Find Suppliers for Any Category

Find suppliers across any category or industry with advanced filtering, real-time search capabilities, and weekly data updates.

The semiconductor shortage has been a critical issue since early 2020, with prospects remaining bleak into 2023 and beyond. Initial forecasts have shown that semiconductor manufacturing capacity growth will likely remain inconsistent until at least 2026.

This semiconductor deficit, predominantly affecting mature technologies, impacts several sectors, including industrial and automotive. The implications of such a shortage are expansive, with consequences ranging from stifled innovation progress to economic repercussions for businesses and consumers alike. However, this pressing situation also presents an opportunity to leverage data to devise strategies for resilience.

There’s an urgent need to develop a comprehensive understanding of the evolving semiconductor supply chain. Current data indicate that semiconductor devices such as microcontrollers and sensors have 20 to 40 weeks lead times, a delay that peaked at 22 weeks in mid-2022 but down to 19 weeks in early 2023. Additionally, a McKinsey study posits that around 90% of the shortage is associated with mature technologies, with about 75% of all publicized shortfalls being linked to integrated circuits. These data points offer valuable insights that can help procurement teams better understand the landscape, identify vulnerabilities, and build fallback strategies.

In addition to understanding the market through data analysis, building a robust network of secondary and even tertiary semiconductor suppliers can significantly mitigate the impact of supply chain disruptions. Strategies such as consistent communication with suppliers, sharing pertinent information, and managing early deliveries can enhance existing supplier relationships while paving the way for alternative sourcing paths.

Through Veridion’s Supplier Search API, you can uncover numerous alternative options for your current supplier base and keep a global view of new potential suppliers for any sourcing initiatives.

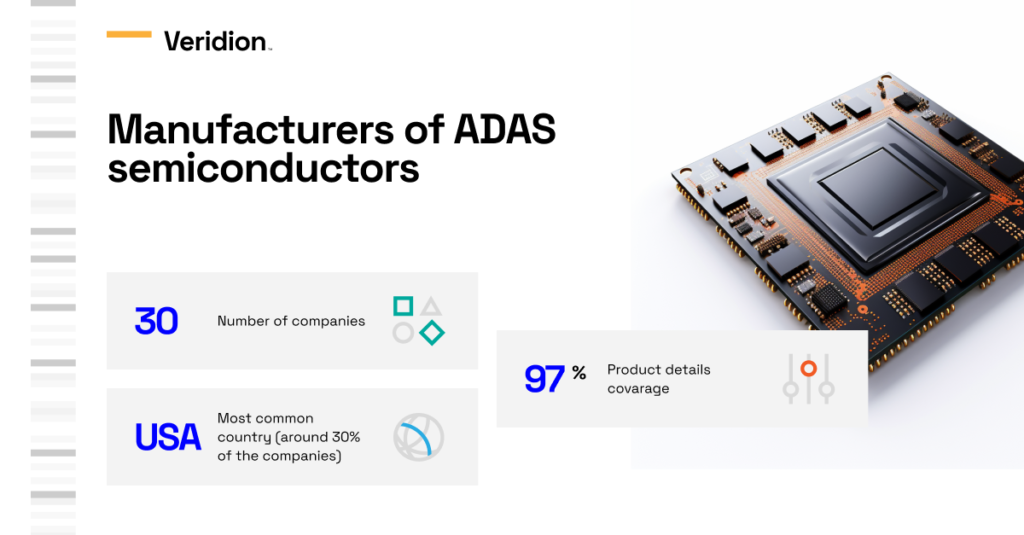

To help you fully understand the capabilities of this API, we’ve run a search for semiconductor suppliers specialized in automotive chips. We’ve also included special requirements to test the coverage for particular sourcing needs. This search consists of the following key elements:

Usually, in this space, big players like NXP, Infineon, and Texas Instruments take most of the market share, but overly relying on just these prominent manufacturers for your production lines can cause severe issues in case of supply chain disruptions. You can explore a sample dataset for this specific search scenario in the table below.

While cost management is crucial, it’s also essential to maintain product quality amid supply chain challenges. The same McKinsey study mentioned before states that over-emphasis on cost-cutting could result in extended lead times, compromised product quality, and strained supplier relationships, exacerbating supply chain issues.

Finally, exploring untapped market capacities can yield significant dividends in this time of shortage. This involves probing into the abilities of global suppliers with free capacities that offer alternative raw material sources. By broadening the scope of potential suppliers, procurement officers can tap into capacities that may have been overlooked.

While the causes behind semiconductor supply shortages seem monumental and largely beyond immediate control, mitigating their impact through strategic analysis and data-driven decision-making is possible. Juggling this with establishing strong supplier relationships, exploring untapped market capacities, and balancing cost management can lead to a more sustainable and resilient supply chain model. These strategies will remain relevant and crucial as circumstances evolve into the latter half of 2023.

With access to comprehensive insights on over 50 million suppliers, we offer crucial data solutions for procurement teams that want to stay ahead of the curve on the path to fully resilient supply chains. Contact us today to see how Veridion can bolster your supplier discovery and decision-making processes.