6 Reasons to Avoid Manual Supplier Onboarding

Key Takeaways:

Have you ever thought, “I’ll just onboard suppliers manually, it’s faster”?

Using familiar tools like spreadsheets and email might seem like the simplest solution.

But manual onboarding often leads to delays, errors, and miscommunication.

In this article, we’ll cover six critical flaws of handling supplier onboarding manually.

We’ll especially focus on how it can drag down your team’s efficiency, introduce avoidable risks, and impact overall business performance.

Let’s dive in.

Even considering the initial learning curve of automating the onboarding process, manual supplier onboarding is still slower.

Why?

Because it involves spending valuable time on low-impact activities, like emailing forms back and forth, printing documents, and chasing signatures.

It’s mostly basic admin work: gathering, storing, and searching for information.

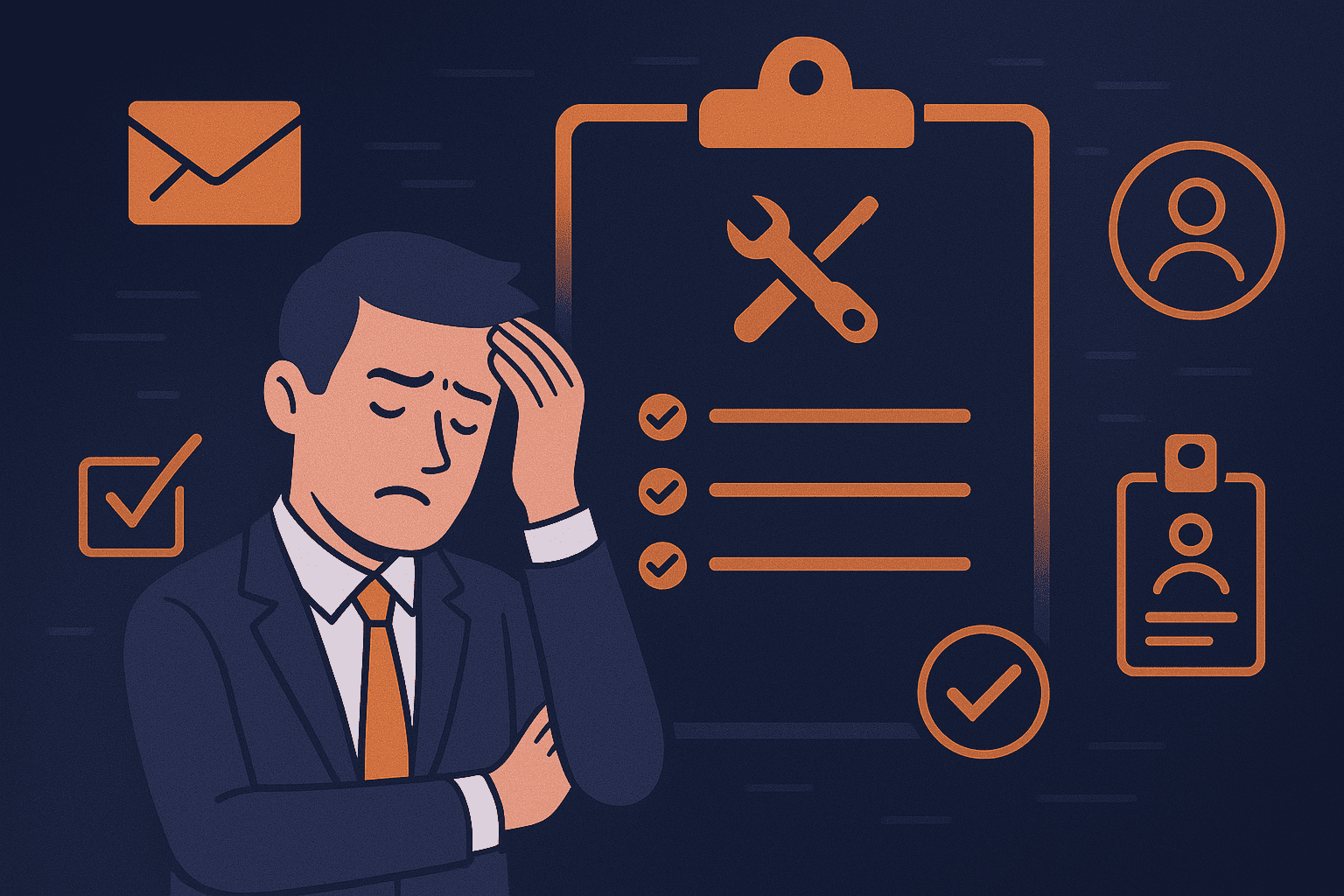

Research shows that even on a typical day, these activities take up too much of our time.

For example, McKinsey’s report shows that the average employee spends 47% of their workweek reading and answering emails and searching and gathering information.

And when you add supplier data and communication to the mix, that time could increase significantly.

Illustration: Veridion / Data: McKinsey

So, it’s not surprising that manual supplier onboarding often ends up being a major time drain.

Harvard Business Review says it often takes a month, but mentions that substantially longer timelines are more than possible.

According to ISM®, for example, the process can last up to six months at large organizations.

Illustration: Veridion / Data: HBR and ISM®

Besides being time-consuming, manual supplier onboarding is also unpredictable.

It doesn’t just depend on the size of the organization, but also on the people involved.

Some stakeholders may be faster at getting back to the other party and completing their tasks than others.

This inconsistency makes it difficult to set proper expectations and deadlines.

For example, how can you plan product launches if you don’t know when you’ll finish onboarding key suppliers?

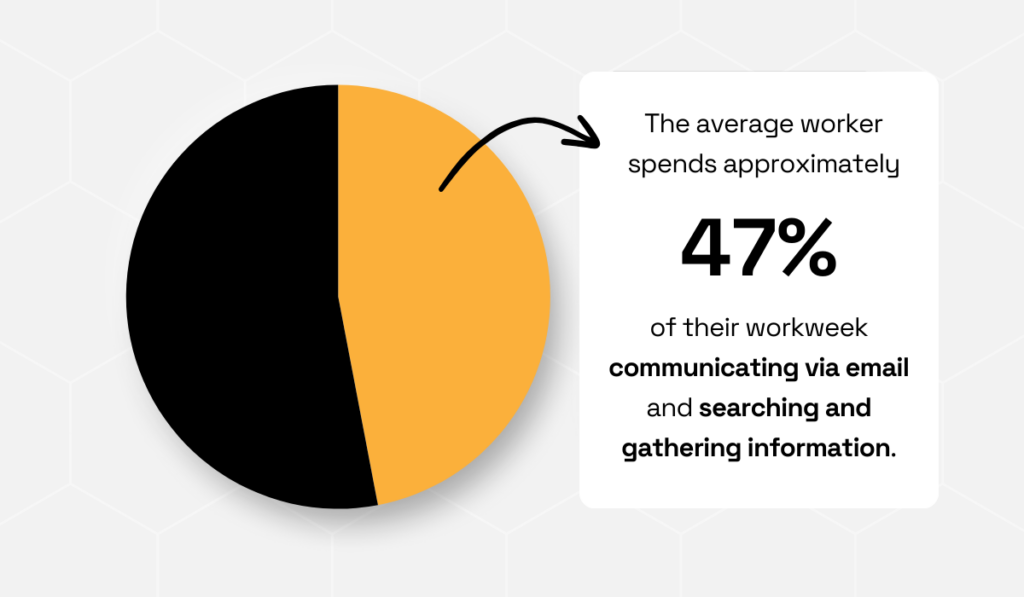

Take it from an automotive company that set out to manually onboard 2,000 suppliers in two years.

Four years later, the company still hadn’t reached that goal.

Source: Deloitte

They learned firsthand that manual onboarding offers little to no visibility over the progress.

Tracking even basic information, like which supplier comes next, becomes difficult.

This illustrates just how unpredictable and messy manual onboarding can be.

Automation and digitization, on the other hand, can significantly speed up and streamline it.

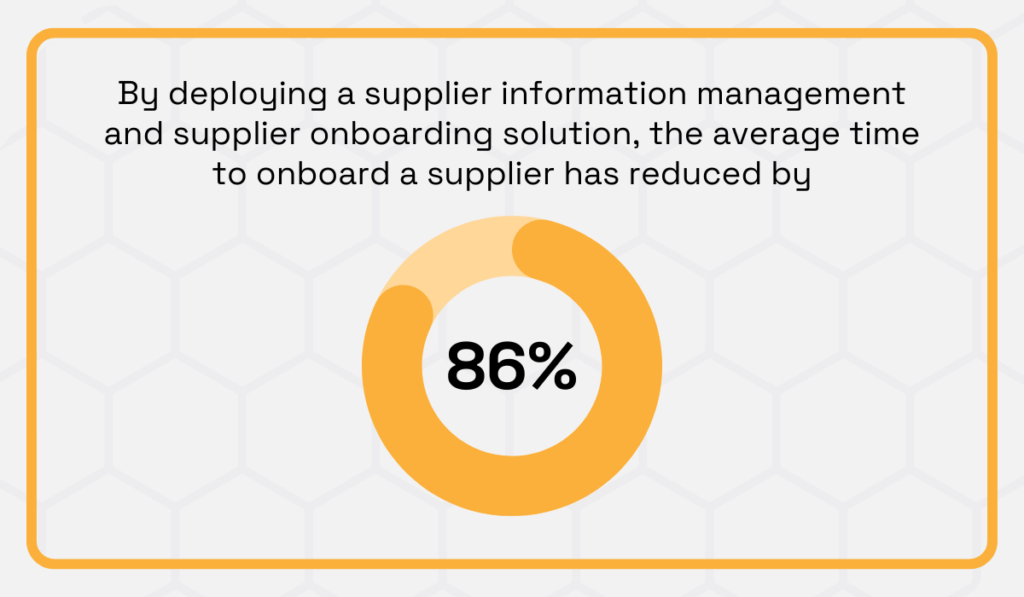

For instance, one case study shows that using a dedicated supplier onboarding portal, equipped with self-service and automation capabilities, can reduce onboarding time by over 80%.

Illustration: Veridion / Data: HICX

Such tools eliminate inefficient data management and reduce the burden on procurement.

In the end, everybody wins: buyers can reach their goals faster, while suppliers have a smoother experience.

Manual supplier onboarding comes with a high risk of human error.

Unlike automated systems, people get tired, distracted, and overwhelmed. That’s when they make mistakes.

And the worst part is, slip-ups can happen at any stage of onboarding.

You could forget to get a supplier’s signature or fail to give them their login details on time.

But human errors are especially common—and especially disruptive—during data entry.

It’s easy to mistype information, skip a required field, or link the wrong record. And since these errors are hard to spot, they often slip through the cracks until it’s too late.

According to the Beamex white paper, the acceptable error rate for manual data entry is 1%.

But even if we assume that humans make data entry mistakes only 1% of the time, this rate is still not negligible.

For example, if we’re entering 10,000 supplier data points, we can expect at least 100 to be incorrect.

These errors, even if they’re simple typos or incomplete fields, can cause many issues, such as misinformation about suppliers.

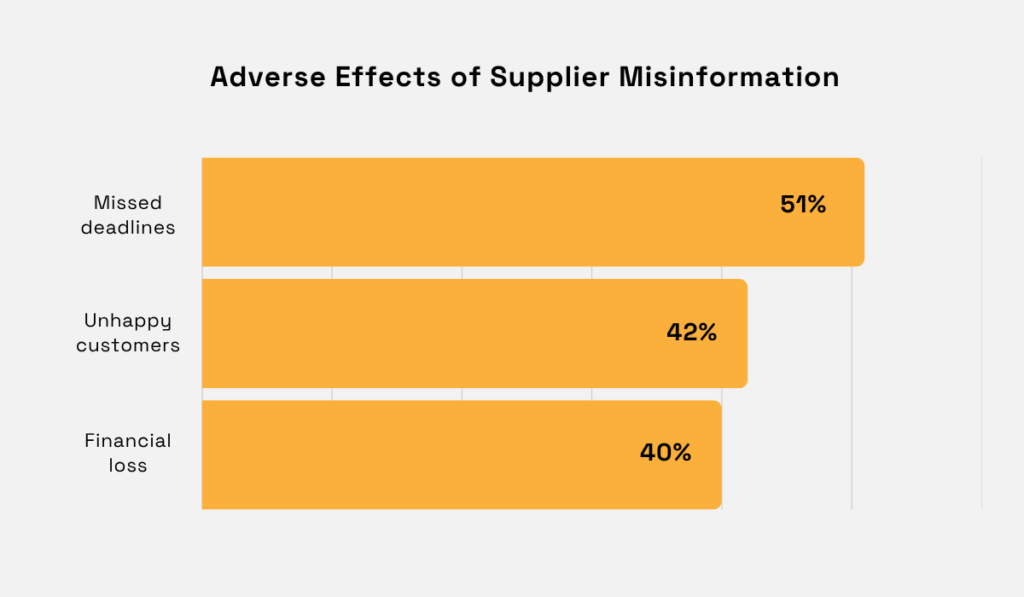

According to TealBook’s 2020 Supplier Information Study, poor supplier data frequently causes missed deadlines, unhappy customers, and financial loss.

Illustration: Veridion / Data: TealBook

Here’s how these consequences can look in real-world settings:

| Missed deadlines | Unhappy customers | Financial loss |

| Payments get delayed because the buyer has incorrect supplier payment information. | The buyer has incorrect product codes and accidentally orders the wrong items, leading to wrong deliveries. | The buyer has incorrect supplier ESG data and unknowingly works with non-compliant suppliers, risking penalties and fines. |

These issues are even more likely when multiple people handle supplier data.

And in many companies, that’s exactly what happens.

Suppliers usually first submit their information manually. Then someone in procurement re-enters that data into internal systems.

Other departments may enter the data again into other systems.

Each of these touchpoints increases the chance of mistakes.

To reduce it, companies need to replace these manual efforts with automation.

Though there are many data validation solutions on the market, many companies still rely on outdated supplier data.

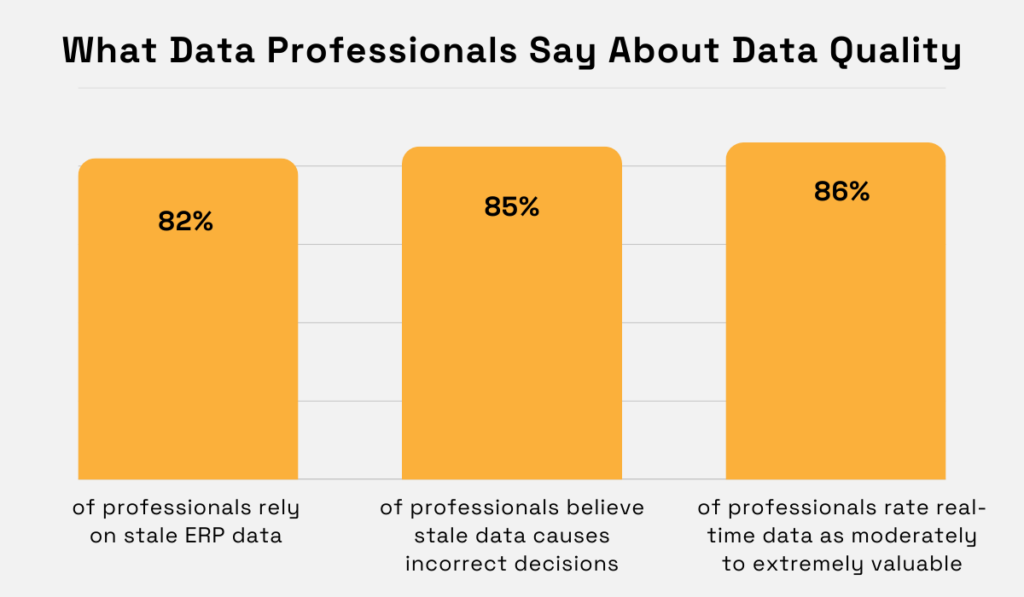

Fivetran’s 2022 report found that 82% of surveyed data professionals rely on stale ERP data, including supplier data.

85% of them agreed that working with such data leads to poor business decisions.

At the same time, as many as 86% rated real-time data as moderately to extremely valuable.

Illustration: Veridion / Data: Fivetran

This shows that most data professionals are aware of the fact that outdated data causes misinformed decisions.

When it comes to supplier data in particular, staleness can lead to supply chain disruptions, compliance risks, and missed opportunities for better sourcing.

As George Fraser, CEO of Fivetran, said, companies that want to make data-driven decisions can’t afford to rely on outdated information.

The ones that succeed will be those with access to current data and the ability to act on it quickly.

Illustration: Veridion / Quote: Fivertran

But let’s face it: manually keeping data fresh and accurate is nearly impossible.

It would require procurement teams to track, verify, and update information daily, leaving little time for everything else they need to manage.

And most of them simply can’t dedicate that much effort to just one part of their workload.

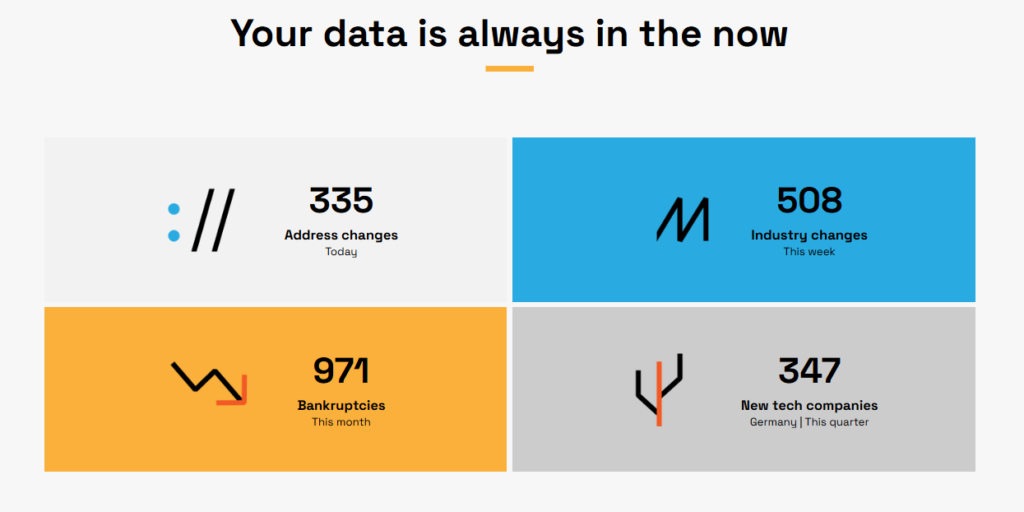

Luckily, data platforms like Veridion can do this heavy lifting for them.

Veridion equips procurement teams with fresh, verified data for over 120M companies worldwide.

It gathers over 60 data points, covering everything from basic firmographics to sustainability metrics.

The data gets updated weekly, allowing teams to make decisions based on the most recent information.

Source: Veridion

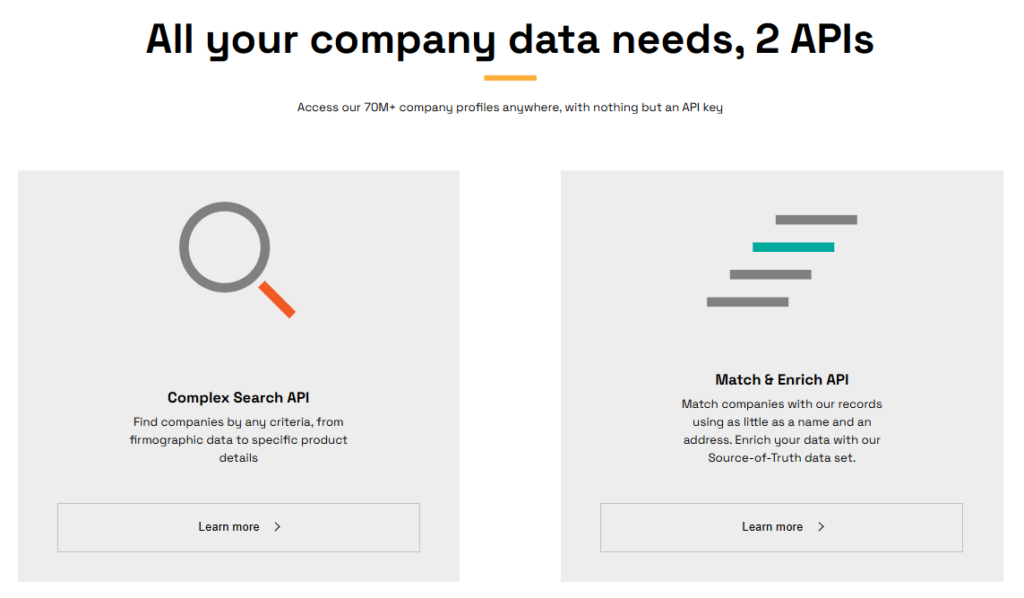

There are two main ways to use the platform:

First, you can use it to quickly find the exact suppliers you need, no matter how specific your criteria.

Second, you can use Veridion as a reliable source of truth, helping you enrich and verify your internal supplier data with ease.

Source: Veridion

In short, Veridion gives you a real-time view of supplier capabilities, risk, and fit, without the need to collect, enter, or verify data yourself.

Additionally, Veridion also keeps data secure and confidential.

This is something manual onboarding processes often fail to guarantee.

Manual supplier onboarding often involves both parties sharing sensitive data through unsecured channels, usually over email.

For example, new vendors may be using email to share tax details, payment accounts, or legal documents.

These communications, however, can be intercepted and misrouted.

When sensitive data is shared through unsecured channels, it can easily fall into the wrong hands, putting both you and the supplier at risk.

And data breaches like these are becoming increasingly common.

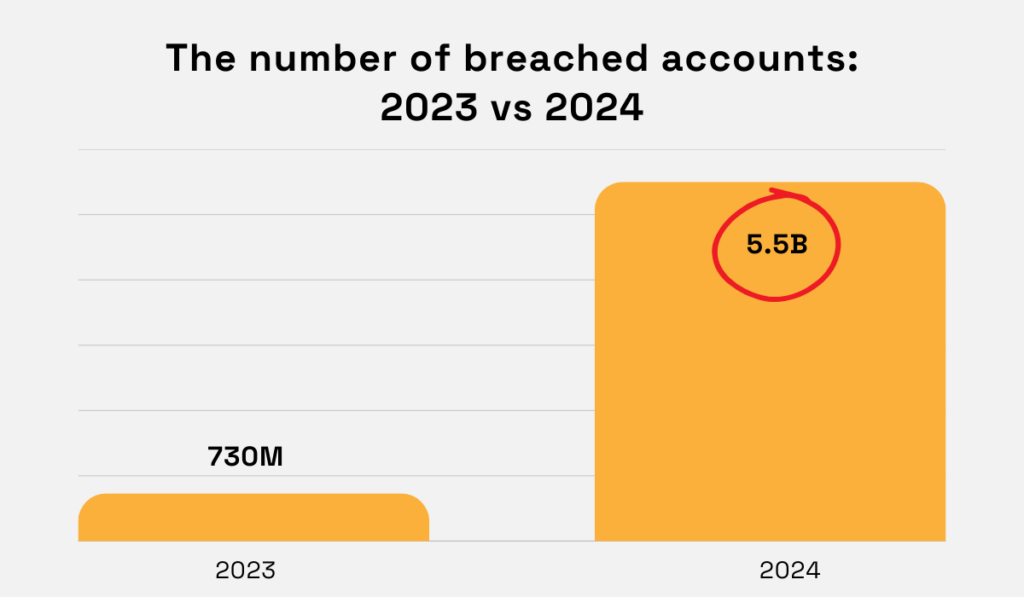

According to a Surfshark study, global data breaches surged from 730 million in 2023 to a staggering 5.5 billion in 2024.

Illustration: Veridion / Data: Surfshark

But the risks don’t stop there.

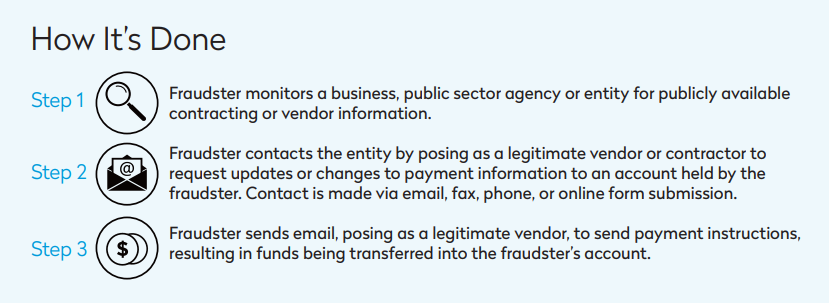

Unsecured channels also open the door to fraud and other security threats. For instance, vendor impersonation fraud is particularly common.

In this type of social engineering scam, a fraudster pretends to be a vendor and, typically, sends the buyer fake payment details via email.

If the buyer uses those details, they’ll send the next payment straight into the scammer’s account instead of the real supplier’s.

Source: Nacha

Of course, these risks are not limited to email communications.

They are present with all types of non-secure channels, be it VoIP apps like WhatsApp and Viber, or traditional phone calls.

The bottom line is, the risk of data breaches, compliance violations, and fraud always exists with open channels.

And these events lead to further negative consequences, such as:

The best way to mitigate this risk is to use automated onboarding systems with built-in security measures.

For ongoing communication, choose platforms that offer data encryption and access controls.

As we already mentioned, manually onboarding suppliers makes it difficult to set clear deadlines and expectations.

Standardizing the process is difficult, especially because it’s so dependent on the people involved.

However, this ad-hoc approach can be extremely problematic for suppliers, too.

They often have no idea what to expect from onboarding and lack clarity about their progress and the buyer’s requirements.

Ian Thompson, Ivalua’s VP for Northern Europe, explains the root cause of this issue.

He mentions that, when handled manually, onboarding is often conducted multiple times in multiple places without a centralized process.

Illustration: Veridion / Quote: LinkedIn

In other words, different departments and leaders often onboard the same suppliers multiple times.

Suppliers frequently end up filing out the same forms over and over again, re-uploading documents, or just waiting in silence while trading partners work out where things got stuck internally.

So, it’s no surprise that many suppliers get frustrated and confused.

Some may get so discouraged that they drop out mid-onboarding. Others will continue, but carry lasting frustration and skepticism into the relationship.

The former CMO of HICX, Anthony Payne, points out how these initial interactions influence long-term collaboration:

Illustration: Veridion / Quote: HICX

So, if onboarding is inconsistent, you can expect the rest of the relationship to reflect this.

Buyers may struggle with delays, miscommunication, and duplicated efforts, while suppliers lose trust and become less responsive or committed over time.

The best way to solve this is, once again, through automation.

By automating onboarding, you can ensure a consistent, clear, and efficient experience for everyone.

Every supplier will go through the same steps.

The buyer, on the other hand, will have clear visibility over their progress and ensure the most efficient resource allocation.

When suppliers are onboarded manually, their data often gets stored across spreadsheets, email threads, and filing cabinets.

This makes it difficult to find the necessary information, especially if it was initially stored or requested by another department.

Grzegorz Filipowski, the Head of Consulting at Marketplanet, a leading digital procurement company, perfectly illustrates the issue.

He describes a scenario where procurement approves a supplier, finance flags missing tax info, and operations reports outdated contact information.

None of these departments is necessarily wrong, Filipowski says.

They may simply be storing the data in different places, with some sources being outdated or incomplete.

Illustration: Veridion / Quote: LinkedIn

A lack of a single source of truth leads to risk and confusion. This becomes especially apparent when teams need to make urgent decisions or face audits.

In these scenarios, the inability to find the right information quickly can cost companies money, time, and their reputation.

For example, compliance teams might scramble to collect documentation scattered across multiple systems, raising red flags for regulators during audits.

And during urgent fulfillment cycles, operations may reach out to suppliers using outdated contact details, delaying critical shipments during peak demand.

Unfortunately, this is the reality for most companies in the US.

A 2025 survey of 250 US supply chain decision-makers revealed that 75% of companies need to consult 3 to 10 systems before they can make supply chain decisions.

The average organization uses five.

Illustration: Veridion / Data: SupplyChainBrain

To avoid similar scenarios—at least when it comes to supplier data—consider using a digital onboarding platform.

These platforms keep all documents and communications in one secure location.

They also make it easy for your team to access supplier records, regardless of department.

When everything is stored in one centralized location, collaboration, retrieval, and oversight become much simpler.

Manual supplier onboarding is no longer a sustainable option, especially as companies face growing demands to implement stricter internal guidelines..

On top of that, manual processes are time-consuming, error-prone, and frustrating for everyone involved.

The good news is that today, there are plenty of reliable tools available to automate onboarding.

Use them to build stronger, more efficient supplier relationships from day one, and watch your onboarding times go from weeks or months to days.