6 Reasons Why Supplier Vetting Is Important

As a procurement professional, you know that supplier vetting is key to a reliable supply chain.

Yet sometimes, you may not fully get just how deeply this process impacts your organization.

However, making an effort to understand why this process is so important can help you prioritize efforts in ways that will help you build a more efficient sourcing strategy.

Ultimately, this translates to overall operational improvements.

So, if you’re ready to go beyond the basics of supplier vetting and explore its broader implications, read on.

Maybe you’re facing increasing supply chain disruptions, struggling with supplier performance issues, or simply looking to optimize your processes.

Whatever the case may be, let’s explore six compelling reasons why supplier vetting is essential.

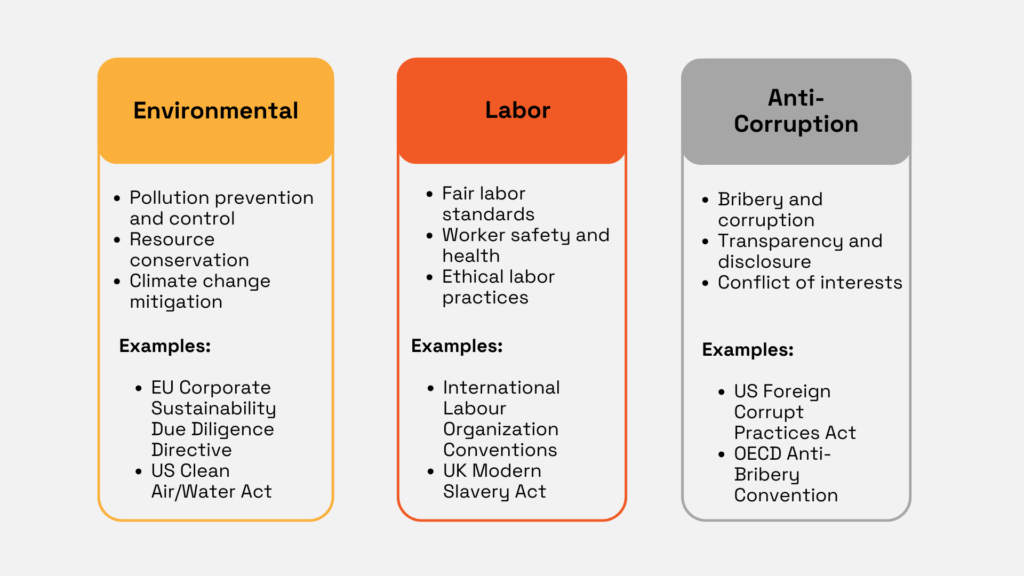

Ensuring your suppliers comply with all applicable regulations is crucial for mitigating supplier risk and protecting your organization.

Why?

Because non-compliant suppliers can expose your business to legal penalties, reputational damage, and disruptions to your operations.

Therefore, a major benefit of thorough supplier vetting is verifying compliance with local, national, and international regulations.

This process involves checking that suppliers adhere to relevant laws and industry standards, safeguarding your business from potential liabilities.

Unfortunately, the regulatory landscape is complex and ever-evolving, with numerous regulations to consider.

Only a fraction of these are shown in the image below.

Source: Veridion

Environmental regulations, such as the US Clean Water Act, are becoming increasingly important due to growing global concerns about sustainability.

Supplier vetting can help ensure compliance in this area by verifying suppliers’ certifications like ISO 14001 and reviewing their environmental audit reports and waste management practices.

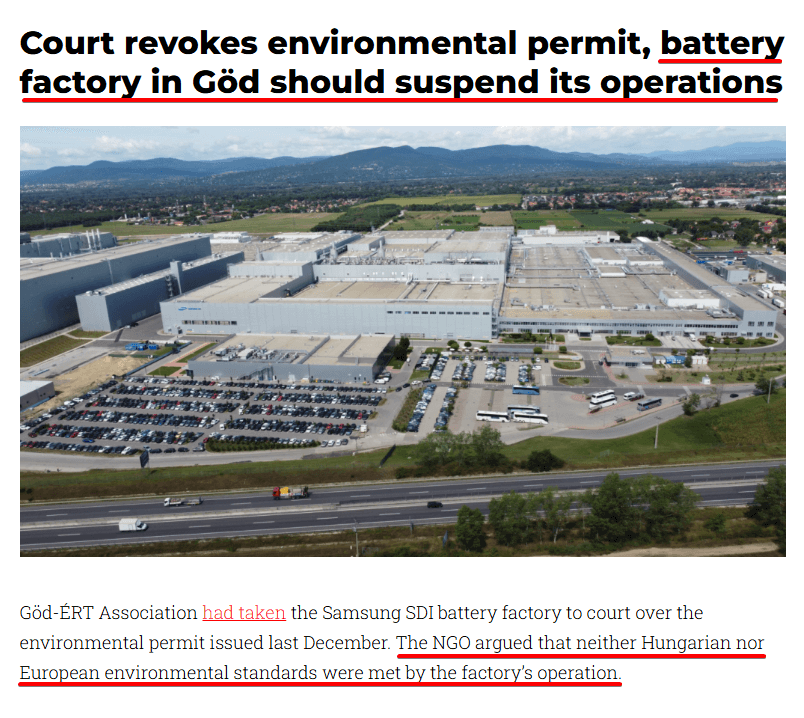

Without proper vetting, you risk encountering situations similar to that of Samsung SDI, a manufacturer and supplier of batteries and other electronics for Samsung.

Earlier this year, one of their factories in Göd, Hungary, had its environmental permit revoked for non-compliance with noise, air, and water pollution regulations, as well as issues related to battery waste generation.

Source: Atlatszo

This revoked permit prevents the factory from operating, and a court could order a complete suspension of production.

Of course, this compliance issue directly impacts Samsung and other organizations that rely on this supplier for components, illustrating the far-reaching consequences of supplier non-compliance.

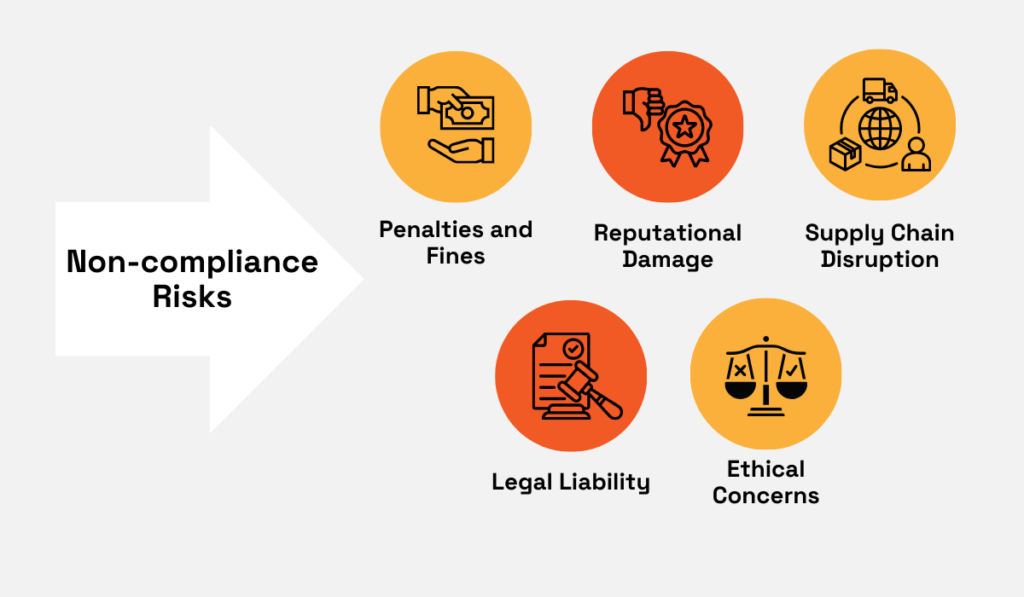

This example highlights just a few of the consequences associated with non-compliant suppliers, including disruption of operations and reputational damage.

Some other potential consequences are shown below.

Source: Veridion

A robust vetting process addresses these by including checks for relevant licenses, permits, and certifications.

It often also involves reviewing a supplier’s history of compliance and its internal policies and procedures related to regulatory adherence.

This proactive approach helps you identify and mitigate potential compliance risks, protecting your business from issues later on.

In the previous section, we discussed a supply chain disruption caused by a supplier’s environmental non-compliance.

While vetting can mitigate such risks, some supply chain issues arise from external factors beyond a supplier’s control.

These include geopolitical instability, natural disasters, pandemics, economic downturns, and transportation disruptions.

Consider, for example, the U.S. government’s sanctions against Mornsun Guangzhou Science and Technology Co. Ltd. for supplying Russia’s defense sector.

This action immediately blocked all Mornsun products in the U.S. or intended for sale to U.S. parties.

Bill Dull, president of Triad Magnetics, commented on the situation:

“Overnight and without warning, all the customers that had designed in and depended on Mornsun’s products were left without a supplier for the foreseeable future.”

Fortunately, supplier vetting can help you prepare for such scenarios by evaluating multiple suppliers and maintaining a list of potential alternatives.

Having these backup suppliers ensures business continuity and minimizes the impact of unforeseen events.

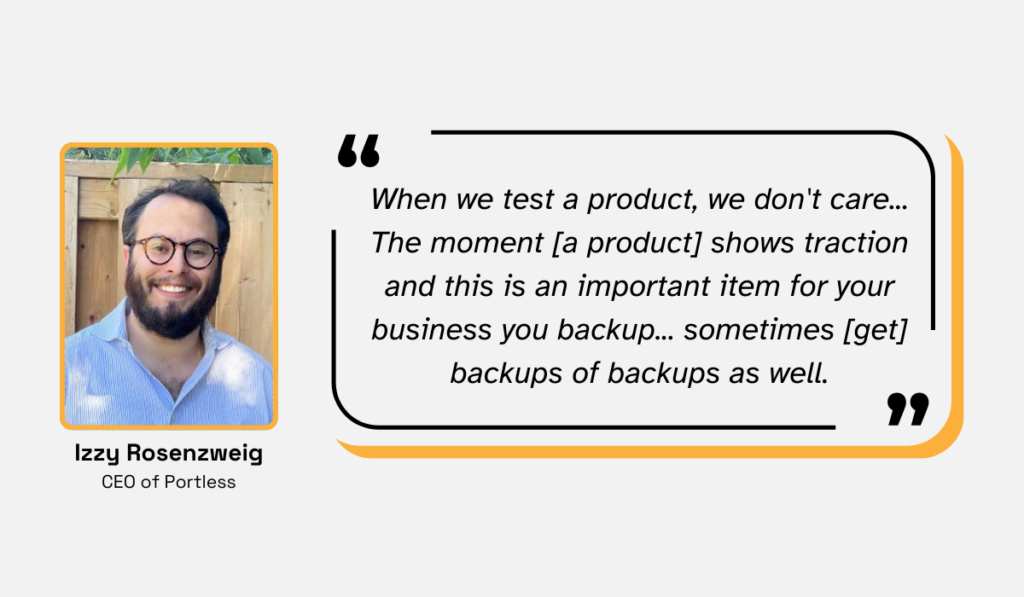

Izzy Rosenzweig, CEO of Portless, discussed the importance of having backup suppliers on The Markademics Podcast.

He points out that, as soon as a product or service gains traction and generates revenue, the next step should be to identify and secure backup suppliers for the necessary components or services.

Illustration: Veridion / Source: Portless

By doing so, you safeguard your business from disruptions and ensure you can continue production even if your primary supplier becomes unavailable.

And if you maintain a shortlist of vetted potential suppliers, finding a backup can be as simple as moving to the next suitable candidate on your list.

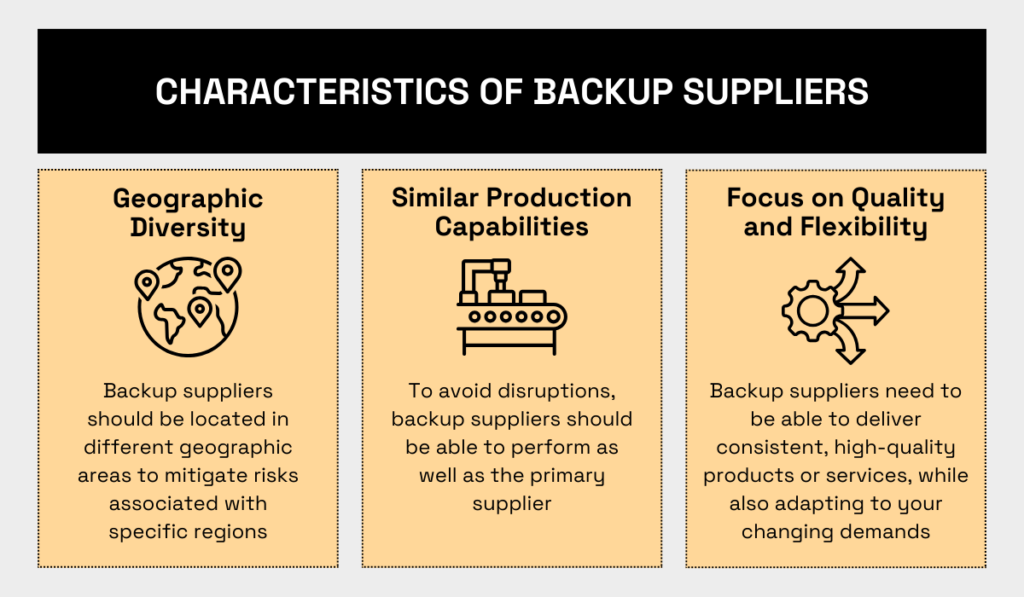

But make sure to take into account some of the following key characteristics of backup suppliers.

Source: Veridion

For instance, if your primary supplier is located in a region prone to instability, you want to source for a backup supplier in a different location.

Also, a backup’s production capabilities should be comparable to your primary supplier, with an added emphasis on being adaptable to your needs—as they may need to ramp up production rapidly in the event of a disruption.

Overall, by prioritizing geographic diversity and flexibility in your backup suppliers, you create a more flexible and robust supply chain.

Supplier vetting helps procurement teams ensure consistent product quality by evaluating suppliers against specific criteria and standards.

This involves thoroughly examining key supplier metrics to confirm they meet your organization’s quality requirements.

For example, consider the areas covered by the supplier inspection services offered by SGS, a leading inspection and certification company.

Source: SGS

Services like manufacturing process inspections help ensure suppliers adhere to established quality control procedures during production.

This can include verifying the use of appropriate equipment or adherence to standardized processes.

Similarly, packing, loading, and handling inspections ensure that products are handled efficiently, minimizing the risk of damage during transit.

Moving on, a supplier’s past performance is also worth investigating.

This involves reviewing their track record of delivering quality products on time and in alignment with their production capacity.

Doing so will help you determine if they can consistently meet your current and future demands.

In fact, this practice is so important that the UK government’s Policy Note 04/15 states that procurers should strongly consider past supplier performance during vetting.

Source: Gov.uk

Lastly, it’s always useful to look for examples of successful sourcing strategies.

Consider Multichem Sourcing, a supplier of active pharmaceutical ingredients (APIs), as a case study in quality control practices.

Illustration: Veridion / Data: KZN

Multichem enforces Good Manufacturing, Distribution, and Warehousing Practices (GMP, GDP, and GWP), as well as thorough risk management and traceability.

Aside from this, they prioritize supplier vetting and maintain a network of trusted vendors.

This rigorous approach helps them consistently source high-quality APIs, ultimately benefitting patients as a result.

The takeaway is that, if you want to ensure your own successful operations, vetting supplier quality from multiple aspects is definitely worth considering.

Supplier vetting plays a critical role in ensuring your supply chain adheres to ethical labor practices, protecting your brand reputation, and mitigating potential risks.

As you may know, headlines exposing unethical practices within the supply chains of well-known companies are not hard to find.

For example, consider Apple’s 2021 situation, where one of their suppliers was found to be using child labor.

Source: Good Electronics

More recently, another Apple supplier faced scrutiny for using AI training data from controversial sources, raising further concerns about ethical sourcing practices.

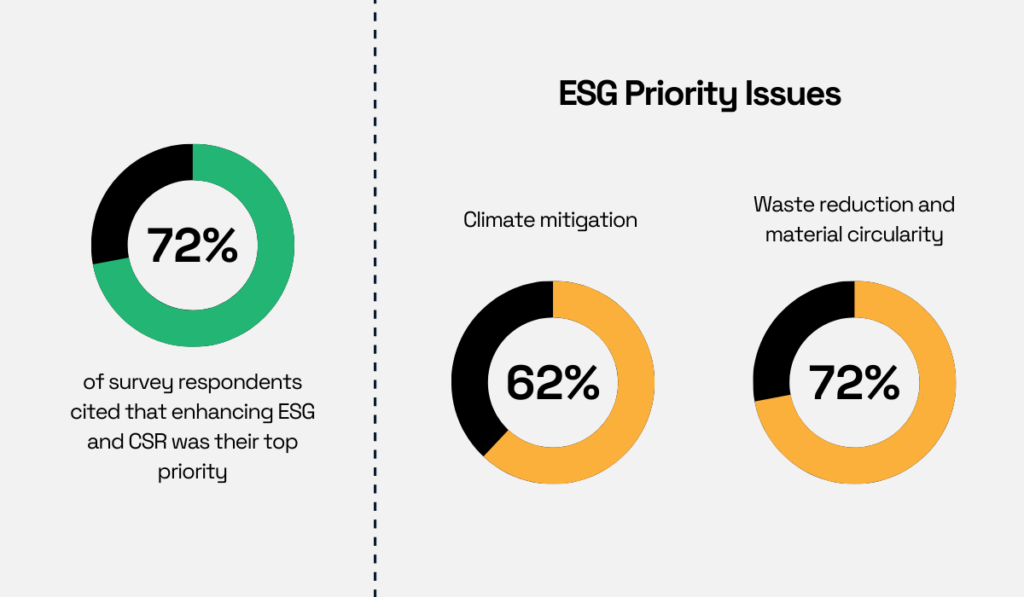

And, with Deloitte’s data highlighting Environmental, Social, and Governance (ESG) issues as a top priority for businesses, thorough supplier vetting around these aspects is more critical than ever.

According to their survey respondents, climate mitigation and waste reduction are among the most pressing ESG concerns.

Illustration: Veridion / Data: Deloitte

As an example, you could vet suppliers for these issues by examining their environmental certifications), inquiring about their carbon footprint reduction initiatives, and checking for material circularity processes within their operations.

And the best part is, you don’t have to do it all manually.

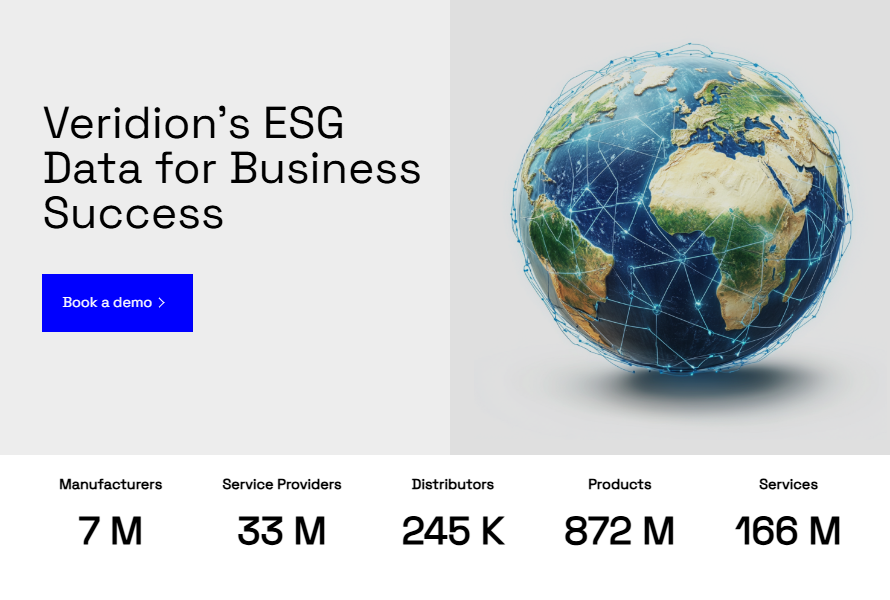

Supplier intelligence platforms like Veridion can help in this process.

Our platform boasts a rich, always-expanding database of over 7 million manufacturers and 33 million service providers which includes detailed ESG data.

Source: Veridion

We offer data points such as diversified ownership, employed ESG policies, and records of ESG controversies, among others.

Moreover, our granular data and real-time updates help you stay informed and avoid being caught off guard by unexpected issues.

And if you want to explore suppliers that already meet your ESG criteria more thoroughly, you can do so using natural language through our Complex Search API.

For instance, a simple query for “ISO-certified, eco-friendly pallet manufacturers” generates a detailed request in JSON format.

Source: Veridion

Moments later, a detailed response with matching suppliers will be returned.

This allows you to quickly identify those that are compliant, further streamlining the vetting process.

So, leverage data-driven insights and comprehensive vetting processes to minimize risks, protect your brand reputation, and build a more sustainable and responsible supply chain.

The supplier vetting practices we’ve discussed so far can also contribute significantly to cost savings.

Oftentimes, procurement teams focus solely on finding the cheapest suppliers, comparing them based on product price alone.

However, as Art Thomas, director of business development at Purdue University Manufacturing, explains, this narrow focus can lead to higher total costs in the long run.

Illustration: Veridion / Quote: SCB

Suppliers might offer lower initial prices by compromising on material quality, employing less qualified staff, or engaging in non-compliant practices like improper waste disposal to cut costs.

These shortcuts can result in lower-quality products, production delays, and potential legal damage.

So, to achieve genuine cost savings while maintaining product quality, a broader perspective is necessary.

It should include several vetting criteria, and you can see them outlined below.

Source: Veridion

Start by examining the supplier’s financial background and past performance.

Why?

Because ensuring a supplier has a stable financial footing can prevent unexpected price hikes or disruptions down the line.

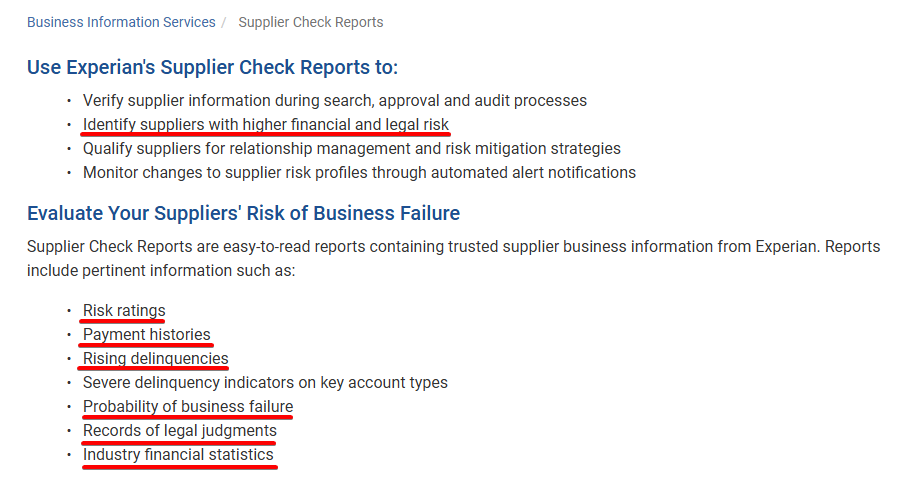

Services like Experian offer Supplier Check Reports to assist in these assessments.

Source: Experian

Combining these kinds of reports with assessments of production capabilities, compliance, and quality control provides a comprehensive picture of the supplier’s overall reliability and potential risks.

This thorough approach allows you to identify suppliers who offer true value for money, and not just the lowest initial price.

Finally, let’s explore how supplier vetting can drive growth and innovation within your organization.

Consider the following quote from Kevin Smeets, a partner at Oliver Wyman, who discusses the evolving procurement landscape.

Illustration: Veridion / Quote: OliverWyman

He emphasizes the increasing importance of identifying suppliers who can support innovation early in the procurement process.

This means going beyond traditional vetting criteria like quality certifications and compliance practices.

Specifically, you should also assess a supplier’s potential to contribute to your organization’s innovation goals.

This might involve evaluating their research and development capabilities, their openness to collaboration, and their track record of bringing new ideas to market.

Some specific aspects to consider when vetting for innovation include:

These factors are crucial because a supplier’s technological capabilities and commitment to continuous improvement directly impact their ability to develop and deliver innovative solutions.

Consider what this mutual growth and innovation looks like in the case of Ethicon, a Johnson & Johnson MedTech company.

Source: JNJ

Seeking continuous improvement in surgical operations, Ethicon launched a collaborative Supplier Enabled Innovation Program with carefully selected suppliers, resulting in a new surgical stapling innovation.

We can strongly assume that, to participate in this program, suppliers underwent thorough vetting to ensure they possessed the necessary production capacity, technological expertise, and collaborative spirit to contribute meaningfully to Ethicon’s innovation goals.

After all, only by identifying and partnering with suppliers who possess the right capabilities and mindset can you unlock new opportunities for growth and create a competitive advantage in the marketplace.

A proactive and strategic approach in this aspect of supplier vetting can really transform your operations into a source of innovation.

And there you have it!

This article has hopefully broadened your understanding of how supplier vetting benefits not just procurement but your entire supply chain and organization as a whole.

We’ve covered how effective vetting contributes to compliance, strengthens supply chain resilience, upholds ethical standards, and even drives cost savings and innovation.

By integrating these insights into your procurement strategies, you can build stronger supplier relationships, minimize potential disruptions, and improve overall organizational performance.

So, take this opportunity to evaluate your current vetting process and look for areas for improvement—a proactive approach will undoubtedly contribute to your success.