How Data Driven Procurement Mitigates Risks

In our previous articles, we discussed what data driven procurement is, its benefits, and how you can transform your procurement with a more data driven approach.

We have emphasized time and again that this approach brings many significant benefits, one of which is mitigating risks.

Procurement risks range from supplier reliability, price volatility, and quality issues to potential disruptions in the supply chain, all of which can negatively impact your organization.

However, relying on data and using it to make strategic decisions can significantly reduce these risks.

In this article, we will explain precisely how data driven procurement mitigates procurement risks and why that is important.

Without further ado, let’s jump straight in.

To effectively mitigate risks in your procurement, you need real-time insight into the supply chain.

That’s why the results of a survey conducted by McKinsey are surprising.

A concerning 45% of companies either lack visibility into their supply chain or have limited visibility, often extending only to their first-tier suppliers.

That’s a risky business, so let’s see how data driven procurement can improve those numbers.

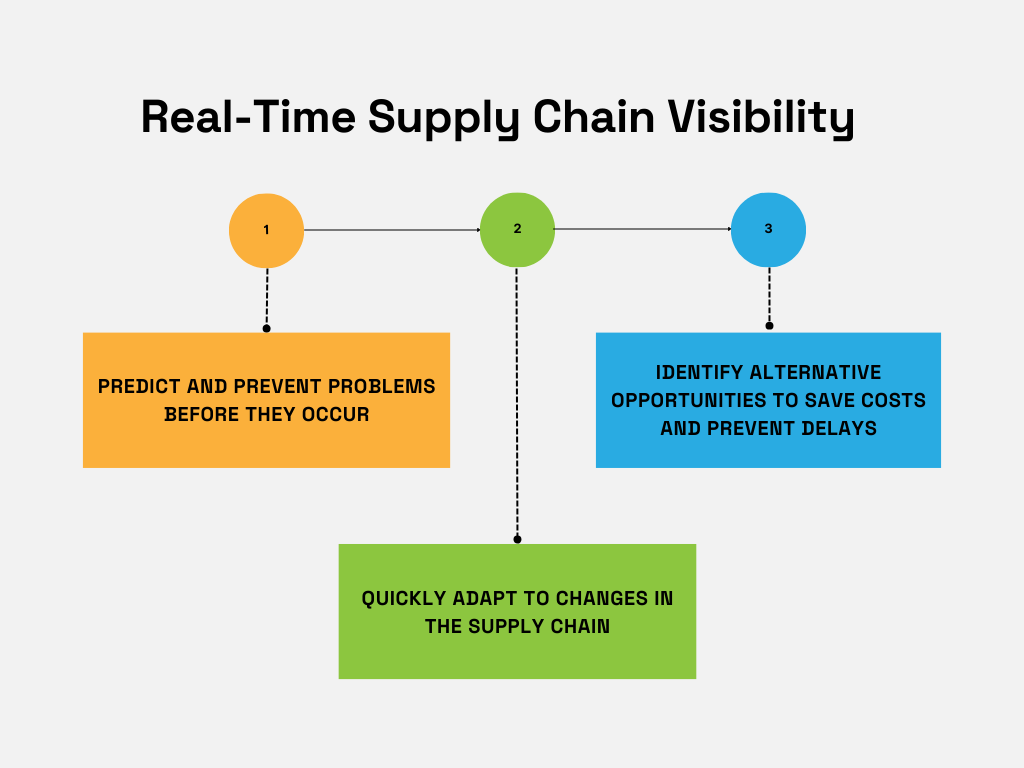

Data enabled by procurement technology allows you to monitor, analyze, and respond to real-time supply chain events to ensure agility, risk reduction, and efficient procurement.

In simpler terms, real-time insight into your supply chain lets you quickly spot disruptions, changes, and market shifts.

This, in turn, helps you adjust your procurement strategies, preventing issues and delays.

Source: Veridion

Using a car manufacturing company as an example, let’s look at how real-time supply chain insights can make a difference.

A company heavily relies on the timely production of engine control units (ECUs) for their vehicles. However, one of their long-standing suppliers encounters an unexpected production delay.

Let’s say this car manufacturer operates with a traditional, non-data-driven approach to procurement.

So, when the supplier’s production delay occurs, it takes them completely by surprise.

The outcome?

A shortage of ECUs disrupts the car manufacturing process, leading to delayed deliveries, financial losses, and severe damage to the company’s reputation.

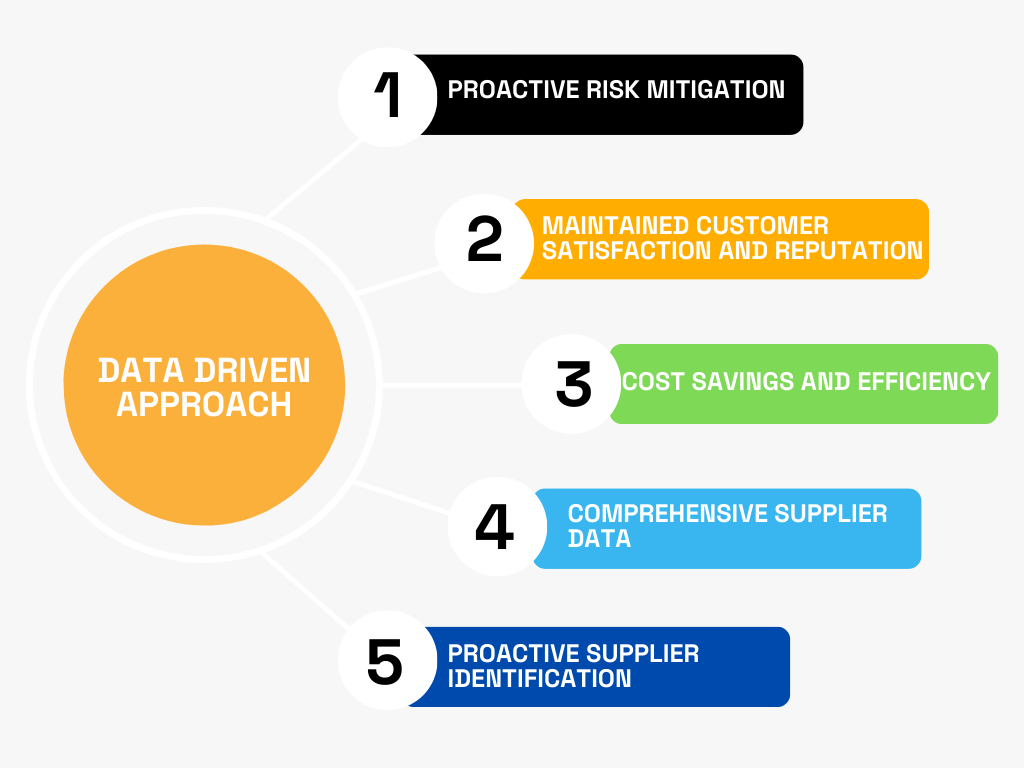

Now, let’s say they’ve adopted a data driven approach to their supply chain management.

These are some of the benefits they would experience as a result:

Source: Veridion

But suppose the car manufacturing company has integrated data systems into their workflows.

In that case, the procurement team would be able to identify alternative suppliers with available ECU stock within minutes.

They would be able to minimize delays and additional costs, ensuring uninterrupted car manufacturing.

But it’s important to note that these data systems must provide up-to-date supplier information, which isn’t always the case.

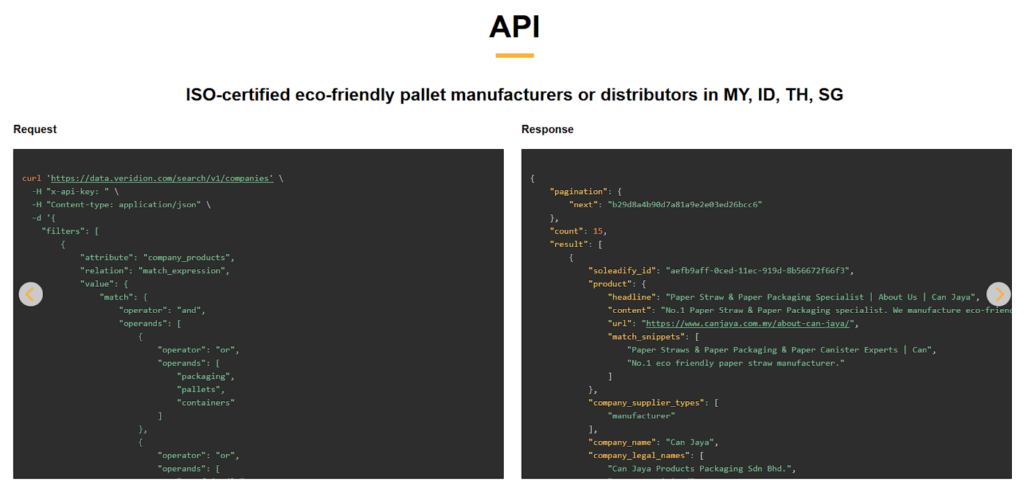

This is where Veridion, our supplier sourcing tool, stands out.

Veridion provides access to a global supplier database with up-to-date information about every supplier, and you can integrate it into your existing workflows.

Through our search API, you can quickly identify all alternative suppliers by searching specific product criteria—like ECUs in our example.

Source: Veridion

But apart from giving you near-real-time information on suppliers, Veridion also delivers valuable market insights, proactively warning your procurement team about potential material shortages in the supply chain.

This foresight enables you to take timely measures to secure the necessary components, guaranteeing uninterrupted production.

Overall, the synergy between data-driven insights and a reliable supplier sourcing tool is the key to reducing risks and maintaining a flexible supply chain.

With real-time supply chain insights, you can quickly adapt to changing circumstances, keeping your procurement processes efficient, effective, and risk-aware.

A reliable supplier is necessary for a successful procurement, but working with suppliers always comes with inherent risks.

So, to make well-informed decisions and select suppliers with the lowest risks, you first have to conduct a supplier risk assessment.

For that, you have to gather and analyze data related to your suppliers, like their performance, reliability, pricing, and other relevant factors, which you can see listed in the image below.

Source: Veridion

The sources for this data are various, from financial reports and supplier performance history to industry reports, market conditions, and geopolitical analysis.

However, these sources often lack the newest, up-to-date information on suppliers.

Why is this important?

Because suppliers’ behaviors and activities change, risk assessment before selecting suppliers is not sufficient.

On the contrary, you should continue supplier monitoring at least every six months.

For that, you need a reliable source of accurate information that will give you constant insights into your supplier’s behavior, preventing potential risks.

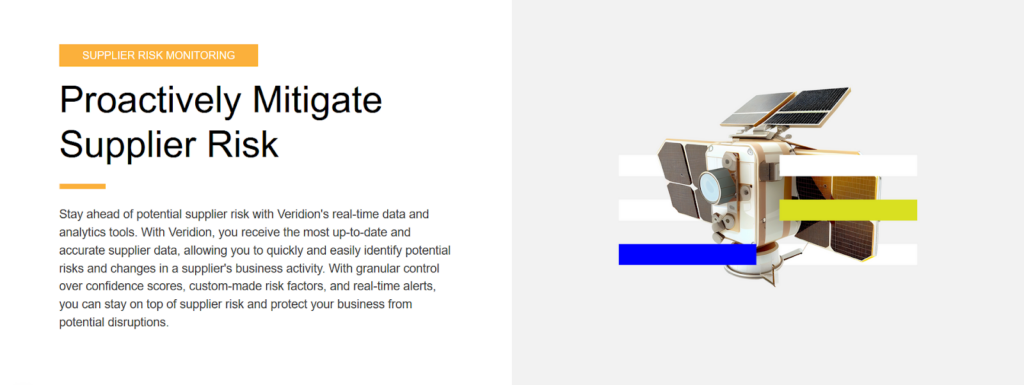

One such valuable data source is our supplier-sourcing enabler Veridion, which we introduced earlier.

One of its core functions is helping you assess and mitigate supplier risks.

Source: Veridion

Let’s explain how.

Apart from providing a comprehensive view of each supplier, Veridion can also monitor changes in suppliers’ activities and profiles.

These changes range from basic details like changes in the company’s location to more specific alerts, such as significant alterations in supplier’s business activities or the loss of certifications like ISO compliance.

With these detailed insights into suppliers’ profiles and behaviors, you can assess risks associated with them and monitor them with a higher degree of thoroughness.

After all, the more comprehensive the assessment, the lower the likelihood of encountering supplier-related risks.

Unfortunately, supplier risk is not the only danger inherent to procurement.

Market risks, like price fluctuations or demand changes, and operational risks, such as quality issues and supply chain disruptions, also require your attention.

What’s more, there is a risk of not meeting legal and regulatory requirements or failing to meet sustainability goals.

Additionally, there are risks that you can’t have much impact on, like geopolitical events that can disrupt supply chains in specific regions or even natural disasters like earthquakes, floods, or hurricanes.

However, if you collect and analyze data, you have a foothold—data that you can hold on to and use to better prepare for the eventualities described above.

Let’s explore how data driven procurement enables you to analyze those three types of risks—market, sustainability, and geopolitical.

By analyzing historical market data, such as commodity prices and demand trends, you can anticipate potential market risks and make informed decisions.

For the sake of example, let’s say you’re in the construction industry.

Data analysis reveals a consistent pattern of fluctuating steel prices due to global market dynamics.

Source: Gordian

With this insight, you can time your steel purchases when prices are lower, optimizing your procurement costs.

By monitoring sustainability metrics and supplier practices, data driven procurement helps you make informed decisions to meet your sustainability goals.

This includes tracking carbon emissions, resource usage, and ethical practices.

For example, your company is highly committed to sustainability, and data analysis reveals that one of your suppliers has a high carbon footprint.

Using this information, you can engage with the supplier to implement environmentally friendly practices or consider sourcing from a more sustainable supplier.

Data analytics enable you to monitor geopolitical events and assess their potential impact on your supply chain.

This includes tracking trade policies, geopolitical stability, and regional risks.

Let’s say you source electronic components from a supplier in a region with geopolitical tensions, but data analysis alerts you to potential disruptions in the supply chain due to political instability.

You can diversify your supplier base to reduce dependence on that region and minimize risks.

As mentioned earlier, this data analysis gives you a base from which you can extrapolate mitigation strategies like these:

Incorporating these data driven insights into your procurement processes allows you to identify, assess, and proactively address different procurement risks.

By doing so, you can be better prepared for uncertainties and changes in your procurement, make informed decisions, and stay resilient.

If you’re interested in learning more about supplier data and risk from first-hand experience, watch this videocast our CEO, Florin Tufan, has made:

Saving costs is a key goal for organizations aiming to operate efficiently and have productive procurement operations.

Data driven procurement becomes a powerful tool in this effort, providing abundant information to discover ways to reduce expenses and manage financial risks effectively.

One of the significant advantages of data driven procurement is its ability to improve your demand forecasting accuracy.

By carefully analyzing historical data trends, you can gain valuable insights into future demand patterns.

This precision in forecasting empowers you to optimize your inventory management, ensuring you maintain just the right amount of stock.

As a result, you can minimize excess inventory costs and mitigate the risk of understocking, which leads to substantial cost savings.

One famous company known for using big data for this purpose is Walmart.

This retail giant relies heavily on data analytics to optimize its supply chain.

By analyzing sales data and historical trends, Walmart adjusts its inventory and transportation schedules to minimize excess inventory and cut operational costs.

Moreover, their suppliers use a real-time inventory management system showing demand for specific products, so they don’t overstock with products that are not being sold much.

And this data driven approach has translated into significant savings for them.

Source: Veridion

Another way that relying on data can help you save money is by enabling you to monitor supplier performance closely.

Collecting and analyzing supplier data allows you to evaluate supplier reliability, delivery times, and product quality in real time.

These insights can be handy during negotiations.

For example, you can secure better pricing agreements with suppliers by negotiating terms based on factual performance metrics rather than assumptions.

In addition, data driven insights help you identify suppliers that offer superior value for money.

This allows you to make informed decisions to switch to more cost-effective suppliers and reduce expenses without compromising quality.

And according to Sergio Juarez of Safe Mobility, looking for cost-saving opportunities should not be overlooked.

Illustration: Veridion / Quote: DigiKey

In essence, data driven procurement empowers you to make informed decisions that lead to cost optimization.

By relying on data, you can navigate procurement more efficiently, ensuring you spend every procurement dollar wisely and seize every opportunity for savings.

In this article, we’ve explored four key ways in which data driven procurement effectively mitigates risks.

It provides real-time supply chain insights, enables continuous supplier risk assessment, supports in-depth risk analysis, and aids in cost optimization.

These aspects underscore the vital role of data in modern procurement, demonstrating its importance in managing risks and maintaining a resilient supply chain.

So, if you want to mitigate risks in your procurement, consider making your procurement more data driven.