Data Driven Procurement Challenges

Data is a valuable source of opportunities and insights for procurement. It brings numerous benefits but can also be laden with challenges.

These challenges often stem from a lack of sufficient data for making fully informed decisions or having too much data but lacking the skills or tools to analyze it effectively.

Furthermore, the potential of data driven procurement can be undermined if only a select few in your team adopt this approach while everyone else sticks to outdated methods like sifting through spreadsheets and relying on obsolete data.

We invite you to keep reading because, in this article, we will address five of the most common challenges of data driven procurement and provide insights on how to overcome them.

Let’s begin by addressing the first challenge on the list—not having (enough) data.

Data is a crucial business asset, especially in procurement.

However, the quality, quantity, and accessibility of this data can differ across companies.

While procurement teams always have access to some data, there are situations where this may be limited, especially in new or smaller businesses.

In contrast, larger and more established companies have lots of data.

However, this data is often isolated or segregated within different teams, systems, or software applications, creating data silos.

These silos can be a significant issue not only in procurement but across the entire company because they make it challenging to access and share data between departments.

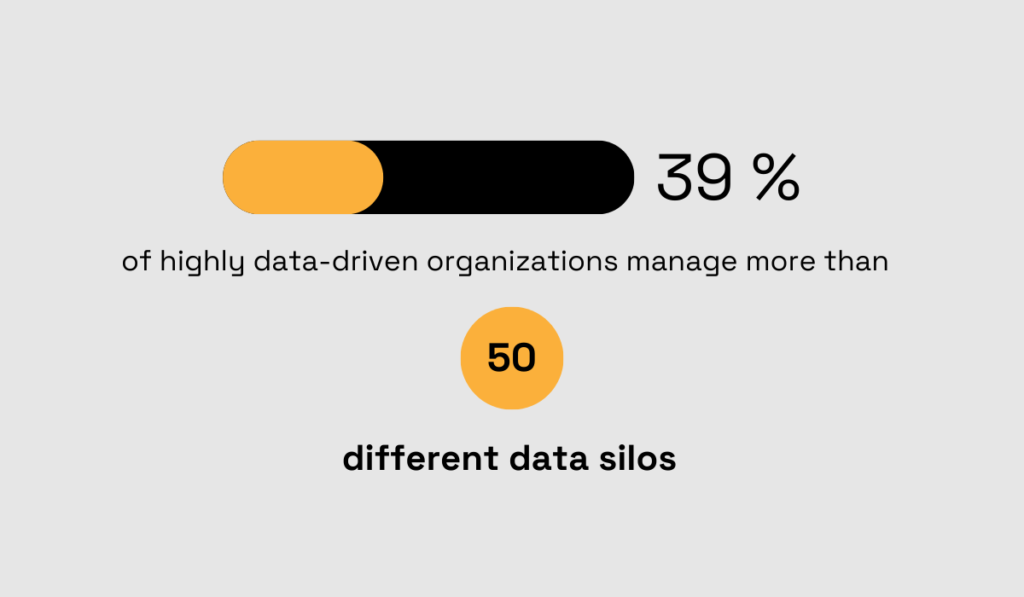

Unfortunately, this is the reality for around 39% of highly data driven organizations that manage more than 50 distinct data silos (according to a report by S&P Global cited in Computer Weekly).

Illustration: Veridion / Data: S&P Global cited in Computer Weekly

Simply put, if you have data stored in such a way that your teams can’t access it, it’s like having no data at all.

To understand how data silos affect procurement, let’s consider a scenario in a manufacturing company.

The procurement department is responsible for acquiring raw materials, and they rely on up-to-date production forecasts from the production planning department to make informed decisions about inventory levels and supplier contracts.

However, the production planning department stores its forecasts in a specialized software system that isn’t easily accessible to the procurement team.

Instead, the procurement team relies on periodic reports or manual data transfers, which are not only less efficient but also prone to errors.

This data silo between the production planning department and the procurement department’s systems creates several challenges:

What can be done to address these issues?

First of all, breaking down data silos can be achieved by implementing integrated software solutions or data-sharing protocols that ease data transfer between departments.

Looking at our example, this would enable the procurement team to access production forecasts on time, ultimately improving their decision-making and overall efficiency.

In other words, they would have the data they need precisely when they need it to make better decisions.

So, to overcome the challenge of lacking data—or not having access to it—companies should invest in technology that will either help them collect data from external sources or help them break down silos and enable easy and quick sharing of information between departments.

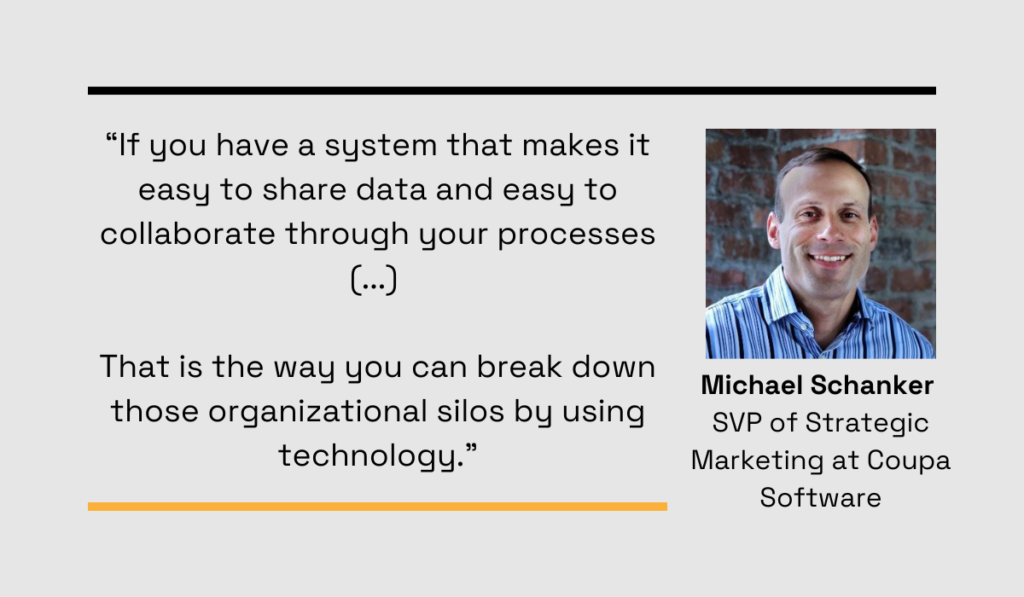

Let’s conclude with this insight from Coupa Software’s SVP Michael Schanker.

Illustration: Veridion / Data: Procurement Magazine

He proves our point—technology is the catalyst that can eliminate data silos and provide your procurement team with the data they need for successful data driven procurement.

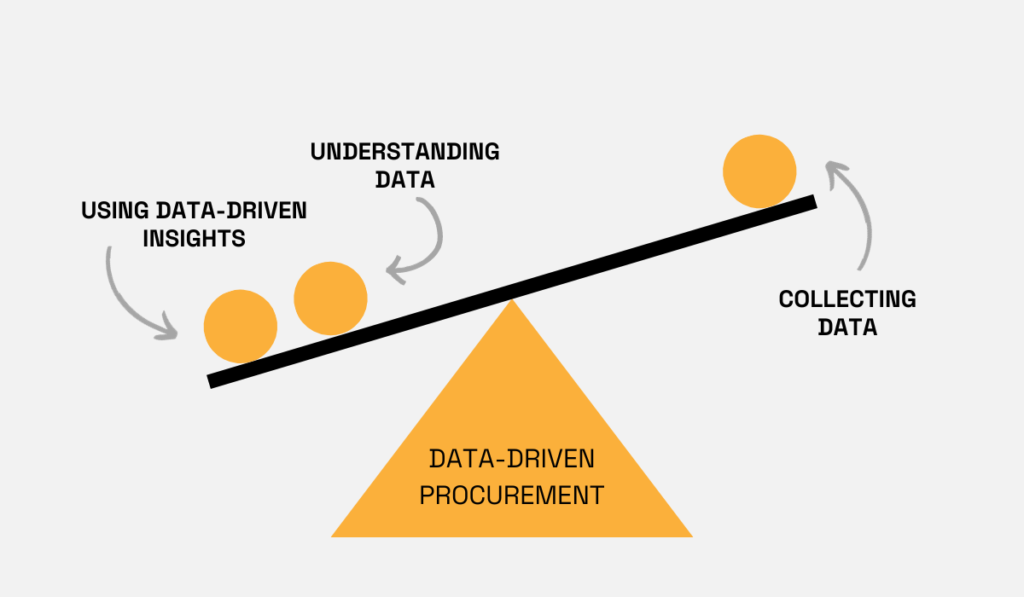

Trying to implement a data driven procurement process in your company without first making sure that the entire team is equally data driven is like having a library of books that no one reads.

Source: Veridion

In that kind of company culture, decisions are not based on intuition alone but are informed by data and insights.

The mindset encourages data collection, analysis, and makes action based on hard facts.

But when just a few put data at the heart of decision-making, while others still rely on old ways, organizations miss on important benefits that a data driven culture brings:

So, how can you overcome this challenge and establish a company culture that weaves data into every decision?

Source: Veridion

You can start from the top. In other words, if you are a procurement executive, take the lead.

Executives and managers must champion the importance of data and set an example for data driven decision-making.

They are also the ones who should allocate resources for data initiatives and communicate the value of data to the entire team.

The latter is critical because only by promoting data literacy and training your team members can you make sure that they understand how to collect, interpret, and use data effectively in their roles.

Another crucial factor is investing in relevant technology.

That means investing in tools that will enable data analysis but also those that will ensure this data travels fast across your organization and comes into the hands of those who need it on time.

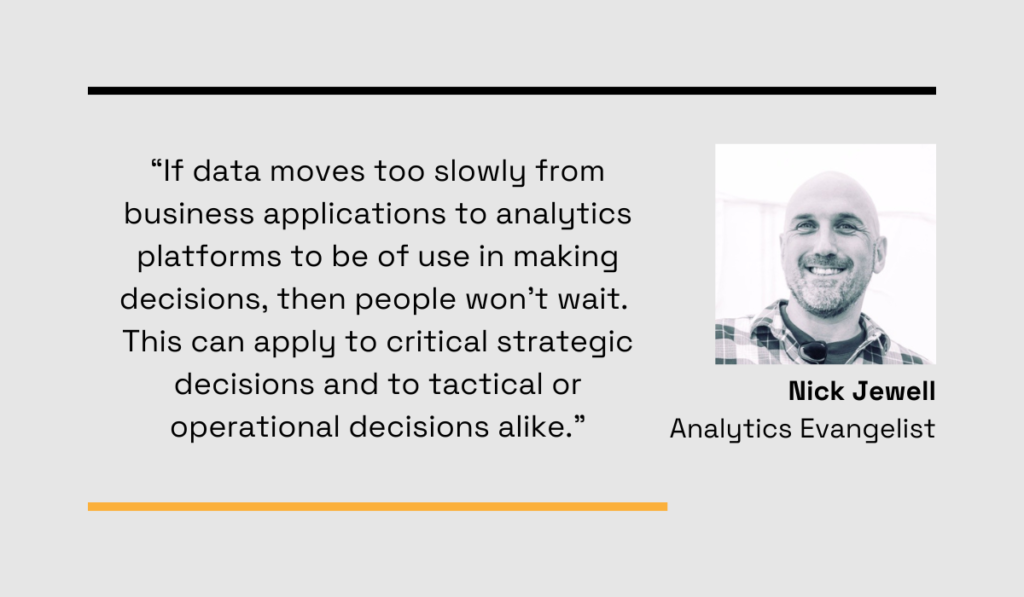

Nick Jewell, an analytics evangelist, says that if a company’s data pipelines are too complicated and too slow, your teams, even though you want to promote a data driven culture, will still rely on their guts rather than waiting for meaningful data insights.

Illustration: Veridion / Data: Forbes

So, to embed data driven decision-making into existing processes, you must first make sure that your teams are equipped with the systems and software that can provide them with data at a moment’s notice instead of waiting for days until data is analyzed.

Only then will you have all the necessary tools and create the right environment that fosters a data driven culture where data will guide and inform every procurement aspect.

Having too much data can be as problematic as not having enough data.

Procurement teams are often overwhelmed with large volumes of data from different sources, and managing it all can be quite a challenge.

These sources can include systems with data related to transactions, purchase orders, invoices, and inventory levels.

Then, we have supplier databases containing contact details, performance metrics, and contractual agreements.

On top of that, your procurement team has to be in the loop with your company’s financial data and market trends, from procurement budgets and cost analysis to market pricing.

While all these sources provide valuable insights, they are often dislocated across several individual systems.

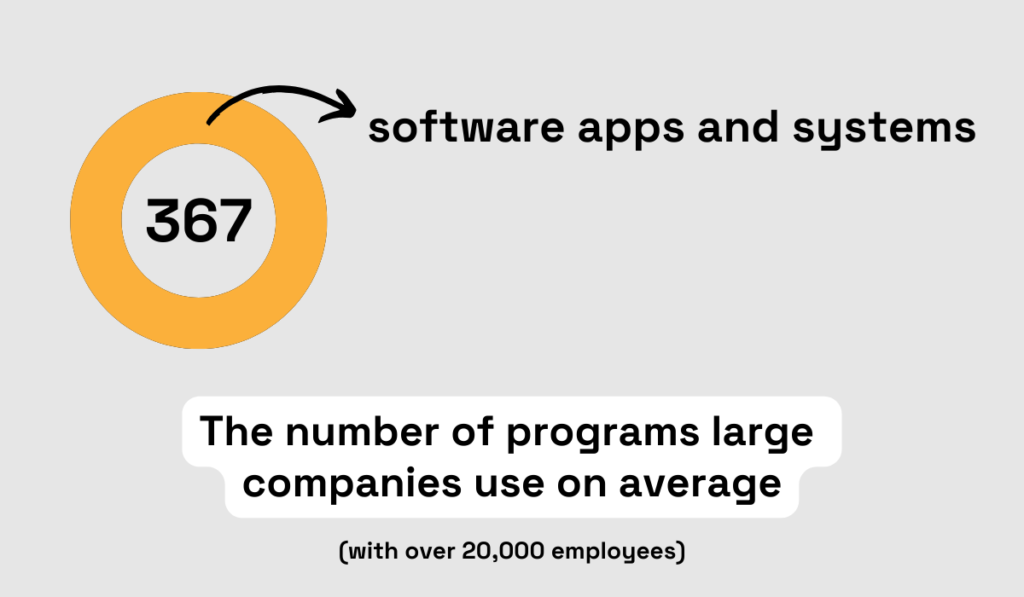

In fact, Airtable and Forrester have found that large companies often employ too many distinct tools within their workflows—367 on average.

Illustration: Veridion / Data: Airtable

This can create difficulty for employees wanting to access the necessary information, often leading to data silos, as we explained earlier.

Moreover, managing all this data requires bridging the gaps between various tools and systems.

This either calls for additional integration tools or for time-consuming and error-prone manual data entry from one system into another.

And time consumption grows with the number of the tools used.

The same survey by Airtable and Forrester revealed that employees spend approximately 2.4 hours each day navigating the piles of data through tools and spreadsheets, which hinders their productivity.

Illustration: Veridion / Data: Airtable

And that’s not all.

Jon Linch, a Senior Technical Product Manager at Amazon, points out another challenge when dealing with extensive volumes of data—analysis paralysis:

Sometimes metrics synthesized from large datasets can be overly complex, while other times the plethora of data can lead to analysis paralysis where the team spends too much time analyzing and doesn’t execute in a timely manner.

Apparently, too much data can block us.

And this inability to make decisions in time leads to missed opportunities and even poor choices.

So, how can you effectively address the challenge of managing large volumes of data?

Once again, the solution lies in investing in the right technology that can not just gather, but also automatically analyze the data for you.

Implementing procurement automation can significantly reduce the need for labor-intensive manual processes to manage extensive data volumes.

Also, it’s essential to seek solutions that can store extensive datasets, provide comprehensive data visibility, and automate tasks efficiently.

These solutions should also be able to integrate with other tools and make data sharing fast and easy.

Armed with data, procurement specialists can improve supplier relationships, cut costs, and make better decisions.

However, merely gathering data isn’t as important as making data driven decisions by interpreting and gaining meaningful insights from it.

Source: Veridion

Therefore, the challenge arises when data is collected but isn’t used effectively.

Let’s imagine a scenario in which the procurement team doesn’t quite understand the data they deal with and the consequences of that.

A manufacturing company’s procurement team regularly collects supplier performance data, including delivery information, product quality scores, and pricing trends.

They have been diligent in gathering this data, and they have noticed a consistent decline in one supplier’s product quality scores over the past few months.

However, without a deep understanding of the data, they misinterpret it as a minor fluctuation and continue to place orders with the same supplier.

But in fact, the declining product quality indicates potential issues in the supplier’s manufacturing process.

This oversight leads to a series of consequences:

This simple example underscores the importance of having data-savvy employees who can truly understand what the data says and use it to make better decisions.

So, how do we tackle this challenge?

First and foremost, executives need to empower their procurement teams.

This means providing them with the right skills and tools to make sense of the data they collect.

Offering training programs that focus on data analysis, interpretation, and making decisions based on insights from data should, therefore, be necessary for every team member involved in the process.

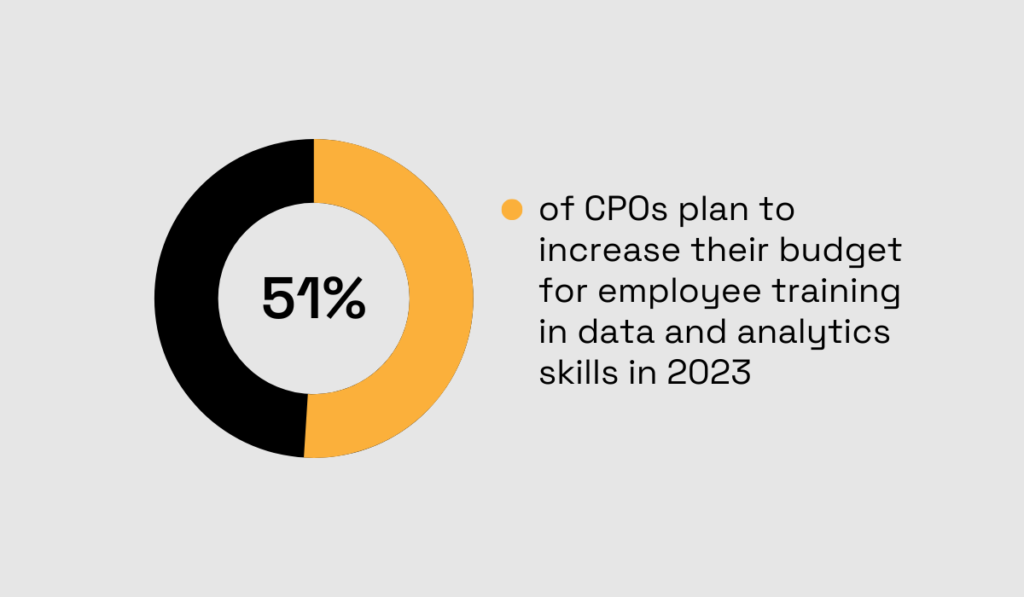

And we have data that supports this.

According to Deloitte’s Global Chief Procurement Officer Survey, CPOs are acknowledging the importance of data and analytics training.

Illustration: Veridion / Data: Deloitte

But enabling team members in understanding the data goes beyond this.

Or, better said, before this—it starts with hiring.

When hiring new team members, it would be wise to consider their data analytics and management skills.

It would help if you looked for candidates who understand procurement processes, but can also handle data effectively.

You can highlight the importance of data skills already in the job ad.

That’s what Maersk, a shipping and logistics company, has done for the role of Procurement Manager:

Source: Maersk

In that case, you can attract individuals who are better prepared to handle data driven decision-making.

You see, data driven procurement is more than just collecting data—it’s about understanding and making use of it.

You can achieve this by continually training your procurement team, providing them with the right tools, and hiring new team members who already have some experience handling data.

Ensuring that procurement data is complete, up-to-date, and accurate, and that you can count on it at all times presents a significant challenge.

This problem persists when you rely on old-fashioned data stored in spreadsheets or use data services that rarely update their information or don’t cover the whole market.

The key to overcoming this final challenge on our list is investing in a tool that provides the freshest and most up-to-date data available, ensuring you can always rely on it.

One such solution is our Veridion, an AI-powered procurement automation tool that offers a comprehensive and constantly updated global supplier database.

Source: Veridion

We at Veridion are fully committed to providing our users with always fresh data—never over two weeks old.

But the value of our reliable data goes beyond just being up-to-date. This tool can benefit your entire procurement.

Let’s see how.

Using Veridion’s search service, you can access detailed information about suppliers, including their adherence to ESG (Environmental, Social, and Governance) criteria using API.

Source: Veridion

Why should this matter?

ESG criteria are becoming increasingly important.

The survey by Deloitte that we mentioned earlier revealed that 72% of companies consider improving their ESG performance a top priority in 2023.

Therefore, sourcing suppliers that align with ESG principles is vital if you want to improve sustainability and maintain competitiveness.

Another thing that sets Veridion apart from the rest of the tools is that the platform provides alerts whenever there are changes in a supplier’s business activity.

Should a supplier stop adhering to certain ESG criteria, you’d know.

This allows you to respond and mitigate potential risks before it’s too late.

Unreliable data is, unfortunately, a common challenge in data driven procurement.

To address this issue effectively, make sure you use tools which offer up-to-date information, like Veridion.

Only when you use up-to-date and reliable data, can you say your procurement is fully data driven.

Now you know that data driven procurement does come with its share of challenges.

Too much data, insufficient data, data overload, and unreliable data are situations to be aware of.

But here’s the recurring theme throughout this article—these challenges can all be tackled by investing in the right procurement automation tools.

These tools have the power to transform data into understandable insights.

And once your procurement team grasps these insights, they can make well-informed decisions, which is the very essence of data driven procurement.