Direct vs Indirect Spend: What’s the Difference?

How do you optimize your procurement strategies and drive cost savings?

There are multiple ways, but the starting point is having a good grasp of key spend categories.

Understanding the nuances between direct and indirect spend will bring you closer to making more informed decisions, improving supplier relationships, and streamlining operational costs.

On the other hand, lacking clarity or oversight over these categories puts you at risk of creating a drain and eroding your profit margins.

So, if you want to avoid that and equip yourself with new knowledge, it’s time to dive into our breakdown of differences between direct and indirect spend!

Direct spend, also known as direct procurement, refers to the procurement of goods, materials, and services that directly relate to the production of goods or services you offer.

In a nutshell, it’s the input you’re directing towards the profit-driving output.

As such, direct spend typically makes up the largest portion of your total spend. This is especially true for D2C (direct-to-consumer) brands or companies with physical products.

Some common categories that fall under direct spend include:

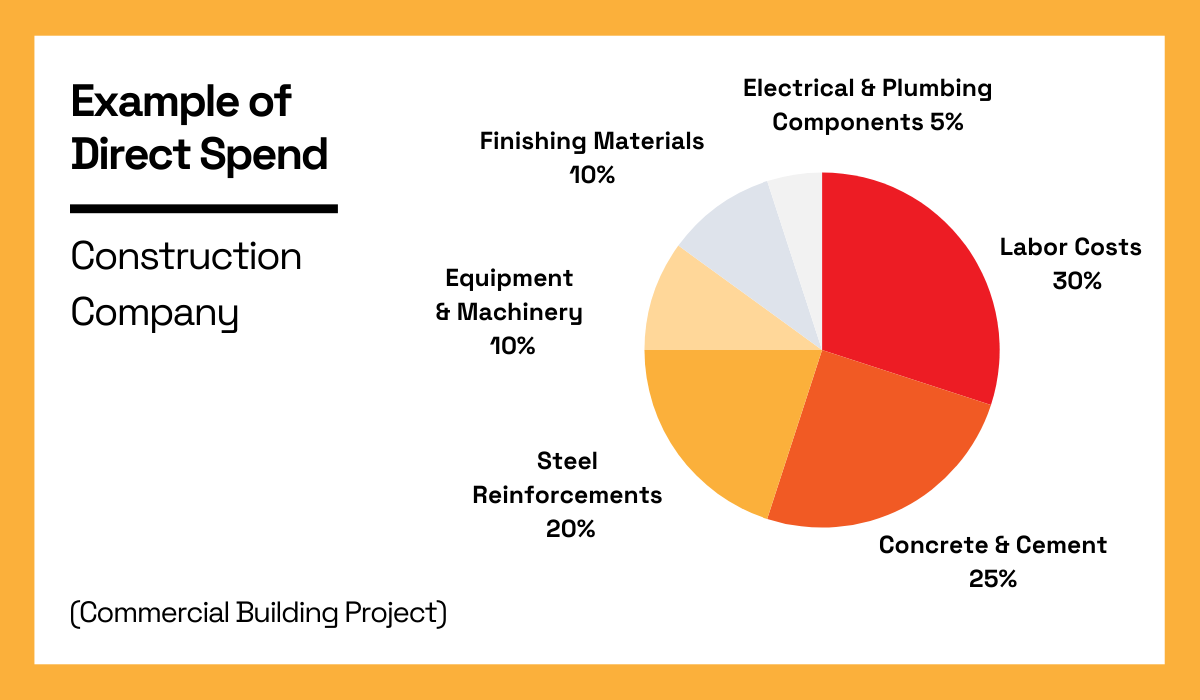

With that in mind, here’s a rough breakdown of direct costs for one commercial building project.

Source: Veridion

The context changes based on the industry, but the construction example neatly underlines that direct expenses aren’t just the raw materials, but also subcontracted labor, because the work couldn’t be completed without it.

In many industries, wages are categorized as indirect expenses, but if labor is directly tied to production, the situation is completely different.

Indirect spend refers to all the operational expenses that keep your business running but aren’t directly tied to the production or delivery of the product or service you’re selling.

However, these expenses are critical for maintaining the operations that support revenue generation.

That’s because indirect spend is everything that helps employees and business owners do their jobs and do them effectively, such as:

However, same as with direct spend, these categories are not set in stone. Their number and scope depend on your company’s work model and category management.

As pointed out by Alex Dussurgey, Head of Procurement at Sastrify, companies that provide SaaS solutions have a completely different setup.

Illustration: Veridion / Quote: LinkedIn

In this case, cloud infrastructure and software are integral to the company’s product or service, and the categorization has to reflect that.

Consequently, in some companies, the indirect spend category will be big, and small in others.

According to McKinsey’s research, indirect spend in retail accounts for about 10% of total revenue. But while this number may seem small, indirect costs can escalate rapidly across all sectors, often slipping under the radar.

One reason is poor spend visibility and lack of control, which seems to be a familiar situation for many companies.

In fact, Globality’s 2023 research reveals that 82% of procurement professionals feel their indirect spend is poorly managed, underscoring a widespread industry challenge.

Illustration: Veridion / Source: Globality

The consequences are significant. Companies struggling with uncontrolled indirect spend not only face operational inefficiencies but also miss out on substantial cost-saving opportunities.

That’s a shame because indirect procurement frequently offers greater opportunities for cost reduction than direct spend, given its wide scope and varied categories.

Issues such as duplicate purchases, unmanaged supplier relationships, and inconsistent contract terms frequently arise from poor visibility. By improving visibility and enhancing spend control, these inefficiencies can be significantly reduced.

Now that we’ve defined both direct and indirect spend, it’s time to take a closer look at the key differences between them from a few different perspectives.

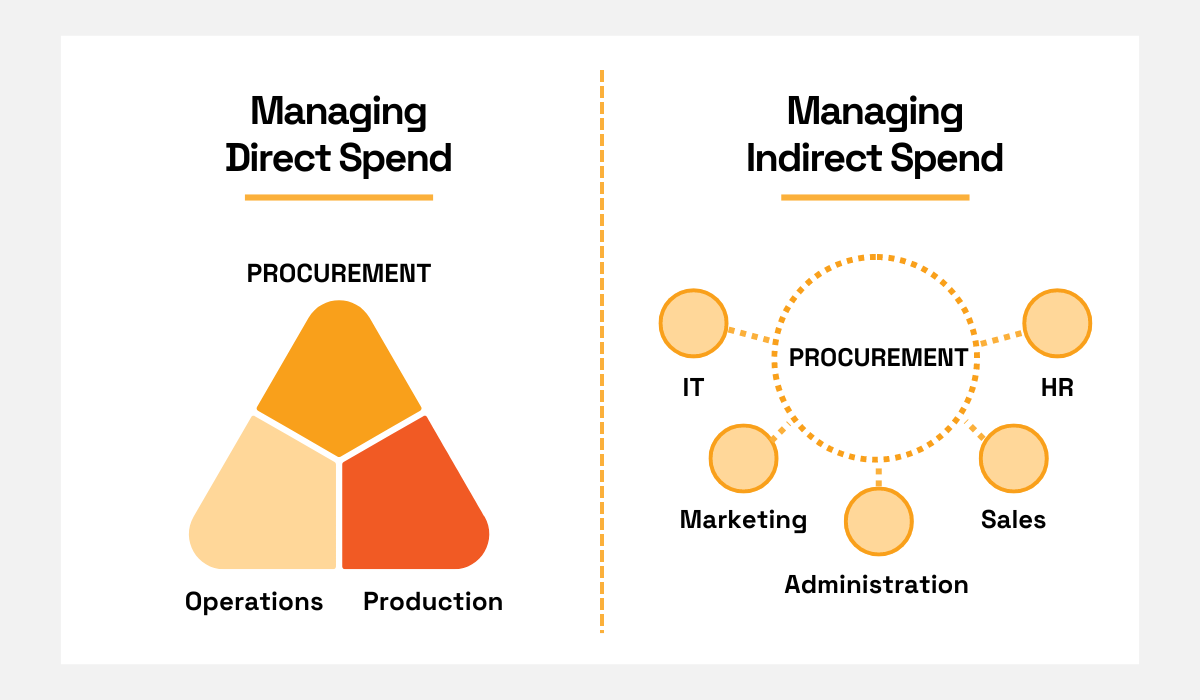

Generally speaking, procurement teams maintain tight control over direct spend while simply overseeing indirect spend.

This difference reflects the organizational setup and the main purpose of each type of spend.

Direct procurement has a critical role in core business activities, so the expenses are usually managed directly by a centralized procurement team, working closely with production and operations.

On the other hand, indirect procurement is often decentralized because it involves a range of categories that meet specific departmental needs.

Decentralization enables department heads to make quick purchasing decisions, but problems often arise if there is too much autonomy and not enough oversight.

Source: Veridion

So, does direct spend have to be centralized while indirect spend remains scattered?

Yes and no.

Direct procurement has to perfectly match production schedules and processes while keeping costs and quality in check. As such, it requires strict management and the procurement team’s direct involvement.

Meanwhile, departments need to have a degree of control and autonomy when it comes to purchasing decisions that are directly relevant to them.

Nevertheless, independent budgets and spend protocols leave room for unnecessary purchases.

This is why more supervision and standardization are sure to improve efficiency and keep indirect costs in check.

The nature of each spend also reflects on the relationship we build with our suppliers.

Direct procurement teams prioritize fewer long-term supplier relationships while indirect procurement often involves more transactional relationships that meet emerging needs.

That’s because building good relationships with key suppliers of direct categories makes it easier to secure crucial components and services.

By maintaining long-term strategic relationships with suppliers, you achieve continuity and cost-optimization while ensuring the high quality of your end products or services.

On the other hand, dealing with non-critical goods and services allows procurement teams to prioritize cost efficiency and quality, but typically put more time and effort into managing internal stakeholders than vendors.

Nevertheless, certain indirect spend categories, such as facility management, still require or simply benefit from long-term partnerships.

Supplier relationship management is part of both direct and indirect procurement, but there are several key differences in the overall approach:

| ASPECT | DIRECT PROCUREMENT | INDIRECT PROCUREMENT |

|---|---|---|

| Procurement Timeframe | Long-term, for critical inputs | Short-term, lower-value input |

| Nature of Collaboration | Strategic | Tactical |

| Supplier Relationships | Fewer key partnerships | Multiple transactional relationships |

Of course, finding reliable suppliers is often a time-consuming and resource-intensive endeavor in itself.

Regardless of whether you’re looking for vendors for direct or indirect categories, you need to be able to find them quickly and efficiently.

That’s where AI-driven supplier sourcing services like ours can help you.

Veridion’s comprehensive database of over 80 million companies worldwide is updated in near-real-time, enabling you to pinpoint perfect suppliers based on criteria like product specifications, location, or ESG characteristics.

Source: Veridion

In short, our data service empowers you to narrow down your search based on specific needs and create a list of potential long-term partnerships in no time.

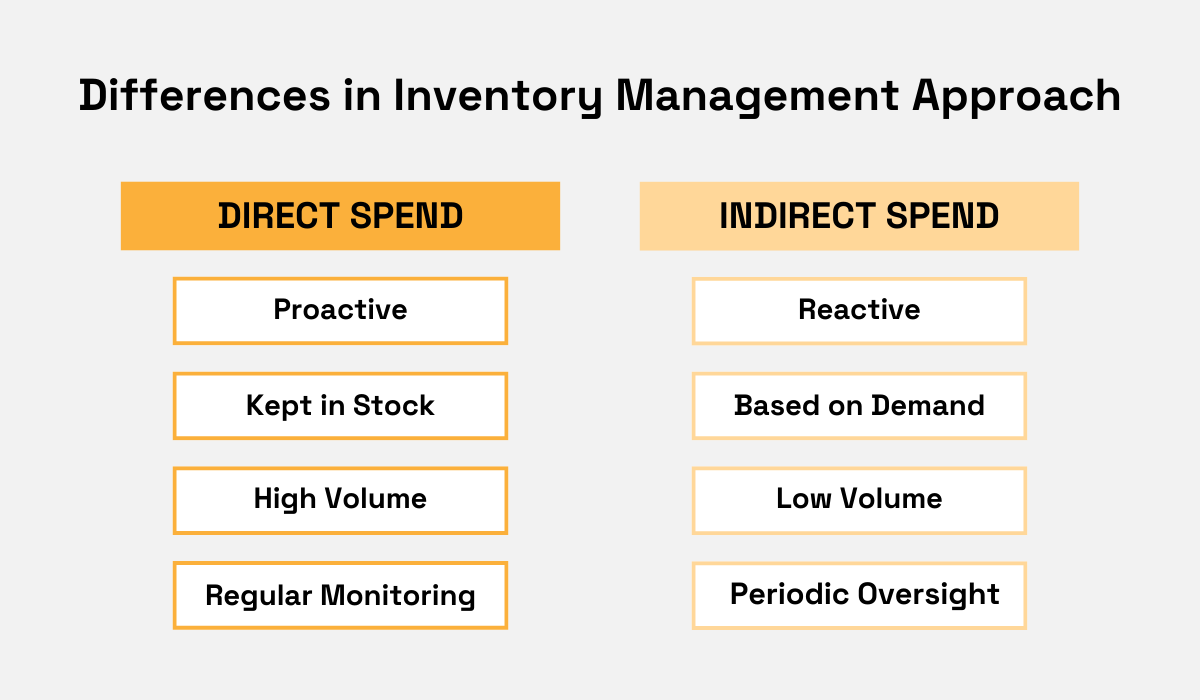

Direct procurement requires proactive inventory management which carefully aligns with production schedules and forecasts while indirect procurement focuses on more immediate needs.

The difference boils down to the sense of urgency as the absence of production-critical materials could cause significant delays and incur additional costs.

To counter this, purchases of direct category items are carefully planned out and happen at higher volumes to ensure that the production remains uninterrupted.

Since commodities are typically stockpiled, this also requires more vigilant monitoring and inventory management.

In contrast, indirect spend is largely reactive and governed by demand.

Source: Veridion

For instance, the HR department may put in a request for several laptops for new hires.

In this case, there is still a degree of urgency because access to equipment is integral for efficient operations (and employer branding).

However, core processes won’t come to a halt without them, and there is no need to stockpile 100 laptops for future onboarding.

Moreover, as the purchase is smaller, and the items won’t be used up during production, inventory monitoring can be done periodically rather than daily or weekly.

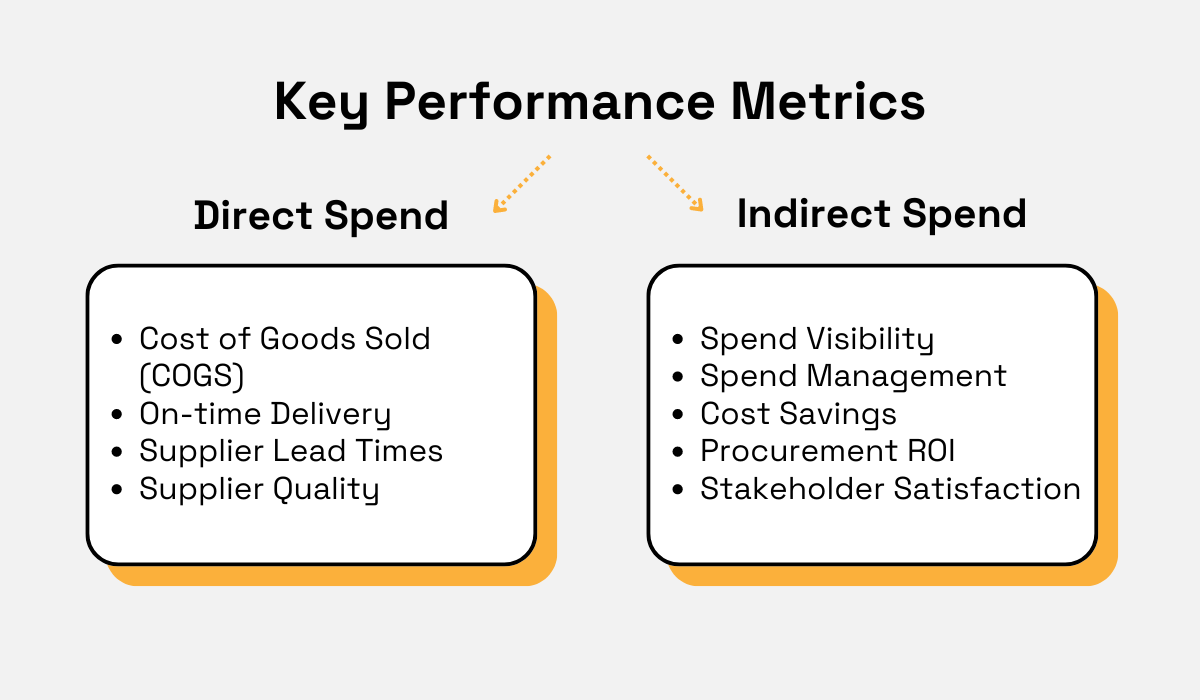

Measuring performance for different types of spend requires a different set of metrics.

For direct procurement, the objective is to secure a steady flow of essential goods and materials.

Conversely, the focus is on measuring COGS (Cost of Goods Sold), as well as tracking quality and supplier lead times.

The metrics related to indirect procurement are usually less standardized. Since this type of spend is scattered across multiple departments, spend visibility and cost savings are the metrics that matter most.

Source: Veridion

And here’s why that is so.

Direct spend takes up a large part of COGS, so effective management and monitoring of production costs helps ensure that the costs remain competitive.

On the other hand, inefficiencies linked to unmanaged indirect spend reduce profit margins.

Unmanaged spend leaves the organization open to maverick purchases, meaning that the costs can easily spiral out of control and affect your overall budget.

That’s why it’s beneficial to focus on spend visibility as a performance metric.

Send visibility keeps things in check, and helps you identify where you can consolidate purchases to achieve cost savings.

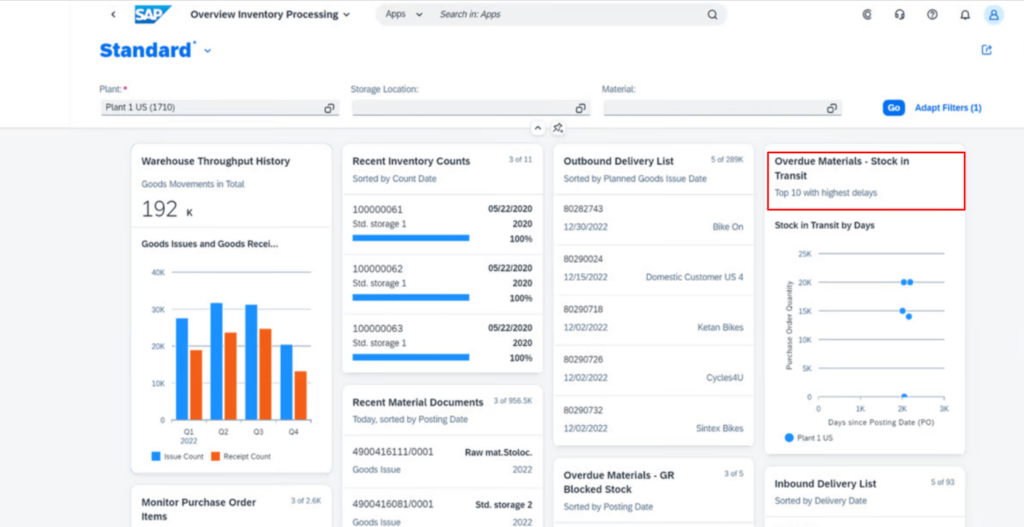

Optimizing direct and indirect spend requires different technology.

Direct procurement is a complex undertaking that has to take into account production schedules, inventory control, and supply chain management.

Therefore, all these elements need to be integrated into one central place. This is where complex procurement systems and enterprise resource planning (ERP) tools are immensely beneficial.

Here’s an example of one cloud ERP software solution, SAP S/4HANA, whose dashboard gives you an overview of key info on inventory processing, including outbound deliveries and overdue materials.

Source: G2

As you can see, such technology helps you stay on top of complex, intertwined processes that are aligned with direct procurement.

Unlike direct procurement, which relies on technology to connect purchasing with production processes, indirect procurement benefits from user-friendly platforms that streamline purchasing for multiple departments.

These tools should make it easy for employees to initiate purchases, but they must also enforce rules and approvals to prevent inefficiencies and overspending.

E-procurement tools are one example.

Findings by RS & CIPS show that over a quarter of procurement professionals in the UK and Ireland use e-procurement solutions precisely as a way of automating tasks.

Illustration: Veridion / Data: RS & CIPS

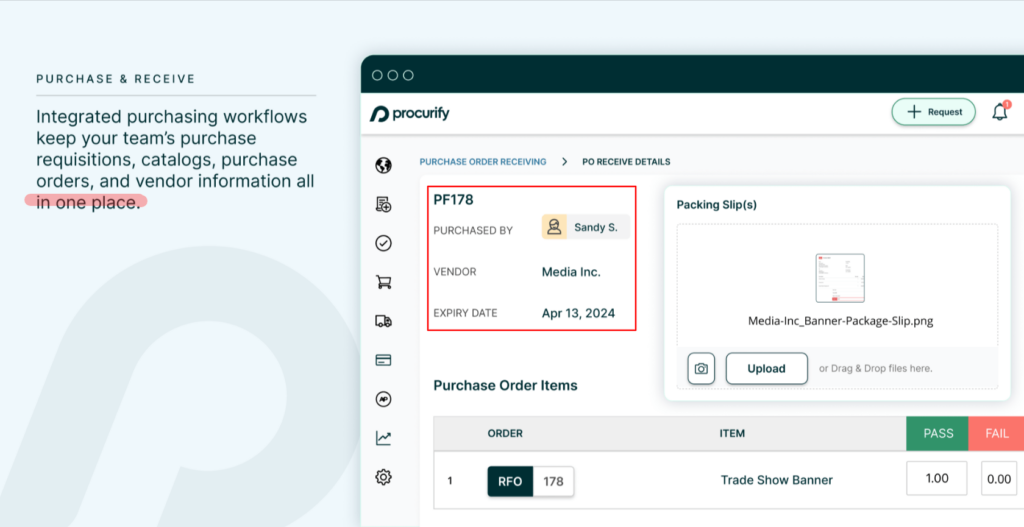

These tools ensure that your procurement team can set up approval workflows and easily keep track of all requisitions and purchase orders, as shown with Procurify’s software below.

Source: G2

Automating purchase requisitions, PO creation, invoice processing, and similar tasks improves compliance and visibility, ensuring that all departments stick to approved vendors.

To recap, direct spend technology helps you tackle complexities with a single source of truth, while indirect spend solutions automate routine tasks to enhance control and accelerate processes.

Understanding the difference between direct and indirect spend enables you to optimize costs and enhance your organization’s financial health.

Managing direct spend impacts core production and revenue.

Meanwhile, having more control over indirect spend helps you unlock hidden cost savings and operational improvements.

The key takeaway?

Taking a strategic approach requires you to be well aware of several key differences between the two, from the nature of supplier relationships to the technology you should use.

Keep them in mind, and you’ll drive cost efficiency and gain a competitive edge in no time!