How to Implement a Sustainable Procurement Strategy?

Key Takeaways:

You want to make procurement more sustainable, or perhaps leadership has set this as a priority.

But where do you actually begin?

If you’re unsure, you’re not alone. Many teams have the same goal, but lack a clear roadmap.

That’s why we have put together this guide.

It breaks down the process into seven practical steps you can start implementing right away.

Let’s dive in!

Leadership and other stakeholders often need to green-light any major changes in procurement.

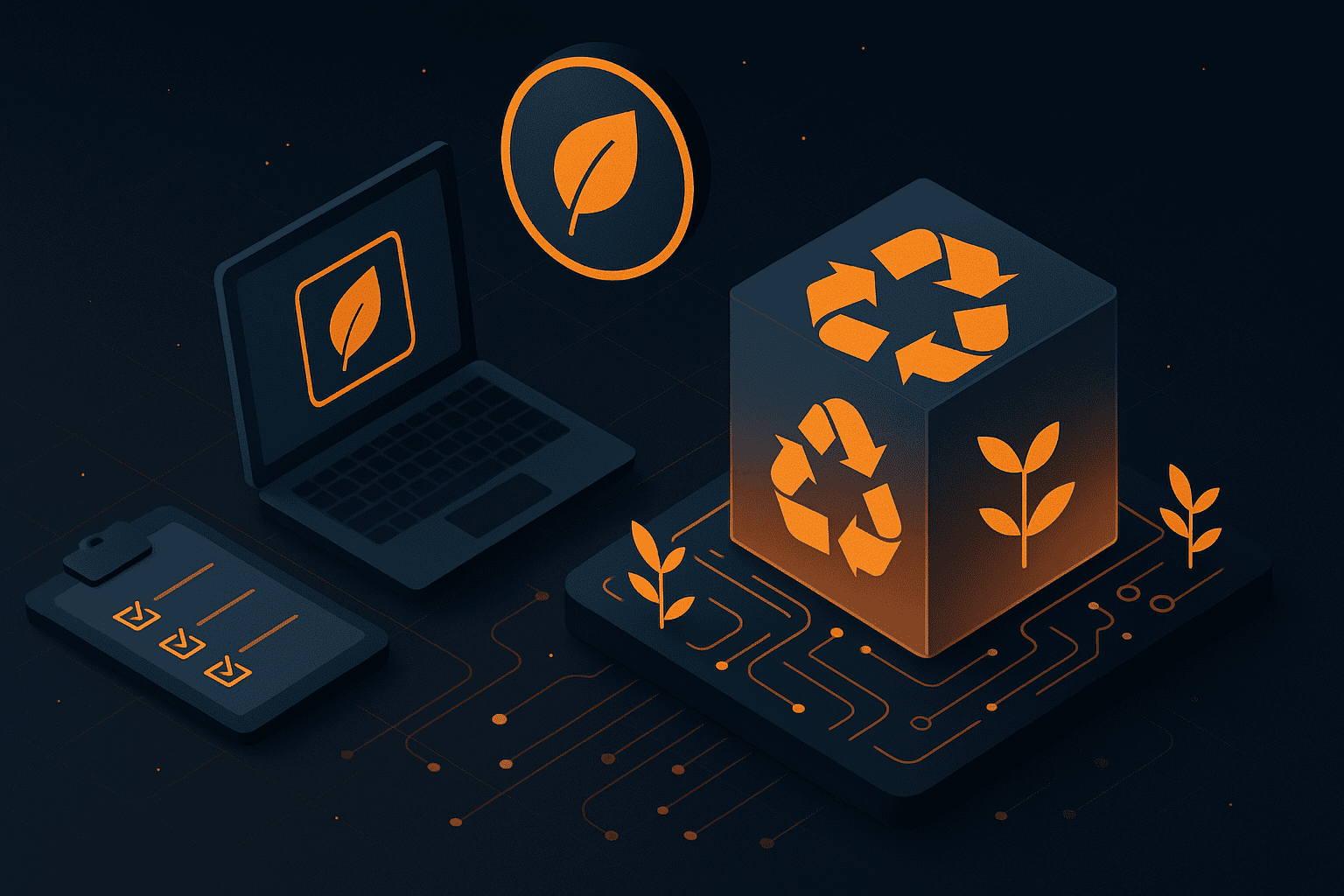

And introducing sustainability is no different, according to the Sustainable Procurement Barometer 2024 by EcoVadis.

The survey of approximately 600 buyer companies found that getting the C-suite’s buy-in is the main obstacle to sustainable procurement.

At the same time, sustainable procurement leaders consider it to be the most critical factor driving change.

Illustration: Veridion / Data: EcoVadis

So, getting buy-in from all relevant parties will be your first step toward implementation.

But how do you get buy-in from all stakeholders?

Well, the solution is twofold.

First, you need to prove the cost of inaction. Then, point to the benefits of doing the opposite, i.e., taking action.

For the first part, you could emphasize how unsustainable procurement exposed you to potentially hefty fines, supply chain disruptions, and reputational damage in the past.

Offering specific examples and numbers will make your case stronger.

When it comes to the benefits, sustainable procurement yields many. So, you can pick and choose which ones to focus on.

For example, McKinsey found that strong ESG performance reduces long-term costs by up to 10%.

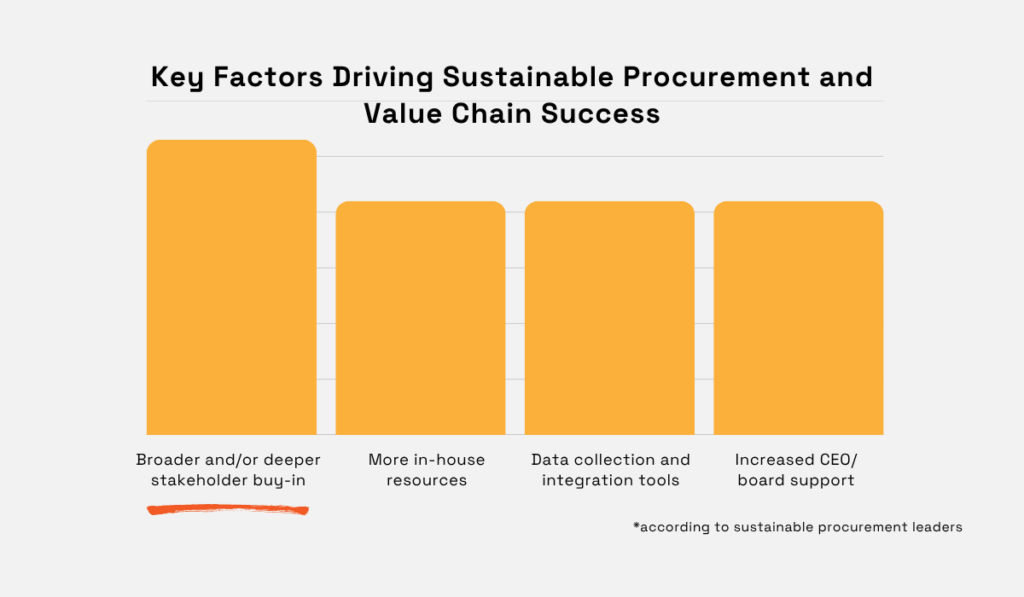

Kroll’s ESG and Global Investor Returns Study also showed that it drives higher annual returns.

More specifically, the ROI for ESG leaders averages around 12.9%, compared to 8.6% for laggards.

Illustration: Veridion / Data: Kroll

If leadership needs more convincing with real-world examples, Unilever could be a perfect fit.

This global consumer goods business, with household brands like Dove and Ben & Jerry’s, began shifting toward a sustainable business model in 2010.

This turned out to be a profitable move for the company.

Just two years later, they reported a turnover exceeding €50 billion.

By 2014, their sustainable living brands also started growing twice as fast as their other product lines. The same holds today, with these lines now driving about 50% of the company’s growth.

Source: Unilever

Many similar examples clearly show that sustainability is good for business.

Use them to frame sustainable procurement as a value driver, not just a compliance issue. This will be critical for getting the initial go-ahead.

Once you get it, it’s time to move on to the second step.

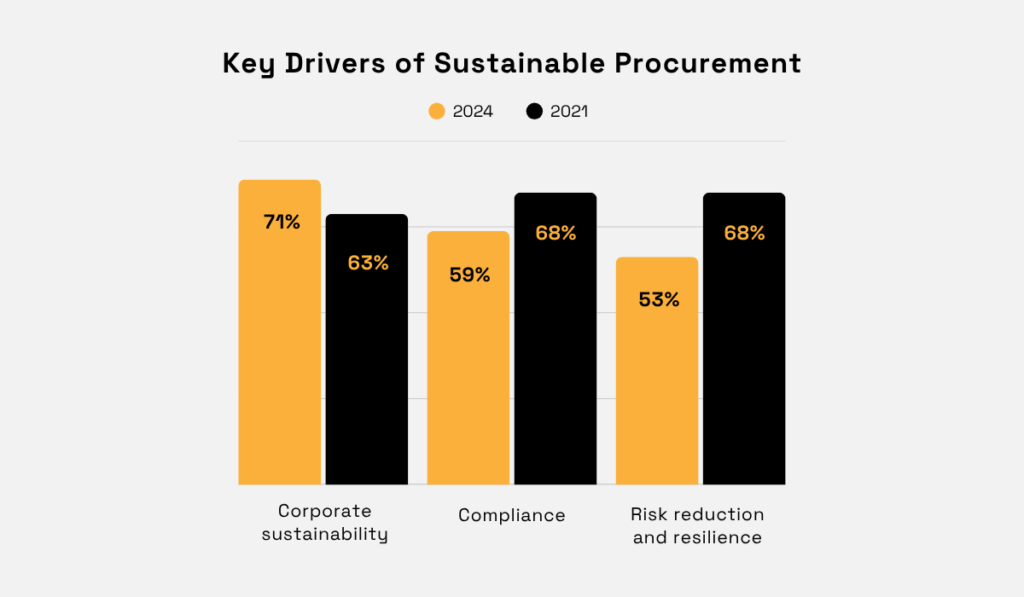

The Sustainable Procurement Barometer also revealed that in 2024, meeting corporate sustainability goals was the top driver for sustainable procurement.

This marks an increase from 2021, when it ranked third.

Illustration: Veridion / Data: EcoVadis

So, aligning procurement with overall sustainability goals will help you secure buy-in, too.

But it’s also essential for ensuring that your strategy actually benefits the organization as a whole.

In fact, Peter Smith, the author of Procurement with Purpose, suggests that procurement should be the one driving corporate sustainability efforts.

Illustration: Veridion / Quote: Intretech

If that’s not the case, meeting sustainability objectives will be significantly harder.

Many companies agree, and IKEA is one of them.

IKEA made procurement its core ESG lever by translating the company’s mission into sourcing practices.

They created IWAY, the code of conduct, which sets clear ESG expectations and requirements for suppliers.

For example, suppliers must respect labor rights, protect workers’ health and safety, and uphold the other eight principles of IWAY.

This standard plays a key role in helping IKEA achieve its broader sustainability goals.

Source: IKEA

To align your own procurement strategy with broader objectives, you’ll need to:

Let’s say your core corporate objective is to reduce environmental impact.

Procurement can support this goal by choosing suppliers with low-emission operations and responsible water usage practices.

To track the impact of this, you can use carbon emissions and water consumption as your main KPIs.

You should leverage these metrics when choosing suppliers and, in the next step, reworking your procurement policies.

With key objectives and performance metrics out of the way, you’re ready to start embedding sustainability into your policies.

This step is critical because it ensures consistency across teams.

The ISO 20400 framework can help you rework your current policies with sustainability in mind.

Source: ISO

As ISO 20400 emphasizes, making procurement sustainable isn’t about modifying just one or two steps.

It requires a full transformation and rethinking of the process, all the way up to learning from existing supplier contracts.

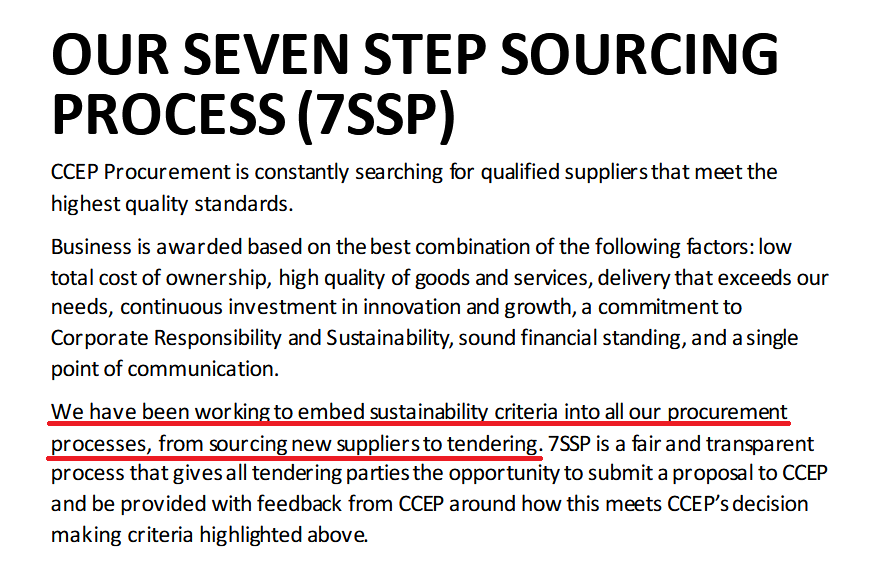

Coca-Cola Europacific Partners offers a good example of how to do this.

In its Responsible Sourcing Policy, the company explicitly mentions embedding sustainability criteria in all stages of procurement, from sourcing to tendering.

Source: Coca-Cola EP

The policy also clearly defines the methods and tools to use to verify supplier compliance.

So, again, it covers all stages of procurement and goes beyond mere implementation guidelines.

Here are some ways in which you can transform your process in its entirety, too:

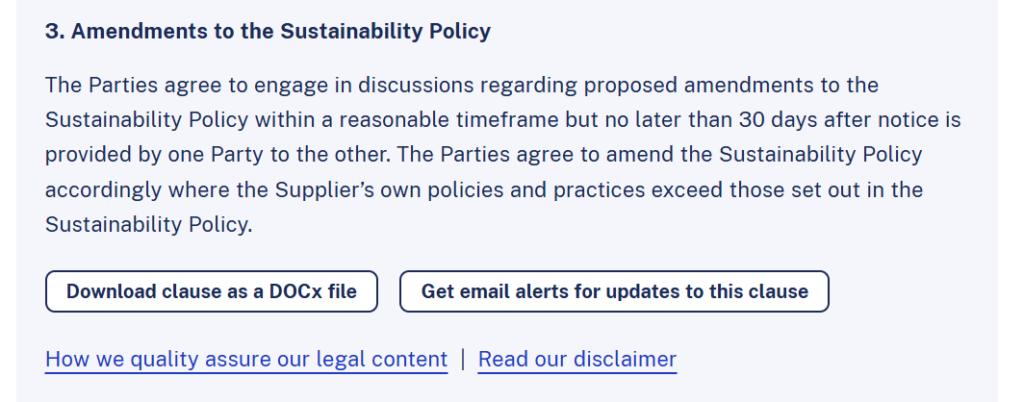

There are many resources online that can help you implement these changes more easily.

For example, a quick Google search will surface a number of sample sustainability clauses.

Source: The Chancery Lane Project

Of course, it’s important to tailor them, as well as any other templates, to your specific objectives.

If needed, ask other departments for help.

Working with the legal department, for instance, can ensure your clauses actually say what you want them to say.

It’s time to put your newly developed policies into practice.

The best way to start is by evaluating suppliers based on ESG risk, performance, and improvement potential.

You can and should use these metrics to assess future suppliers, too.

But before you start bringing in new ones, it’s best to ensure that your existing network is in order.

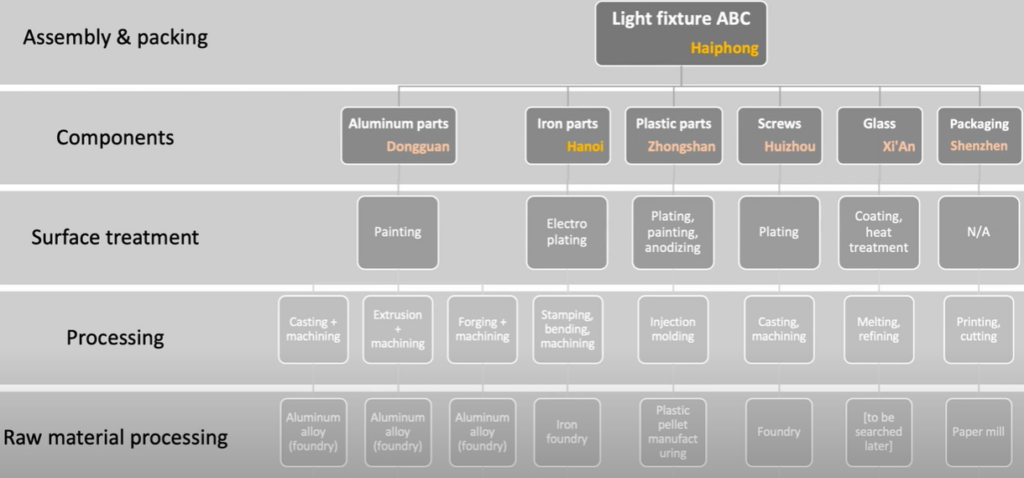

So, start by mapping your current supply chain.

You can create a visual representation like this one:

Source: Sofeast on YouTube

Putting the structure down on paper will help you better understand it and ensure you don’t forget anyone in the chain.

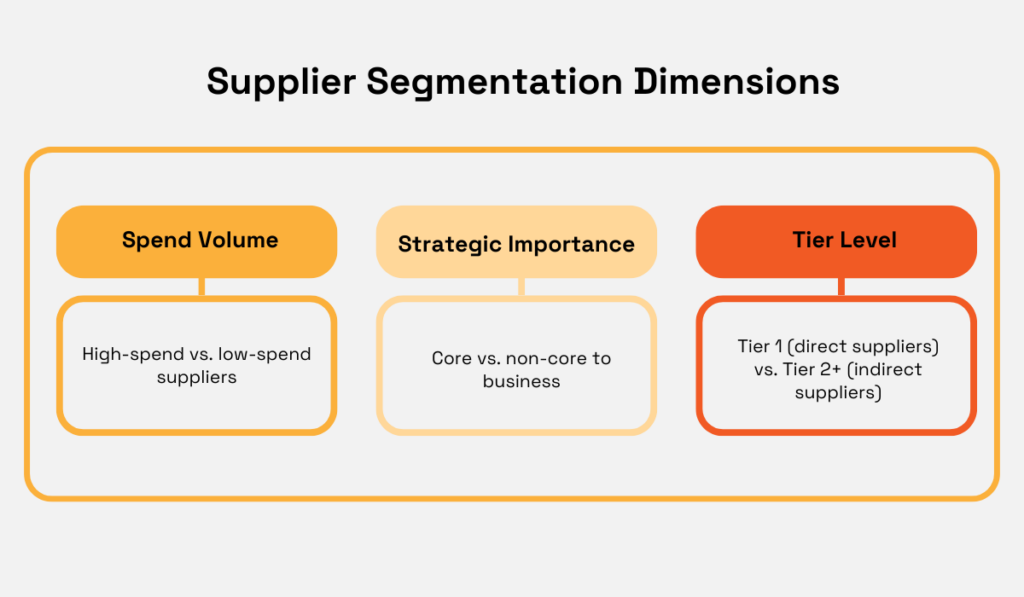

It can also be helpful to segment your suppliers using relevant-to-you criteria.

For example, the above illustration segments them by category or product type (“assembly & packaging,” “components,” etc.).

You can go a step further and segment them based on additional criteria as well.

Here are some other potential dimensions:

Source: Veridion

Putting several dimensions together can help you prioritize which suppliers to assess.

For example, high-spend suppliers from Tier 1 that are core to your business should be the first in line.

But to assess their sustainability practices, you need reliable sustainability data.

The chances are, you haven’t been collecting this data yet.

Even if you were, you likely relied on your suppliers to self-report, which isn’t the best way to accurately assess anyone.

A more effective approach is to use unbiased, verified data from third parties, like Veridion.

Veridion collects ESG data on over 120M companies worldwide, helping you accurately vet suppliers, regardless of their location.

Source: Veridion

All data is updated weekly and covers all three ESG dimensions, as seen in Veridion’s comprehensive data taxonomy.

Source: Veridion

Veridion collects information from multi-language, global, and local news channels to keep you up-to-date with suppliers’ latest activities that could impact their sustainability.

Once you collect such reliable data, you can evaluate your suppliers based on previously set criteria and KPIs.

If some of them fall short of your new standards, focus on the next step: help them improve.

If some suppliers aren’t meeting your sustainability criteria, don’t immediately stop working with them.

Instead, collaborate to help them improve.

Getting them up to speed with your new code of conduct is a great first step.

But many suppliers may not know how to put these guidelines into practice on their own.

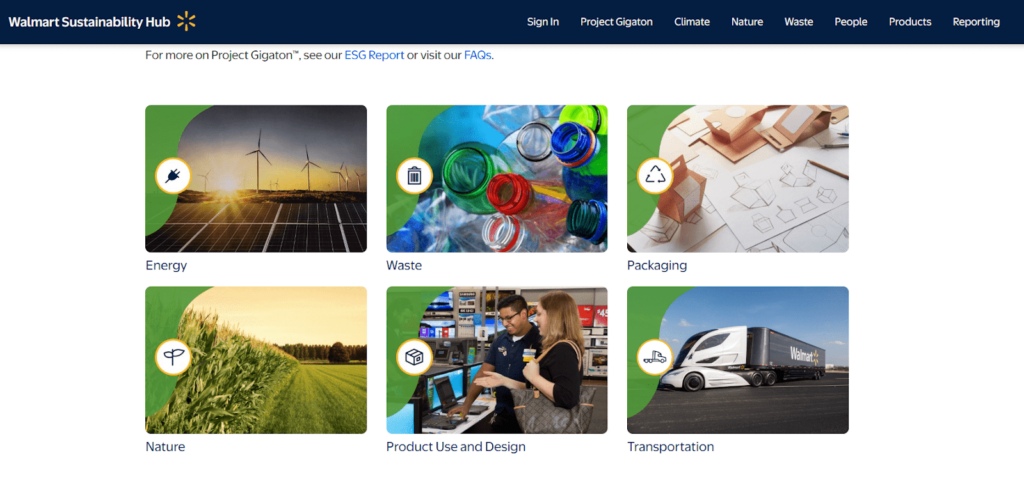

That’s why companies like Walmart have launched programs that break down sustainability commitments into manageable steps and provide helpful resources for suppliers.

Source: Walmart Sustainability Hub

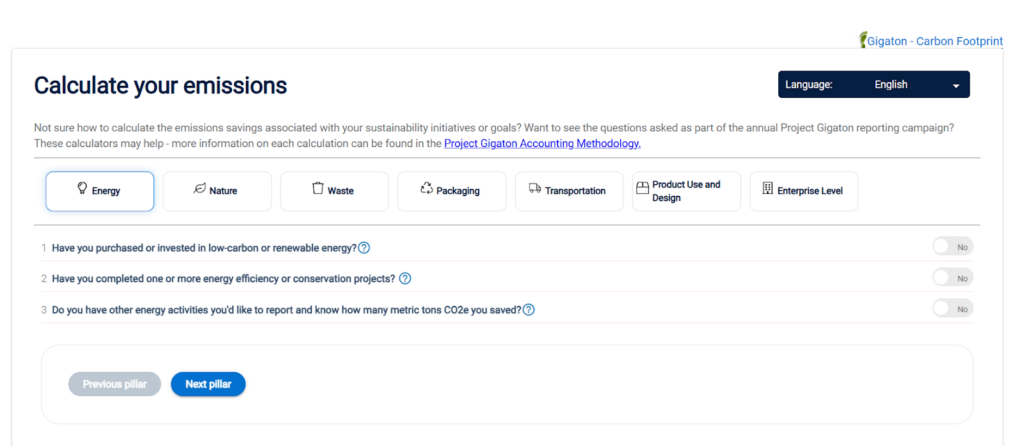

Walmart’s Project Gigaton focuses on helping direct suppliers improve ESG performance in six areas, from energy to transportation.

For each area, Walmart prepared practical guidance for goal setting, a digital calculator for progress evaluation, and instructions on how to report results.

Source: Walmart Sustainability Hub

For an even stronger impact, combine similar written resources with in-person training.

Face-to-face education, workshops, and clear communication are hard to beat. So, create opportunities for direct engagement.

Finally, to motivate suppliers to meet your standards, build mutually beneficial, long-term relationships.

When suppliers expect lasting collaboration and value the relationship, they’re more motivated to comply.

Experts from Ardea International, a consultancy specializing in sustainability, business, and human rights, agree.

Illustration: Veridion / Quote: Ardea International

Additional ways to motivate your suppliers include offering incentives, like preferred supplier status or innovation pilots.

However, to accurately award these recognitions, you need to monitor suppliers’ performance, which leads us to the next step.

If you want to incentivize your suppliers and make steady progress, you need to track their performance against your sustainability KPIs.

To do this effectively, you’ll need:

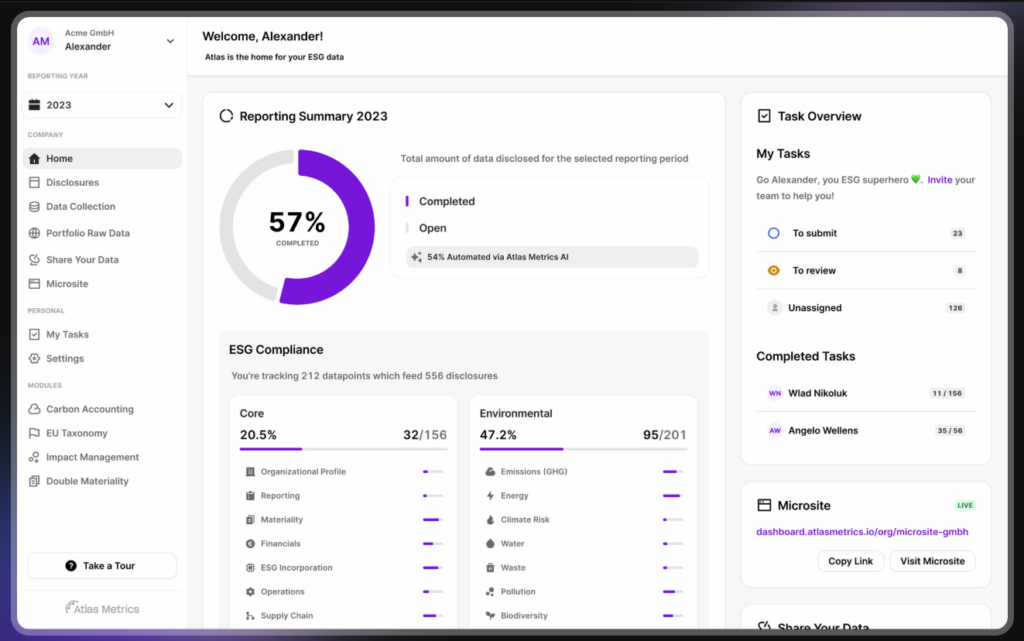

ESG metrics dashboards can be extremely helpful in this, acting as centralized spaces for all supplier data, whether provided by you, your suppliers, or third-party sources.

They also help visualize supplier performance and can often automate at least some of the reporting.

Here’s an example of what that might look like:

Source: Atlas Metrics

The data you collect can and should be reported both internally and externally.

By reporting it internally, your organization gains a clearer picture of the current state and how to move forward.

By sharing your data externally, you’re communicating your sustainability commitments to the public.

This can greatly improve your reputation among customers, potential investors, and even future employees.

But the way you report on and use this data internally and externally should be different:

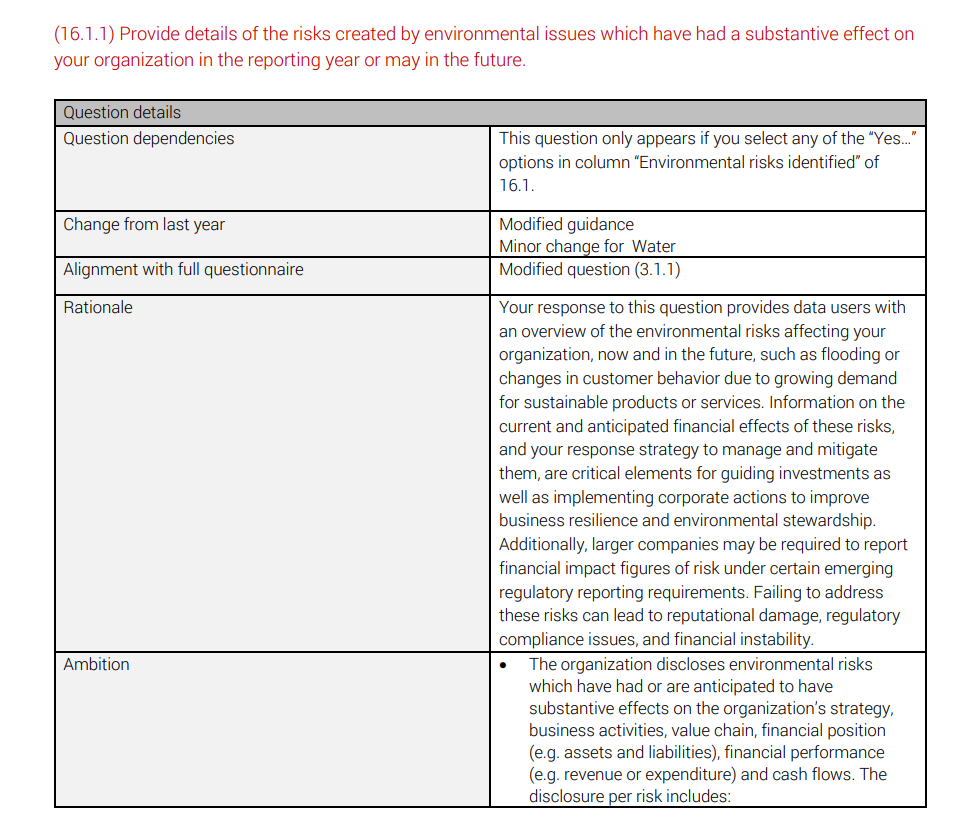

For external disclosures, you can use tried-and-tested reporting standards, like CDP or GRI.

You’ll get a ready-made list of questions you’ll simply need to answer.

This makes reporting and disclosure much easier.

Source: CDP

Keep in mind that, depending on your local regulations, you may be required to disclose your sustainability performance.

In that case, external reporting is not optional and should be handled with extra care.

To drive further change and outperform sustainability results YoY, you’ll eventually need to start covering deeper layers of your supply chain.

Certain sustainability initiatives may even require this.

Spencer Young, principal at Deloitte Consulting, explained this when discussing Scope 3 emissions.

Young says that strategically reducing Scope 3 emissions just isn’t possible with inputs from direct suppliers alone.

Illustration: Veridion / Quote: Wall Street Journal

So, always consider what you can and can’t do depending on the suppliers you’re working with.

And if you decide to scale, don’t forget to implement feedback loops and test different approaches.

What works for one initiative or one tier won’t necessarily work for another.

Experimenting and listening to your suppliers is key to success.

Also, keep in mind one important idea from Fanny Ganti, founder of Transformative Procurement Change: sustainable procurement isn’t a one-off campaign or pilot project.

Illustration: Veridion / Quote: LinkedIn

As she puts it, sustainability needs to permeate every stage of procurement, and it must continue evolving with the market, regulations, and stakeholder expectations.

So, plan ahead for regular adjustments and iterations.

Sustainable procurement isn’t a quick win or a simple checkbox exercise. It’s a strategic transformation that will challenge the way you’ve always worked.

But now, you know where to begin.

From building a solid business case and aligning procurement with broader sustainability goals to embedding these commitments into policies, assessments, and supplier relationships, each action sets the foundation for meaningful change.

You may not achieve every target on your first attempt.

But every step forward will make your supply chain more resilient, your organization more competitive, and your impact on the world more responsible.

Because at its core, sustainable procurement is not just about compliance or risk management.

It’s about creating long-term value for your company, your suppliers, and the planet we all depend on.