What Is the Role of Data In Procurement?

Data’s role in procurement is swiftly growing thanks to technology-driven automation that streamlines procurement processes and enables real-time data storage.

While data has always been necessary for informed decision-making, automation has made data collection and analysis significantly more accessible.

So, what does data do in procurement?

In the most straightforward and most honest terms, it benefits your procurement.

Data streamlines supplier selection, provides insights into supplier performance, and aids in risk mitigation, ultimately enhancing the efficiency and cost-effectiveness of the procurement process.

In the following sections, we’ll look into these and other roles of data in procurement, so we invite you to keep reading to discover more.

Procurement data is a powerful tool in the supplier selection process.

It assists you in faster and better identification of suppliers that best meet your needs and goals.

Supplier selection is one of the most important steps for successful procurement.

However, it’s equally notorious for being time-consuming and resource-intensive.

According to McKinsey & Company, conducting a single supplier search demands approximately three months of effort, with sourcing professionals dedicating over 40 hours to the task, all to explore only a few dozen suppliers from a vast pool of thousands.

Illustration: Veridion / Data: McKinsey & Company

Naturally, many businesses persist in working with their existing suppliers due to the considerable time and effort required to seek out new ones.

Regrettably, this approach has its flaws, often leading to less-than-ideal supplier matches for the company.

This, in turn, escalates the risk of supply chain disruptions and suboptimal supplier performance.

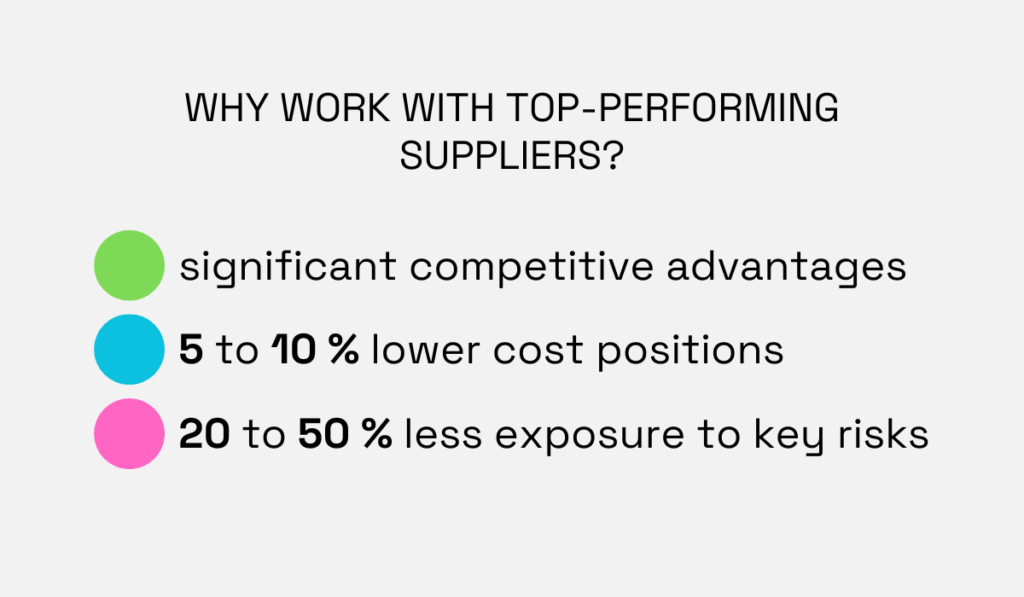

Conversely, when you strategically choose top-performing suppliers that align with your specific objectives, you can reap many benefits:

Illustration: Veridion / Data: McKinsey & Company

This is where data enters the equation.

Simply put, by harnessing fresh, up-to-date, and accurate supplier data, you can gain valuable insights into supplier performance and, in turn, evaluate how well they align with your goals.

For instance, you’ll need data on their product quality, cost, delivery capabilities, and sustainability values, all of which are vital considerations before making a selection.

As previously mentioned, this process can be quite time-consuming.

However, thanks to technological advancements like AI and machine learning, solutions that provide comprehensive supplier data are now available, allowing for faster and more precise supplier selection based on your specific criteria.

One such solution is Veridion, our AI and machine learning-powered platform that scours the vast expanse of the Internet to provide current information on over 80 million global suppliers in mere seconds.

Source: Veridion

This transformative tool streamlines the supplier selection process, eliminating the need for three months of effort.

What sets Veridion apart is the combination of speed and precision it brings to the table.

When you seek to align your suppliers with your unique business goals, Veridion’s company search service empowers you to set criteria that matter most to your organization.

For example, you can identify suppliers that meet your environmental, social, and governance (ESG) objectives, ensuring you find the best match.

Source: Veridion

In addition, Veridion is designed to provide you with all the essential information required to make an informed decision.

This includes a supplier’s location, company size, certifications, industry classifications, insurance coverage, and product descriptions.

Notably, all this data remains consistently fresh and accurate.

Having almost real-time information about suppliers is super important.

Just imagine this: say you’re looking at a pool of 50k suppliers. In this scenario, it’s very likely many of them change something about their business activity.

Or, they might be in locations that are subject to geo/political risk, etc. If you find out too late, your entire project can be compromised.

In summary, one of the most important roles data has in procurement is streamlining supplier selection.

Current, accurate, and up-to-date data ensures that you discover and select suppliers that align with your needs, objectives, and values, which is critical in today’s competitive and conscientious business environment.

And you can access this data through automation tools like our Veridion in seconds.

Beyond helping you find suitable suppliers, data assists in evaluating and tracking supplier performance, ensuring they remain the best match.

This data-driven approach provides objectivity by relying on performance indicators, ensuring your chosen suppliers consistently meet your needs, expectations, and contractual obligations.

Why does this matter?

To measure these performance key indicators, you must collect and analyze data, including delivery times, pricing, product quality, compliance, and the ability to adapt to changes in demand.

Source: Veridion

For instance, monitoring delivery times helps identify suppliers who consistently fail to meet deadlines, which can disrupt production, thus incurring extra costs and disappointing customers.

Or, when it comes to product quality, data can highlight instances where a supplier’s products consistently fall short of agreed-upon standards.

Based on the results of supplier performance tracking, you can decide how to proceed with the supplier relationship.

Here are a few examples:

An essential point to note is that sharing supplier performance data with your suppliers can lead to a remarkable 61% improvement rate.

This data sharing promotes transparency, accountability, and a shared commitment to quality and efficiency, so these results are not surprising.

In conclusion, another essential role of data in procurement is its ability to shed valuable light on managing supplier relationships, which can open doors for negotiation and cost-saving opportunities.

Above, we have discussed how data helps identify supplier performance issues that could pose risks for your company.

But the scope of data’s utility goes further—it empowers you to analyze various data sets to identify and effectively manage other potential risks across the supply chain.

The most common risks include:

| Operational Risks | These are the day-to-day risks associated with your procurement processes. They can arise from inefficiencies, errors, or failures within your organization or from your suppliers. For instance, a supplier’s production line breakdown causing delays in product delivery is a prime operational risk. |

| Compliance Risks | Compliance risk pertains to the danger of non-compliance with laws, regulations, or industry standards. These can lead to legal issues and fines, and damage your reputation. An example is purchasing goods from a supplier who employs children, which violates labor laws. |

| Market Risks | Market risks revolve around the potential impact of market fluctuations on your procurement decisions. This encompasses price volatility, demand fluctuations, and market condition changes that can affect the cost and availability of goods or services. An example is sudden increases in the price of raw materials affecting your production costs. |

| Geopolitical Risks | These risks are tied to instability or conflicts in specific regions or countries. Political events, trade disputes, or natural disasters in these areas can disrupt the supply chain. A practical example is tariffs imposed on goods from a specific country due to a trade dispute. |

| Natural Risks | Natural risks encompass potential disruptions caused by environmental factors, such as earthquakes, hurricanes, floods, or pandemics. These events can severely impact the supply chain, as seen when a supplier’s factory is damaged by an earthquake, halting production. |

When considering where to obtain this vital data, you have several sources available.

You can access internal company records, market intelligence reports, supplier performance databases, and government regulations and compliance data.

Moreover, new automation tools that leverage AI and machine learning can aid in collecting and analyzing large volumes of supplier data, which can improve your risk management strategies.

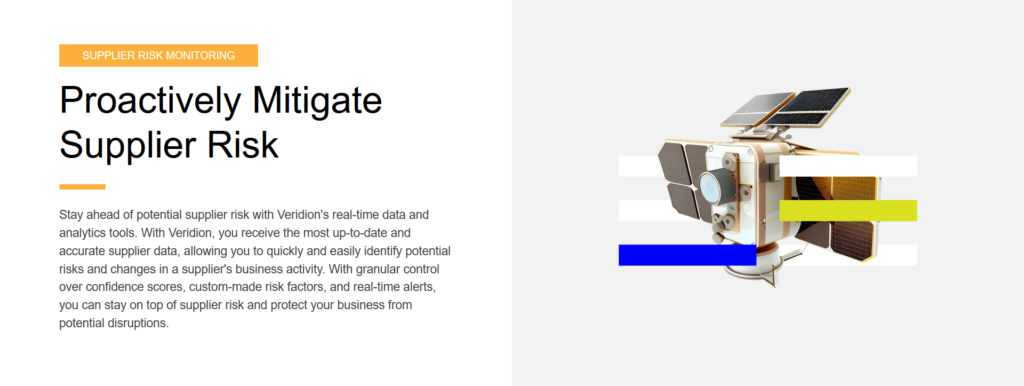

As a notable example, real-time data and analytics tools like our Veridion help companies identify potential risks by alerting them about changes in a supplier’s business activity in real time.

Source: Veridion

For instance, if a supplier decides to relocate to an area with a history of geopolitical disruptions, this change can immediately be flagged as a warning.

It signals that you should exercise extra caution and closely monitor this supplier, as the new location might introduce risks that could impact your supply chain and business operations.

Then, once you’ve identified the potential risks in your procurement processes by leveraging these sources, you can devise strategies to manage them effectively.

These strategies may include diversifying your supplier base, implementing rigorous compliance checks, creating contingency plans for market fluctuations, staying informed about geopolitical developments, and establishing business continuity plans to address natural risks.

As Nicolas Walden, Associate Principal and UK & Europe Practice Leader at The Hackett Group, states, “data-driven risk management is the future,” and indeed, there’s “no feasible alternative.”

His statement underscores the critical role of data in securing your procurement operations and supply chain.

Cost analysis is an essential aspect of procurement, and data plays a compelling role in making this analysis efficient and effective.

In other words, by analyzing data, you can:

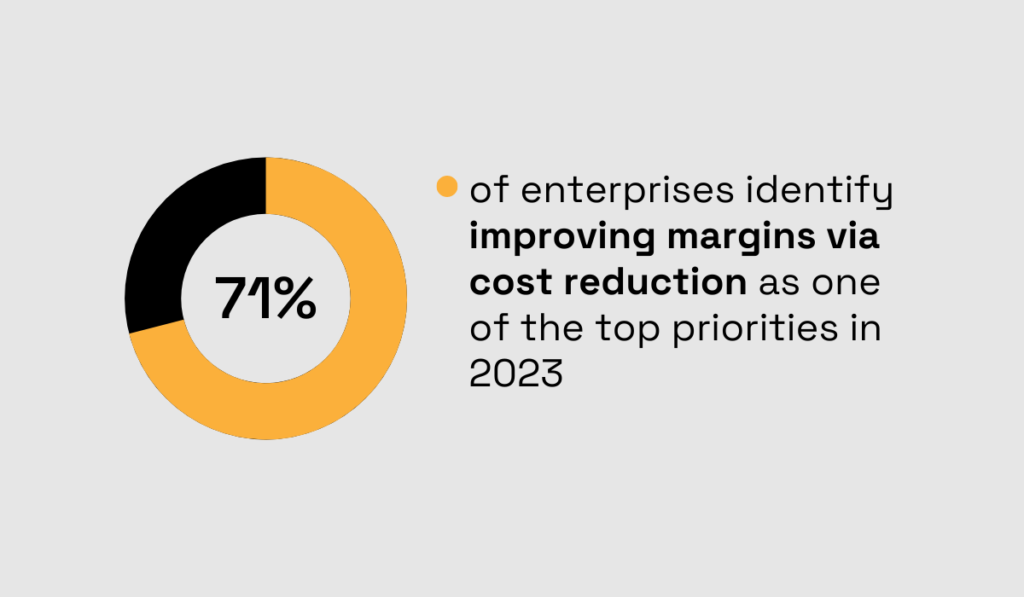

The latter remains one of the top priorities in procurement, according to Deloitte’s 2023 Global CPOs Survey.

Illustration: Veridion / Data: Deloitte

So, where can you obtain the necessary data for cost analysis?

Your organization already holds a wealth of cost-related data, including purchase orders, invoices, payment records, transportation costs, expense reports, and contracts.

If you employ automation tools like procurement software, this data is aggregated and readily available for analysis.

For example, by analyzing internal data such as supplier invoices, you may uncover that a specific supplier consistently charges higher prices for a product or service.

With this data-driven insight, you can initiate negotiations to secure better pricing, ultimately reducing costs.

In addition to internal data, you can tap into external data sources, such as market reports.

These reports offer insights into market trends, pricing dynamics, and cost benchmarks for various products and services.

This external data can assist you in understanding how your procurement costs compare to industry standards. It also highlights opportunities for cost reduction.

For instance, data might reveal that your transportation costs are significantly higher than industry benchmarks, indicating the need to explore more cost-effective logistics solutions.

In a nutshell, data has an important role in cost analysis.

And when you leverage both internal and external data sources, you can develop a comprehensive view of your procurement costs.

This, in turn, empowers you to make informed decisions and implement strategies that lead to substantial cost reductions, all while maintaining quality and value.

By now, we’ve established how indispensable data is for efficient procurement.

Let’s now address another role data plays in that process, the last for this article—data’s ability to improve inventory management.

As an experienced procurement professional, you understand the importance of maintaining optimal inventory levels to prevent overstocking or understocking.

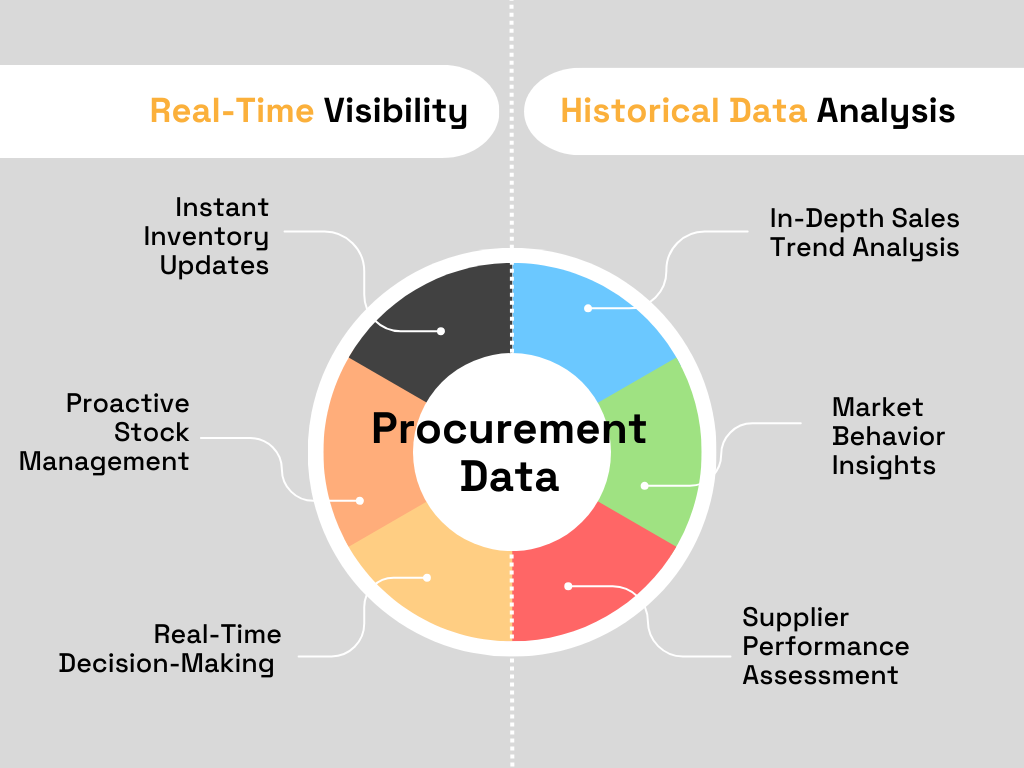

It’s precisely data, both real-time and historical, that equips you for this task.

Let’s explore how.

Real-time data visibility in procurement allows you to monitor your inventory in a dynamic and proactive manner.

It ensures that you are well-informed about the current stock levels at any given moment.

This visibility extends to warehouses, supplier stock, and even items in transit.

By integrating real-time data sources, such as inventory management software, IoT devices, and real-time tracking systems, you can gain immediate insight into the availability of goods.

This includes real-time information on stock levels, location tracking, and estimated arrival times.

You can quickly identify shortages or excess inventory, enabling timely decisions for restocking or destocking, all while ensuring that products are consistently available when needed, which fosters customer loyalty and satisfaction.

Source: Veridion

Another crucial aspect of data-driven inventory management is the analysis of historical data.

This encompasses a deep dive into past sales trends, consumer behavior, and various variables that influence inventory levels.

Historical data sources include sales records, customer orders, supplier performance records, and market research data.

When you analyze this data, you can gain insights into seasonal fluctuations, market trends, product lifecycle dynamics, and the performance of suppliers and manufacturers.

You can make more accurate forecasts regarding future demand, optimize inventory levels, and make data-driven decisions on when and how much to reorder from suppliers.

This strategic approach minimizes holding costs, reduces stockouts, and enhances overall supply chain efficiency.

In conclusion, data-driven inventory management, with its real-time visibility and analysis of historical data, is a crucial component of modern procurement.

These strategies empower you to monitor and optimize your inventory effectively, ensuring it remains in sync with actual demand.

This leads to efficiency gains, cost reduction, and heightened customer satisfaction, fostering your competitive edge in the field of procurement.

Throughout this article, we have explored five fundamental roles data plays in procurement.

From its role in streamlining supplier selection to its invaluable function in measuring supplier performance, mitigating procurement risks, enabling insightful cost analysis, and efficiently managing inventory levels, the influence of data is undeniable.

In fact, in an era defined by the advent of cutting-edge technologies and procurement automation tools, collecting and analyzing data for these purposes shouldn’t be a choice anymore.

Only by doing so can you remain competitive and agile in today’s ever-evolving business landscape.