How to Find the Right Suppliers for Your Business

Key Takeaways:

Supplier sourcing decisions can make or break a business.

Choose the right one, and you gain a long-term partner who supports you in tough times, drives innovation, and even offers competitive pricing.

Choose the wrong one, however, and you risk damaging your profitability, efficiency, and reputation.

Here’s the thing, though: finding the right supplier isn’t about luck.

It’s about knowing what to look for and where to look.

So, keep reading, and you’ll discover a clear, step-by-step process to identify, evaluate, and secure suppliers that align with your business goals and needs.

Before reaching out to any suppliers, be sure to clearly define what exactly you’re looking to source.

It’s like building your ideal supplier profile.

The more detailed you are early on, the better your chances of finding a partner who truly fits your business.

So, take the time to outline your preferences in terms of:

| Pricing and budget | Target price range and total cost of ownership |

| Product or service requirements | Quantities, materials, dimensions, and technical specifications |

| Delivery timelines and frequency | One-time vs recurring orders, lead times, and delivery schedules |

| Quality standards | Required certifications, quality control expectations, return policies, and defect tolerances |

| Compliance requirements | Industry standards, environmental or regulatory requirements |

| Location | Domestic vs. overseas suppliers, single vs multiple delivery locations |

Feel free to add any other criteria that are specific to your organization to this list.

Now is the ideal time to define these details to ensure a smoother and more efficient sourcing process down the line.

For example, Corey Ferreira, Senior Growth Marketer at Voiceflow, a platform for designing conversational AI experiences like chatbots and voice assistants, prioritizes supplier experience:

Illustration: Veridion / Quote: Shopify

That’s what this phase is really about—reducing risk and increasing alignment.

When you establish your non-negotiables and preferences early, you save yourself from costly missteps later.

In fact, you can take your list of supplier criteria a step further and break it into these three buckets:

When you go into the sourcing process with clear, documented, and prioritized requirements, you’re setting yourself up for success.

Selecting a stable and reliable partner is easy. You just need to know what stability and reliability look like for you.

Once your needs are clearly defined, it’s time to look for suppliers who can meet them.

But where do you start?

Let’s break some of the options down, from the simplest to the most advanced.

Most people start with a Google search:

Source: Google

It’s accessible and easy, but often overwhelming.

You’ll likely find yourself digging through outdated websites, vague company descriptions, and contact forms that go nowhere.

It’s useful for quick, preliminary research, but not something you want to rely on for making a final decision.

The next method entails tapping into your network.

Getting referrals from industry peers, partners, or colleagues can surface trusted suppliers faster than any search engine.

Peter Scott, Client Director at supply chain consultancy Proxima, prefers this approach:

Illustration: Veridion / Quote: American Express

That said, this method works only if your network is broad. Those with limited networks will have limited options.

Now, if you’re the kind of person who prefers to shake hands and see the product up close, trade shows might be your best option.

These events bring together hundreds—sometimes thousands—of suppliers under one roof.

The downside?

They require time, travel, and money, which is not always realistic for smaller teams or fast timelines.

Another great option is online supplier directories, which compile thousands of manufacturers, wholesalers, and suppliers in one, easily searchable platform.

Popular directories include:

These directories give you access to thousands of profiles, but not all of them are up-to-date or legitimate, so caution is key.

But what if none of these methods work?

Maybe you’re sourcing something incredibly niche, struggling to find recent data, or exploring overseas markets where language barriers or lack of visibility make the process nearly impossible.

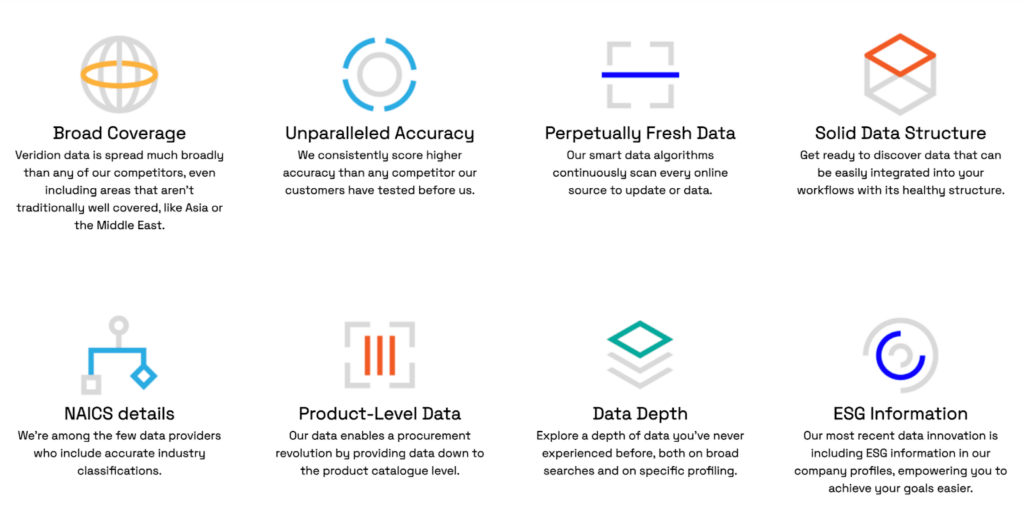

That’s when it’s time for something smarter: AI-powered supplier sourcing platforms like our Veridion.

Veridion profiles any supplier or company with a digital footprint, covering over 120 million businesses across 200 countries.

Source: Veridion

The database is updated weekly and delivers information about all aspects of a business, from legal names to specific product traits to ESG Materiality mapping.

And now, thanks to our newest tool, Scout, finding suppliers has never been easier.

Just type what you’re looking for in plain language, and Scout searches across millions of profiles to deliver highly targeted results:

Source: Veridion

Whether you need suppliers with niche certifications, sustainable practices, or those offering specialized or customizable solutions, Scout filters and delivers.

Forget endless Google searches, dead-end directories, or expensive trade shows.

Scout puts the entire supply chain at your fingertips, so you can find the right partners in moments, not months.

When every other method comes up short, choose Veridion.

After you’ve completed your initial research and compiled a longlist of potential suppliers, you’ll quickly see that the market offers no shortage of viable options.

But you’re not just looking for a decent supplier—you’re searching for one that’s the perfect fit for your business.

That’s why the next step is to narrow your longlist into a focused shortlist of the most promising candidates.

At this stage, it’s time to dig deeper into each supplier’s operations, risks, and overall capabilities.

Peter Scott from Proxima, whom we’ve already mentioned, elaborates:

Illustration: Veridion / Quote: American Express

A smart way to do this is by creating a standardized supplier checklist or scorecard.

This allows you to assess each supplier systematically using criteria that align with your business priorities.

Daniel Dowd, VP of Supplier Quality at Estée Lauder Cos., an American multinational cosmetics company, uses this method as well:

Illustration: Veridion / Quote: Supply Chain Dive

While they use it for assessing their current suppliers, the same method can be applied to potential candidates as well.

At this point, you’ll need more detailed information about each supplier’s capabilities and stability, which likely won’t be available online.

This is where a Request for Information (RFI) comes in.

RFIs serve as an opportunity to ask suppliers the specific questions you need answered before moving forward.

The structure and content of your RFI will vary depending on your industry, but generally, it should include:

| Project overview | Provide context by outlining the project’s goals and expected outcomes. |

| Time frame | Clearly state the project timeline and the deadline for suppliers to respond to the RFI. |

| Specific requirements | Share any technical or operational parameters that will help suppliers respond accurately. |

| Response guidelines | Define how suppliers should submit their information and in what format. |

| Additional insights | Leave space for suppliers to offer suggestions or relevant details beyond your specific questions. |

Once the responses are in, you can go back to your scorecard, evaluate the candidates side by side, and build a shortlist of those who are truly worth your time.

And just like that, you’re one step closer to finding that perfect-fit supplier who will help your business thrive.

Next, you’ll need to request quotes through a Request for Quotation (RFQ) to obtain detailed pricing and commercial terms from suppliers who have passed the initial screening.

This is where things get even more specific, covering aspects such as quantities, costs, delivery timelines, and contract terms.

An RFQ typically includes several key details to help vendors provide accurate proposals:

| Product/service details | A clear breakdown of your project’s specifications. |

| Submission deadline | The date by which vendors should submit their quotes. |

| Delivery requirements | Expected timelines for project completion or product delivery. |

| Contract terms | Any legal or contractual considerations, such as penalties, liabilities, or service-level agreements. |

| Evaluation criteria | Information on how you will assess and compare the submitted bids. |

Ian Jennings, Associate Director at Carne Group, a third-party management group in Europe, recommends including a Q&A period in the RFQ process as well.

According to him, this yields much better responses:

Illustration: Veridion / Quote: Smartsheet

Just be sure to give vendors enough time to prepare a comprehensive and thoughtful reply.

For smaller RFQs, a two-week response window is a good starting point. For larger or more complex projects, consider extending the deadline.

Jennings notes:

“I provide timelines that consider the complexity of our needs and the time vendors need to create comprehensive responses. When you give ample time, you receive well-thought-out proposals rather than rushed and incomplete ones.”

Remember, suppliers get a lot of these requests, so be patient and make sure you don’t overwhelm them with too many questions.

In procurement, seeing is believing.

Requesting samples from a select few suppliers helps verify quality and ensure the product meets your company’s standards before committing to a larger order.

This is always a good idea, but it’s especially important when dealing with:

Take UNICEF, for example.

They procure a wide range of commodities, like medicines, medical devices, school supplies, and more, that help support children’s health, education, and protection.

Ensuring the quality of these products and services is critical.

Counterfeit, substandard, or contaminated medicines, devices, or nutrition items can be dangerous and even fatal.

That’s why UNICEF always requests and tests samples to ensure these items are safe and meet their specifications and standards, according to their website:

Illustration: Veridion / Quote: UNICEF

You should do the same whenever possible.

The quality of a sample offers valuable insight into a supplier’s capabilities: not just in product quality, but also in meeting deadlines and ensuring goods arrive in proper condition.

It’s an early indicator of reliability and professionalism.

Lastly, it’s time to finalize the deal.

This is the stage where you negotiate and clearly define all key aspects of your supplier relationship, including:

Laying out these parameters upfront ensures both parties understand their responsibilities, reducing the risk of misunderstandings or disputes.

It also offers legal protection if issues arise later on.

That’s why Ben Price, Co-Founder of Heatable, a boiler installation company, doesn’t shy away from negotiating the terms they don’t like:

Illustration: Veridion / Quote: American Express

After all, you want to minimize risks as much as possible.

However, you shouldn’t be focused only on securing the best deal for your company.

Instead, prioritize a win-win approach, where both parties walk away feeling good.

That’s the kind of relationship that lasts.

To achieve this, Henry Stannard, Head of Strategy and Value Creation at Coalesce Capital, a private equity firm, suggests giving suppliers flexibility in how they fulfill their side of the agreement:

Illustration: Veridion / Quote: Raconteur

He gives the example of incentivizing a facilities management provider to achieve certain cleanliness standards, rather than dictating how often cleaning must occur.

Ultimately, a good contract doesn’t box the other party in. It enables both sides to succeed.

A supplier that’s the right fit for your company will understand this and work with you to create a contract that is flexible, practical, and built for real-world execution.

Behind every great supplier sourcing decision is one thing: data.

You need reliable, up-to-date information about every aspect of a potential partner’s operations to make truly informed decisions and protect your business from future disruptions.

So, the next time you’re researching a potential partner, pause and ask yourself: Can I trust this info? Or am I just hoping it’s accurate?

Your business deserves better than guesswork.

Take the time to dig deeper, ensure you’re leveraging reliable supplier intelligence sources, and make decisions based on data you can stand behind.