How Big Data Improves Your Procurement Bottom Line

Big data brings a myriad of benefits to procurement, all with the overarching aim of improving your bottom line.

In this article, we will dive into the four ways in which big data achieves this.

Starting with perhaps the most emphasized benefit, reducing unnecessary spending and optimizing costs, to improving supplier relationships and negotiation strategies, and beyond.

We won’t keep you waiting, as you must be eager to discover how big data can transform your procurement processes.

So, let’s dive straight into the first “how.”

Excessive spending is like a leak in the ship of your procurement budget, often unnoticed until it impacts your bottom line.

Fortunately, big data can be the way to notice those leaks and patch them up to ensure smoother sailing.

In other words, by leveraging big data analysis, procurement teams can first pinpoint and then reduce overspending.

Let’s see how.

Excessive spending can happen very quickly if you don’t carefully observe where the money goes.

And it can happen for numerous reasons:

Big data analysis comes to the rescue because it allows you to perform in-depth spend analysis to track all your spending.

Based on these insights, you can improve your procurement to be more cost-effective.

If we focus more closely on maverick or rogue spending, we can already see what potential big data has in reducing excessive spending or, in this case, unauthorized purchases or off-contract buying.

Maverick spending is a significant challenge for many organizations, mostly because it prevents them from saving money.

In fact, Hackett’s Maverick Spend Report from 2019 showed that as much as 16% of negotiated savings are lost when maverick spending occurs.

Illustration: Veridion / Data: The Hackett Group

What’s more, when purchasing is done outside of contracts, you miss opportunities for better deals with already established suppliers and also risk purchasing lower-quality products.

On top of that, non-compliance with established procurement processes can result in regulatory issues and penalties.

Big data analytics enable you to analyze your spend and detect irregularities and spending outside of contracts, so you can implement better financial discipline to prevent it from happening again.

Big data can help you reduce excessive spending in one more way.

When you analyze historical sales data, market trends, and other external factors, you can predict future demand more accurately.

This enables you to adjust inventory levels based on anticipated needs, reducing the risk of overstocking.

And if you also set up real-time monitoring of inventory levels, you can automate the reordering process when certain thresholds are reached.

By doing this, you can maintain optimal stock levels and prevent both excess and insufficient inventory.

As you can see, excessive spending is a big challenge for procurement.

However, big data enables you to analyze when and where your resources go so you can find strategies to improve your bottom line.

Big data is crucial in safeguarding the procurement bottom line by predicting and mitigating supply chain disruptions.

Given the complexity of a supply chain involving numerous entities, organizations, people, activities and resources, supply chains are inherently prone to disruptions.

They can be caused by various factors, such as natural disasters, pandemics, supplier issues, trade policy changes, or geopolitical tensions.

Such disruptions can, unfortunately, be extremely costly and sometimes even fatal for businesses.

However, by examining data related to supplier stability, geopolitical factors, and market trends, you can pinpoint and mitigate potential risks.

Or at least prepare yourself better for the upcoming challenges.

This can result in better stability and reliability of your supply chain, and of course, some cost savings.

Let’s focus for a moment on COVID-19, which caused a ruckus in the supply chain of numerous organizations across the globe.

Take the example of Gap, a company that faced substantial losses—approximately $300 million in sales only during the fourth quarter, due to the second wave of COVID-19.

With 30% of its production based in Vietnam, the closure of factories during the pandemic’s second outbreak and port congestion impacted Gap’s ability to meet customer demand.

Illustration: Veridion / Quote: CNN Business

To cope, the company had to incur an additional $350 million in air freight costs for 35% of its holiday merchandise.

Although big data may not entirely prevent such financial losses because, after all, the pandemic was something none of us expected, its potential becomes evident when considering that Gap faced these challenges after the pandemic’s second outbreak.

Let’s see what they could have done differently.

By utilizing big data for modeling and simulating the impact of a pandemic on different suppliers and regions, Gap could have identified potential hotspots and made informed decisions on supplier diversification after the first outbreak of the virus.

Diversifying suppliers across different regions could have minimized the impact of disruptions in specific, heavily affected areas.

Admittedly, implementing these strategies is easier said than done, particularly now that some time has passed.

Yet, Gap’s example is a reminder that better preparation for supply chain disruptions is crucial to avoid substantial losses.

And big data can, indeed, prepare you better!

Raytheon (now RTX), a technology and innovation leader in defense, is an example of a company that recognized big data’s potential in avoiding supply chain disruptions early on.

As early as 2015, the company’s then VP of contracts and supply chain, David Wilkins, emphasized the power of big data.

Raytheon developed a platform integrating structured and unstructured data from various sources that allowed them to make fast, data-driven decisions.

Data included information on suppliers’ financial stability and performance, and it also gave them immediate insights into environmental happenings in their suppliers’ locations.

Illustration: Veridion / Quote: Supply Chain Management Review

This agile approach facilitated quick decisions during crises and enabled cost reductions within their supply chain.

You can achieve the same Raytheon did—with Veridion.

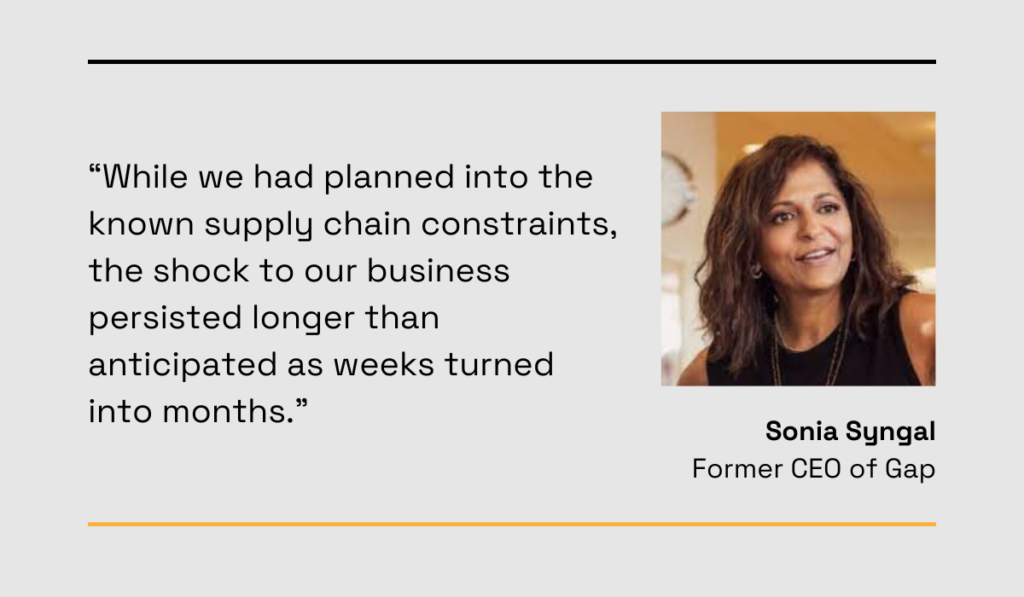

Veridion monitors data about global suppliers in near real-time and keeps it fresh.

So when a supplier’s conditions change, you’ll be immediately notified so you too can be agile and make decisions.

Source: Veridion

In conclusion, big data proves instrumental in preventing supply chain disruptions and improving the overall procurement bottom line.

The ability to model, simulate, and respond swiftly to dynamic conditions ensures a more resilient and adaptive supply chain, which can reduce financial costs associated with supply chain disruptions.

Big data is a valuable tool for improving negotiations with suppliers.

And you, more than anyone, know that only negotiation and strong collaboration with reliable suppliers can improve your bottom line.

Let’s see how big data does it.

When you analyze historical data on supplier performance, pricing, and quality metrics, you can use those insights to identify cost-effective suppliers with a track record of timely deliveries.

Then, you can negotiate with them to get better deals.

And the power of negotiation and long-term relationships with suppliers goes a long way in procurement.

Let’s look at Avaya, a multinational company specializing in cloud communications and workstream collaboration services.

Avaya’s transformation from having what was once considered the worst supply chain to the best in class was attributed, in part, to investing in long-term partnerships with suppliers.

According to Benji Green, Avaya’s former senior director of integrated supply chain planning and operations, such partnerships result in mutual satisfaction.

Avaya enjoys controlled rates and predictable availability, while suppliers benefit from consistent, predictable order volume and revenue.

Illustration: Veridion / Quote from Supply Chain Digital

But beyond performance metrics, big data enables you to find suppliers that share the same values as you, particularly in areas such as sustainability.

Big data platforms like our Veridion offer detailed supplier insights, ranging from a supplier’s location and size to product description and ESG criteria.

Source: Veridion

The latter is especially crucial in today’s market, where sustainability is highly valued by customers.

That’s why identifying suppliers that follow sustainability practices has never been more important to survive in the competitive business environment.

Once you start working with such suppliers, relying on data can further help you negotiate better deals and establish successful partnerships.

As you can see, big data can positively impact your decisions on who you will work with, negotiate more favorable terms with those suppliers, and finally, build strategic partnerships with them.

All this ultimately improves your procurement bottom line.

The last way in which big data improves your procurement bottom line we’re going to cover today is by helping you save resources.

Saving resources goes beyond identifying excessive spending, which we discussed at the beginning of this article.

Many organizations spend more resources due to inconsistent procurement processing, bottlenecks in approval workflows, and a lack of visibility.

All because they do many of their processes manually.

Let’s take approval workflows as an example.

Every stage of procurement requires some approvals, from purchase requisitions, purchase orders, and contracts to invoices.

Approvals often have to come from other departments, such as finance, legal, or even executive management.

Evidently, this process involves many steps, and if approvals for each step are done manually, it simply takes too much time. And time is money.

So, what can big data do here?

First, if you analyze your historical data, specifically approval cycles, you can identify inefficiencies in the process.

Then, you can use this knowledge and improve the approval workflow.

What’s more, when you start automating approvals, the tools used will generate a wealth of data that you can analyze and optimize the process further.

In addition, automation will allow visibility so everyone included in approval-making will be able to do it then and there.

This will shorten the approval workflow and save you time and money because there won’t be extra delays.

Source: Veridion

According to Deskera, big data will go even further in approval workflows.

Namely, machine learning and artificial intelligence capabilities within big data tools will not only predict approval timelines and identify bottlenecks but also automate the overall decision-making.

Beyond approval workflows, big data analytics tools can streamline other repetitive tasks.

One is collecting data in the first place and performing analysis.

By using automated systems like cloud-based platforms that are designed to gather, process, and analyze big data in a matter of seconds, you can avoid wasting resources for doing it manually.

Just collecting internal procurement data takes procurement professionals too much of their precious time.

The survey by Airtable and Forrester revealed that employees spend approximately 2.4 hours each day just searching for data.

Illustration: Veridion / Data: Airtable

And that is an average employee. What about someone who has to deal with large amounts of data from external sources, too?

When you think about it thoroughly, investing in big data and cloud services that you pay-as-you-go is much more cost-effective and less prone to errors, which is another way to save resources.

All in all, big data enables you to automate many procurement processes and, in this way, save more resources.

In addition to identifying excessive spending, this is the best way to improve your procurement bottom line.

Big data is a powerful tool for procurement.

But this isn’t a recent revelation.

As we saw, in 2015 and even earlier, companies already recognized the game-changing potential embedded in big data, which has only intensified with time.

From identifying and reducing excessive spending to enabling automation to save time and resources, big data is and will remain crucial for improving procurement bottom line and overall organizational efficiency.

Now is the time to introduce it in your procurement!