Master Data Management: Best Practices to Follow

Key Takeaways:

As supplier networks grow more complex, master data management (MDM) plays a critical role in maintaining data consistency, supporting informed decisions, and reducing operational risk.

Yet siloed supplier data affects 9 in 10 organizations, compromising procurement accuracy and strategic planning, especially in enterprise environments.

This guide outlines the best practices you can apply to establish reliable, long-term supplier data management.

Let’s dive in.

Preventing bad data is always cheaper than fixing it, and in procurement, these costs can quickly ripple across operations.

Enterprises today process massive amounts of procurement data, including incoming supplier information.

The moment that data grows inconsistent, incomplete, or duplicated, it slows processes down, creating friction through mismatched records, compliance lapses, and failed payments.

One root cause? Data silos.

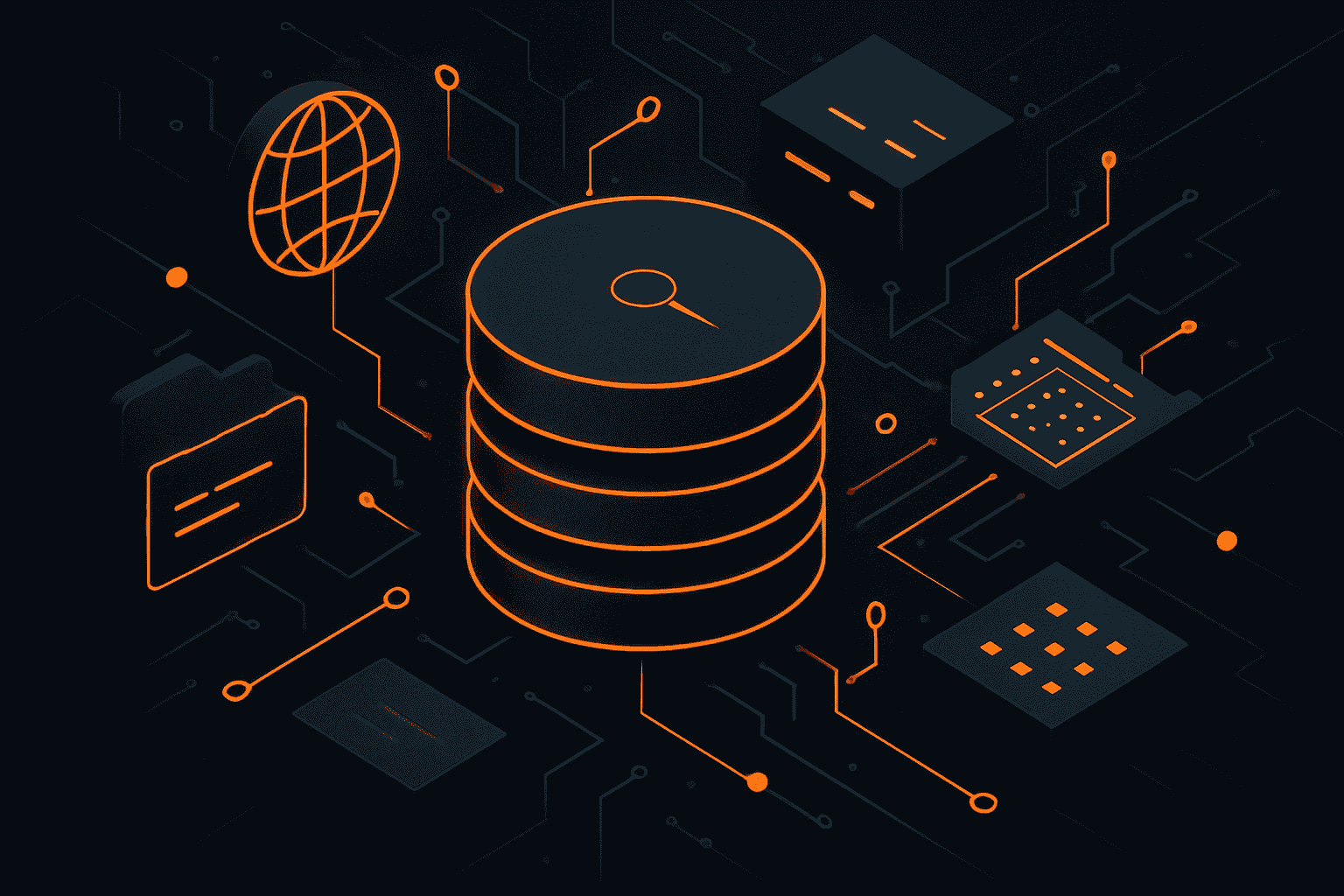

60% of IT leaders across sectors admit to notable issues with partly or completely isolated data.

Illustration: Veridion / Data: Workday

And with MuleSoft reporting that the average enterprise uses 897 applications, and 46% use over 1,000, it’s clear why data remains scattered and hard to manage.

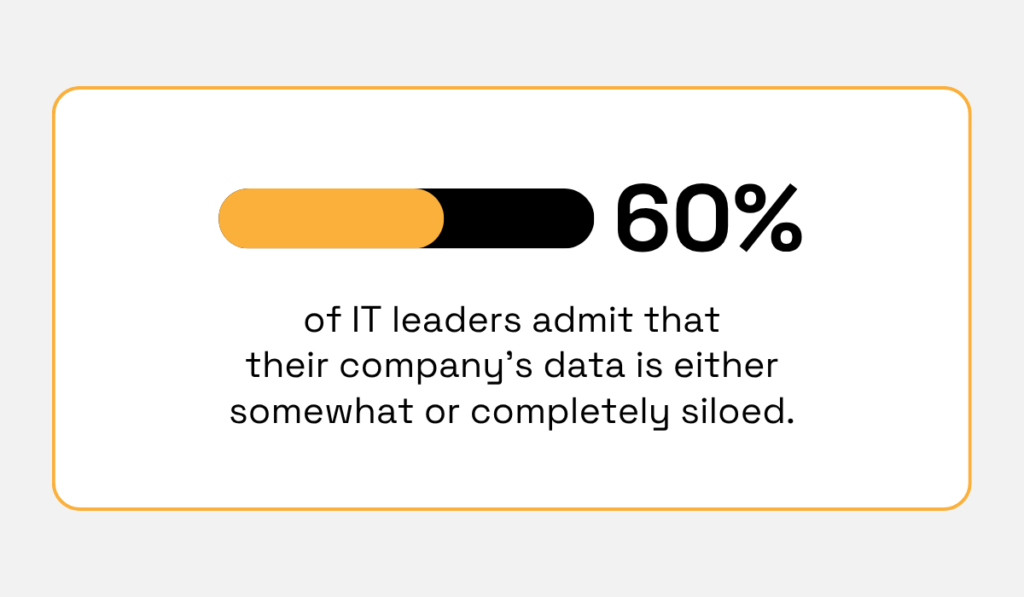

Giles Breault, Co-founder of the advisory firm The Beyond Group AG, explains that this fragmented landscape makes it harder to recognize poor supplier data and its impact.

Illustration: Veridion / Quote: HICX

A key driver of the problem?

Relying on tools that aren’t designed to prevent bad data at the source.

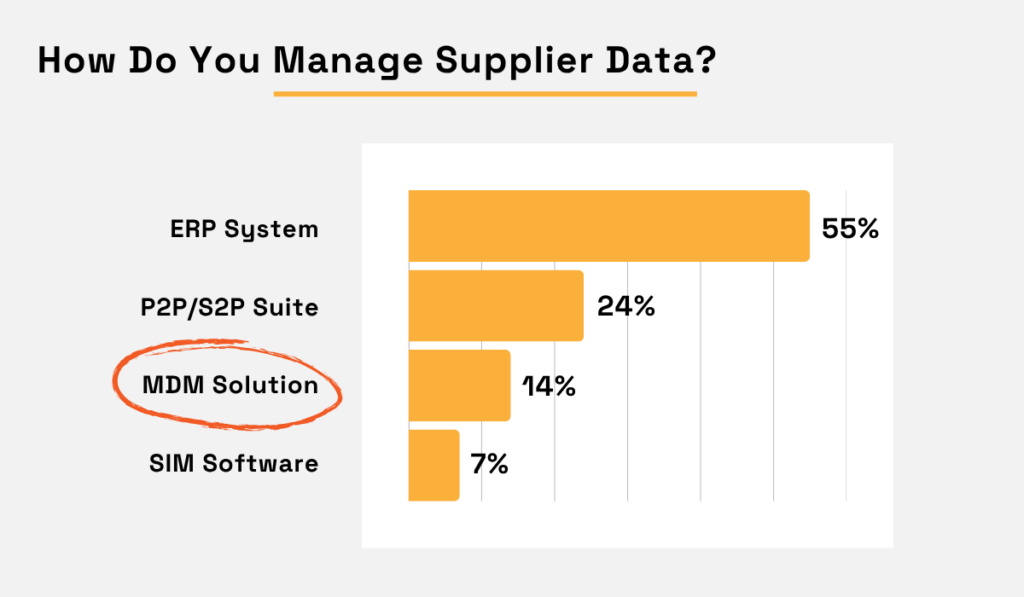

According to HICX’s 2023 research, the most commonly used tools for vendor data management are ERP and P2P platforms, which are built for execution, not governance.

Meanwhile, only 14% of organizations use dedicated Master Data Management (MDM) solutions.

Illustration: Veridion / Data: HICX

Here’s how this typically plays out.

Say a procurement analyst at a consumer goods company tries to gather supplier information for label printing.

They might find the purchase order in the P2P system, the invoice in another system, and the contract in the CRM.

The process itself is inefficient and leaves room for duplications and costly mistakes.

On the other hand, MDM systems are built to centralize supplier data, break down data silos, and enforce validation rules that improve data quality and ownership.

Since these systems are often difficult to adopt and require a certain level of data and analytics maturity, there are other ways to ensure structured intake and built-in validation.

Supplier self-service portals are one of them.

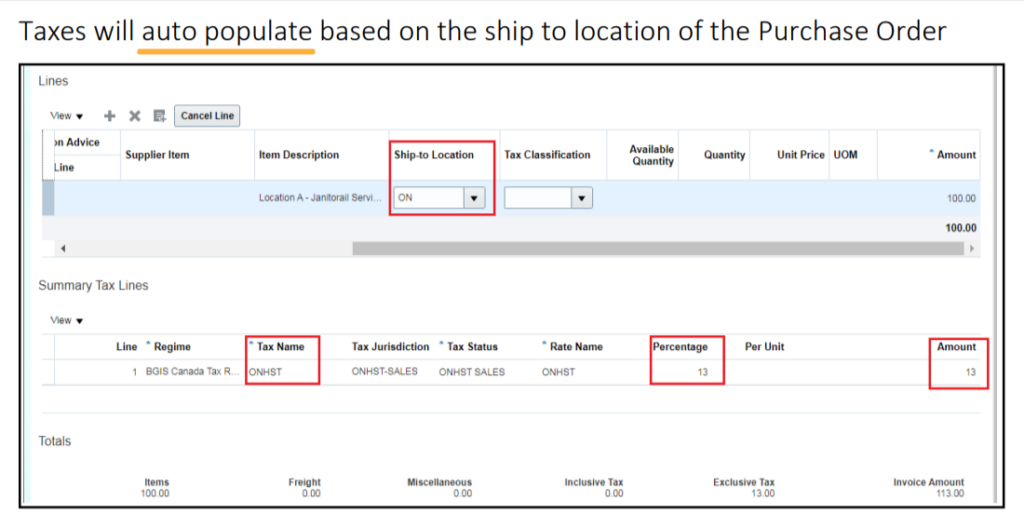

By using standardized formats with dropdowns, auto-fill fields, and real-time validation, you flag typos, duplicates, and mismatches before they enter your system.

Source: BGIS

And that kind of validation delivers more than just clean data. It supports compliance, reduces risk, and drives efficiency at scale.

That’s the point.

By preventing bad data at the source, you eliminate downstream risks and build a reliable foundation for achieving your procurement goals.

Knowing who’s responsible for supplier data is fundamental to avoiding data silos and misalignment across teams.

Supplier data management spans several pillars, including:

Research shows that 9 in 10 organizations experience issues related to fragmented and isolated data, many of which stem from unclear ownership and weak structure.

That’s why Sally Parker, Senior Director Analyst at Gartner, underlines that adopting enterprise MDM software, or any tool, won’t deliver results on its own.

Illustration: Veridion / Quote: Gartner

In other words, getting the technology right is critical, but without clear roles and governance, you’ll still face duplication, gaps, and costly errors.

And this lack of clarity doesn’t just waste time and erode supplier trust—it actively blocks progress.

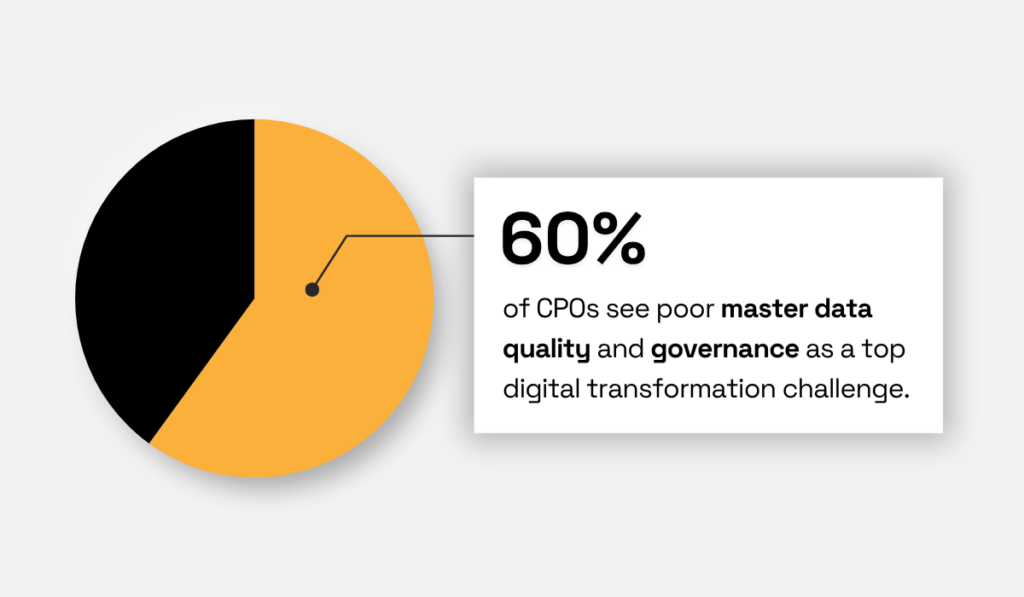

The HICX report shows that 60% of CPOs see poor master data quality and governance as a major barrier to digital transformation as a whole.

Illustration: Veridion / Data: HICX

The key question becomes:

Who actually owns supplier data in your organization?

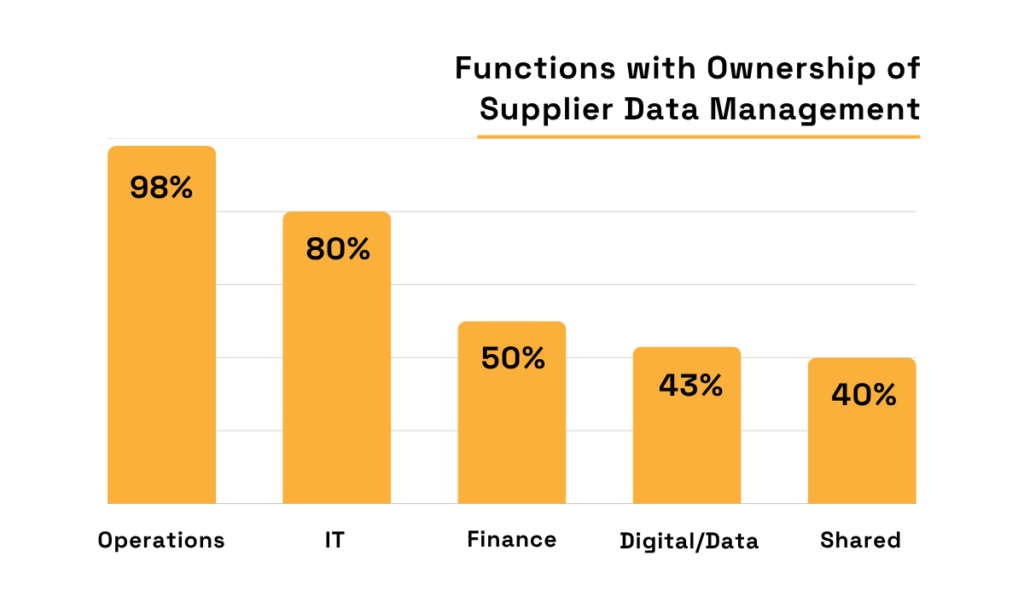

According to the same report, in 83% of organizations, ownership is split across multiple departments, from procurement and operations, to IT and finance.

The graph below shows a more detailed breakdown of the functions involved, excluding procurement.

Illustration: Veridion / Data: HICX

While this makes sense in theory, it’s problematic in practice.

In fact, 78% of CPOs agree that procurement’s lack of end-to-end ownership makes supplier data problems harder to fix.

Since procurement is the only function consistently involved across the supplier lifecycle, it has the best understanding of what data is needed, when it’s collected, and how it’s used downstream.

That’s why assigning ownership to procurement creates a single point of accountability.

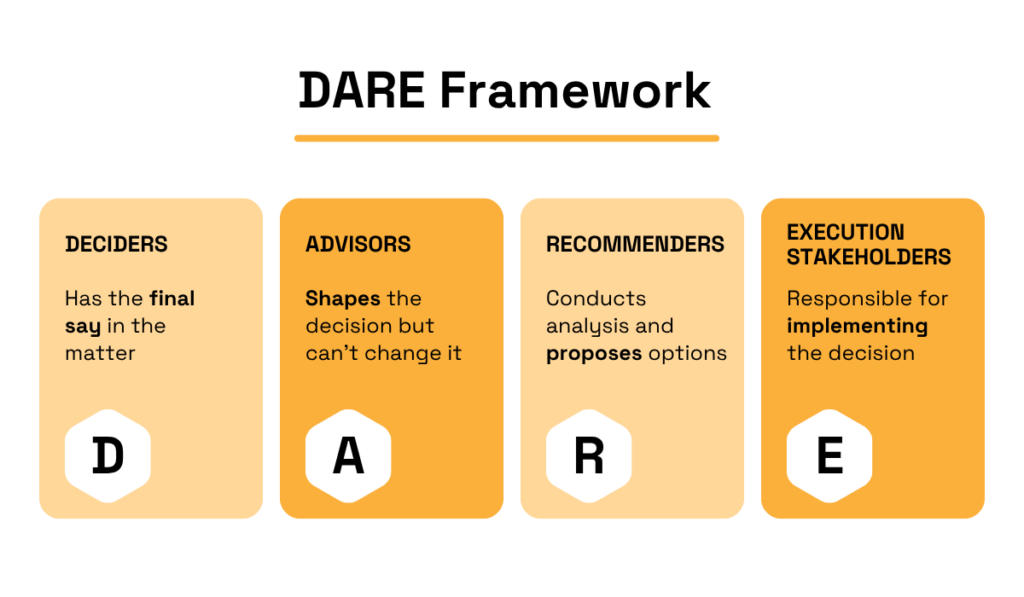

To formalize roles and enable effective collaboration, organizations often use the RACI matrix, which defines who is Responsible, Accountable, Consulted, and Informed.

However, McKinsey points out several limitations with RACI, and proposes an alternative: the DARE framework.

The DARE matrix helps clarify which teams contribute input, who makes final decisions, and who is responsible for execution.

Source: Veridion

Ultimately, getting ownership right requires you to go beyond defining responsibilities and toward actively enabling collaboration across departments.

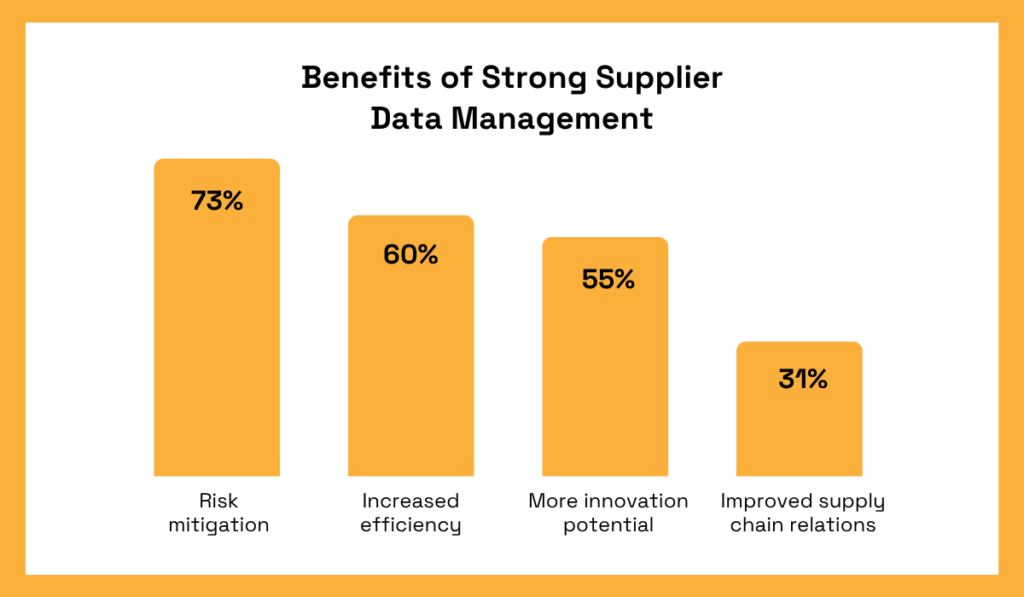

To unlock real value, supplier MDM must directly serve procurement goals, rather than simply chase efficiency metrics.

According to HICX, 73% of companies see master data management as a way to mitigate risk, and 60% believe it boosts efficiency.

Illustration: Veridion / Data: HICX

But unless you align the data you collect and manage with actual workflows and strategic targets, those benefits will stay theoretical.

Let’s take supplier onboarding as an example.

A new vendor is entered into your system with incomplete banking or tax data.

Procurement, unaware of the issue, proceeds with a PO, only for the invoice to get blocked months later due to missing verification.

That kind of delay is avoidable with structured, strategic data capture.

When data management is embedded into processes like RFQs, contract approvals, and onboarding, it enables cleaner handoffs between departments.

Mapping each step, as pictured below, ensures that the right, quality data is collected at the right time.

Source: Veridion

Key procurement KPIs like supplier lead time, invoice cycle time, and vendor compliance rate all depend on that alignment.

So, if your data doesn’t support these metrics, your data management efforts are disconnected from actual goals.

Ensuring alignment between the two is especially critical in ESG-focused procurement.

If your organization aims to reduce Scope 3 emissions or source only from low-risk regions, you need clear indicators built into onboarding.

This is where tools like Kodiak HUB can help you out.

The interface enables procurement teams to check sustainability-related scores and third-party certifications during onboarding, and quickly identify which vendors align with ESG targets and which don’t.

Source: Kodiak Hub

To sum up, aligning MDM with procurement goals means building smart processes where every data point has a purpose.

Whether that’s reducing cycle time, ensuring regulatory compliance, or hitting ESG milestones.

Even with the cleanest, most comprehensive data processes in place, supplier data degrades over time.

An outdated contact information here, a missing compliance document there, and your organization’s data quality starts to slip.

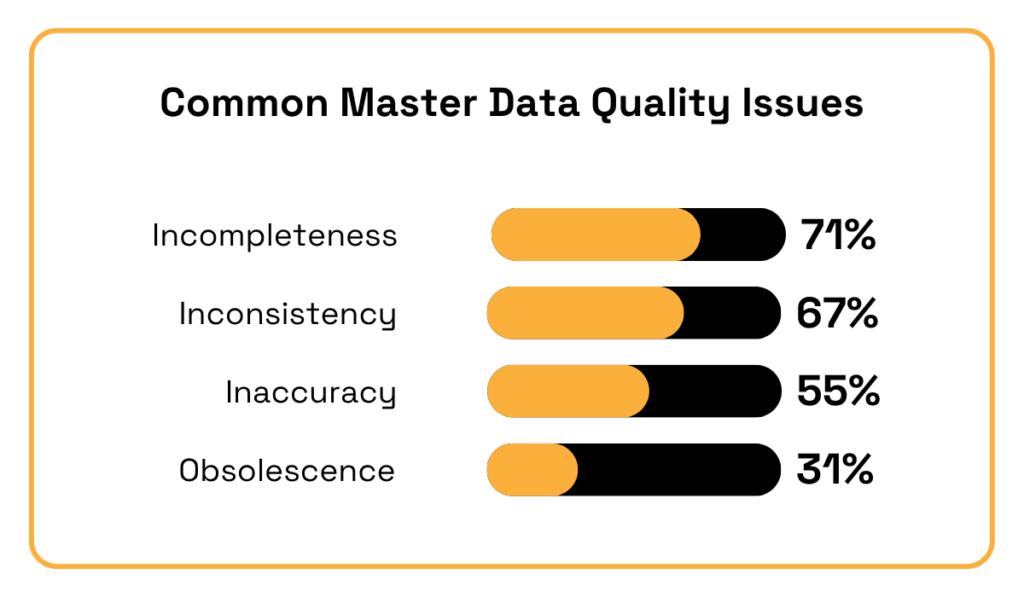

McKinsey’s research breaks this down clearly, pointing to incompleteness, inconsistency, inaccuracy, and obsolescence as key master data quality issues.

Illustration: Veridion / Data: McKinsey

These challenges are compounded by the fact that supplier data often receives less attention than customer or product data, despite being just as critical to procurement performance.

Inconsistencies can cause delays, incorrect supplier selections, and compliance risks.

But even though it ranks lower in surveys, obsolete data can be just as damaging.

Frank Wadsworth, a long-time CPO of the Americas Division at Sumitomo Mitsui Banking Corporation (SMBC), warns that if your data turns stale, we are no longer talking about data management.

Illustration: Veridion / Quote: TealBook

In other words, timely updates are essential if you want to get value from your data.

And that calls for agile, automated processes.

When supplier data becomes outdated before you can analyze it, it weakens every procurement decision.

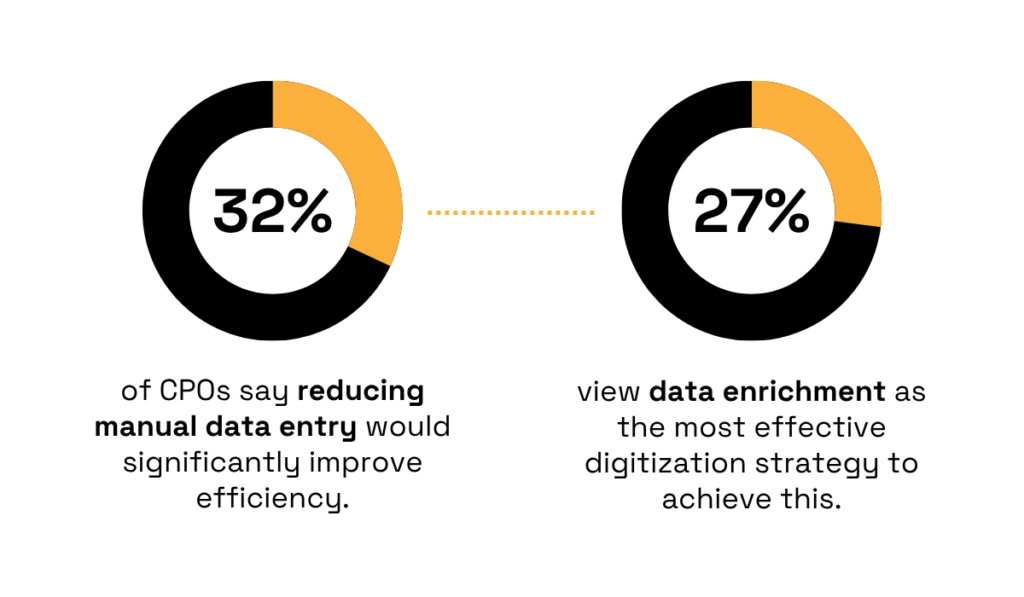

Manual data entry is slow and error-prone, which is why nearly one-third of surveyed CPOs are turning to digitization, particularly data enrichment.

Illustration: Veridion / Data: TealBook

That said, automation comes with its own challenges.

The aforementioned MuleSoft report shows that 83% of organizations struggle with integration issues during digital transformation.

This makes it essential to choose automation tools that are simple to integrate, yet powerful enough to scale.

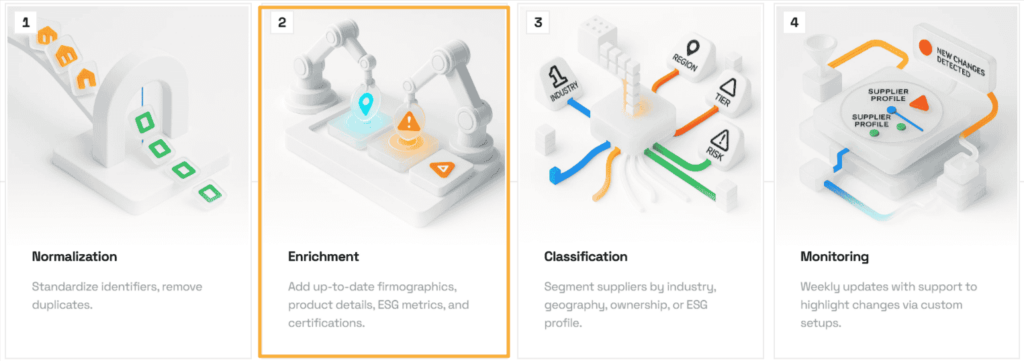

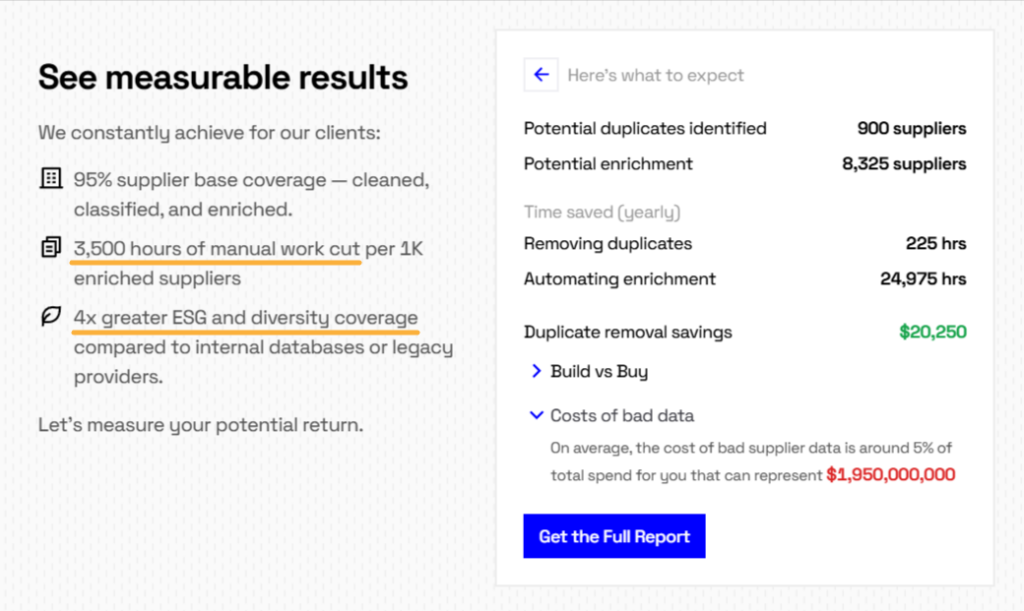

Enter Veridion and our weekly-updated data for vendor management.

With global supplier coverage spanning 134M+ suppliers, Veridion’s AI-powered Match & Enrich capabilities deliver 220+ enriched attributes, from ESG scores and financial data to corporate hierarchies and product details.

Source: Veridion

The platform simplifies ongoing maintenance through 99%+ deduplication accuracy, helping teams remove duplicates and validate supplier data in real time.

And with API-based integration, you can connect Veridion directly to your ERP, P2P, or procurement suite without overhauling your tech stack.

Here’s what Veridion can deliver when managing real-time supplier data for 9,000 vendors across $3.9B in spend:

Source: Veridion

Enhanced coverage comes with huge cuts in manual work and notable savings.

Whichever solution you choose, automation transforms supplier data management from a reactive cleanup process into a proactive undertaking with numerous benefits.

Finally, managing supplier master data isn’t a one-and-done project.

Your supplier base evolves alongside your business, and if you don’t actively monitor those changes, your data will quickly become inaccurate or outdated.

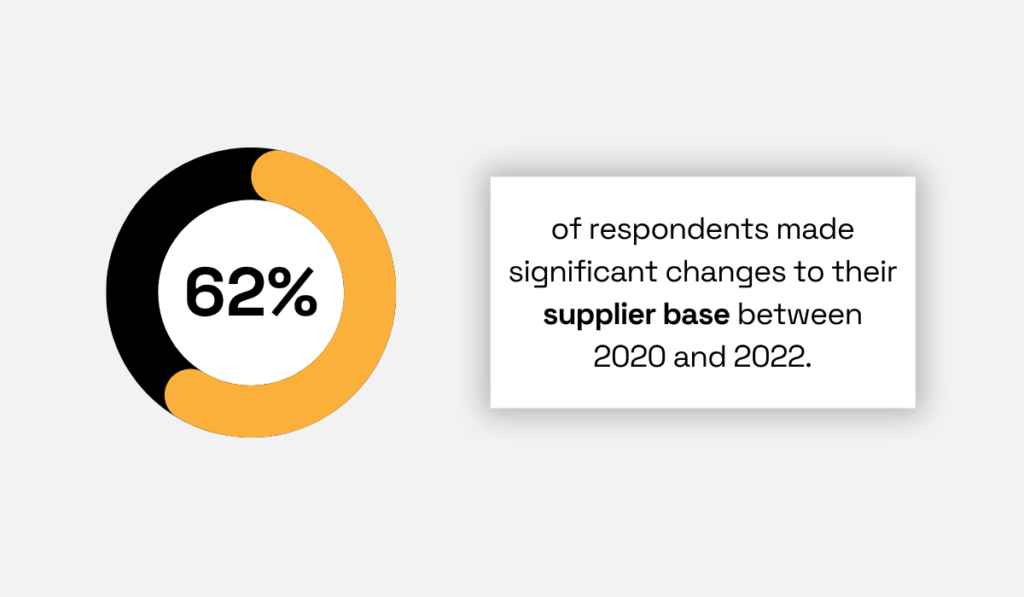

Just consider the findings of the Ernst & Young Industrial Supply Chain Survey.

Namely, 62% of companies made significant changes to their supplier base in a two-year period.

Illustration: Veridion / Data: Ernst & Young Global Limited

Even if you’ve onboarded just 50 new suppliers and terminated contracts with 10, that’s 60 changes to relationship statuses, terms, compliance checks, and payment processes.

All of them require constant updates across systems to avoid errors, delays, or risk exposure.

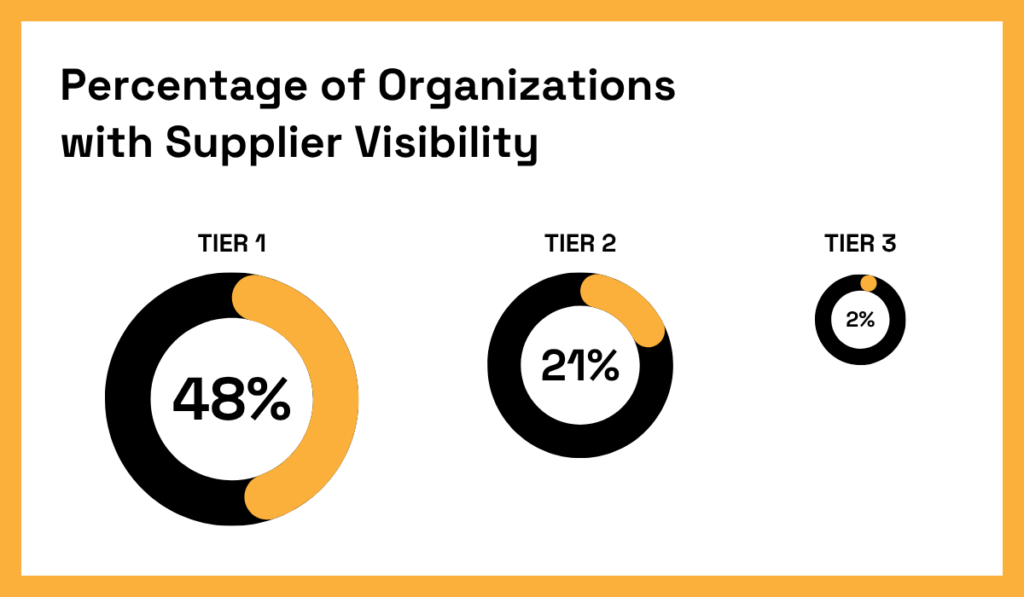

Yet most organizations don’t keep up.

McKinsey’s 2021 survey showed that while nearly half of companies maintained high or moderate visibility into their Tier 1 suppliers, only 2% could say the same for Tier 3.

Illustration: Veridion / Data: McKinsey

The deeper you go into your supply chain, the murkier the data becomes.

Without regular audits and cleanup cycles, outdated records, duplicates, and missing information accumulate and gradually turn your supplier data unreliable.

The best way to prevent this?

Introducing feedback loops, purge policies, and regular audits that catch systemic errors and

preserve system value.

Establishing key metrics is at the core of your auditing efforts and is your most reliable early warning system.

Here are the metrics to keep in mind:

| Data accuracy rate (%) | Measures how many supplier records are error-free |

| Duplicate supplier records | Tracks the number or rate of duplicate entries in the system |

| Incomplete profiles (%) | Percentage of suppliers missing key fields like tax ID or contact info |

| Use of classification standards | Measures the adoption of systems like UNSPSC or NAICS, as well as formatting rules |

| Adherence to governance policies | Assesses whether records are being reviewed or approved as required |

| Record update frequency | Shows how recently supplier data has been refreshed, identifying outdated entries |

When it comes to the general approach, Cravern’s case study of a supplier master data cleanup promotes long-term resilience through:

This brings us back to the fact that effective supplier data management relies on cross-team collaboration.

Quarterly reviews are typically sufficient for supplier data management, especially when paired with dashboards, feedback loops, and sunset rules to phase out outdated records.

While the setting is different, Kaushikkumar Patel, Director of Data Development at TransUnion, highlights how weekly review sessions, focused on openly sharing challenges and solutions, helped shift his team’s mindset.

Illustration: Veridion / Quote: LinkedIn

The cultural change itself often delivered more value than any technical fix could.

And that’s the point.

Audits aren’t about blame. They’re about building ownership and adaptability in the face of constant change.

That’s how you create resilient, usable data over time.

Effective supplier data management requires strategic planning and discipline.

Advanced digital tools are essential, but without established governance, clear standards, and regular audits, even the most effective tools can fall short.

The common thread across all these practices is intentionality:

A proactive approach always beats reactive cleanup.

Companies that treat MDM as an ongoing practice, and not a one-off fix, position themselves for stronger supplier relationships, better risk management, and greater operational resilience.