10c Model of Supplier Evaluation

Key Takeaways

No matter the industry, finding the perfect supplier is both crucial and challenging.

A reliable partner can feel like you’ve hit the jackpot, but even promising relationships can falter.

Meanwhile, business waits for no one.

Luckily, thorough supplier evaluation is one way of countering risks and ensuring the best possible outcomes.

One proven method?

The 10c model of supplier evaluation.

With this comprehensive approach, organizations consider a range of factors from the get-go, reducing the chance of any surprises later on.

Curious if 10c is the right fit for your needs?

Let’s dive right in and see how it can help you streamline your supplier evaluation process!

The 10c model is a popular supplier evaluation framework that is considered one of the fundamentals of procurement.

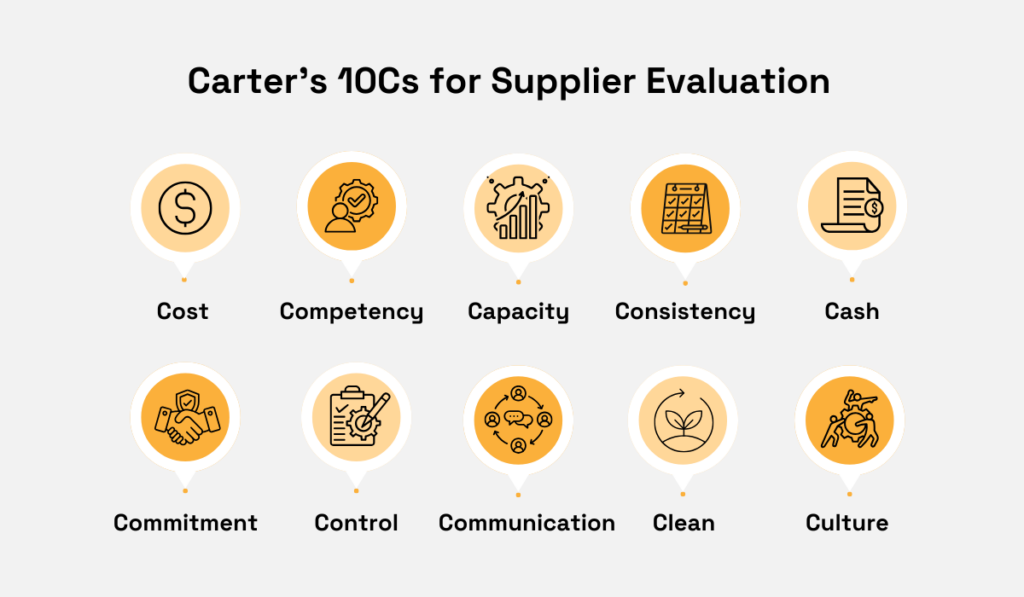

Each of its “Cs” represents one critical factor to consider when choosing a supplier.

Dr. Ray Carter developed this model in 1995, largely to help his students better understand supplier selection and evaluation.

Starting with 7 Cs, the model evolved organically and is now a part of the current Chartered Institute of Procurement and Supply (CIPS) Level 4 Module exam.

As examined in the video below, supplier relationship management (SRM) is an unavoidable topic for anyone aiming for CIPS qualifications.

Source: Procurement Mastery Hub on Youtube

The 10c model earned its place in the classroom, but it has also been adopted and adapted by many organizations.

The 10c gives organizations across different sectors a structured and detailed approach to supplier selection and evaluation.

Moreover, it enables procurement teams to break down the complexity of supplier relationships into 10 clear categories or criteria.

Procurement expert and educator Andrea Reynolds emphasizes that the model’s basic function is that of an evaluation checklist.

Illustration: Veridion / Quote: Cordie Ltd on Youtube

While it’s frequently used as a checklist for evaluating new partnerships, it’s also a comprehensive, long-term supplier evaluation tool.

Geoff Kontzle, procurement education expert and a long-time associate of Carter’s, stresses this versatility.

Illustration: Veridion / Quote: DPSSConsultants on Youtube

Simply put, the model offers a broader perspective on the supplier’s long-term suitability for your business.

By adding dimensions that go beyond their ability to meet demands or stay financially stable, the framework enables you to assess suppliers’ commitment, company culture, control over processes, and more.

Here you can see the full list of Cs you need to keep in mind.

Source: Veridion

Taking note of all 10cs ensures you can pinpoint and cultivate high-value supplier relationships, allowing you to meet your procurement objectives swiftly and successfully.

In short, the 10c model delivers both structure and simplicity, which makes it a go-to model for many organizations.

Using the 10c model to evaluate suppliers means having a good grasp of key metrics, i.e. what each C stands for.

To understand it better, we’ll take a closer look at individual components of this supplier evaluation model.

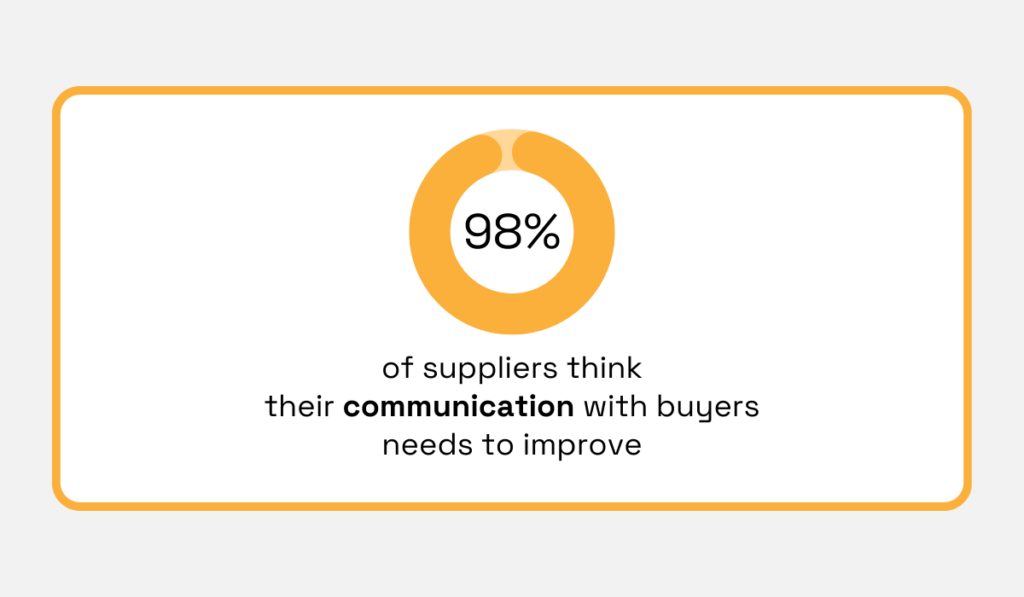

Effective communication with suppliers drives business, making it one of Carter’s essential Cs.

Knowing that the supplier is clear and responsive and that they prioritize keeping the lines of communication open creates a stable foundation for a long-term relationship.

Study after study has shown that communication dictates the course of the buyer-supplier relationship, with the overwhelming majority of suppliers expressing the need for improved communication.

Illustration: Veridion / Data: HICX

To evaluate your supplier’s communication, here are the questions you need to answer:

Communication is essential even when everything is going well, but it becomes even more important in case of any hiccups or major obstacles, so take the time for evaluation.

Competence is the supplier’s ability to deliver the products or services in line with the customer’s needs.

While having open communication matters, it’s no substitute for technical expertise and experience.

The first step here is to examine the supplier’s main capabilities and track record:

Looking into the qualifications of the supplier’s key staff members is another clear indicator of their expertise and capability to meet your specific needs and expectations.

You also need to remember that the market conditions are ever-changing.

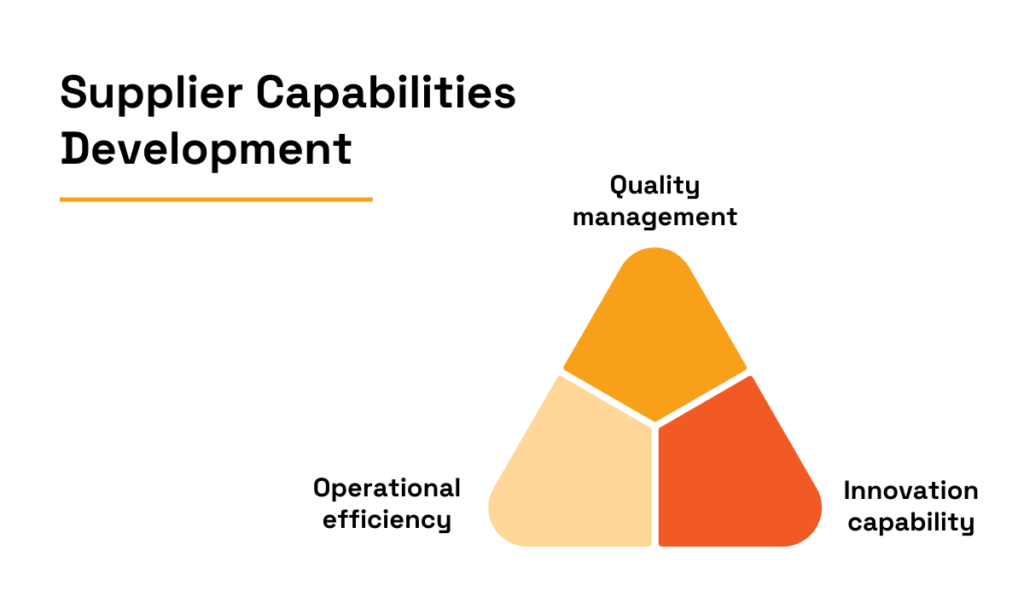

As such, the supplier’s competencies need to evolve to match them.

This is why larger organizations like Walmart invest in supplier development programs that help improve capabilities across different areas.

Source: Veridion

Ultimately, competency is not a fixed point, so make sure you think about both your current and future needs.

Growing, healthy organizations are bound to experience increased demand eventually and want to know if their suppliers can continue supporting them.

Patrick Gilgour, Managing Director of a global business consulting firm Protiviti, urges organizations to think along the lines of scalability and capacity.

Illustration: Veridion / Quote: CIO

There are a couple of strategies you can use to evaluate the supplier’s capacity, however, among the most effective ones are site visits.

Walking the premises reveals how the supplier conducts their business in general while giving you a firsthand experience of their capacity and workload.

Plus, it can quickly confirm or undermine potential claims of being at full capacity.

Commitment stands for a supplier’s dedication to quality, long-term partnerships, and continuous improvement.

As L-Charge executive and Forbes Council member Vera Maslova puts it, mutual commitment is the key ingredient of more reliable supply chains.

Illustration: Veridion / Quote: Forbes

How do you assess commitment?

A supplier’s attentiveness is an encouraging first sign, but their commitment to quality is best demonstrated through certifications and practices such as:

This focus on quality and improvement also means they’re likely to have contingency plans for different risk scenarios, and won’t leave you hanging dry.

Control refers to the supplier’s ability to manage their processes and supply chain effectively.

The more control suppliers have over their operations, the more reliable they become as partners.

Conversely, a lack of internal control on their part can lead to numerous issues, such as operational disruptions and regulatory non-compliance—problems that inevitably spill over and affect your business.

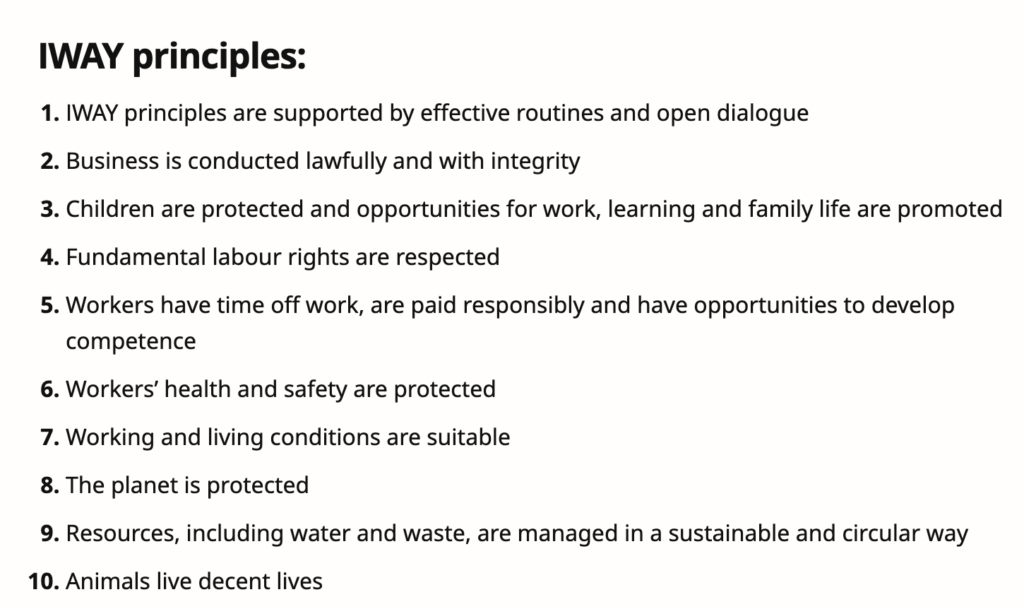

For example, IKEA works with over 1,600 direct suppliers.

And in order to keep the engine running smoothly, these suppliers need to keep the internal processes in check.

That’s why IKEA requires all of its suppliers to follow the IWAY, and audits them based on these requirements:

Source: IKEA

That’s one way to impose some control on your supplier’s internal processes.

To ensure that your suppliers have everything in control, it’s recommended to assess how they control several key aspects of their operations, including:

If your suppliers lack control over their operations, you can help them by creating your own set of principles they should abide by, just like IKEA did.

Next up, it’s vital to evaluate the supplier’s financial health and cash flow.

The only way a supplier can effectively deliver on your expectations is when they’re financially stable.

You don’t want to have your business shaken up by a sudden supplier bankruptcy.

Source: DigiTimes

To avoid the scenario German automotive industry faced, you need to be able to answer these three questions:

The bottom line is that you need to check the balance sheets and credit ratings, as well as the supplier’s reputation to ensure they can weather economic uncertainties.

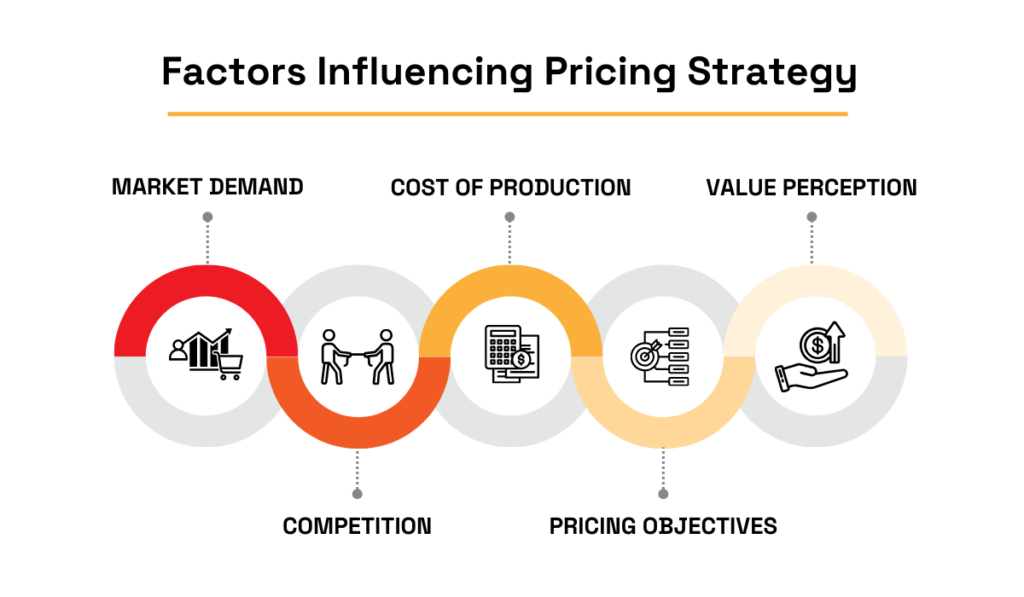

Another C that revolves around finances, “cost” stands for the total cost of the supplier’s goods or services.

Many factors influence suppliers’ pricing schemes, and navigating them successfully requires a thorough understanding of the full costs involved and how they compare to the competition.

Source: Veridion

Going for the cheapest option may work for you for a short while, but you need to keep in mind two things:

Without sufficient profit, it’s unlikely that the supplier will remain in business for a longer time, meaning that you’d be left fishing for alternatives.

To sum up, once you get full cost breakdowns from the supplier, conduct your analysis of fixed and variable costs, as well as margins and break-even points.

Another point of evaluation is the supplier’s ability to consistently deliver quality and performance over a longer period.

Consistent performance means that the supplier delivers on time and per all agreements, quality, and otherwise.

This translates to higher reliability, highlights EQUANS’ Business Development Director Mustansir Paliwala.

Illustration: Veridion / Quote: Forbes

Consistency is easy to evaluate. Just analyze your supplier’s historical behavior in different areas.

| Communication consistency | E.g. response times, methods, appointed points of contact |

| Quality consistency | Are their products/services always at the same level |

| Delivery consistency | E.g. do they always deliver at the same speed |

Detecting fluctuations in these areas will help you detect your suppliers’ weak points.

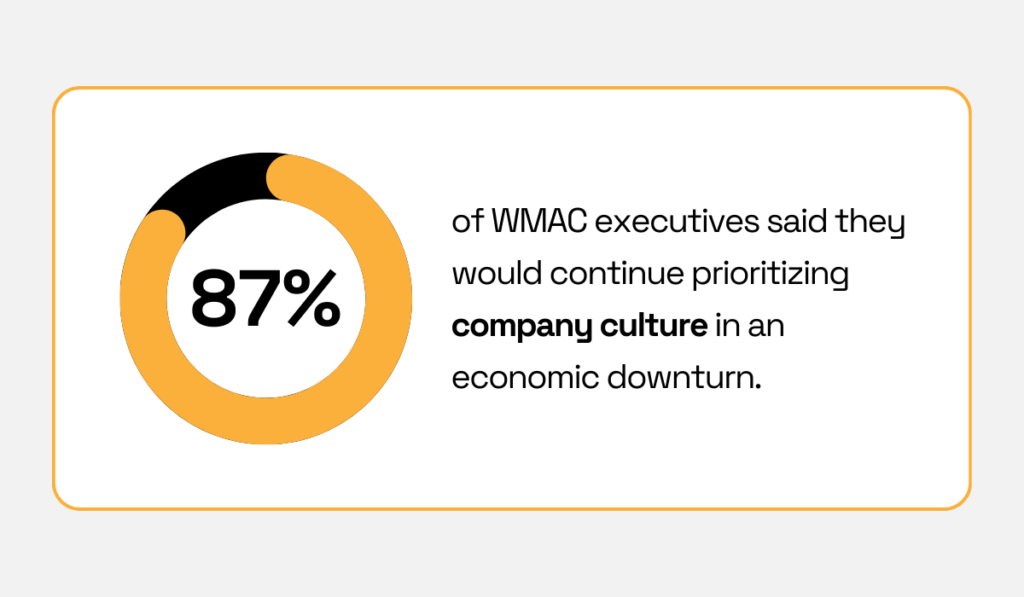

This metric is the point of alignment between the buyer’s and the supplier’s values, ethics, and practices.

Culture matters. It is an underlying foundation impacting everything else in day-to-day operations.

And successful companies know that.

That’s why most executives of Fortune magazine’s World’s Most Admired Companies (WMACs) would prioritize culture even in an economic downturn.

Illustration: Veridion / Data: HR Executive

Therefore, make sure culture is important to your suppliers too.

In other words, here’s what you need to establish:

If you want to avoid investing in a new relationship in vain, make sure to periodically assess cultural fit too.

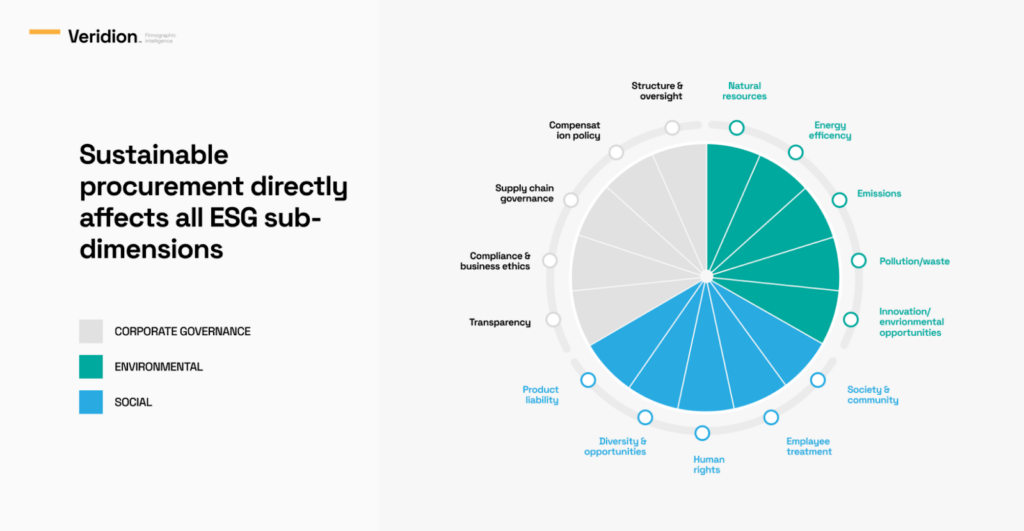

Cleanliness refers to corporate social responsibility or CSR.

With sustainability shaping the future of procurement, your suppliers’ commitment to ethical practices, sustainability, and social responsibility is more important than ever.

This became even more true in recent years given the stricter and more widespread climate and sustainability reporting rules.

Illustration: Veridion / Source: Carbon Cloud

For example, reporting requirements often include Scope 3 or indirect emissions from a company’s supply chain.

Evaluating supplier sustainability means gaining insight into their:

Don’t forget to take into account positive and negative media publicity, as well as insights from ratings agencies, news archives, and such.

Evaluating suppliers on the metrics we presented isn’t without its challenges

Namely, one notable downside to the comprehensive 10c model is its subjectivity and the lack of comprehensive, verifiable, and accurate supplier insights.

Because of these concerns, Carter explains that the more recent version of the model takes a closer look at the validity of the evidence provided by suppliers, factoring it into final ratings.

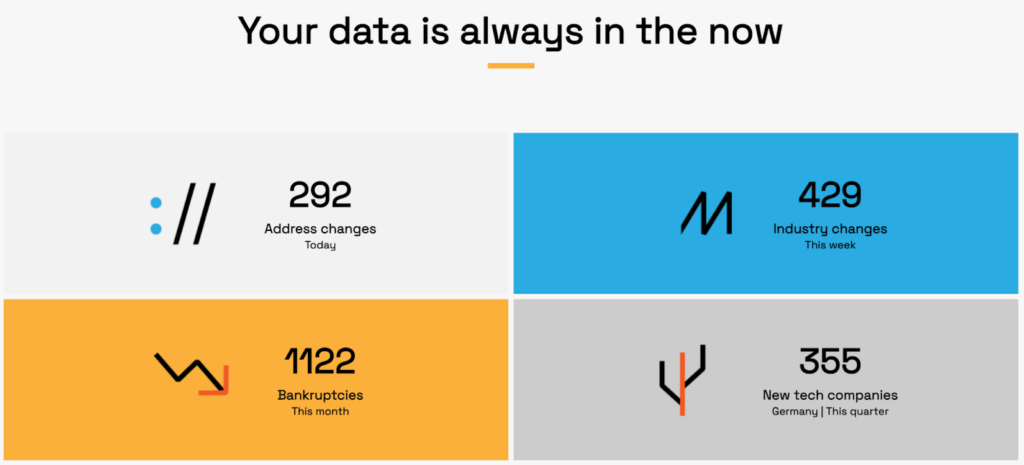

Despite these improvements, access to up-to-date data remains a problem.

Fortunately, that’s where supplier data platforms like Veridion deliver enormous value.

Thanks to Veridion’s vast global coverage and weekly data updates, you have everything you need to quickly and confidently re-evaluate your supplier relationships using the 10c model.

Source: Veridion

With Veridion, you can enrich your existing supplier data using our Match & Enrich solution, uncovering hidden third-party risks or zeroing in on ESG data.

For instance, when it comes to ESG standards, your procurement team can easily identify and prioritize suppliers with strong sustainability practices, enabling a quick transition toward more sustainable procurement.

Source: Veridion

There’s no analysis without reliable data, and services like Veridion can remove the data accuracy concern from your list.

Organizations that adopt and adjust this framework can effectively evaluate suppliers by key factors.

This model is highly flexible, but to make it truly effective you’ll need to pair it with advanced tools for gathering accurate, real-time data.

In this way, you’ll quickly identify risks and opportunities, validate claims, and make informed decisions on key supplier relationships.