agree on a reasonable discount, maybe next season [our] business volume might be affected. We were also told that if we don’t give the discount then there might be cancellations coming, and that kind of pressure… I wanted to give them a $20-25,000 discount, but eventually with the pressure I have to probably agree on almost double that amount… we didn’t want to offend them by any means.”

However, this attitude can only take you so far.

Suppliers appreciate collaboration and compromise, and a rigid stance during negotiation will create tension down the line.

But, by adopting a win-win approach instead, you build trust between you and your suppliers.

Vineetha Jayaram, Global Category Manager at nVent, a global leader in complete heat-management systems and electrical and fastening solutions, agrees.

Illustration: Veridion / Quote: Procurement Magazine

And, ultimately, this trust allows you to foster partnerships that will last and help you navigate today’s volatile supply chains.

Viewing supplier-buyer relationships as purely transactional prioritizes immediate costs and deliverables.

However, it overlooks the strategic value of building a collaborative relationship with suppliers.

This can become an issue, as such a mindset diminishes trust and causes sourcing teams to miss out on opportunities for collaboration.

Some suppliers may also deprioritize your needs in favor of clients with whom they share stronger connections.

This can translate to slower response times and less flexibility when it matters the most.

In contrast, companies that implement efficient sourcing strategies and invest in their supplier relationships often gain invaluable perks.

For instance, Nicholas Fiorentino, CEO of The Meatery, explains that strong relationships with suppliers have helped his business navigate beef shortages.

Illustration: Veridion / Quote: Shopify

That’s exactly what you miss out on if you make this mistake.

If you see suppliers as just a means to an end, they’ll view you the same way.

After all, why would they go the extra mile for a partner who hasn’t even tried to build a connection?

As Costas Xyloyiannis, CEO of HICX, the supplier experience management platform, points out, in today’s world, that kind of approach won’t get you far.

Illustration: Veridion / Quote: Global Trade

And guess what?

It’s really not that hard to build collaborative, strategic partnerships.

Even simple gestures, like meeting in person, can have a powerful impact, says Melanie DiSalvo, founder of virtue + vice, a sustainable women’s clothing brand.

“The best advice I can give is to meet people in person if you can. When I worked in fast fashion, my boss always joked that I could get things done that no one else could. Which was true. But I was also the only one who spent a ton of time in the factories, getting to know everyone from members on the sewing line to the owners. When you know someone, and they like you, it’s amazing how many favors they will do for you.”

That’s right: these small actions can sometimes position you as a preferred client, opening doors to cost savings, faster service, and even unique opportunities for innovation.

This strategy, while sometimes offering short-term benefits like cost savings or simplified logistics, can lead to serious issues down the line.

When a company leans too heavily on just a few suppliers, even one disruption—such as a natural disaster or factory shutdown—can ripple through the entire operation, causing production delays and other costly issues.

Midwest chicken farmers experienced this firsthand when their primary food supplier went bankrupt and shut down the plant.

Source: Patch

As Allen Sommerfeld, an Agriculture Department spokesperson, explained, they had to either give away or “humanely depopulate” roughly 300,000 chickens because they just couldn’t feed them anymore:

“The MDA, farmers, and partners were able to process some birds, and others were given away by farmers. While the chickens do not pose a health or safety risk, the MDA utilized emergency resources to ensure the remaining chickens were humanely depopulated according to American Veterinary Medication Association standards and overseen by experts from the Minnesota Board of Animal Health.”

In other words, the losses were quite severe for these farmers.

To mitigate such risks, it’s best to develop a contingency plan with secondary or backup suppliers.

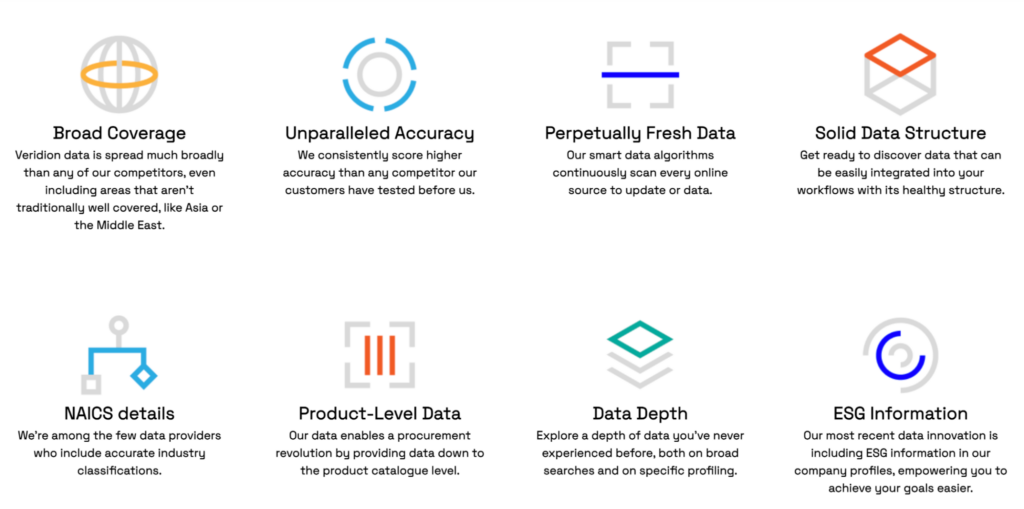

Contrary to popular belief, this doesn’t have to be labor-intensive or time-consuming at all, thanks to AI-powered supplier discovery tools like our Veridion.

Instead of spending weeks searching for reliable suppliers through Google, our platform enables you to discover ideal candidates from a pool of millions across the globe in mere moments.

Source: Veridion

Plus, it constantly scans the internet to provide the latest, most relevant data, ensuring you’re never at risk due to outdated information.

Whatever your criteria may be, Veridion will find suppliers that fit.

No need to worry about supplier risk anymore—you finally can rest easy knowing your supply chain is built to last!

Overall, the biggest mistake you can make in supplier sourcing is rushing the process.

Moving too quickly without fully evaluating your needs or suppliers’ performance and values means you’re not just passing up valuable perks.

You’re also exposing the business to financial and operational risks.

Sure, with some suppliers—especially those providing non-essential products—these slip-ups might not have a huge impact.

But when it comes to sourcing critical goods, it’s absolutely vital to try to avoid these mistakes to maintain supply chain resilience and ensure smooth, disruption-free operations.