5 Common Challenges in Strategic Sourcing

Key Takeaways:

Very few procurement teams can confidently say they’ve completely optimized their strategic sourcing practices.

But it’s not for lack of trying.

The truth is that strategic sourcing is a complex process riddled with challenges.

These can pop up anywhere, from the initial stages of implementing a strategic sourcing process to the ongoing struggle of incorporating sustainable practices and managing global uncertainties.

So, in this article, we’ll break down five of the most common challenges you will likely encounter during the strategic sourcing process—and offer solutions to overcome them.

Let’s dive in.

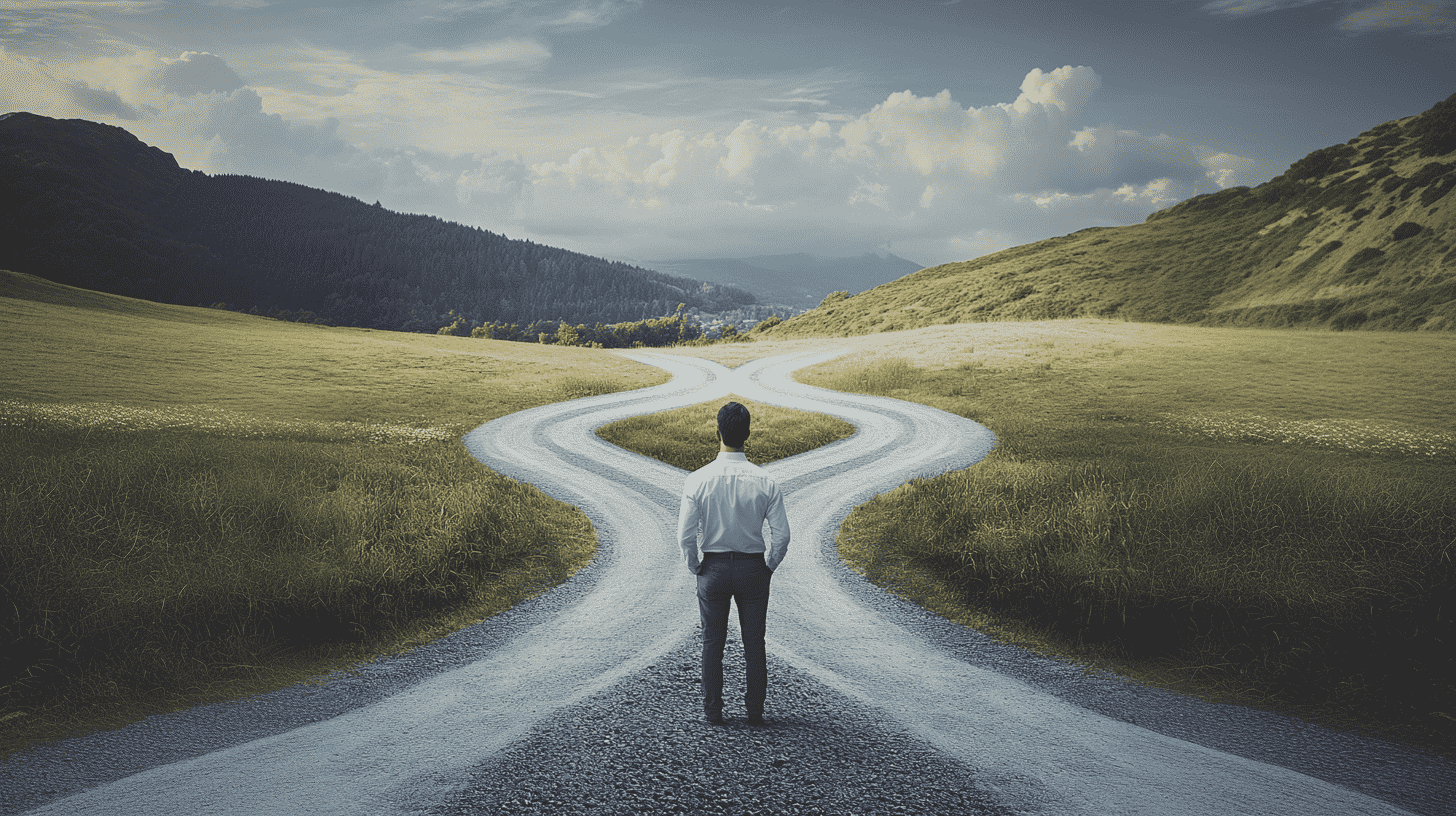

Strategic sourcing is a multifaceted process.

And one of the first problems you can encounter is successfully implementing this process within your organization.

After all, strategic sourcing involves multiple stages, each crucial in achieving optimal results.

These steps are interconnected and build upon one another, forming a solid foundation for effective sourcing.

Let’s take a closer look at these stages, illustrated in the image below.

Source: Veridion

Teams used to less structured sourcing practices might be tempted to skip the initial stages of market research, spend analysis, and creating a sourcing strategy.

However, these steps are vital in laying the foundation for successful sourcing.

They help identify key spend categories, uncover areas of tail spend, assess the state of the supply market, and determine whether global or local sourcing strategies are best.

So, only after completing these steps can you effectively define supplier selection criteria and begin the sourcing and negotiation process.

Even with a solid strategy in place, it’s important to have well-defined procedures for supplier selection and negotiation.

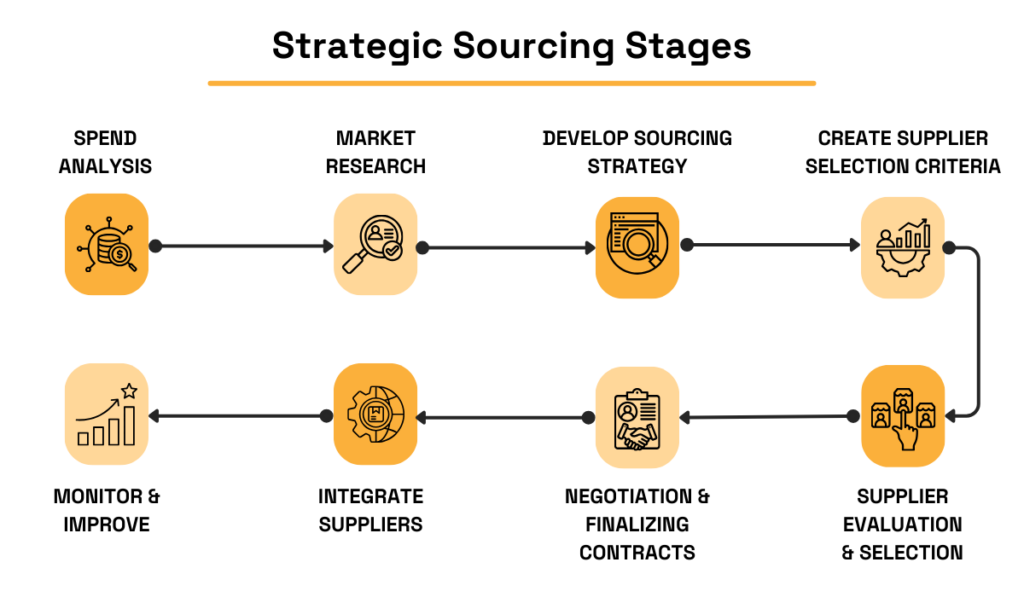

Lax policies and vague requirements can lead to maverick spend—unauthorized purchases outside established channels.

Given that recent research by SDI shows an increase in maverick spend among businesses, it’s a critical area to consider.

Illustration: Veridion / Data: SDI

In fact, you need to focus on effectively enforcing the strategic sourcing practices to prevent maverick spend and other inefficiencies.

But this is a challenge in itself, as you’ll likely encounter stakeholder resistance.

Philip Ideson, founder of Art of Procurement, points out that stakeholders may perceive a new sourcing process as a threat or disruption to their established workflows.

He emphasizes the importance of clear communication in overcoming this resistance.

Illustration: Veridion / Quote: Art of Procurement

Beyond highlighting the benefits of strategic sourcing and training stakeholders, leveraging technology can significantly ease the implementation process.

Tools such as spend analysis software, supplier relationship management (SRM) platforms, e-procurement systems, contract management solutions, and other strategic sourcing providers can streamline workflows and make it easier for staff to adopt the new practices.

Overall, successfully implementing a strategic sourcing process requires a structured approach, careful attention to each stage, and proactive communication with stakeholders.

Strategic sourcing is all about maximizing value, and securing the best possible suppliers is an essential challenge that needs to be overcome.

However, this is often easier said than done.

One of the biggest roadblocks is an ineffective evaluation process.

Think poorly defined criteria, inadequate due diligence, or simply relying on outdated information.

This often happens when teams rely on manual, time-consuming processes or stick with existing suppliers they’ve built relationships with, even if better options exist.

Unfortunately, going with subpar suppliers can create a range of problems down the line, some of which are shown here:

Source: Veridion

While higher costs and delivery delays are certainly painful, choosing the wrong suppliers can also significantly increase risk and introduce compliance issues, exposing your organization to disruptions, legal issues, and reputational damage.

So, what’s the solution?

Well, for starters, companies need better evaluation practices during the selection process.

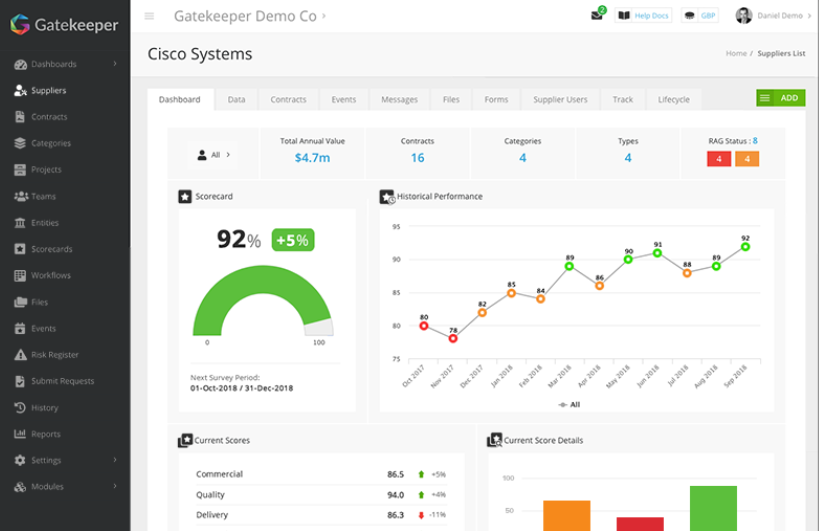

One highly effective method is using supplier scorecards.

Whether you manage them manually or use systems like Gatekeeper, scorecards incorporate a range of supplier criteria, each weighed and scored according to your specific needs.

Source: Gatekeeper

Ultimately, scorecards help you take a more structured, objective approach to supplier selection, making it much easier to compare vendors directly.

But, you need the right supplier data to even get to the point of comparing the best suppliers.

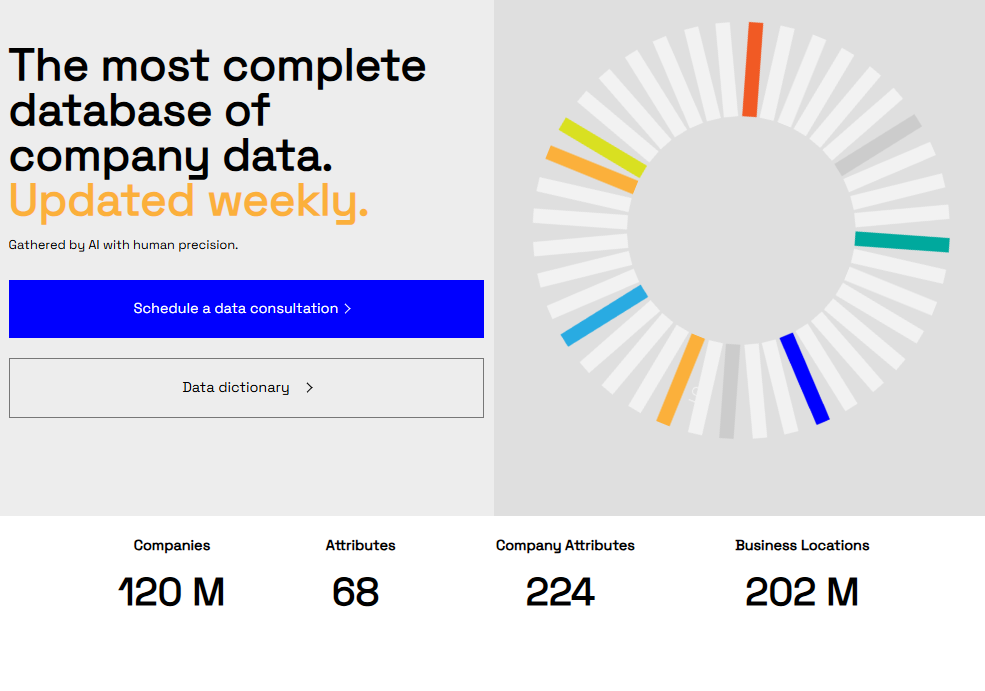

And that’s where AI-powered supplier sourcing solutions like Veridion can be a game-changer.

Veridion uses artificial intelligence (AI) and machine learning (ML) algorithms to scan the entire internet, with our database containing detailed profiles for over 120 million suppliers worldwide.

Source: Veridion

This data is refreshed weekly and is accessible through our Search and Match & Enrich APIs, or by using natural language queries with our Scout solution.

This makes it easy to find any supplier, anywhere, and pinpoint the best fit for your needs.

In fact, when it comes to comparing your shortlisted suppliers, our detailed company profiles with over 60 data points will help filter out the very top suppliers.

For instance, check out the ESG data you get for each supplier.

Source: Veridion

Some of the other insights include supplier company data, financial stability information, product offerings, supplier certifications, and more.

All in all, data is irreplaceable in the strategic sourcing process.

By combining data engines like Veridion with best practices like scorecards, you can ensure you’re selecting the very best vendors to partner with.

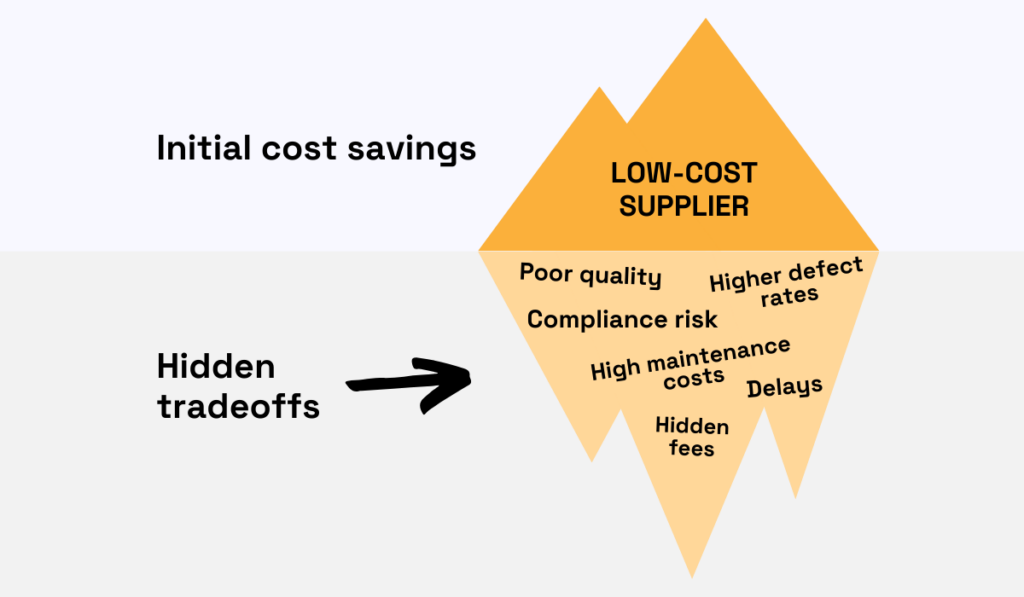

When evaluating suppliers, traditional sourcing often prioritizes cost savings above all else.

However, this approach isn’t always the best, and finding the right balance between cost and other crucial factors is a major challenge.

After all, while a supplier might offer a lower initial price, this can come at the cost of several tradeoffs.

Source: Veridion

A supplier’s low cost could be due to several factors, from using inferior materials and less robust manufacturing processes to cutting corners on service levels and support.

These compromises can directly impact the quality of the final product and introduce inefficiencies into your supply chain, ultimately costing you more in the long run.

That’s why Idar Nouti, Consulting Director for KPMG, emphasizes the importance of careful supplier cost analysis and adopting a long-term perspective:

Illustration: Veridion / Quote: Linkedin

In essence, companies have to look beyond the initial price tag and consider the total cost of ownership (TCO).

TCO encompasses all costs associated with acquiring, using, and maintaining a product or service over its entire lifecycle.

This includes not only the purchase price but also factors like transportation, storage, installation, training, maintenance, and even disposal.

So, while a supplier might seem more expensive upfront, they could prove to be more cost-effective in the long run due to higher quality, better reliability, and superior service.

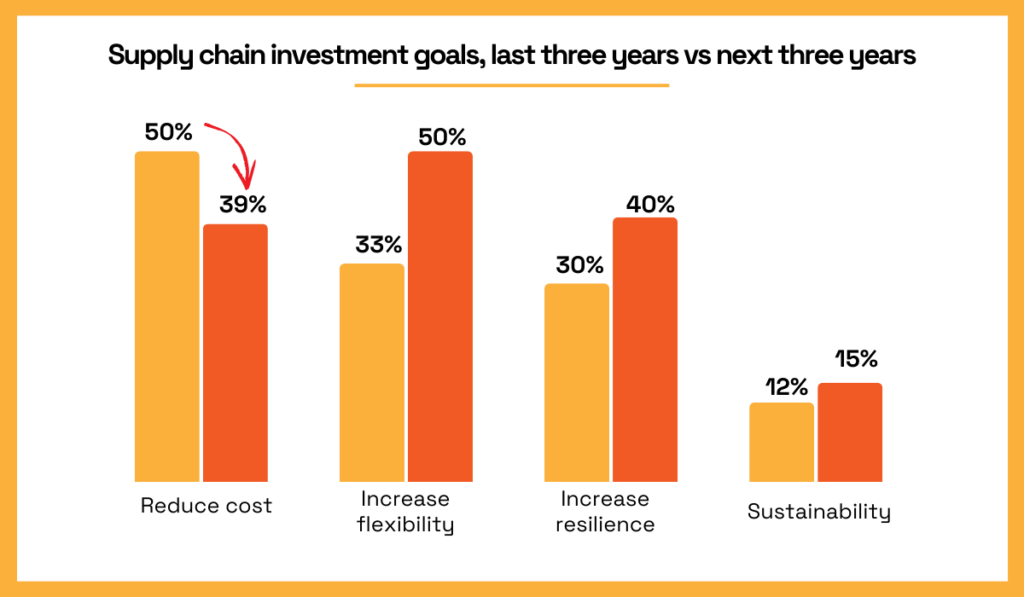

Interestingly, research suggests that companies are following this approach and becoming less fixated on cost savings.

A 2022 survey by Bain & Company of 275 supply chain leaders revealed a shift in investment priorities.

Illustration: Veridion / Data: Bain & Company

As the graph illustrates, investment in cost reduction is declining, while there’s a growing emphasis on flexibility, resilience, and sustainability.

These insights can guide your sourcing strategies, moving the focus of procurement from solely cost savings to a more balanced, long-term approach.

Modern supply chains face constant disruptions.

And a top issue in strategic sourcing is staying resilient in the face of global challenges and geopolitical uncertainties.

In the last five years alone, we’ve seen it all: the COVID-19 pandemic, the war in Ukraine, natural disasters, trade wars, and escalating political tensions.

Source: Veridion

The wrong strategic approach in this environment can be disastrous.

For example, let’s say you rely heavily on a single supplier in a politically unstable region.

If that region experiences unrest or faces sanctions, your entire operation could be disrupted.

Your production could grind to a halt, impacting delivery schedules and potentially damaging customer relationships.

The same goes for focusing solely on outsourcing strategies, where labor disputes, port closures, or even currency fluctuations can ripple through your supply chain.

A diversified approach is essential to prepare for multiple outcomes.

This means spreading your sourcing across multiple suppliers and geographic locations, creating redundancy, and reducing dependence on any single source.

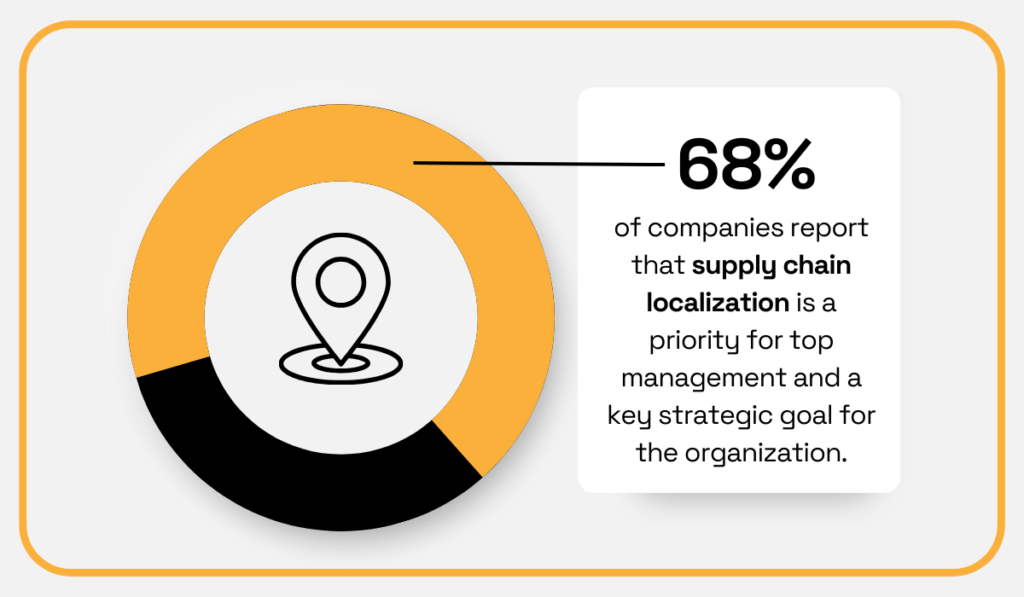

According to 2024 PwC data, the vast majority of organizations have supply chain localization as a top priority.

Illustration: Veridion / Data: PwC

Expanding on the benefits of this approach, the report notes that, in addition to building resilience, it also enhances market responsiveness and reduces costs through streamlined logistics.

When using local suppliers is not an option, nearshoring becomes a common solution.

It offers a balance between cost savings and reduced risk compared to offshoring to distant locations.

In any case, even with these strategies, it’s essential to stay vigilant about geopolitical risks.

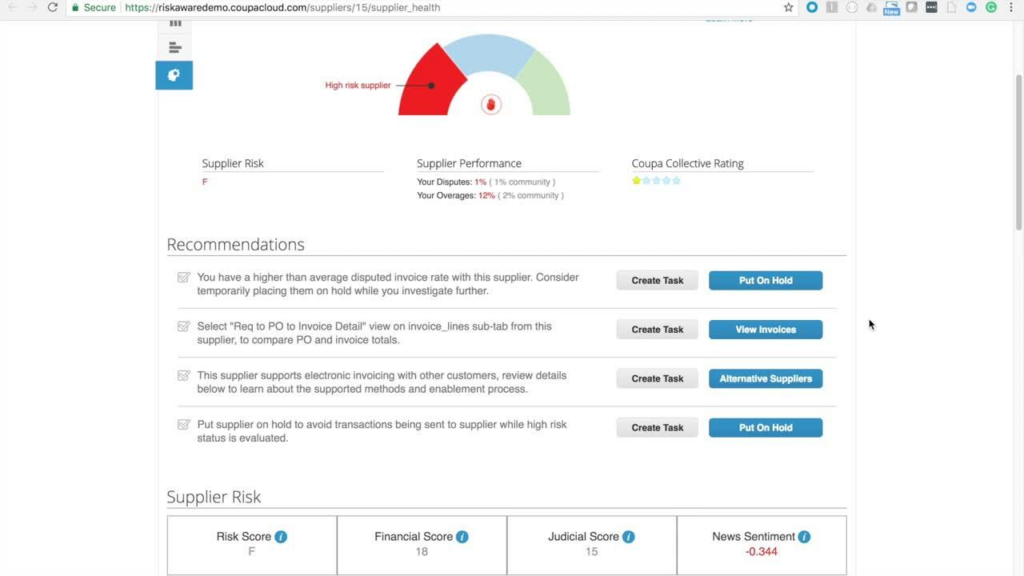

You need to monitor supplier risk continuously and be prepared for changes.

Platforms like Coupa can help with this.

Its Risk Aware feature provides real-time visibility into potential disruptions by aggregating data from various sources to assess supplier risk based on factors like financial stability, location, and industry trends.

Source: Coupa

It even has a news sentiment score that tracks what media outlets say about a particular supplier, which can be especially useful when tackling geopolitical issues.

In short, global supply chain complexities require a proactive and adaptable approach.

With the right supplier diversification and ongoing risk monitoring, however, you can create a more resilient supply chain.

There’s a growing trend of companies running sustainability initiatives within their supply chains.

While this shift is positive, it also brings its own set of challenges.

In fact, sustainable sourcing is not only a desired practice but is becoming part of widespread mandates and regulations.

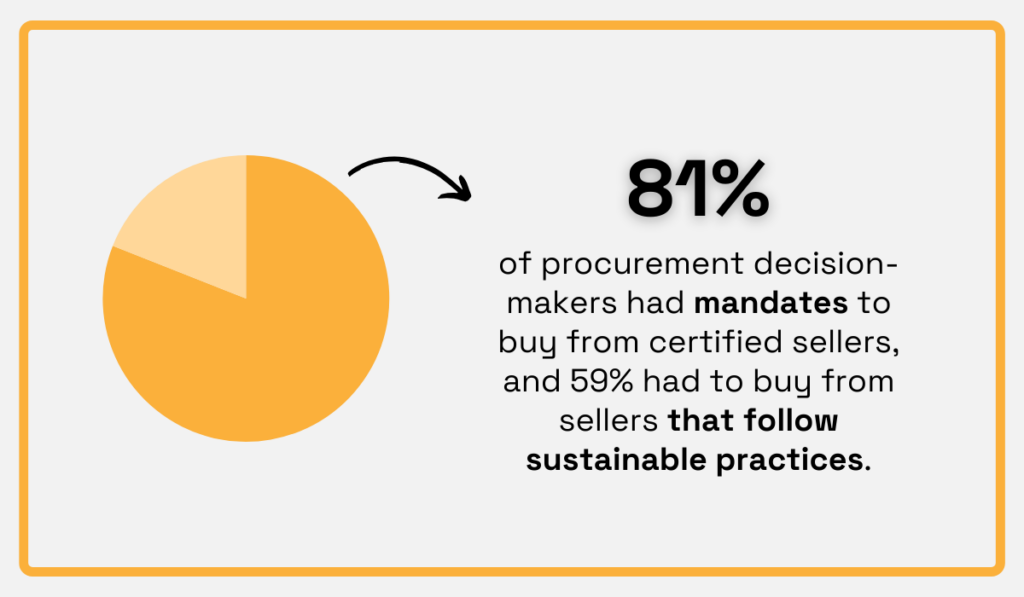

Amazon’s 2025 State of Procurement Data report shows that out of the 3000 surveyed procurement professionals, the vast majority had internal or external mandates to buy from certified sellers.

And the most prominent mandate?

Choosing suppliers that follow sustainable practices, with 59% of respondents citing this requirement.

Illustration: Veridion / Data: Amazon

Clearly, incorporating sustainability into your sourcing strategy is essential.

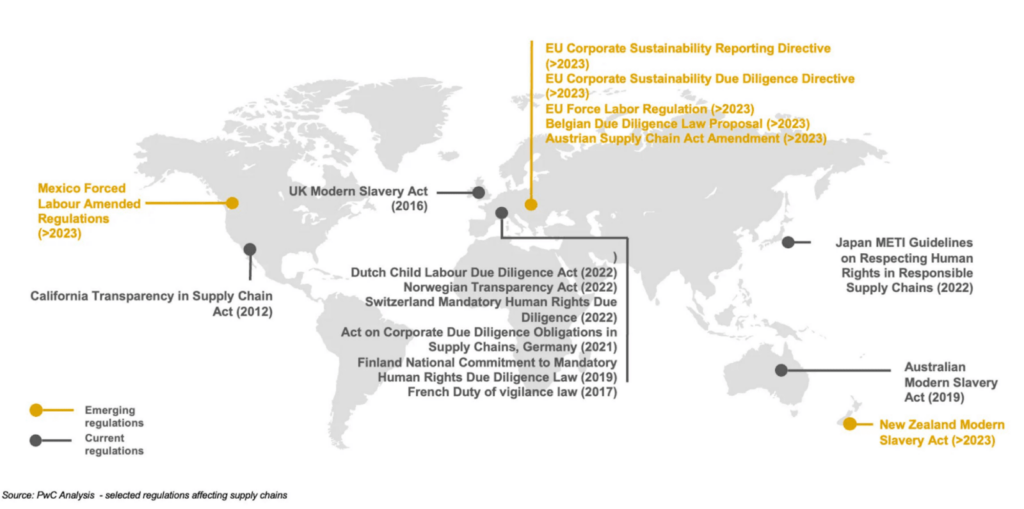

However, it’s also challenging to navigate, especially when considering the various regulations and laws surrounding sustainable and ethical practices worldwide.

Take a look at the map below, highlighting some of the key regulations impacting supply chains across the globe.

Source: Veridion

As you can see, with so many established and emerging regulations, ensuring compliance can be complicated, especially for companies with global supply chains.

A best practice is to source from sustainable suppliers that meet your specific ESG criteria, as well as any compliance requirements set by applicable regulations.

As we discussed, tools like Veridion can be a great help here, providing data and insights to identify suppliers committed to sustainability.

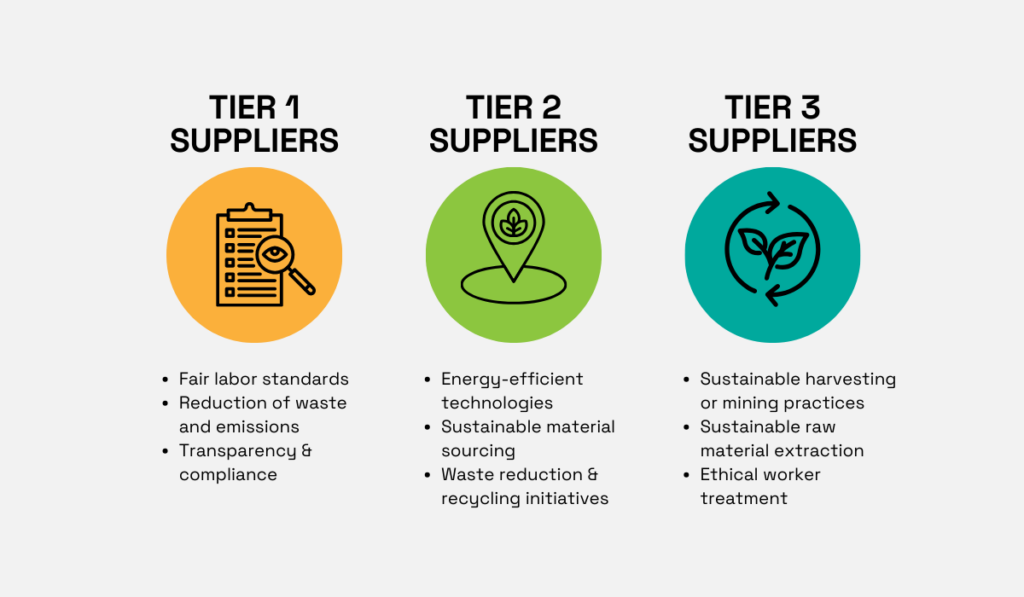

However, it’s also essential to audit the sustainable and ethical practices of your tier 2 and 3 suppliers during this process.

While not mutually exclusive, some key focus areas for each tier are listed below.

Source: Veridion

This practice is crucial because, even if your direct suppliers are compliant, violations further down the supply chain can still affect your company.

These violations can range from environmental damage and labor exploitation to corruption and human rights abuses.

Ultimately, you are responsible for the entire supply chain, not just your direct suppliers.

Strategic sourcing is a journey, not a destination—one filled with challenges but also immense opportunity.

As you navigate complexities like supplier selection, cost balancing, and global risks, remember that these obstacles can be overcome with the right tools and mindset.

Embrace the power of data, diversify your supplier base, and stay agile in a fast-evolving landscape.

With a little creativity and a proactive approach, you can build a more resilient, efficient, and sustainable procurement function.