5 Challenges of Procurement Data Management

Analyzing data in procurement presents incredible opportunities to increase value, reduce costs, and mitigate risks.

But effectively managing and transforming massive datasets into valuable and reliable insights requires procurement professionals to invest in technology, organizational process changes, and strategic approaches.

While the opportunities presented by data management are indeed significant, there are substantial challenges that accompany this journey.

To successfully implement a long-term procurement data management system, and deliver insights to decision-makers in a clear, intuitive format, you will have to put extra effort into addressing the following key challenges.

In today’s procurement arena, data is generated in large volumes. Organizations are already collecting a broad spectrum of information sourced from both internal and external channels.

Internal procurement data is typically obtained from various systems within an organization, such as the enterprise planning systems (ERPs) or accounting software, the general ledger, invoices, and purchase orders, as well as data provided directly by suppliers or other business units.

Nevertheless, relying solely on internal databases is far from sufficient to make well-informed procurement decisions.

To be able to conduct a comprehensive procurement analysis and stay ahead of the curve, you must fill in the gaps with up-to-date and accurate third-party information.

These external data assets may include public systems with information on suppliers, commodity prices, or currencies available on the Internet.

It can also encompass third-party proprietary sources, providing data like supplier industry codes, credit ratings, or supplier risk profiles.

Source: Veridion

However, companies often face challenges in enriching their internal supplier data with externally obtained information. This is primarily because of the vast amounts of data scattered across numerous external sources.

Besides, it takes time to assess where these external sources can add value to internal data.

To begin making sense of it all, procurement teams must move away from manual data management and invest instead in robust procurement software that can extract, transform, manage, and enrich the data.

Cloud-based procurement solutions and application programming interfaces (APIs) have enabled more automated, faster, and more flexible uses of procurement data.

Our own solution, Veridion, addresses the challenge of enriching internal procurement data with external sources through its powerful Match & Enrich function.

Being an AI-powered supplier sourcing enabler, Veridion provides access to a global and regularly updated supplier database, saving procurement teams valuable time that would otherwise be spent searching for suppliers.

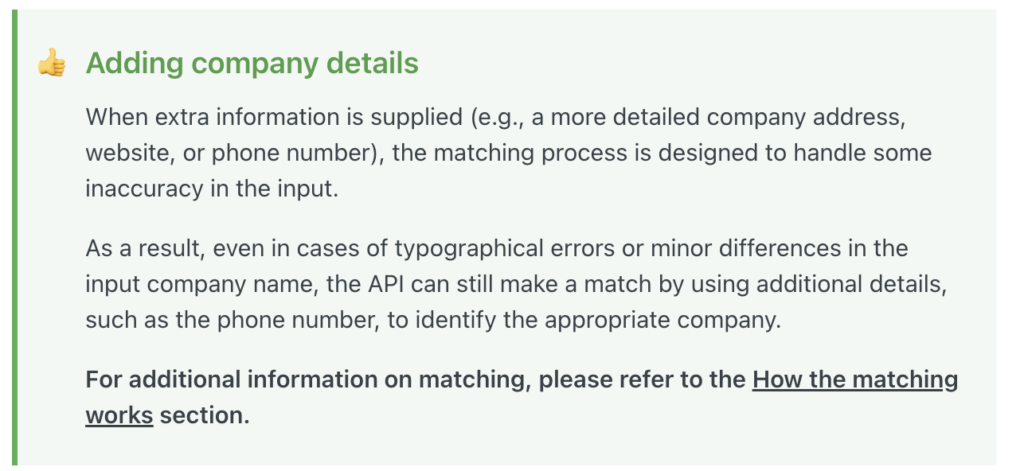

The Match & Enrich API allows users to input a company’s details, typically the commercial or legal name along with the country of operation, and in return, receive an enriched company profile.

To enhance accuracy and avoid false positive matches, users can include additional information such as company address, phone number, and website.

Source: Veridion

Veridion’s matching algorithm ensures a single, best-match result, contributing to a more comprehensive view of potential partners.

This capability not only accelerates the procurement process but also aids in mitigating supplier risks and making sustainable decisions.

Whether searching for specific products, services, or suppliers aligned with ESG goals, Veridion’s Match & Enrich API provides a streamlined and effective solution for enriching and optimizing internal procurement data.

When data is pouring in from diverse sources, it can often end up scattered on different platforms or storage systems. This causes additional issues for procurement teams, such as the inability to locate and access necessary data for analysis.

Manually accomplishing this task would consume countless hours for your team, going through spreadsheets and endless research to uncover valuable insights and cost-saving opportunities.

To be able to take advantage of the data collected from multiple sources, you need to integrate and organize the data in one structured database.

Clearly, this can be a challenging task since conventional procurement tools lack the capability to handle such extensive and diverse datasets.

Source: Veridion

The solution to these challenges lies in procurement automation tools that will allow you to seamlessly systemize and analyze the obtained data.

First of all, automation supports the reduction of manual processes and minimizes human errors, placing the procurement cycle on a fast track. Tasks that once spanned days can now be completed in a matter of hours or even minutes.

In fact, digital procurement tools allow end-to-end process connectivity and can accelerate transaction processing by up to 30%.

Utilizing automated tools enables procurement executives to collect and analyze vast amounts of complex data related to past procurement decisions, supplier performance, existing patterns, market trends, and process bottlenecks.

Not only is this data easy to obtain, structure, and analyze, but it also allows management better visibility across the supply chain, ultimately leading to more informed decisions.

As Bob Murphy, IBM’s former CPO puts it:

“Fueled by analytics, procurement can derive insight from disparate sources of information and uncover intelligence for competitive advantage. This paves the way for us to develop an even deeper understanding using cognitive technologies that will help us further transform the procurement landscape.”

Essentially, by employing automated procurement solutions, organizations will be able to unlock value from information that has been hidden from sight, identify inefficiencies, and peek into future spending trends.

Once your data has been collected from various internal and external sources, well-structured and organized, it needs to be actionable.

This means that the data should serve your needs, enable you to make decisions grounded on facts and take action without any doubts.

In essence, to make it truly actionable, data needs to be:

Reliability can be solved through the use of good software, like for example, Veridion.

Access to current, comprehensive, and globally aggregated data contributes to reliable insights for both tactical and strategic decision-making, mitigating risks and preparing for potential downturns.

Moreover, the use of procurement software ensures data reliability by:

Enabling accessibility involves determining data-sharing boundaries while considering data privacy. Think about who needs access to which data and how you can grant it.

And lastly, focusing on the most useful and timely data aligned with business goals is key. Not all data needs to be put to use right away.

To that point, the more detailed the data, the greater the potential for enhanced insights, which leads to improved decision-making, planning, and forecasting.

Think of products and services delivered without a hitch, events going off without a delay, or a product going to market before the deadline. It all comes down to the efficient usage of data.

Procurement functions produce data beyond the capacity of any employee to track and manage.

McKinsey points to an example of a midsize manufacturing company with approximately $2 billion in annual revenue, where procurement generated data on more than 20,000 transactions for a single category.

In the context of these large volumes of data, it’s very likely that certain inconsistencies will occur. These could be incorrect invoice descriptions, missing product codes, misspelled vendors’ names, duplicate invoices or incorrectly categorized data.

Data that is inconsistent, incorrect, and outdated is considered bad or “dirty” data.

Analysts have identified three leading causes of bad data that can directly affect operational efficiency:

| Human error | Bad data quality often stems from human oversight, especially when there’s a lack of standardization in the data entry process or when employees manually input values into spreadsheets. These situations significantly raise the likelihood of errors. |

| Disparate systems | Organizations commonly store data in different systems, each with its own set of rules. Creating a dataset may require integrating information from various systems, leading to issues like duplicated data, missing fields, or inconsistent labels. |

| Inconsistent supplier data | Picture the challenges of dealing with varying product data coming from numerous suppliers in your trading network. Each supplier might use different item numbers, and the description fields may have contradictory or non-standard information. |

For instance, if an expenditure is listed under the wrong category—say, cleaning services get listed under IT spend—it can cause confusion that could potentially affect your planning for the year.

Considering that procurement teams depend on data to identify cost-saving opportunities and mitigate risks, bad data can result in poor decision-making and missed opportunities.

Moreover, it can have serious financial implications and negatively impact the company’s bottom line.

According to a recent Gartner research, around $15 million per year in losses can be attributed to poor data, and this issue is likely to intensify as information environments become more complex.

Source: Veridion

So, what’s the best way to ensure you have clean, accurate, and reliable data?

The answer lies in using software, as it resolves all causes of bad data.

Leveraging a cloud-based solution for enhanced data classification and quality is a great approach to boost your data management endeavors.

Tackling the challenge of bad data might seem daunting, but with a good technology partner, you can break it down into manageable steps and gain the momentum needed for positive change.

To that point, Veridion’s can serve as another example.

It provides businesses with a global, comprehensive, and up-to-date supplier database that is refreshed on a regular basis.

Our systems ensure that the data collected and analyzed is always current, with information no older than two weeks, eliminating concerns about outdated or unreliable data.

At last, keep reminded that dealing with bad data is an ongoing process that can be effectively handled with determination and the right technology.

A data-driven culture encompasses creating an analytical environment within your procurement team. But it doesn’t end there.

Data-driven culture involves everyone in the business, from top to bottom, reflecting how individuals value and use data.

Fostering a data-driven culture is fundamental for staying competitive in today’s marketplace. As of 2020, 50% of organizations worldwide are implementing data-driven decision-making, and that number is on the rise.

Indeed, promoting a strong data-based culture empowers companies to:

But despite its progressive nature, the adoption of procurement analytics may still receive mixed reactions. An issue that could stand in the way of its successful execution is your employees’ resistance to change.

For some individuals, automated procurement data management raises uncertainties about their future in the business—questions about their ability to handle new technologies and adapt to this evolving situation.

Also, procurement managers, in the traditional sense, might prioritize tasks like sourcing, negotiating, and building relationships over delving into extensive data.

So to overcome this setback, first, you have to prepare and educate your team by offering tools, guidance, and specialized training.

Aim to show all the benefits, explain how their professional lives would be easier, and create an engaging learning experience to cultivate a shared enthusiasm for a data-driven culture.

By implementing strong change-management practices you’ll be able to transform conventional mindsets and establish a culture where data is viewed as a powerful tool that drives better business results.

Data is more than just a competitive advantage—it’s the lifeblood of any business, particularly in procurement.

Regardless of the organization’s size or scope, the key to achieving cost savings and improving business performance lies in the transformation of data into insights and insights into actionable strategies.

Sure, data management comes with a few challenges, but none that you can’t overcome.

Now that you are aware of them, along with the potential solutions, you’re one step closer to making the most of data analytics and transforming your procurement department.