Evaluating Supplier Sustainability in Your Supply Chain

Key Takeaways:

The pressure is coming from all angles.

Customers expect ethically sourced products, investors seek transparency, and governments are introducing stricter regulations.

This growing focus on sustainability means your suppliers must align with these expectations.

To ensure this, you have to evaluate their sustainability practices.

Today, we will explore how to do that successfully, which criteria to evaluate, where to gather that data, and how different technologies streamline the process.

We have a lot to cover, so let’s get going!

Supplier sustainability is about much more than just being “green.”

It’s a broad concept rooted in environmental, social, and governance (ESG) criteria.

When evaluating suppliers, it’s essential to go beyond surface-level assessments and look at how they perform across these three key areas:

| Environmental sustainability | focuses on minimizing the ecological footprint of their operations, like reducing carbon emissions, waste, and resource consumption. |

| Social sustainability | relates to ethical labor practices, worker health and safety, and fair treatment of employees. |

| Governance | ensures suppliers respect ethical business practices, uphold integrity, and maintain transparency. |

This matters now more than ever, as only sustainable suppliers can help you achieve your own sustainability goals.

But why is supplier sustainability such a critical focus now, and who is driving this shift?

As supply chains grow more complex and customers increasingly want to know where their products come from, stakeholders, senior management, and investors are pushing for greater transparency.

This trend is impacting companies across industries—take Inditex, the company behind fashion brands like Zara and Oysho as an example:

Source: edie

Regulators and stakeholders have pressured the company to disclose more about the conditions and sources of its supply chain.

Additionally, governments are introducing more regulations that demand transparency about how and where products are sourced.

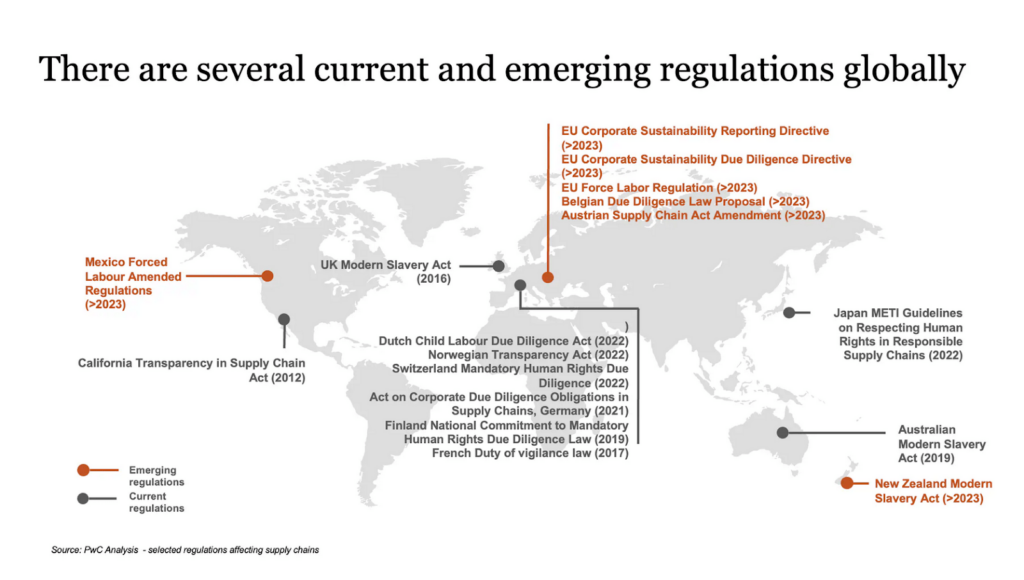

For a visual perspective, PwC’s global map highlights the current scope of sustainability regulations worldwide, showing how quickly this landscape is evolving:

Source: PwC

It’s important to note that sustainability requirements can vary widely across industries.

In retail, issues like forced labor, human trafficking, and child labor have surfaced due to the complex, often opaque nature of global supply chains.

Source: The Guardian

Retailers sourcing from regions with weaker labor laws face more substantial challenges in ensuring fair working conditions.

In manufacturing, the emphasis is on environmental concerns.

Challenges here revolve around resource extraction, energy-intensive production processes, and waste management.

Source: E+E Leader

Manufacturers are under increasing pressure to adopt cleaner technologies and reduce emissions, which means their sustainability focus leans heavily on the environmental side of ESG criteria.

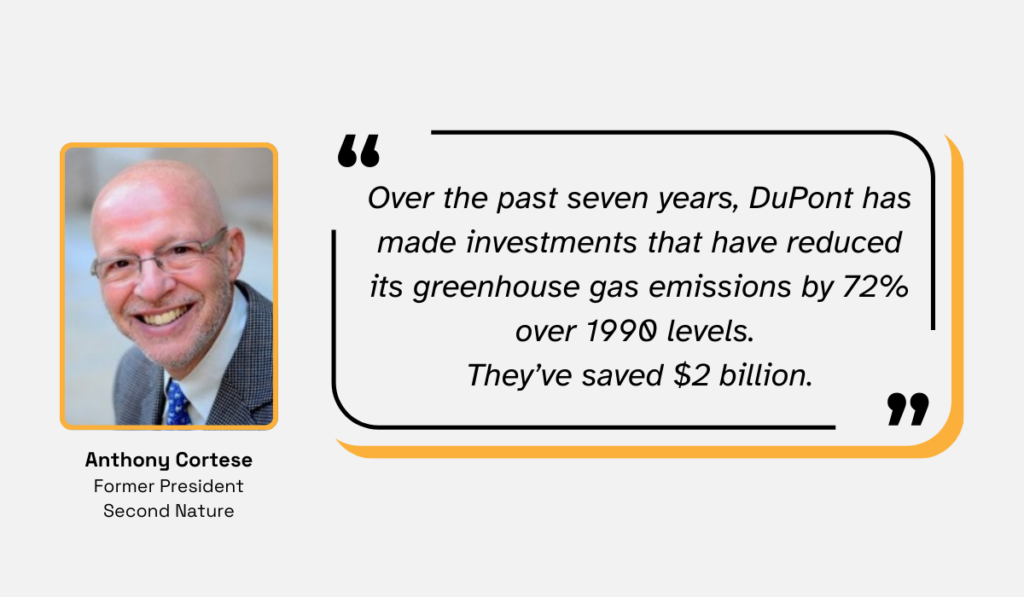

There’s also a persistent misconception that sustainability is solely about environmental issues, or that it’s too expensive to implement.

While some sustainability initiatives involve upfront expenses, the long-term benefits outweigh the costs.

Anthony Cortese, founder of the sustainability education organization Second Nature, cites an American multinational chemical company DuPont as a prime example:

Illustration: Veridion / Quote: SCI AM

Cases like this one demonstrate that sustainability isn’t just an ethical choice—it can also be a financially sound one.

However, besides compliance and cost savings, companies also recognize sustainability as their moral obligation to a better community and environment.

Iberdrola, a Spanish multinational electric utility company, explains that in its sustainability statement:

Source: Iberdrola

Iberdrola has set an ambitious target to ensure that 85% of its main suppliers meet sustainable development policies and standards by 2025.

Naturally, achieving such goals requires evaluating suppliers’ practices effectively across the entire supply chain.

Evaluating supplier sustainability focuses on performance across environmental, social, and governance dimensions, as outlined earlier.

Iberdrola provides a useful example of how these metrics are structured.

The company evaluates suppliers based on these three key areas, allocating 40% weight to environmental criteria, 30% to social factors, and 30% to governance.

Source: Iberdrola

Here’s a more precise breakdown of common sustainability metrics across the ESG criteria:

| Metric | What it measures | Why it matters |

|---|---|---|

| Carbon emissions | How suppliers reduce their carbon footprint and transition to cleaner energy sources | Climate change is a growing concern, and cutting emissions is essential for sustainability and regulatory compliance |

| Water management | Responsible use, recycling, and protection of natural water sources | Sectors like manufacturing and agriculture rely heavily on water, making efficient use crucial for environmental impact |

| Circular economy | Efforts to minimize waste through recycling, reuse, and efficient resource use | Supports a “closed-loop” system, reducing waste and promoting sustainable production and consumption patterns |

| Human rights and diversity | Ethical labor practices, fair treatment of workers, and inclusivity in operations | Identifies issues like forced labor and human trafficking, particularly in industries with global supply chains |

| Ethics and compliance | Complying with regulations, transparency, and maintaining high ethical standards | Ensures legal compliance, builds trust, and minimizes risks associated with unethical practices |

In addition to these fundamental criteria, it’s important to look at whether a supplier has a strong internal sustainability program.

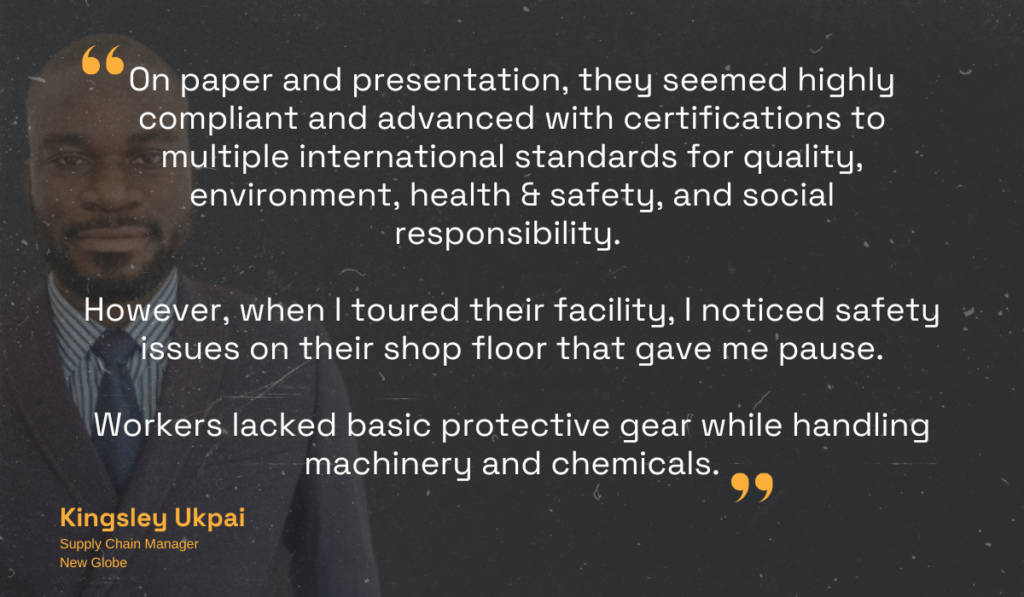

Kingsley Ukpai, Supply Chain Manager at NewGlobe, highlights several criteria to consider:

Illustration: Veridion / Quote: Linkedin

Suppliers that go beyond just complying with your ESG requirements and set their own measurable goals, engage stakeholders, and set standards for their own partners often stand out as leaders.

These are the ones thinking innovatively—whether it’s through green technology, waste reduction, or improving worker well-being.

Another critical aspect that goes hand in hand with this is a supplier’s social impact rating, which can help you decide if you want to work with them.

It measures their contributions to communities and broader societal well-being.

Finally, there’s evaluating lifecycle sustainability.

Known as Life Cycle Sustainability Analysis (LCSA), this approach examines a product’s environmental impact at every stage—from raw material extraction to disposal.

Source: Ecochain

It raises key questions like:

By understanding the full lifecycle impact, companies can identify areas for improvement and encourage suppliers to adopt more sustainable practices.

For example, transitioning to energy-efficient production methods or optimizing transportation can significantly reduce carbon emissions and waste in a product’s lifecycle.

All in all, there are many sustainability criteria for supplier evaluation.

The next logical question is where and how to gather all this data.

Procurement professionals and other experts rely on a few key methods for collecting sustainability data from suppliers.

Let’s break down each of these methods.

Surveys are one of the most common ways to collect data on ESG practices from suppliers.

However, not all survey questions are relevant to every supplier.

For instance, if you’re sending a survey to a supplier in the electronics industry, questions about water usage might not be as relevant as they would be for a supplier in the agriculture or manufacturing sectors, where water management is a major concern.

Sending the same survey to a wide range of suppliers can lead to confusion, frustration, wasted time for suppliers, and even impact the data quality.

That’s why, Anthony Payne, Chief Marketing Officer of HICX, suggests that businesses should segment suppliers into groups and send them only the questions that apply to their specific roles or operations.

Illustration: Veridion / Quote: CPO Strategy

This way, suppliers can provide more accurate and relevant sustainability information, and the overall communication becomes more collaborative.

While surveys provide self-reported data, ESG audits are an effective way to verify those claims and get a more accurate picture of a supplier’s sustainability practices.

Often, suppliers may present certifications and tell you they meet certain standards, but an audit can confirm or challenge those claims.

For example, Kingsley Ukpai, a supply chain manager whom we mentioned above, shares a story about visiting a potential supplier of electronic components:

Illustration: Veridion / Quote: Linkedin

This story shows that audits can reveal discrepancies between suppliers’ claims and what’s happening on the ground.

Therefore, regular audits are simply a must to gather accurate supplier sustainability information!

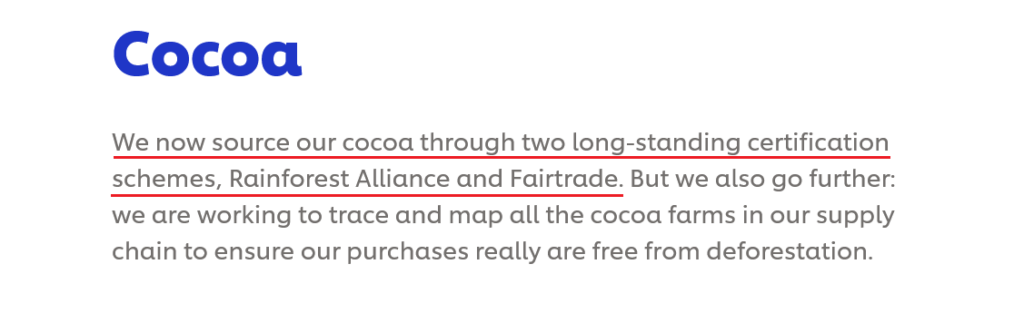

Third-party certifications are another method to gather data and ensure that suppliers meet sustainability standards.

Certifications like ISO 14001 (environmental management), B Corp (social and environmental performance), and Rainforest Alliance (sustainable agriculture) help verify that suppliers are meeting high standards for sustainability.

For instance, Rainforest Alliance certification ensures that farms and companies meet rigorous requirements to improve farmer incomes, protect the environment, and support social well-being.

When you see their frog logo on products, it signifies that the product is part of a supply chain that adheres to these values.

Source: Rainforest Alliance

For example, Unilever relies on certification schemes like Rainforest Alliance and Fairtrade to ensure their cocoa suppliers align with these sustainability goals.

Source: Unilever

Similarly, Coca-Cola HBC requires its suppliers to meet certifications in several areas, including:

This helps them gather sustainability data and ensures that suppliers meet high standards for quality and sustainability.

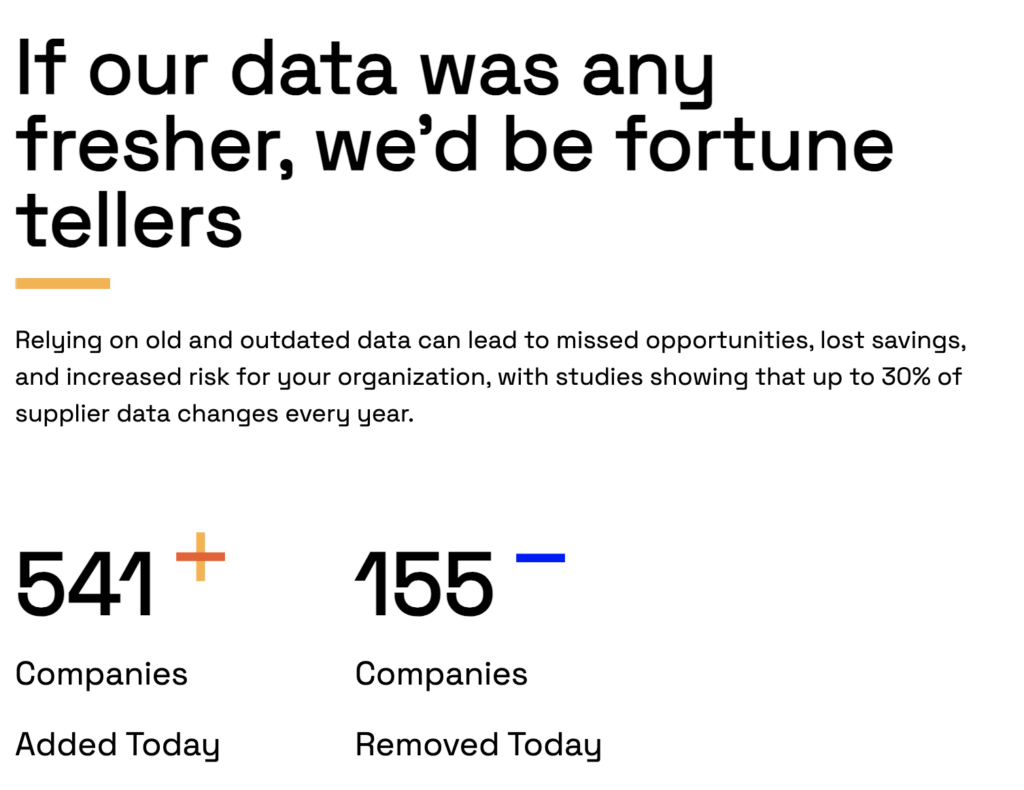

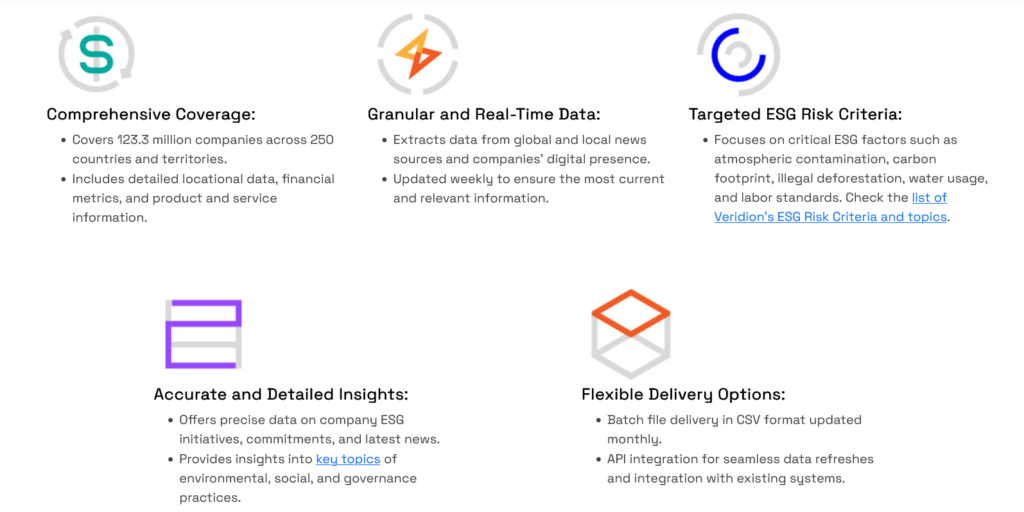

Data platforms play a crucial role in verifying and enriching supplier data because of their speed and data reach.

While audits can’t be conducted very often on every supplier, data platforms can update supplier profiles every week.

Source: Veridion

This ensures businesses are up-to-date with their suppliers’ sustainability data.

Veridion, for example, collects and analyzes supplier data from a variety of sources, including company websites and news outlets, to create up-to-date profiles of suppliers’ ESG practices and refresh that data every week.

Read on to learn more about how this technology streamlines supplier sustainability evaluations.

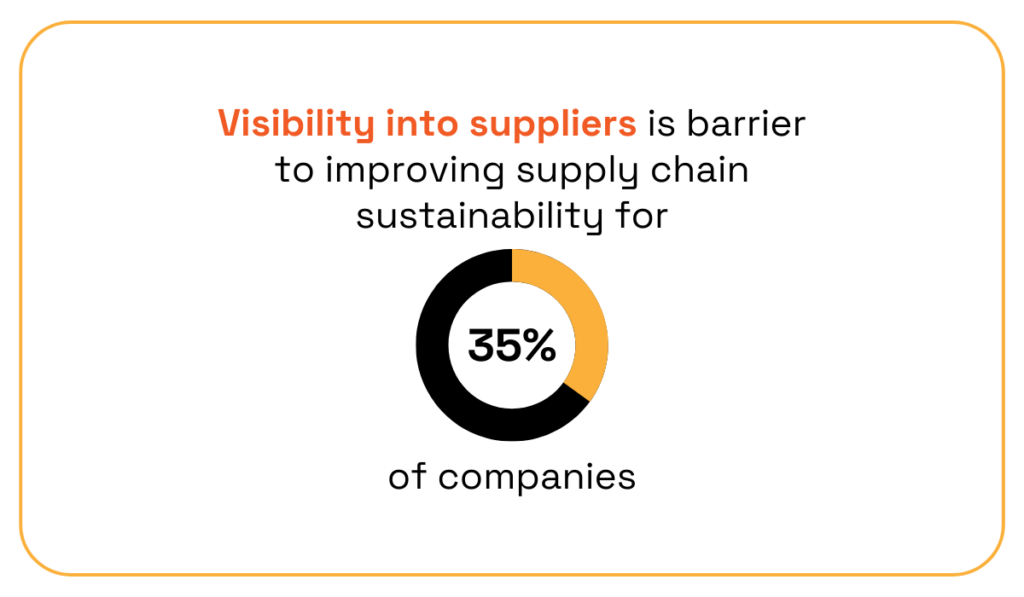

Even though methods like surveys, audits, and certifications are effective, companies face many obstacles.

Many suppliers may be unwilling or unable to provide the necessary data, or they might not even have it in the first place.

As a result, businesses are left with an incomplete picture of their suppliers’ sourcing, production, and transportation methods.

In fact, a recent survey revealed that over a third of businesses have difficulty gaining full visibility into these areas, making it harder to assess and improve sustainability.

Illustration: Veridion / Data: Procurious

On top of that, global procurement is fraught with complexity.

Different regions have varying regulations, making it difficult for companies to know what sustainability data is required for each region.

But here’s where technology steps in to save the day—and the supply chains.

AI-powered analytics, blockchain, and automated ESG monitoring systems are revolutionizing how businesses gather and evaluate supplier sustainability data.

These technologies provide companies with much-needed transparency and help close data gaps, reducing the reliance on manual processes.

Let’s focus for a moment on the power of AI and machine learning.

Our Veridion, for instance, uses AI and machine learning to analyze vast amounts of data on a weekly basis.

By scraping web sources, Veridion creates detailed ESG profiles for each supplier, offering real-time insights into over 120+ million companies across the globe, including regions where traditional data is often scarce.

Source: Veridion

These profiles cover everything from public commitments to controversies, ensuring a comprehensive, balanced view of supplier practices.

Below is an overview of all the data points you can get about supplier’s ESG practices through Veridion:

Source: Veridion

The best thing is that these technologies integrate with other procurement platforms.

Iberdrola, for example, uses the GoSupply cloud solution to calculate ESG scores for suppliers, based on both self-reported and third-party data.

These scores are then integrated into their procurement cycle, helping buyers evaluate suppliers’ sustainability at key stages like tender invitations and negotiations.

There are many other interesting technologies in the market that help companies evaluate their supply chains, in one way or another.

Ferrero Australia, for instance, uses Sourcemap, a platform that visualizes supply chains and enhances traceability, to trace hazelnuts to the farm level:

Illustration: Veridion / Quote: Ferrero Australia

Supply Trace is also a piece of interesting tech that will soon help companies in supplier sustainability evaluations.

This is an accessible, open platform that exposes potential risks in global supply chains.

In its pilot phase, it focuses on the apparel sector and links between forced labor in the Uyghur Region of China and shipments to the US.

The platform democratizes access to risk data making it available to all stakeholders—especially smaller companies that may not have the resources to access traditional risk data.

Dr. Shawn Bhimani, assistant professor of supply chain management at Northeastern University, and lead developer of Supply Trace, explains their vision:

Illustration: Veridion / Quote: Just Style

Maybe with this piece of technology, even businesses with limited budgets can evaluate supplier sustainability more effectively.

All in all, with proper technologies, supplier sustainability evaluations don’t have to be so complex and difficult.

Ensuring that your suppliers actually follow through on sustainability commitments requires making sustainability a formal part of your supplier relationships.

Instead of just hoping they’ll be sustainable, make it clear in your contracts what’s expected.

You can do this by including these three key elements in your contracts:

First, adjust your SLAs to reduce sustainability impacts.

Amazon AWS recommends adjusting SLAs to trade off certain service levels (like response time) in exchange for reduced environmental impact.

Next, if reducing embodied carbon is a focus, include KPIs such as verifying the origin of materials or providing independent process verification.

Other KPIs could include:

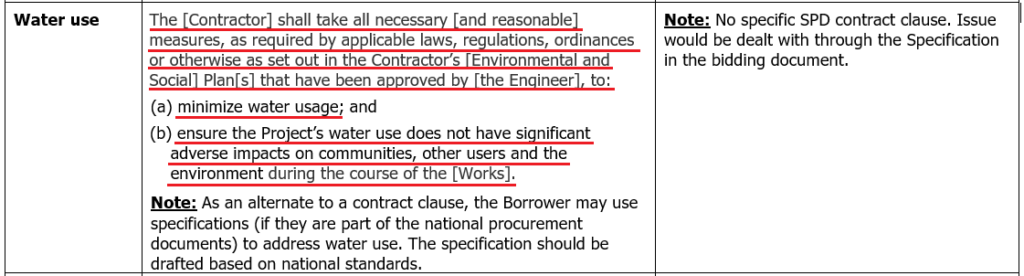

Lastly, include legal clauses to ensure suppliers follow environmental or ethical guidelines.

For instance, a clause might require compliance with local water usage laws or reducing energy consumption.

Here is an example of a water use clause that you can add to the contract:

Source: World Bank

If suppliers don’t comply, penalties or contract termination could apply.

However, beyond simply mandating compliance, you should also collaborate with suppliers to help them improve their sustainability practices.

You can offer training, share your best practices, or co-create solutions to reduce environmental impacts.

A great example of this is General Motors’ (GM) Supplier Sustainability Council, which helps suppliers share ideas and work together on sustainability.

This collaboration has resulted in GM suppliers, like AAM, creating their own councils, leading to measurable sustainability improvements.

Margarita Kruyff, a representative of Ryder System, Inc., one of GM’s suppliers, highlights the benefits of being part of GM’s Supplier Sustainability Council:

Illustration: Veridion / Quote: EcoVadis

By working together, you and your suppliers can drive positive, measurable change that benefits everyone in the supply chain.

And that’s the whole point of sustainability, anyway.

We’ve shed some light on why you should evaluate supplier sustainability, and how, but also on why supplier sustainability matters in the first place.

And if you’ve been paying attention, it really does matter. A lot.

It’s not just because it should be everyone’s moral obligation, but because sooner or later, you won’t be able to keep your business going if you don’t comply with laws and regulations that demand it.

Ultimately, suppliers play a pivotal role in achieving sustainability goals, making their evaluation a critical procurement task.

So, take the time to do it right, stay on top of it, and base your decisions on solid data.

And don’t forget: numerous technologies can help you streamline the process.