Top 5 Benefits of Strategic Sourcing

Key Takeaways:

Given today’s global uncertainties, strategic sourcing has become a key lever for companies to protect their operations and drive long-term value.

Instead of just chasing the lowest price, procurement teams leverage data, strengthen supplier partnerships, and manage risks to secure better deals and more resilient supply chains.

When done right, strategic sourcing creates lasting competitive advantages.

But what are these key benefits, exactly? And how do companies achieve them?

Read on to find out.

While getting the best price has traditionally been the main procurement objective, strategic sourcing adopts a more holistic approach.

Among other things, it focuses on analyzing the total cost of ownership, optimizing supplier selection, and negotiating smarter contracts.

By looking beyond just the lowest price, procurement teams can achieve sustainable, long-term cost savings.

Conversely, focusing solely on price can come at the expense of quality, reliability, and delivery.

As Boyan Ivanov, a Forbes Councils Member, points out, problems stemming from low-cost sourcing can ultimately result in higher costs.

Illustration: Veridion / Quote: Forbes

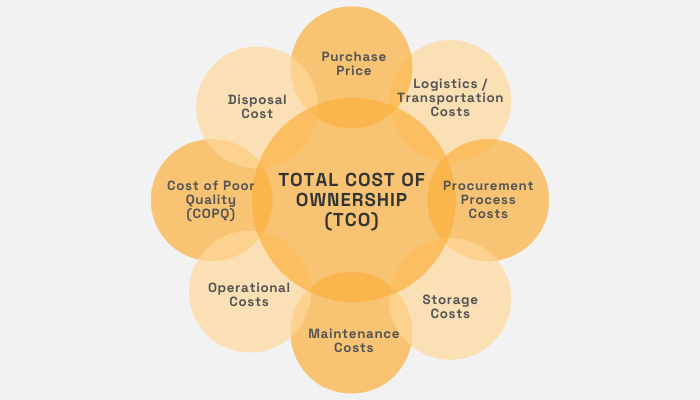

The trap of selecting cheaper options that may incur hidden costs later can be avoided by evaluating the total cost of ownership (TCO).

This key concept helps procurement teams look beyond just the upfront price and consider all costs associated with procurement.

By thoroughly assessing TCO, companies can make more informed decisions that result in greater long-term savings.

TCO considerations include factors such as logistics and transportation costs, storage and operational costs, as well as the potential cost of poor quality.

Source: Veridion

The insights gained from TCO analysis ultimately enable procurement teams to refine supplier selection and negotiate better terms.

At the same time, strategic sourcing ensures that suppliers align with a company’s long-term goals.

While some of these goals may not seem directly tied to cost savings, they often drive long-term financial benefits in less obvious ways.

For example, IKEA directs its strategic sourcing efforts toward finding local, sustainable suppliers and fostering long-term partnerships.

Source: IKEA

So, how does this help IKEA achieve long-term cost savings?

In many ways—starting with localized sourcing, which helps IKEA reduce transportation costs (and the associated emissions) in key markets.

Additionally, the advertised strong and long-lasting partnerships play a critical role.

Source: IKEA

By offering suppliers longer-term contracts, IKEA not only ensures supply stability but also secures price discounts tied to contract duration and volume.

Lastly, sustainability—both in IKEA’s and its suppliers’ operations—minimizes waste and maximizes efficiency, further contributing to long-term savings.

The point we’re making is that strategic sourcing is a holistic, multidimensional discipline, where benefits should complement rather than compete with each other.

Ultimately, achieving long-term savings requires strategically balancing cost, quality, sustainability, and supplier relationships.

The IKEA example clearly illustrates how strategic sourcing prioritizes long-term supplier relationships over short-term cost-cutting deals.

To understand why this matters, it’s important to distinguish between Supplier Performance Management (SPM) and Supplier Relationship Management (SRM).

While these two concepts overlap, they serve distinct purposes.

SPM ensures that suppliers meet contractual performance requirements and expectations.

SRM, on the other hand, includes performance monitoring (KPIs, reassessments, audits) but goes beyond compliance—it focuses on fostering collaborative, value-driven partnerships.

Alan Day, Managing Director of State of Flux, explains this distinction clearly:

Illustration: Veridion / Quote: State of Flux

So, how are close, mutually beneficial supplier relationships built in practice?

It starts with open, transparent communication, where suppliers feel valued for their contributions to your company’s success.

Beyond communication, relationships can be strategically strengthened through initiatives like:

While not every supplier may be suited for these efforts, even small steps toward deeper collaboration can drive meaningful benefits.

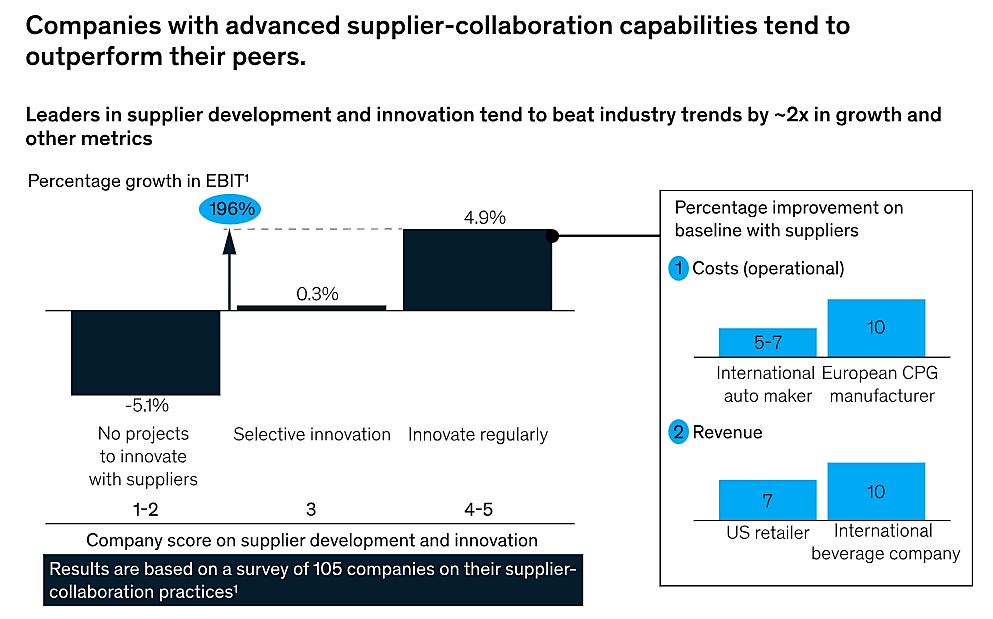

A McKinsey survey of large corporations highlights this point.

It shows that organizations that prioritize supplier collaboration consistently outperform their peers.

Source: McKinsey

As the data illustrates, companies with advanced supplier collaboration capabilities regularly achieve lower supply costs, higher revenue, and stronger growth.

This comes as no surprise.

Strong relationships extend beyond numbers, helping to resolve challenges that purely transactional suppliers might not prioritize.

Moreover, in times of crisis, suppliers who see themselves as partners are far more likely to go the extra mile for their clients.

A great example is The Meatery, which sells rare beef sourced from a limited number of suppliers.

When a beef shortage emerged, the strength of these relationships became clear.

As Nicholas Fiorentino, owner of The Meatery, explains:

Illustration: Veridion / Quote: Shopify

The Meatery’s experience highlights a crucial point: suppliers who feel valued are more likely to prioritize your needs.

Not just in emergencies, but in day-to-day operations as well.

Beyond crisis mitigation, strong relationships can also lead to strategic advantages, including:

Remember, companies that actively invest in supplier collaboration don’t just manage their supply chains—they create strategic partnerships that drive mutual growth.

Ultimately, strong supplier relationships serve as a foundation for sustainable competitive advantage, reinforcing other benefits of strategic sourcing.

One of these benefits—greater supply chain stability—is explored next.

In today’s volatile global landscape, supply chain disruptions are no longer the exception—they’re the norm.

From geopolitical conflicts, tariffs, and regulatory shifts to extreme weather events, organizations must constantly navigate risks that threaten supply chain stability.

These challenges reinforce the role of strategic sourcing as a crucial risk management tool.

And considering the current state of global affairs, mitigating risks and building supply chain resilience has never been more critical.

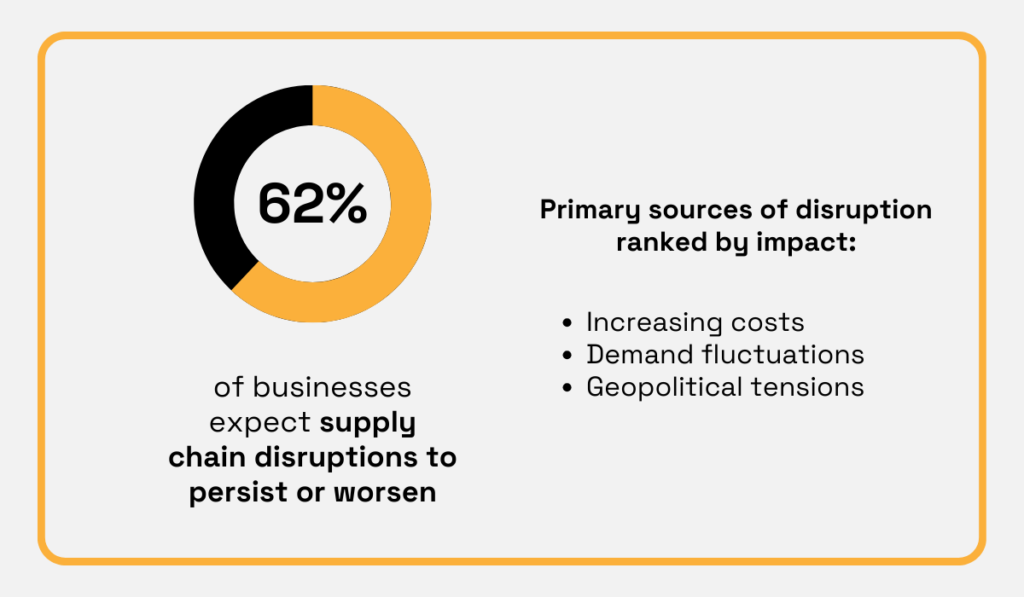

A 2024 QIMA survey of over 800 companies with international supply chains underscores these concerns, revealing the extent of disruption and the key pressure points businesses face.

Illustration: Veridion / Data: QIMA

So, what can strategic sourcing do to help mitigate the risks arising from these disruptions?

Organizations can implement a range of risk management strategies, including:

Let’s look at each of these strategies and how they’re connected.

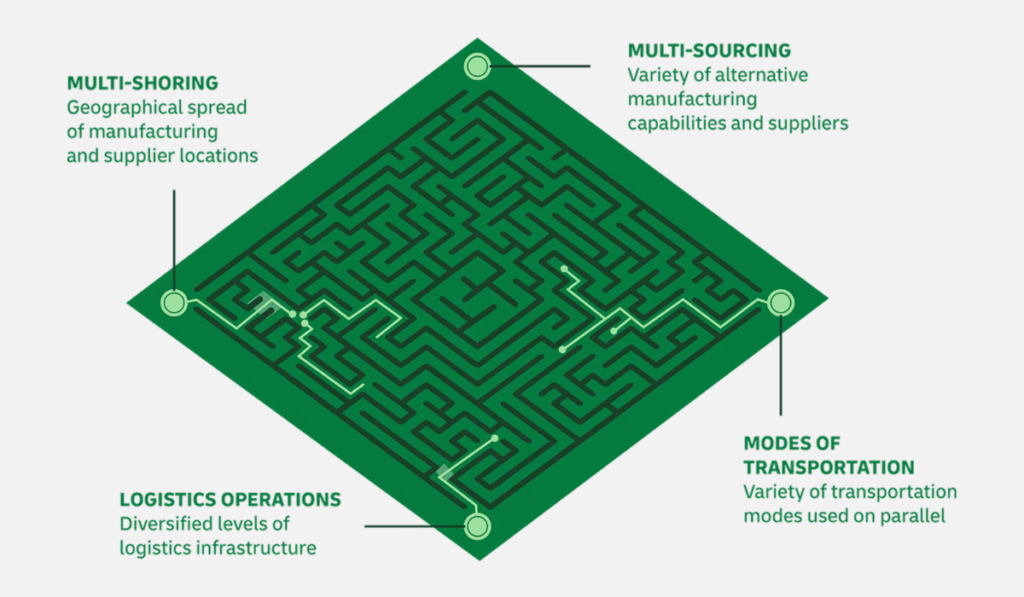

Diversification is a long-standing, effective method to increase supply chain stability.

It involves proactive strategies across one or more of the four key dimensions of supply chain management shown below.

Source: DHL

However, to successfully diversify your supply base, you need tools and methods to discover, evaluate suitability, and assess the risks of new potential suppliers.

This involves first identifying and then evaluating suppliers against various risk factors, such as:

Methods like supplier scorecards and risk assessment matrices are helpful, but nowadays, digital tools are crucial for these efforts.

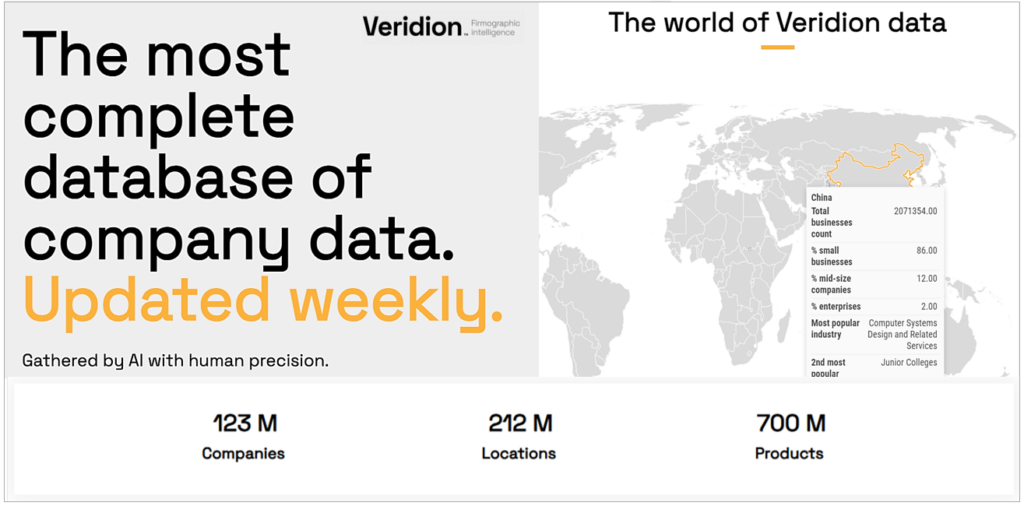

For example, our AI-powered supplier data engine, Veridion, allows you to find eligible suppliers anywhere in the world within seconds.

Source: Veridion

Beyond quickly identifying new suppliers, Veridion’s global, weekly-updated database enables you to assess risks associated with potential suppliers.

You can evaluate each supplier based on custom risk factors, such as financial instability, regulatory non-compliance, ESG controversies, and more.

This approach helps your team identify high-risk suppliers early, preventing issues down the line.

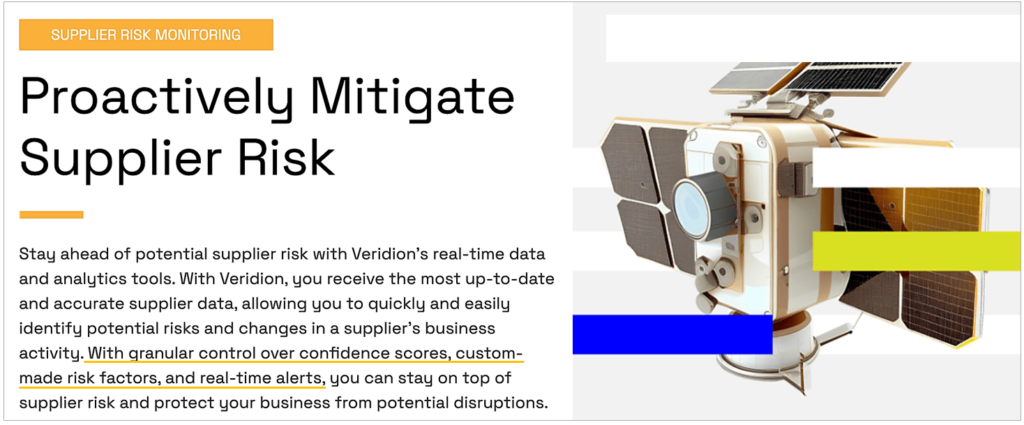

Moreover, Veridion’s real-time market intelligence allows you to automate risk monitoring for your existing suppliers.

Source: Veridion

As highlighted, Veridion will notify you of any changes in a supplier’s activity, along with confidence and reliability scores, allowing you to proactively manage emerging risks.

Moreover, real-time supplier data and market intelligence empower your team to verify and monitor suppliers’ compliance with regulations and industry standards.

This approach doesn’t just help identify and vet reliable alternative suppliers, though.

It also supports the development of contingency plans tailored to the most relevant risk scenarios.

In summary, strategic sourcing is focused on continuous risk monitoring and mitigation to build resilience and enhance the stability of your supply chain.

At the beginning of this article, we highlighted that strategic sourcing goes beyond initial price considerations and focuses on the total cost of ownership (TCO).

This includes evaluating the long-term costs associated with product quality, maintenance, and potential risks.

Ultimately, all of this ensures that higher-quality products are chosen for their overall value.

It all starts with supplier evaluation and selection, which lay the foundation for effective quality assurance from the outset.

This process involves thoroughly assessing suppliers based on product (or service) quality, alongside other key factors, as shown in this sample scorecard.

Source: Slide Team

Ultimately, the goal is to ensure that only suppliers who meet high-quality standards are selected for long-term partnerships.

Once suppliers are onboarded, their performance is continuously monitored to assess their quality consistency, regulatory compliance, and other quality-related factors.

This includes verifying their adherence to quality control processes and ensuring they meet or exceed industry benchmarks.

Here’s again where the benefits of strategic sourcing overlap.

By fostering strong supplier relationships, this approach also facilitates a supplier’s quality control compliance, fosters collaboration, and can even drive innovation.

Moreover, strategic sourcing also considers how the risk of product quality failures can be mitigated.

Having alternate suppliers is a common approach.

This is because they can step in if one supplier faces quality issues, like in Apple’s case.

Source: MacRumors

This example highlights the advantage of having several suppliers for the same or similar components.

If one supplier fails to meet quality standards, others can step in, ensuring minimal disruption while issues are resolved.

Ultimately, prioritizing quality and long-term value over cost alone is a key principle of strategic sourcing.

However, selecting high-quality suppliers is just the first step—ongoing performance monitoring and quality control are equally essential.

Along with fostering strong partnerships, these strategic measures help companies uphold high standards, mitigate quality-related risks, and protect their reputation.

Finally, strategic sourcing can be a powerful driver of innovation.

By collaborating with suppliers who bring new ideas, technologies, and processes to the table, companies can accelerate product development and stay ahead of market shifts.

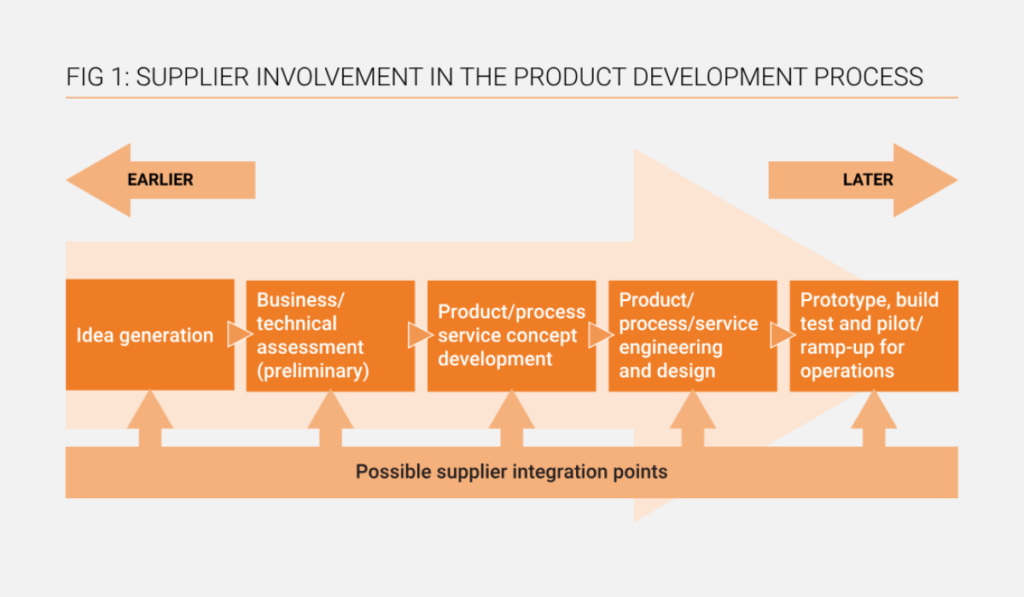

One key approach is Early Supplier Involvement (ESI).

In it, suppliers are engaged early in the product design phase to contribute technical expertise and process innovations.

As shown below, suppliers can be integrated at multiple stages in the product development process.

Source: Procurement Leaders

But why is this early involvement approach so beneficial?

Because it can not only improve final product design and performance, but also enhance its manufacturability and cost efficiency.

Additionally, companies can encourage suppliers to propose innovations through gain-sharing contracts.

In such contracts, both parties benefit from efficiency improvements or cost savings resulting from new solutions.

Another innovation-fostering sourcing strategy is co-development partnerships.

This approach is characterized by two or more parties working together to create groundbreaking products or sustainable alternatives.

For example, Dow and Procter & Gamble have joined forces to develop a proprietary recycling technology aimed at processing hard-to-recycle plastic waste.

Source: Packaging Dive

By combining their patented technologies and expertise, Dow and P&G aim to produce near-virgin quality recycled plastics.

This collaboration shows how supplier partnerships can drive industry-changing innovations that, if successful, will benefit both parties.

When companies actively involve suppliers in problem-solving and product development, they unlock new opportunities for innovation.

Whether in sustainability, manufacturing efficiency, or cutting-edge technology, strategic sourcing helps businesses adapt to changing markets and stay competitive.

So, what can be gleaned from the benefits of strategic sourcing we covered?

First, it’s clear that this comprehensive approach is an intricate interplay of sourcing strategies, tools, and methodologies, where advantages reinforce each other.

Second, strategic sourcing goes beyond cost-cutting to build stronger, mutually beneficial supplier relationships that drive long-term value.

Ultimately, this generates all the benefits organizations seek—cost efficiency, supply chain resilience, and a competitive edge.

Given this, it’s clear that, by embracing strategic sourcing principles, tools, and methods, your company can turn procurement into a powerful driver of success.