6 Steps of the Supplier Relationship Management Process

Are you among the 83% of CPOs planning to enhance core procurement capabilities like supplier performance and relationship management?

Solid supplier relationships drive organizations’ operational resilience, cost savings, and innovation, and the fastest way to see the difference is by investing in the six essential steps of supplier relationship management (SRM).

In this guide, you’ll find practical advice, real-world examples, and proven frameworks you can start using today, so let’s dive right in.

Classifying your suppliers is the first step in any supplier relationship management process.

After all, you shouldn’t treat every supplier the same way.

Segmenting suppliers means taking into account their strategic importance, spend volume, and risk to help you create a clear picture of who matters most to your business.

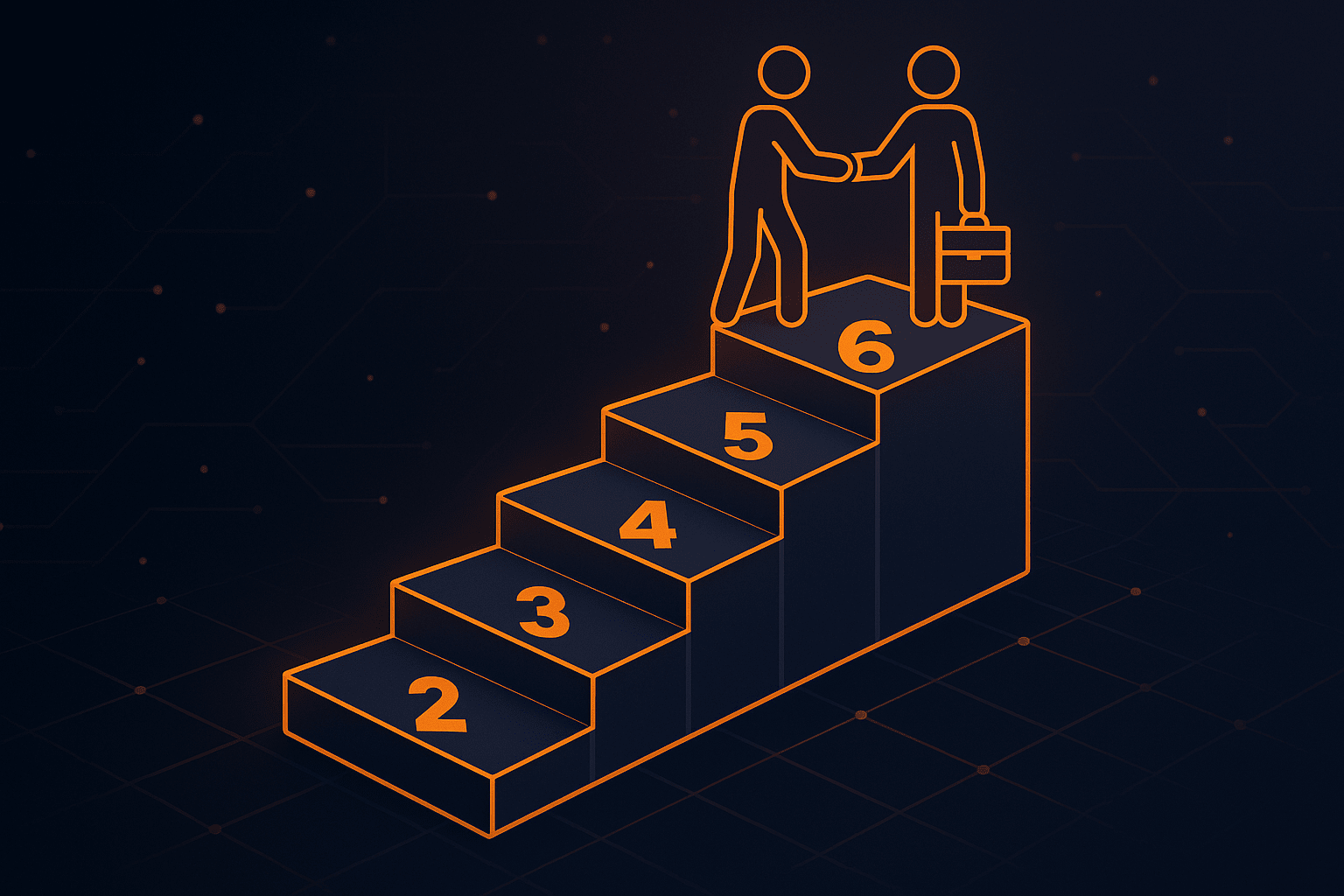

Recent procurement trends reflect this shift toward more hands-on SRM.

Deloitte’s findings show that supplier-focused strategies dominated the 2023 CPO strategies, with 25% focusing on restructuring supply bases.

Illustration: Veridion / Data: Deloitte

Although this strategy is the least represented in the percentages, reassessing your supply base lays the groundwork for the other two.

Think about it: you can’t collaborate or negotiate effectively until you’ve clarified which suppliers require which level of effort.

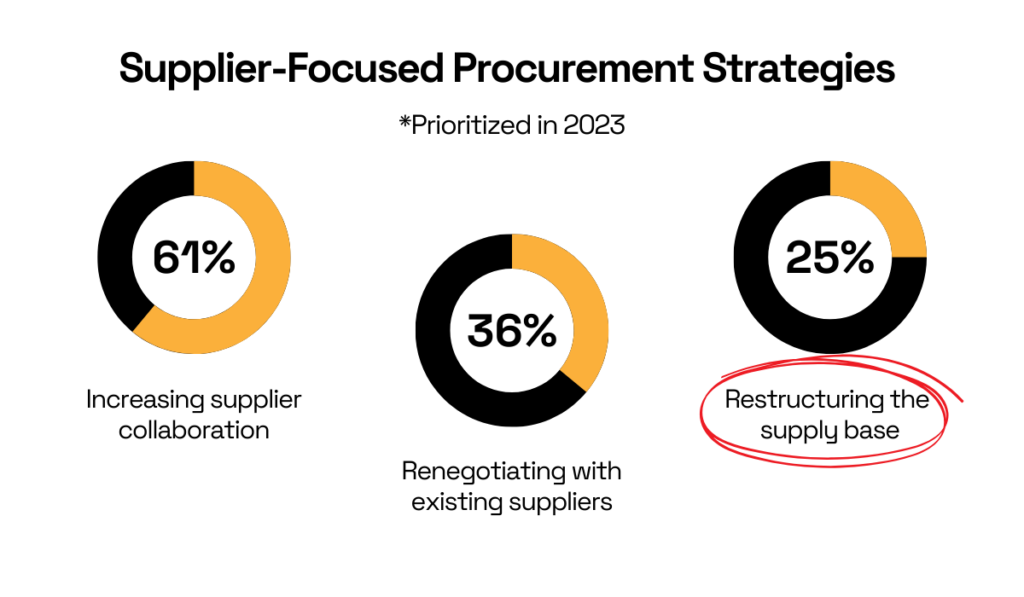

One practical tool for this initial identification is the Kraljic Matrix, which sorts suppliers into four categories based on profitability impact and supply risk.

For instance, strategic suppliers have both high business impact and risk, which calls for closer partnerships and contingency planning.

Source: Veridion

As illustrated, the matrix also includes leverage and bottleneck suppliers, which call for cost optimization and risk mitigation, respectively.

Meanwhile, non-critical suppliers require less intensive management.

The Kraljic Matrix’s broad division of suppliers is effective when used at the right stage of SRM, but just like with every method, you should keep in mind that it’s neither perfect nor definitive.

As noted by the Expert Program Management (EPM) team in a video, one obvious limitation is the lack of clarity around what constitutes “supply risk.”

Illustration: Veridion / Quote: EPM on YouTube

So in practice, you’ll likely need to supplement this framework with custom criteria and SRM objectives tailored to your company’s needs.

The main takeaway?

Effective segmentation lays the groundwork for smarter, more strategic supplier management, while the Kraljic Matrix and similar frameworks help keep SRM efforts aligned with your organization’s risk, value, and business priorities.

Building on these segmentation efforts means introducing clear, measurable objectives for each group.

What’s the use of thorough classification and distinct strategies if you can’t track performance or aren’t sure what constitutes a win-win partnership in specific cases?

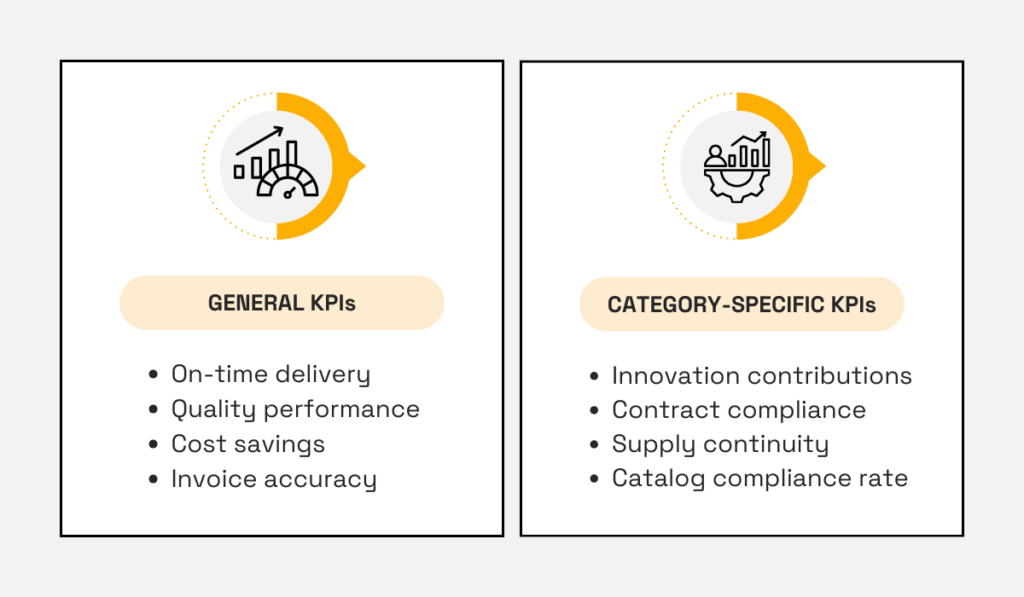

Fortunately, this is where supplier KPIs come in—measuring cost efficiency, delivery reliability, quality standards, and innovation performance.

These indicators turn expectations into something concrete and trackable.

For example, you might set a KPI for on-time delivery rates above 98% for your strategic suppliers or negotiate quarterly cost-saving initiatives with non-critical suppliers.

But besides general supplier metrics, there are also category-specific KPIs such as innovativeness, contract compliance, supply continuity, and catalog compliance rate, tailored to different supplier segments.

Source: Veridion

Of course, the point isn’t just measurement: It’s alignment.

When suppliers know exactly what you expect and how it will be evaluated, it removes ambiguity and encourages mutual accountability.

Mutual expectations are the backbone of long-term supplier collaboration.

When both sides work toward shared, measurable goals, supplier relationships that start as transactional deals can evolve toward partnerships with strategic value.

Take Danone, for example.

The company recently finalized several high-impact partnership agreements, marking a new phase of collaboration with key suppliers.

Source: Food Tech Biz

Isabelle Esser, Danone’s Chief Research, Innovation, Quality and Food Safety Officer, explains how this initiative serves to expand scientific expertise and co-develop new products.

How does it do that?

By setting more ambitious objectives for the company’s most valuable supplier partnerships.

Illustration: Veridion / Quote: Danone

Clear, category-appropriate objectives enable mutual growth while driving competitive advantage.

Ultimately, setting SRM objectives is a strategic tool that ensures both sides are working toward the same outcomes, laying the groundwork for operational improvements and deeper, long-term partnerships.

Next up, it’s time to build tailored relationship strategies that reflect both the importance of the supplier and the nature of your collaboration.

To put it simply, you have to decide how you manage each supplier from day one, from overall communication and contract management to performance monitoring.

Many organizations focus on finding and bringing in different software to make this process smoother, but there’s no skipping steps.

That’s why Darren Lynch, VP for Consulting at GEP Europe, emphasizes the importance of first building foundations that can accommodate different supplier segments, and only then choosing specific tools and platforms.

Illustration: Veridion / Quote: Supply Chain Digital on YouTube

Taking things one step at a time ensures the match between the management structure and your supplier’s role.

So, what do you need to keep in mind?

For starters, you need to develop distinct communication plans, governance frameworks, and development strategies for each category.

After all, there’s a big difference between how often and how formally you communicate with strategic partners compared to more transactional suppliers.

Strategic relationships call for quarterly business reviews and leadership-level meetings, while transactional ones might only need periodic check-ins.

Here’s one practical way to outline those key considerations:

| Supplier category | Communication frequency | Governance | Focus |

|---|---|---|---|

| Strategic | Quarterly reviews, project calls | Steering committee | Co-innovation and risk sharing |

| Leverage | Monthly ops calls | Contract management | Cost savings, performance improvement |

| Bottleneck | Risk-based check-ins | Contract management | Supply continuity, risk mitigation, lead time reduction |

| Non-critical | Annual review emails | Automated monitoring | Process efficiency |

Once you’ve established all the specifics, you need to make sure they’re accessible to all the relevant departments and staff in your organization.

This typically includes knowledge bases, books of procedures, and supplier manuals that centralize relevant information.

Oscar Benitez Cárdenas, an experienced sourcing specialist and procurement consultant, recommends outlining clear roles, responsibilities, and decision-making limits to prevent any misalignment.

Illustration: Veridion / Quote: LinkedIn

In short, relationship strategies ensure that expectations turn into action, with the right people engaged at the right times for the right reasons.

By building tailored relationship strategies, you pave the way for proactive supplier management, fostering efficiency and long-term collaboration by design, not by chance.

With strategies in place, the next step is to put them into action and introduce the tools that make them stick and work for you.

This means actively managing supplier relationships, streamlining processes, and resolving internal roadblocks before they can affect your supply base.

And that’s no small task.

A recent survey by Fictiv found that 32% of CPOs rank internal complexity among their top three organizational risks.

Illustration: Veridion / Data: Fictiv

When internal approval bottlenecks, poor data visibility, and inconsistent processes persist, the supplier experience suffers, leading to delays, payment issues, and missed opportunities.

The implementation stage is where you prevent this, starting with aligning internal teams and ensuring suppliers are properly onboarded into the new workflow.

And this is the time to introduce modern supplier management tools that can make a real difference.

For instance, supplier onboarding solutions help you design approval workflows, send personalized registration forms, and store supplier records in centralized catalogues for easy access.

Precoro recently enhanced their platform’s onboarding features, offering a smoother, more transparent experience for both buyers and suppliers, as showcased below:

Source: Precoro on YouTube

Of course, the data is immediately entered into an extensive catalogue, which you can access at any time to review completed forms, attachments, and notes.

For supplier discovery and risk monitoring, data services like Veridion give you access to a global supplier database, enriched with detailed profiles, risk factors, and weekly AI-powered updates.

Imagine having detailed third-party risk data at your fingertips, catching shifts in supplier relationships before they snowball into operational setbacks.

Source: Veridion

And to stay ahead, you can set up custom alerts for critical changes, ensuring minor issues don’t quietly escalate into major problems down the line.

Executing your SRM strategy rests on visibility, alignment, and consistency—the very qualities that turn a framework into lasting supplier partnerships.

Managing supplier relationships doesn’t end once strategies are in place—it requires continuous performance tracking to stay effective.

You need mechanisms to continuously measure and monitor supplier performance against the objectives you set earlier.

In fact, 83% of 350 CPOs surveyed by Deloitte say they’re prioritizing enhancements to foundational capabilities like supplier performance and relationship management.

Illustration: Veridion / Data: Deloitte

This means consistently tracking previously mentioned key metrics, such as on-time delivery, lead time adherence, contract compliance, and innovation contributions.

Doing so helps you see beyond isolated numbers and map trends that reveal where your suppliers are excelling and where risks might be forming.

In other words, it’s all about turning raw data into actionable insights.

A major part of this involves structured performance reviews and different supplier evaluation methods.

As procurement consultant Jassim Alampara points out, regular assessments, audits, and structured feedback loops are essential for tracking progress, mitigating risks, and identifying opportunities for improvement.

Illustration: Veridion / Quote: LinkedIn

And this is where modern tools step in.

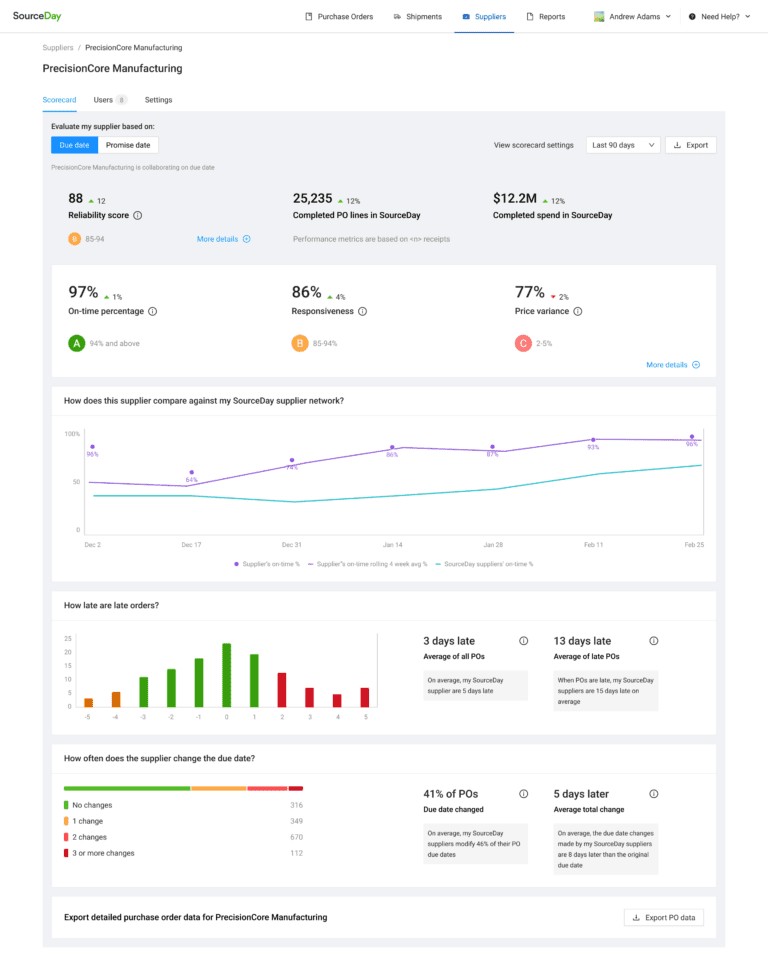

Supply chain software solutions like SourceDay are equipped with performance management features that make it easy to track essential KPIs at a glance.

As shown below, you can monitor on-time delivery rates, lead time performance, responsiveness scores, and price variance — all from an intuitive, real-time dashboard.

Source: SourceDay

The ability to see trends like average late days, frequency of due date changes, and supplier ranking against your network ensures nothing slips through the cracks.

The key is keeping these tools easy to navigate, with quickly updated information and visualizations that give procurement teams the control and clarity they need to act fast.

In SRM, proactive monitoring creates a world of difference, ensuring you make the most of every relationship and rise above industry peers.

With performance measurement mechanisms in place, you unlock one of the biggest advantages: actionable insights.

These insights shift your supplier relationships from transactional to strategic.

Research shows that 77% of companies across industries are actively investing in deeper, more collaborative supplier partnerships.

Illustration: Veridion / Data: Gartner

And while Gartner’s figure came from 2020, more recent studies back it up.

The aforementioned Deloitte survey reaffirms that supplier collaboration remains a top procurement strategy for building more resilient supply chains and delivering long-term value.

But how do you actually use the data you’ve gathered to strengthen supplier relationships?

For starters, analyzing performance reviews helps you identify mutual improvement opportunities.

If a supplier consistently delivers on time but struggles with responsiveness, you know you need to open a conversation about streamlined communication methods.

And if data shows rising lead times across several suppliers, consider joint efficiency initiatives or collaborative forecasting.

You can also use these insights to recognize and reward top-performing suppliers.

The point is to turn metrics into meaningful conversations about shared goals, product development opportunities, or ways to reduce operating costs together.

Tools and platforms that focus on improving supplier experience make this even easier.

Take Pharmx, a healthcare distribution technology provider, that recently rolled out a new supplier portal that cut integration times from 12 days to just one.

Source: Pharmx

The platform also provides suppliers with real-time analytics, order management tools, direct connections to pharmacy customers, and marketing support.

In the end, Pharmx’s goal was simple: reduce barriers to entry and strengthen supplier participation in its growing network, which is exactly what they did.

But remember, you don’t need a formal platform to strengthen relationships with your suppliers. Much of it comes down to adopting the right mindset.

Kate Vitasek, founder of Vested and an expert on collaborative supplier relationships, sums it up well by noting that every individual win or loss is also a shared one.

Illustration: Veridion / Quote: Art of Procurement

Yes, it really is that simple.

Because when partnerships are built on mutual success, continuous improvement follows suit, ultimately creating a powerful competitive advantage.

When managed strategically, strong supplier relationships become a real business advantage.

Following these six SRM steps gives structure to your supplier interactions—aligning goals, tracking performance, and building long-term trust.

The payoff?

A more resilient, collaborative supply base that supports your growth.

Whether you’re refining processes or investing in key partnerships, a well-executed SRM approach turns day-to-day supplier management into a real value driver.

So, explore the tools and frameworks, and see the advantages for yourself.