Vendor Selection: Step by Step Process

Key Takeaways:

Choosing the wrong vendor can cost your enterprise millions.

But get the process right, and you can build a competitive advantage that resonates across your entire supply chain.

So how do you get it right?

By clarifying your needs, researching candidates, issuing RFPs, and rigorously vetting finalists before signing contracts.

This comprehensive guide will walk you through a proven, systematic approach to vendor selection that balances cost considerations with quality, reliability, and risk management.

In the end, you’ll be able to select partners who will contribute to your long-term success.

The foundation of effective vendor selection should be set long before you evaluate your first proposal.

It starts with a crystal-clear understanding of what your organization needs to achieve.

Not just today, but throughout the anticipated relationship lifecycle.

Philip Ideson, Founder of Art of Procurement, agrees.

Illustration: Veridion / Quote: Art of Procurement

Let’s imagine you’re selecting construction vendors.

Their capabilities must align with your project timeline and business objectives.

If you overlook this, you might choose a technically qualified supplier, but they might be unable to deliver within your deadlines or budget.

Engaging cross-functional stakeholders from the outset is crucial.

This includes representatives from procurement, finance, operations, IT, and any department that will interact with the vendor or use their products or services.

This collaborative approach ensures all perspectives are considered and builds organizational buy-in for the ultimate selection.

When defining requirements, categorize them into:

Be specific about technical specifications, compliance requirements, scalability needs, and integration capabilities with existing systems.

Record these requirements in a detailed requirements document that will later inform your Request for Proposal (RFP).

A common pitfall at this first stage is focusing solely on immediate needs while overlooking future requirements.

Consider your organization’s strategic roadmap:

Will this vendor need to support international expansion, product diversification, or technological transformation in the coming years?

Additionally, cultural compatibility also significantly influences long-term partnership success, but is often overlooked.

Most supplier relationships fail not because of capability, but because of cultural misalignment, says Martin VanTrieste, President and CEO of Civica Rx.

He adds that both parties must be aligned on the same long-term objectives from day one.

Illustration: Veridion / Quote: KPMG

Getting that compatibility right upfront is critical because once you’ve gone through regulatory onboarding, switching partners becomes extremely difficult.

This alignment early on avoids surprises and keeps everyone focused on the end goal.

Armed with clearly defined requirements, you’re now ready to embark on a comprehensive exploration of the vendor landscape.

This phase involves a meticulous market analysis to identify potential partners who meet your needs and also align with your long-term goals, followed by a structured shortlisting process.

McKinsey research reveals that traditional supplier discovery requires significant manual effort, but modern supplier discovery tools can reduce identification time by 90% or more.

Platforms such as Veridion, for example, leverage artificial intelligence to scan global supplier databases against your specific criteria, dramatically accelerating what was once the most time-consuming phase of vendor selection.

Using AI for vendor selection can help you create a shortlist of vendors that meets precise criteria in just hours instead of months.

Illustration: Veridion / Data: McKinsey

To begin with, create a long list of potential suppliers, then narrow it using key filters like pricing, product features, geographic fit, certifications, or reliability.

Next, develop a supplier selection scorecard that assigns weights to each evaluation criterion based on its importance to your organization.

This structured process converts subjective impressions to objective data, which evens the playing field and allows for more equitable comparisons.

A well-designed scorecard might highlight the following factors:

| Criterion | Weighting | Sub-Criteria |

|---|---|---|

| Quality & Performance | 30% | Defect rates, certifications, and sample evaluations |

| Cost Structure | 25% | Total cost of ownership, payment terms, volume discounts |

| Delivery Capabilities | 20% | On-time delivery record, logistics network, lead times |

| Technical Expertise | 15% | Industry experience, specialized knowledge, innovation |

| Financial Stability | 10% | Credit ratings, financial statements, and business longevity |

This scoring framework will become increasingly valuable as you proceed through the evaluation process, providing a consistent way of comparing vendors at each step.

Once you have a shortlist, formally invite those vendors to submit proposals.

An RFP (Request for Proposal) is a detailed questionnaire that asks vendors for specific information: pricing breakdowns, technical capabilities, delivery timelines, and compliance details.

The RFP process transforms your preliminary research into actionable data by inviting shortlisted vendors to demonstrate how they would meet your specific requirements.

A well-crafted RFP does more than collect pricing.

It reveals each vendor’s approach, creativity, and understanding of your challenges.

The goal is to get apples-to-apples data so you can compare bids fairly and with transparency.

So, make sure to give vendors a clear timeline and format requirements for the RFP.

Encourage them to highlight how they meet each criterion, and ask targeted questions about risk controls (like security practices or disaster recovery).

When the RFP responses come in, use the scoring framework you established during the research phase to evaluate them.

Using supplier scorecards, as Gary Gustafson, President of G-Force Consulting, highlights, allows procurement teams to evaluate vendors objectively, without the influence of personal biases or anecdotal evidence.

Illustration: Veridion / Quote: Smartsheet

This ensures a fair and transparent evaluation process.

Assemble a cross-functional evaluation team to review each proposal, with different members focusing on their areas of expertise.

Technical staff can assess capability claims, financial analysts can review pricing structures, and operational leaders can evaluate implementation plans.

Follow up with vendors to clarify ambiguities, as their responsiveness during this phase often indicates the service level you can expect as a customer.

This iterative communication also helps identify vendors who are genuinely interested in your business versus those simply going through the motions.

By handling RFPs rigorously, you also ensure vendors compete on the same terms and that your decision won’t be swayed by anecdote or preference alone.

Before picking a winner, you must vet each finalist’s risk profile.

This step protects you from disruptions or surprises like bankruptcies, compliance violations, or security breaches.

Review each vendor’s financial health, including credit rating, funding, and ownership history, to ensure stability.

Check regulatory compliance records to see if they have any open violations or a history of recalls or fines.

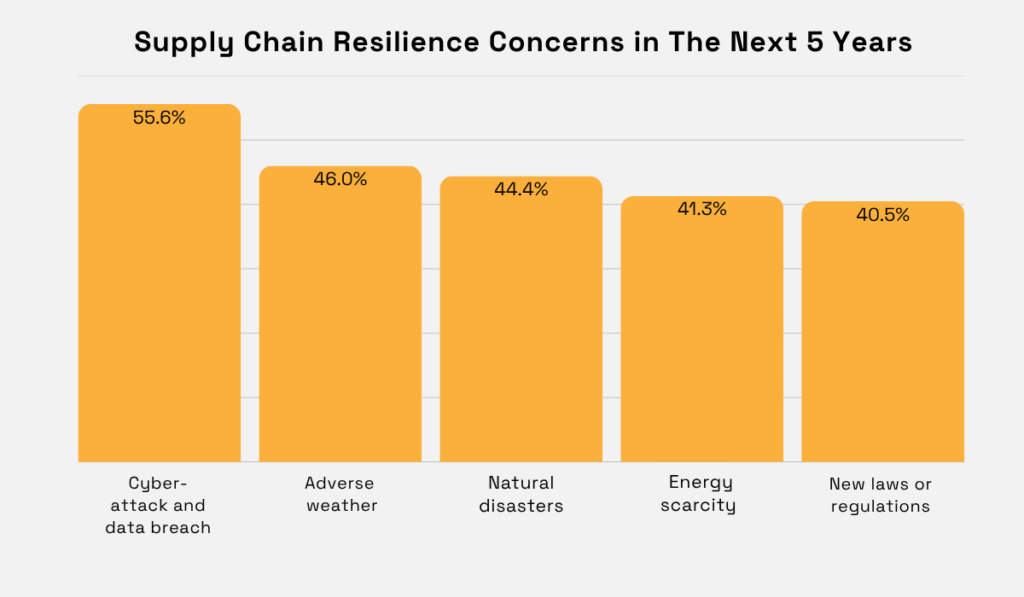

Cybersecurity posture is also crucial.

According to the BCI Supply Chain Resilience Report 2023, cyber-attacks and data breaches have now become the number one future concern for 55.6% of businesses, after a 62% growth in cyber-related incidents was reported in the supplier network in 2024.

Illustration: Veridion / Data: BCI

You don’t want a breach that a vendor experienced to become your problem.

Business continuity is another risk that organizations often ignore during supplier selection.

Verify that vendors have backup plans in place for disasters, and that they carry adequate insurance.

ESG compliance is increasingly important, too.

In fact, 43% of companies in a Deloitte survey said managing social and environmental issues in the supply chain motivated their third-party risk programs.

Yet, 74% had no dedicated budget for climate risk, 57% for environmental risk, and 54% for modern slavery and labor.

Wherever possible, use reliable data sources.

For example, Veridion’s data for supplier Discovery and data for TPRM provide up-to-date company profiles, credit ratings, ESG scores, and more to confirm a vendor’s legitimacy.

This can help you quickly flag concerns such as hidden ownership or past fines.

Source: Veridion

Geopolitical and operational risks have become increasingly significant in today’s global supply chains.

The ongoing Russia-Ukraine war has acted as a catalyst for global disruptions, particularly in energy and raw materials.

Supplier diversification is, therefore, a smart risk reduction strategy.

Why?

Because relying on a single source is a gamble you can’t afford.

In today’s volatile environment of tariffs, geopolitical tensions, and port strikes, concentrating your supply on one vendor leaves your business dangerously exposed.

The more diversified your supplier base, the more resilient and competitive your brand becomes.

Sheng Lu, a Professor at the University of Delaware, stresses that supply chain diversification is no longer optional. It’s essential.

Relying too heavily on a single region, like China, creates massive vulnerability.

Illustration: Veridion / Quote: Inspectorio

Ultimately, when you assess risk carefully, you can avoid a supplier that looks good on paper but could cause significant problems if something goes wrong.

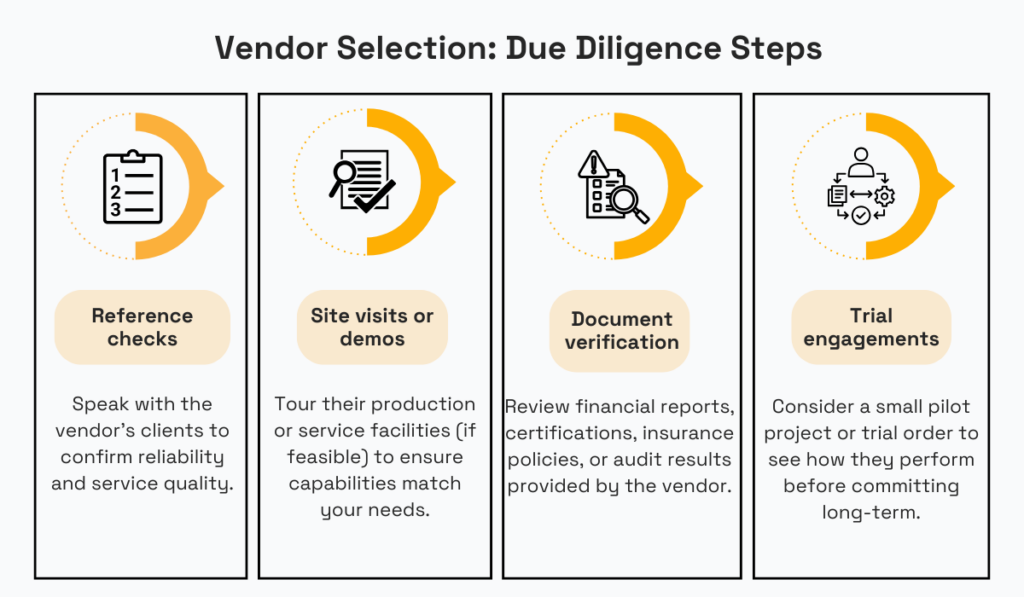

Due diligence is the reality-check phase.

Here, you validate everything the vendor claims through empirical evidence.

This investigative phase bridges the gap between promised capabilities and demonstrated performance.

Morgan Stanley Bank learned the hard way just how crucial this step is.

In 2016, the bank was fined and settled multiple regulatory and legal actions after a vendor tasked with decommissioning hardware and destroying data failed to do so.

Namely, raw hardware with personally-identifiable client data was sold via online auction.

The bank did not conduct appropriate due diligence on the vendor’s capabilities and controls for this sensitive activity.

Source: CNBC

When conducting due diligence, start by talking to references—vendors’ current or past customers—about their experience.

Ask about delivery punctuality, product or service quality, responsiveness, as well as any issues they faced.

Doing this often reveals red flags.

When possible, tour the vendor’s facilities or request a demo of their product.

Site visits allow you to observe operations firsthand, assess facility conditions, meet the team that will handle your account, and evaluate safety and quality protocols.

Product testing or trial implementations provide concrete evidence of capabilities before making a long-term commitment.

Also, verify any certifications or awards they claim. Ask for evidence of ISO certifications, quality audits, or security audits wherever relevant.

Make sure they have a track record of meeting SLAs with their other customers.

Under due diligence, also make sure to evaluate:

These qualitative factors often determine whether a vendor relationship remains merely transactional or evolves into a strategic partnership that drives mutual innovation and value creation.

Source: Veridion

Mismatches between marketing hype and operational readiness also come to the surface during this phase.

Due diligence enables you to make fully informed decisions at such moments.

By the end of due diligence, you should feel confident in the vendor’s claims.

This confidence then builds trust before signing and greatly reduces the chance of nasty surprises, like discovering a sub-contractor mishap only after a contract is in place.

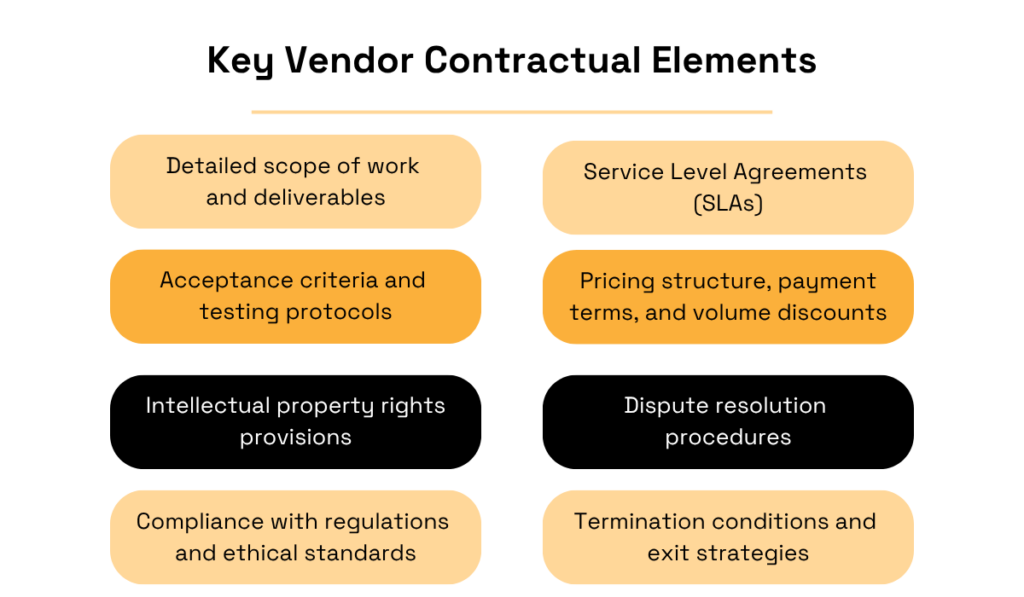

With due diligence complete, it’s time to negotiate terms and sign.

The final selection and contracting phase formalizes your partnership, translating expectations, responsibilities, and remedies into binding agreements.

While negotiations naturally focus on price, the most successful contracts balance cost considerations with relationship structures that promote long-term success.

Source: Veridion

Service Level Agreements (SLAs) deserve particular attention, as they spell out exactly what the vendor must deliver (e.g., uptime, quality levels, response times) and what happens if they don’t.

So, be explicit: if delivery is late, what penalty applies?

If quality is subpar, how is it corrected?

Spell out warranties, penalties, and recourse clearly.

Include clauses for performance guarantees and exit conditions.

For example, you might require regular performance reviews and the right to terminate if a vendor doesn’t meet major KPIs.

Make sure compliance requirements (like data protection or ESG commitments) are in writing.

Finally, have legal counsel review the entire contract.

The goal is a fair agreement that holds the vendor accountable and protects your company’s interests.

Well-constructed contracts, with measurable SLAs and responsibilities, balance accountability with partnership, creating structures that incentivize superior performance while allowing flexibility for changing business needs.

Vendor selection represents one of the most consequential decisions procurement professionals can make.

Its impacts reverberate across supply chain resilience, product quality, cost structure, and brand reputation.

By following these six steps, you ensure each decision is deliberate, evidence-based, and aligned with your goals.

First, define exactly what you need; then research and score potential suppliers; issue structured RFPs to gather proposals; carefully assess vendor risks; perform hands-on due diligence; and finally lock in clear contracts and SLAs.

Taking a thorough approach like this reduces surprises and builds strong, reliable supplier relationships that will drive future growth.