6 ESG Risks Hidden Deep in Your Supply Chain

Key Takeaways:

Some ESG red flags, like high carbon emissions in a supplier report, are easy to recognize.

Others are, however, much harder to spot.

Sometimes, they may even be deliberately concealed. In other cases, they go unnoticed because they’re buried in lower tiers of your supply chain.

Regardless of the reason, these hidden ESG risks can have profound effects on your business.

In this post, we’ll walk you through six such risks, so you can start mitigating them immediately.

The first risk to be wary of is getting inaccurate or incomplete ESG data from suppliers.

This risk is especially prominent in companies that rely on suppliers to self-report their ESG efforts.

Besides distorting your view of operations, trusting unverified supplier claims can also expose you to exaggerated sustainability statements.

You could even unknowingly reproduce those claims in your own public ESG materials, such as sustainability reports.

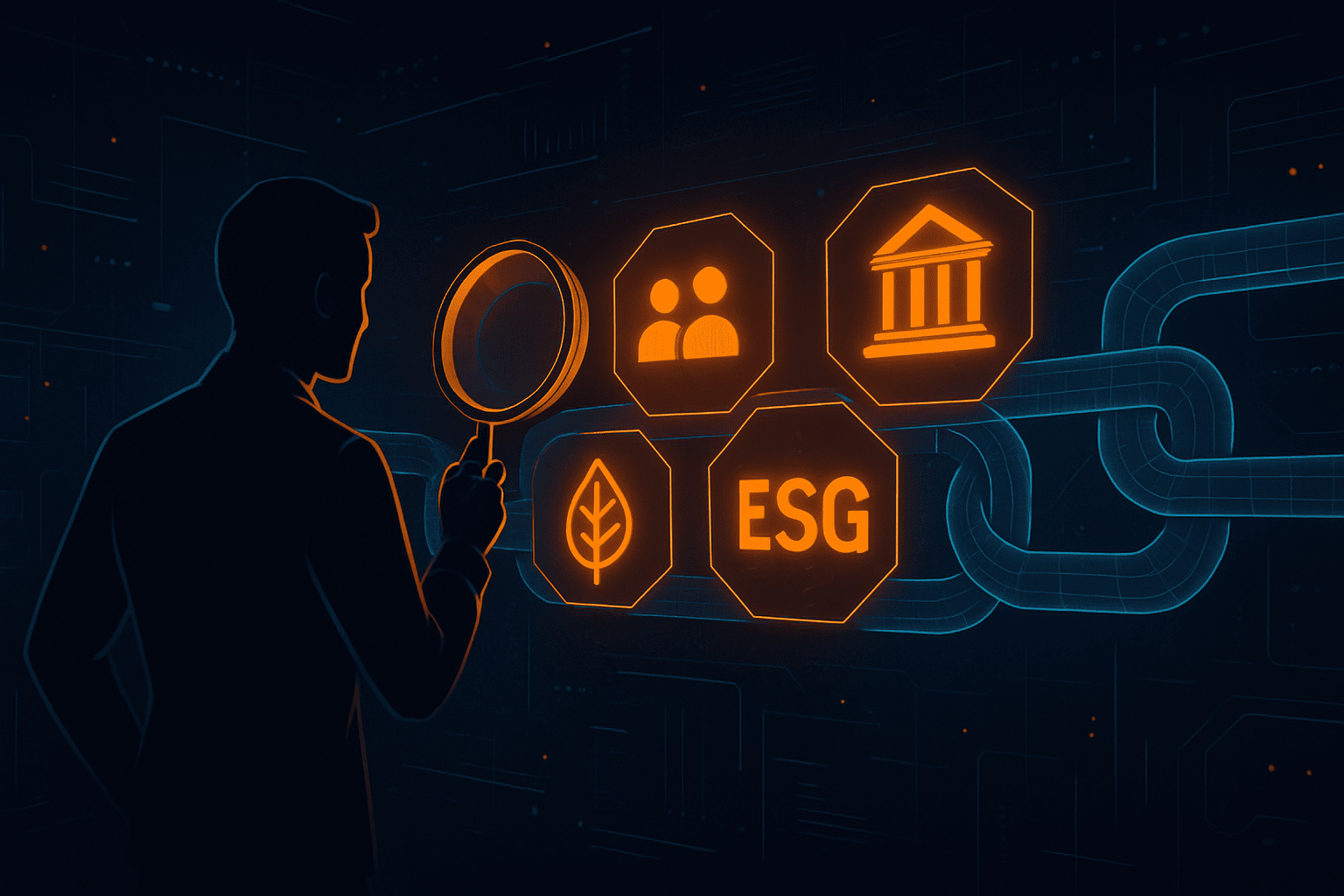

This is important because, according to a study conducted by KPMG in the UK, 76% of consumers consider false and misleading sustainability claims to be the clearest example of greenwashing.

Illustration: Veridion / Data: KPMG

The same study found that over 50% of consumers would avoid companies that engage in this commonly criticized practice.

So, by not verifying supplier data and their claims, you’re risking long-term reputational damage, financial losses, and even potential regulatory penalties.

That’s why leading experts advise taking verification seriously.

Myriam Duguay, KPMG’s partner and national forensic leader, warns that timely due diligence is key to reducing third-party risks.

Illustration: Veridion / Quote: KPMG

So, how can companies mitigate this risk?

The best solution involves three key actions.

First, companies should standardize supplier ESG reporting formats. This will ensure consistency and help them compare suppliers more easily.

Second, they should prioritize working with transparent partners, as this signals accountability and naturally reduces the risk of inflated or misleading claims.

Finally, companies must verify suppliers’ ESG claims.

To do so, they’ll need reliable, unbiased, and up-to-date data, which can be provided by third-party platforms like Veridion.

Source: Veridion

Veridion collects and aggregates ESG data on over 120 million global companies, helping procurement and compliance teams validate supplier claims efficiently.

Its database covers everything from emissions and labor practices to certifications, environmental impact, and regulatory violations.

What sets Veridion apart, however, is its AI-driven, real-time data engine.

It continuously pulls information from a wide range of sources, including company websites and local news, to surface red flags and discrepancies in self-reported ESG disclosures.

Source: Veridion

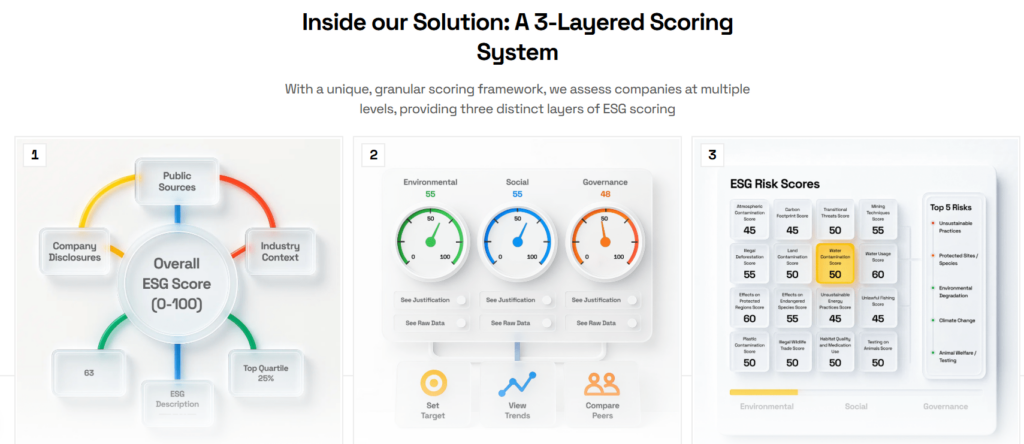

Veridion also has a three-layered ESG scoring system, providing users with a structured, comprehensive view of supplier risk across all three ESG pillars:

Source: Veridion

The platform updates its data weekly, ensuring your decisions are based on the most current intelligence available.

This approach to collecting supplier data is significantly more reliable than using self-reported information.

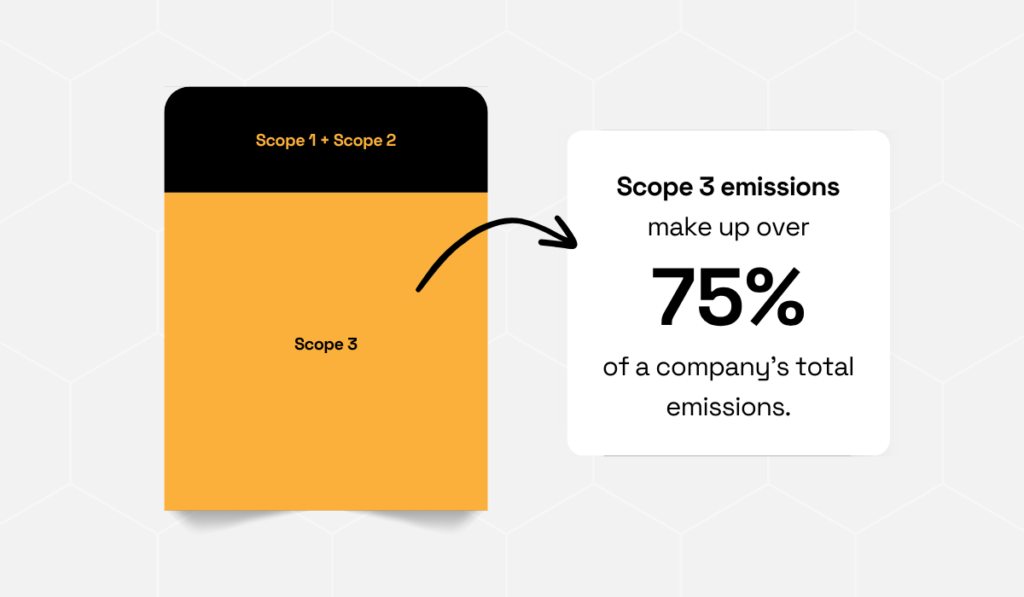

The bulk of a company’s carbon footprint typically lies in upstream and downstream supply chain emissions, such as raw material extraction or transportation.

According to assessments from organizations like CDP, Scope 3 emissions account for over three-quarters of a company’s total emissions.

Illustration: Veridion / Data: CDP

That means achieving climate targets will be nearly impossible without getting Scope 3 emissions under control.

That’s why companies like Stellantis, a global automaker, are not just focusing on their Scope 1 and 2 emissions.

Their decarbonization strategy also targets supplier-related emissions by focusing on two key levers: strong supplier involvement and optimized logistics.

Source: Stellantis

As part of these efforts, Stellantis developed internal logistics guidelines to help reduce its carbon footprint.

It also issued research and innovation recommendations for suppliers, adopted new climate-focused supplier selection criteria, and began tracking approximately 70 prioritized components and materials.

This last point is especially important.

You can’t improve what you don’t track.

But the problem is, Scope 3 emissions are the most difficult part of a company’s carbon footprint to measure and manage.

So, what’s the solution?

According to Tom Chapman, Editor-in-Chief of Supply Chain Digital, the answer lies in digital tools.

Source: Sustainability Magazine

As he explains, supply chain visibility platforms help collect relevant data from suppliers, centralize it, and facilitate tracking and action.

Some platforms also support communication with suppliers, allowing you to easily provide feedback on their practices and share resources that can help them improve.

The most effective approach, though, is to address these risks proactively.

For best results, evaluate potential suppliers for sustainability before entering into a partnership.

Suppliers falling slightly short of your company’s sustainability standards is unfortunate, but not necessarily a significant challenge.

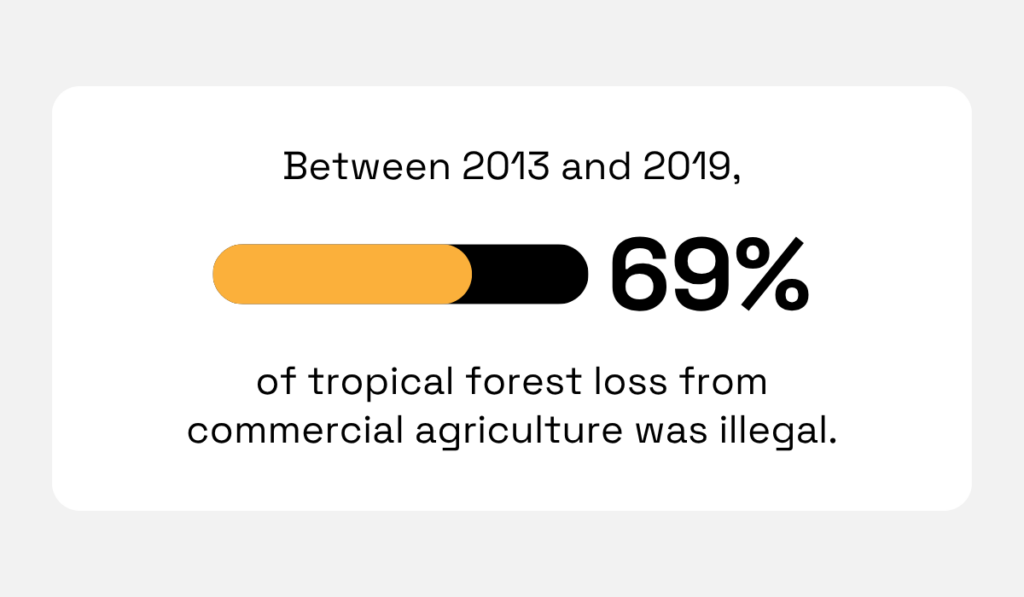

A much bigger issue can arise from suppliers engaging in damaging, and potentially illegal, resource exploitation practices.

This is particularly frequent with commodities like palm oil, soy, and beef.

To grasp the scale of the issue, consider that approximately 69% of tropical deforestation for commercial agriculture between 2013 and 2019 was illegal, according to a 2021 study by Forest Trends.

Illustration: Veridion / Data: Forest Trends

Unfortunately, deforestation is not the only concern.

Overuse and pollution of local water sources are also widespread, especially in water-scarce regions.

Agriculture, in particular, is the leading cause of global water degradation. In the US, it is also the primary source of river and stream contamination.

Illegal and unethical resource exploitation destroys ecosystems and biodiversity.

It is therefore not surprising that many companies face environmental litigation and activist pressure in response to such practices.

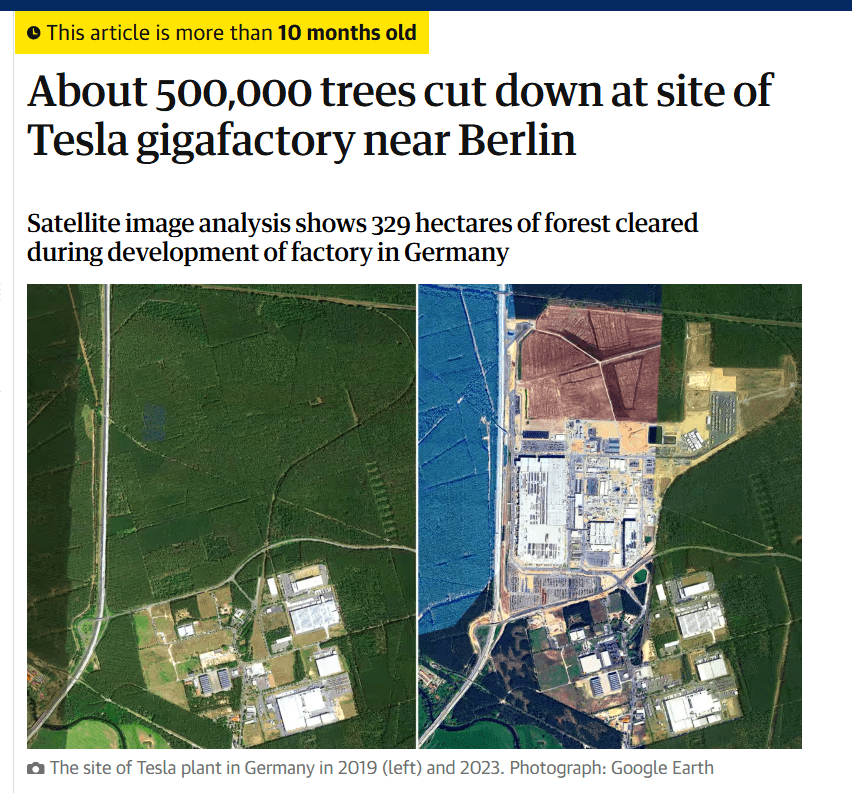

Tesla’s new gigafactory is a recent example.

Source: The Guardian

As seen above, satellite analysis revealed that the development of Tesla’s plant near Berlin resulted in the removal of approximately half a million trees.

This sparked protests, with hundreds of climate activists attempting to enter the site and clashing with police.

Source: The Telegraph on YouTube

To avoid facing similar risks or unknowingly encouraging practices that conflict with your values, you should establish clear supplier guidelines, supplier selection criteria, and monitoring measures.

For example, you can require deforestation-free certifications and integrate satellite monitoring systems.

Satellite imagery is especially helpful for real-time, unbiased monitoring of remote locations.

You can also support suppliers in adopting sustainable practices and technologies, such as water-efficient systems and recycling methods.

Also, consider offering financial incentives, providing training, and co-investing in digital tracking tools.

Labor exploitation, including child labor and forced labor, frequently occurs in lower tiers of supply chains.

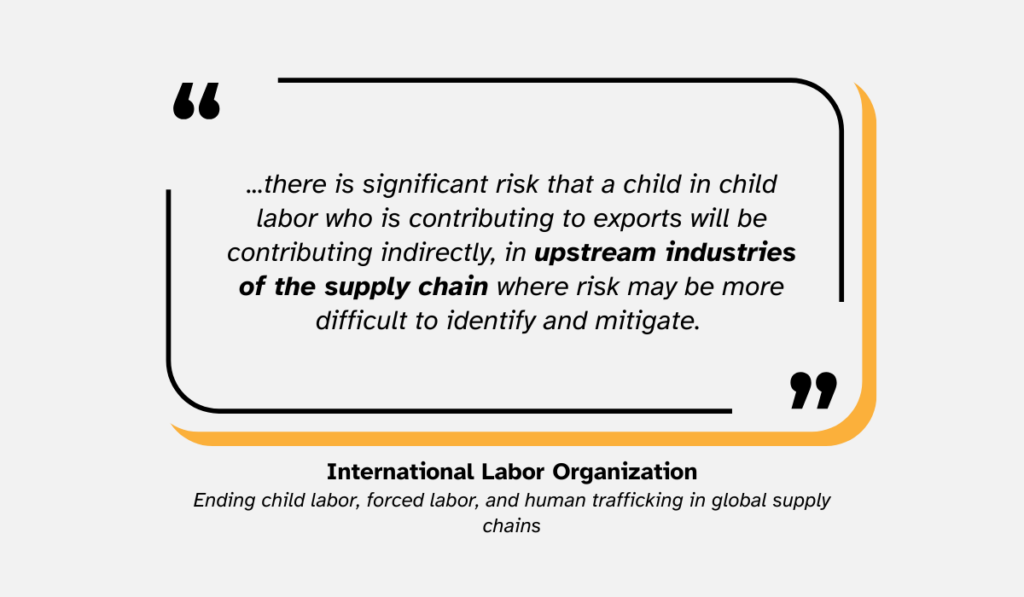

This is precisely what the International Labor Organization (ILO) found in its 2019 study, which provided “the first-ever estimates of child labor in global supply chains.”

After analyzing seven global regions, the ILO found that children make significant contributions to exports, mainly through lower-tier activities such as raw material extraction and agriculture.

Illustration: Veridion / Quote: International Labor Organization

Although the study dates back to 2019, there is overwhelming evidence that labor exploitation continues to exist in today’s supply chains.

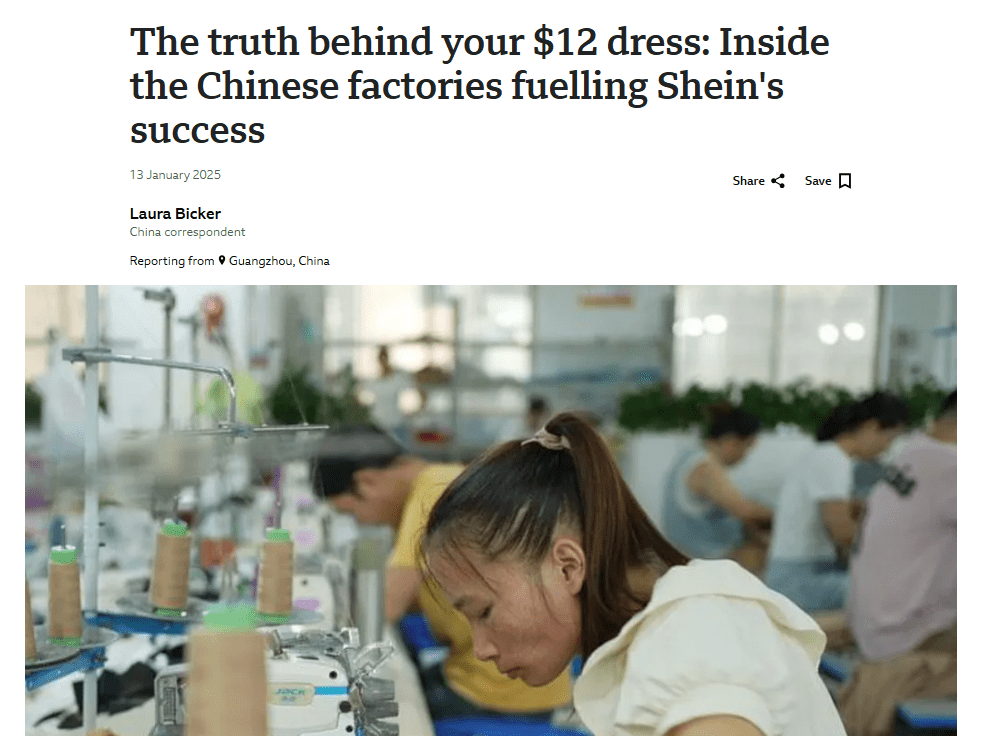

Take Shein’s supply chain as an example.

In early 2025, the BBC did an in-depth investigation and published several alarming findings.

Source: BBC

For example, it reported that standard working hours “appear to be from 8:00 to well past 22:00,” with workers typically working 75 hours a week.

This exceeds the legal maximum under Chinese labor laws, which cap the standard workweek at 44 hours.

Most workers were also found to get just one day off per month, and are paid per piece of garment produced.

In addition to potential legal violations, many consumers consider these practices unethical and, whether out of protest or disapproval, have stopped shopping at Shein.

Source: BBC

Importantly, this type of backlash is not limited to companies directly responsible for poor labor practices.

Even indirect involvement, such as sourcing from non-compliant suppliers, can lead to consumer criticism and regulatory scrutiny.

For instance, Shein’s Code of Conduct states that suppliers must ensure employees’ working hours comply with local laws and regulations:

Source: Shein

Yet the company appears to do little to enforce these rules, which highlights a common risk: stating ethical commitments without adequate oversight or enforcement.

Consumers and regulators increasingly view this kind of inaction as complicity.

To reduce these risks, conduct robust due diligence, map your full supply chain instead of just Tier 1, and, when necessary, work with third-party auditors and NGOs to verify labor conditions.

The prerequisite for much of this work is having accurate supplier data.

On-site visits by subject matter experts can, of course, help confirm it.

In addition to labor exploitation, lower-tier facilities may also have unsafe working conditions.

Even a lack of basic safety oversight can lead to injuries, structural hazards, or toxic exposures, depending on the nature of operations.

This should be a key concern, especially for companies with global supply chains.

Unfortunately, many underestimate the risks.

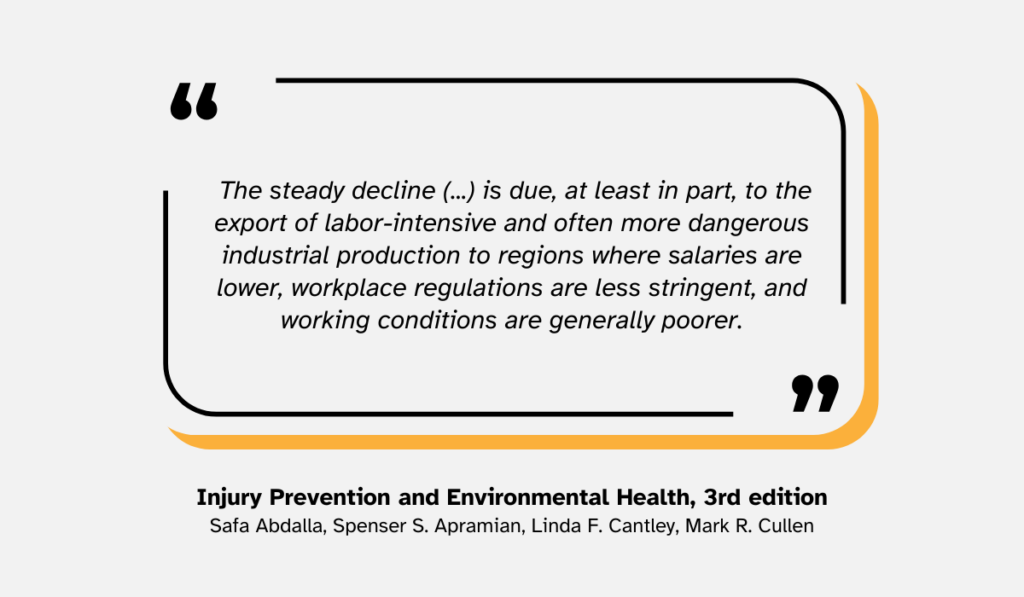

As noted in the book Injury Prevention and Environmental Health, injury rates in wealthier regions are declining, possibly leading to a false sense of overall progress.

However, this decline may simply reflect the outsourcing of hazardous work to other countries, explain the authors of the book:

Illustration: Veridion / Quote: National Library of Medicine

So, the risk is just relocated, not resolved.

While it may be tempting to adopt an “out of sight, out of mind” mindset, companies with global suppliers must be even more vigilant when it comes to hidden hazards and compliance gaps.

This is especially true for those working with suppliers in high-risk or under-regulated regions.

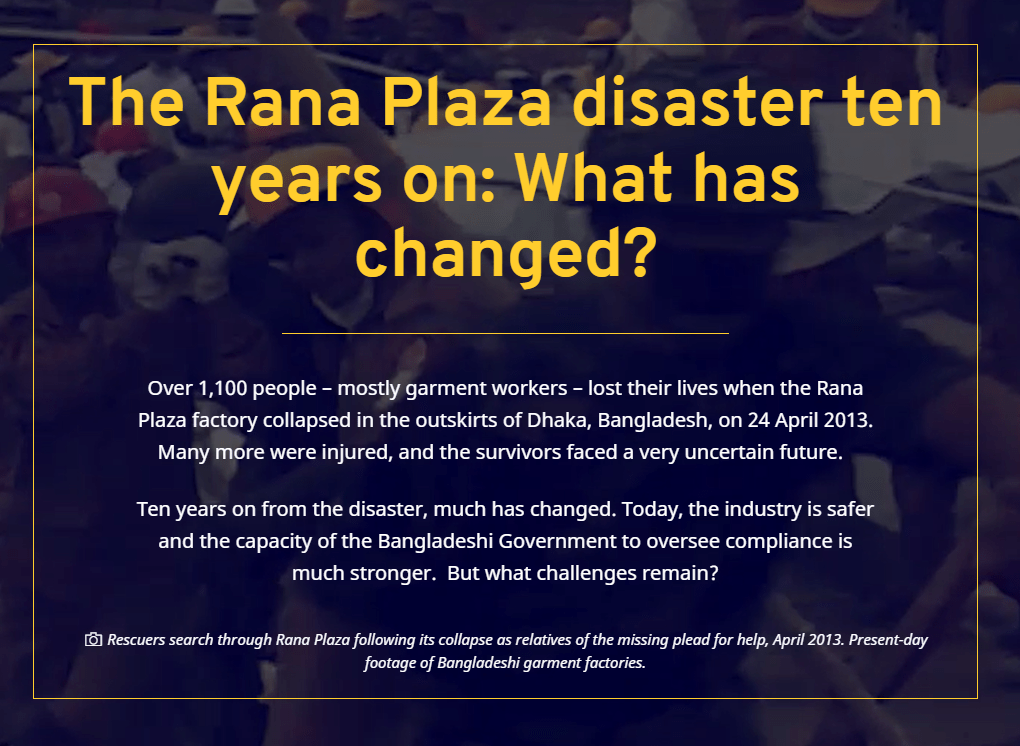

To illustrate some of the dangers, consider one of the most notorious cases of outsourced risk, the Rana Plaza disaster.

Rana Plaza was an eight-story commercial building in Bangladesh, constructed in 2006.

It housed a bank, apartments, and garment factories, which produced clothing for major Western brands.

Source: Fascinating Horror on YouTube

In April 2013, people started noticing deep, visible cracks in the building’s structure. Despite concerns raised at the time, they were largely ignored.

Then, catastrophe struck.

On April 24 of the same year, the building suddenly collapsed.

The disaster eventually resulted in over 1,100 people tragically losing their lives, while many more were left injured.

The tragedy became a symbol of the consequences of poor oversight and accountability in global supply chains.

Source: Guardian

Outsourcing does not absolve companies of responsibility.

In this case, global media and NGOs placed significant blame on Western brands sourcing from the affected factories.

Such incidents can lead to long-term brand damage, lawsuits, and production disruptions. But more importantly, they put workers at serious and avoidable risk.

In the aftermath, the ILO supported the Government of Bangladesh in launching a pilot employment injury scheme and reforming labor laws to align with international standards.

Source: International Labor Organization

To prevent similar risks, companies should implement third-party health and safety audits, establish local worker feedback channels, and invest in supplier training.

Remember, the key is to stay aware of the working conditions and take action when needed.

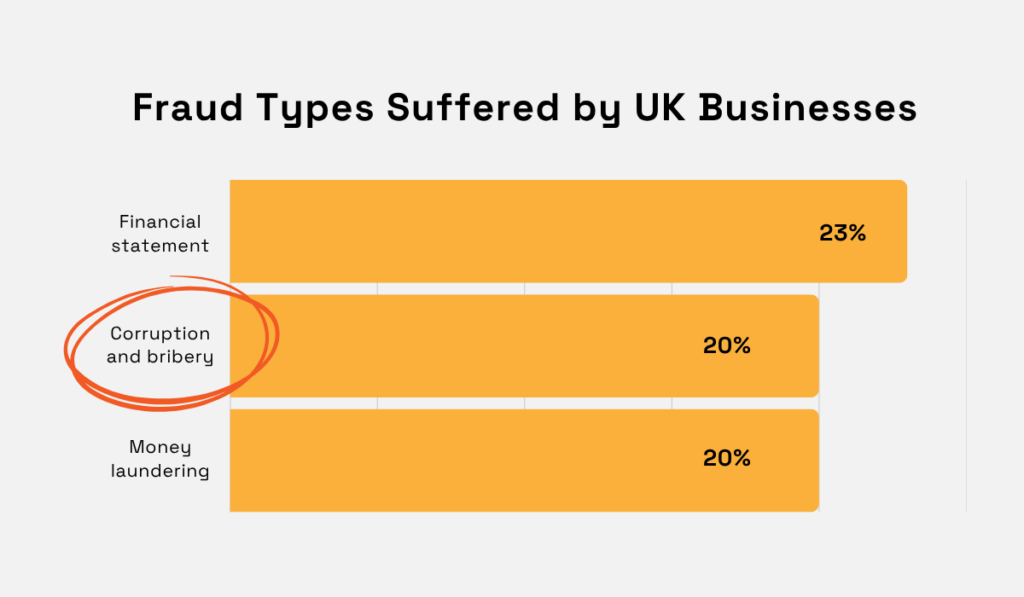

Corruption remains a widespread issue in global business.

In fact, it may be more common than many realize.

For instance, the 2024 BDO Fraud Survey found that 20% of fraud experienced by UK corporate entities was linked to corruption and bribery.

Illustration: Veridion / Data: BDO

This shows that, even though corruption may be more prevalent in less regulated regions, companies in other regions can be affected as well, especially through their supply chains.

In areas with less oversight, suppliers may use corruption to gain advantages, such as expediting permits, bypassing labor laws, and underreporting emissions.

Working with such suppliers can undermine your ethical sourcing efforts and expose your company to anti-corruption law violations.

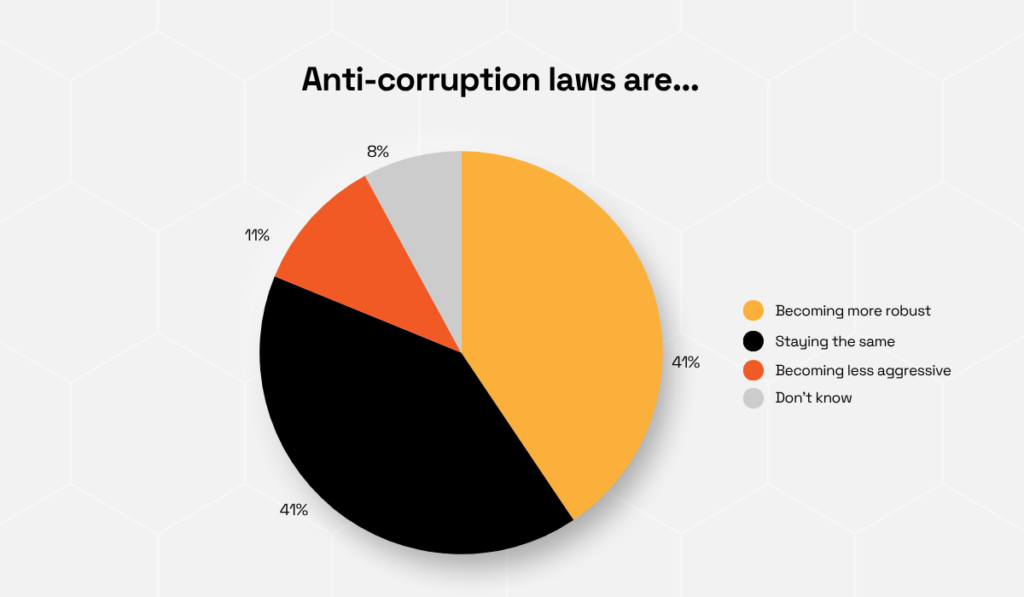

And with over 40% of business leaders believing that the anti-corruption laws are becoming more stringent, these risks cannot be ignored.

Illustration: Veridion / Data: PwC

Beyond potential legal and ethical violations, corruption in the supply chain can also lead to other harmful consequences for buyers.

They may end up overpaying for goods or services, experience frequent disruptions and operational instability, or suffer reputational damage when misconduct eventually gets exposed.

That’s why it’s essential to implement strong supplier codes of conduct, conduct anti-bribery training, and use third-party risk intelligence platforms.

Platforms like Dow Jones, for example, deliver relevant data, due diligence reports, and more.

Source: Dow Jones

These platforms also often offer screening and monitoring tools, which support supplier monitoring in real time.

Hidden ESG risks like data falsification, resource exploitation, and labor abuse may not always be visible, but their impact is real.

Ignoring them can lead to regulatory trouble, reputational damage, and long-term operational setbacks.

The good news is that you can identify and address these risks with the right tools and awareness.

By taking a proactive approach to supplier transparency, you’ll protect your business and simultaneously build a more ethical and resilient supply chain.