Discovering Suppliers: Real-World Applications and Success Stories

Imagine a world where finding the perfect supplier is no longer a tedious and lengthy challenge.

Well, thanks to AI, advanced analytics, and strategic sourcing, industry leaders like PepsiCo, Audi, and Nike have revolutionized their supplier discovery.

They no longer search blindly—they make informed, confident decisions that drive growth.

So, if you’re a procurement professional who wants to learn by example or just curious about the future of sourcing, read on to learn how top companies stay ahead.

By the end, you’ll see how technology is reshaping procurement and how businesses can leverage it to stay competitive.

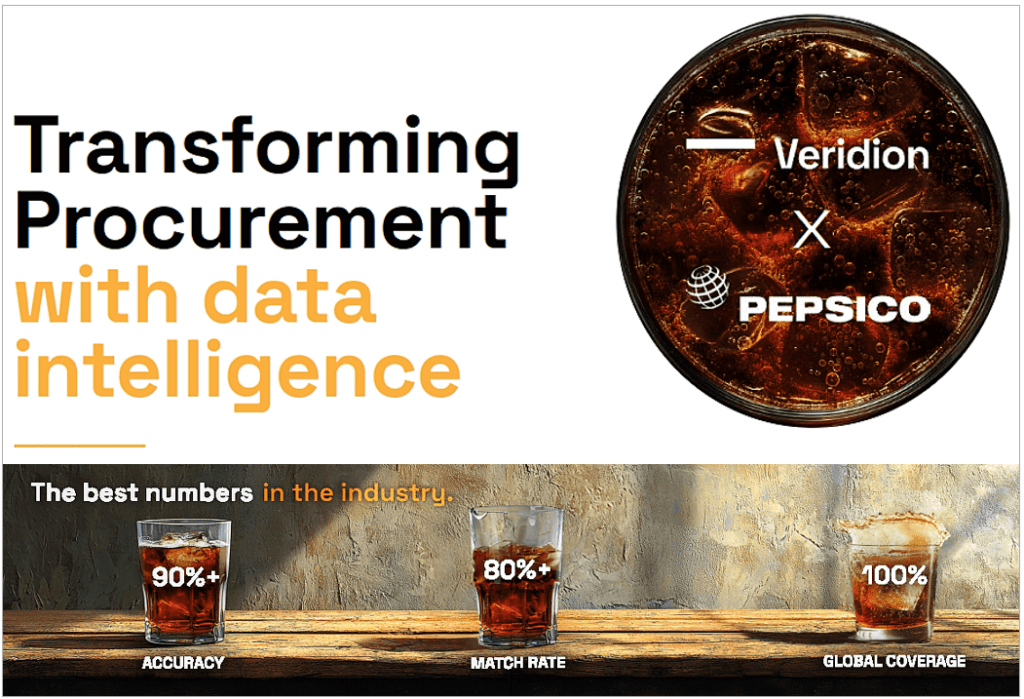

PepsiCo, a global food and beverage giant, has consistently sought innovative ways to optimize its supply chain and fuel growth.

Back in 2021, PepsiCo launched pep+, a comprehensive strategy focused on transforming their supply chain with a strong emphasis on sustainability.

In the following years, the commitment to procurement excellence only deepened.

As Heleen Du Toit, VP of procurement at PepsiCo, explains, staying competitive requires constantly finding new ways to source materials and services.

Illustration: Veridion / Quote: CPO Strategy

But, she says that this pursuit of excellence comes with its own set of challenges.

Du Toit highlights two key obstacles: maintaining supply chain resilience and ensuring cost competitiveness in a dynamic market.

To address these challenges, PepsiCo has employed advanced analytics and artificial intelligence for more robust supplier discovery.

Supporting these efforts are tools like Veridion, which enhance data-driven sourcing and decision-making.

Source: CPO Strategy

Veridion is an AI and ML data engine that has a global database of over 120 million suppliers across more than 240 locations.

Importantly, this database is updated weekly, with our proprietary AI algorithms continuously scraping the entire internet and ensuring companies like PepsiCo are working with the freshest data available.

Veridion provides over 60 separate data points per supplier, covering location, size, revenue, product specifics, classifications, certifications, compliance data, and ESG insights.

Accessing this data is made simple through our Search and Match & Enrich APIs or our Scout system.

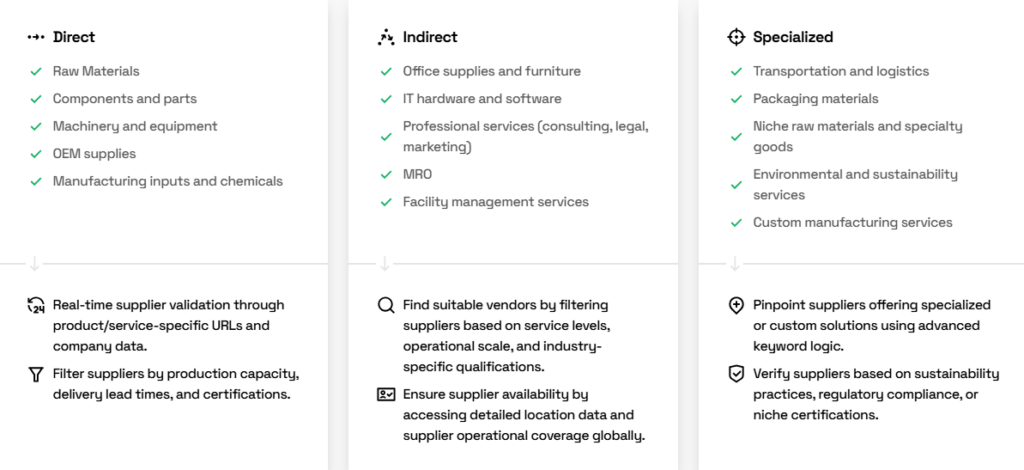

Scout, in particular, enables companies to search for suppliers using simple, natural language, specifying any criteria they require across a wide range of direct, indirect, and specialized products and services.

Source: Scout

These AI-powered supplier discovery capabilities help PepsiCo source more efficiently and accurately, getting decision-grade data for better risk mitigation, supplier evaluation, and sustainability checks.

As Chad Moore, Director of Sales at Veridion, explains, the platform has played a key role in overhauling PepsiCo’s entire data foundation.

Illustration: Veridion / Quote: Wonder Services on YouTube

Ultimately, with Veridion and other advanced systems, PepsiCo is building resilience against the volatility of the modern market and ensuring it consistently identifies the optimal vendors to meet its evolving needs.

This, in turn, contributes to a more agile and adaptable supply chain, and strengthens PepsiCo’s position as a leader in the food and beverage industry.

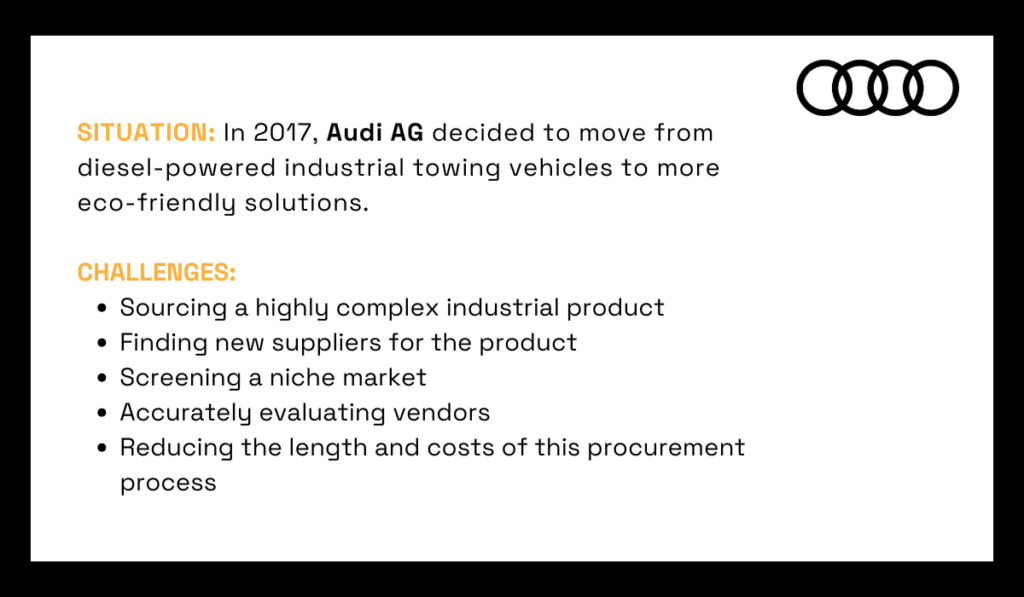

Moving forward, we have Audi AG, a German automobile manufacturer specializing in luxury vehicles and a subsidiary of the Volkswagen Group.

Audi’s success story concerns innovation and sustainability, and the complexities involved in balancing the two.

Specifically, back in 2017, Audi AG decided to source electric industrial towing vehicles as part of their eco-initiatives.

A critical requirement for these vehicles was that they should not be less powerful than their diesel counterparts, as compromising on performance was not an option.

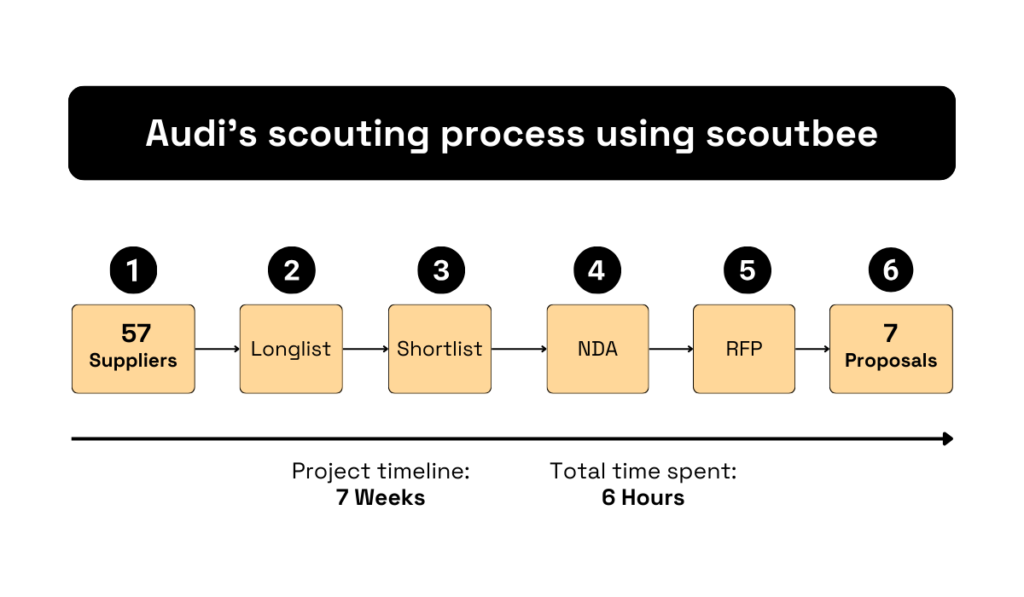

And, as illustrated in the image below, this specific aim came with its challenges, mainly because it was such a niche market.

Illustration: Veridion / Data: Tech Prospect

Early on in the process, Audi decided against using traditional supplier searches.

While a manual search might have eventually yielded results, it would have been incredibly time-consuming and resource-intensive, and the company wanted to avoid unnecessary costs.

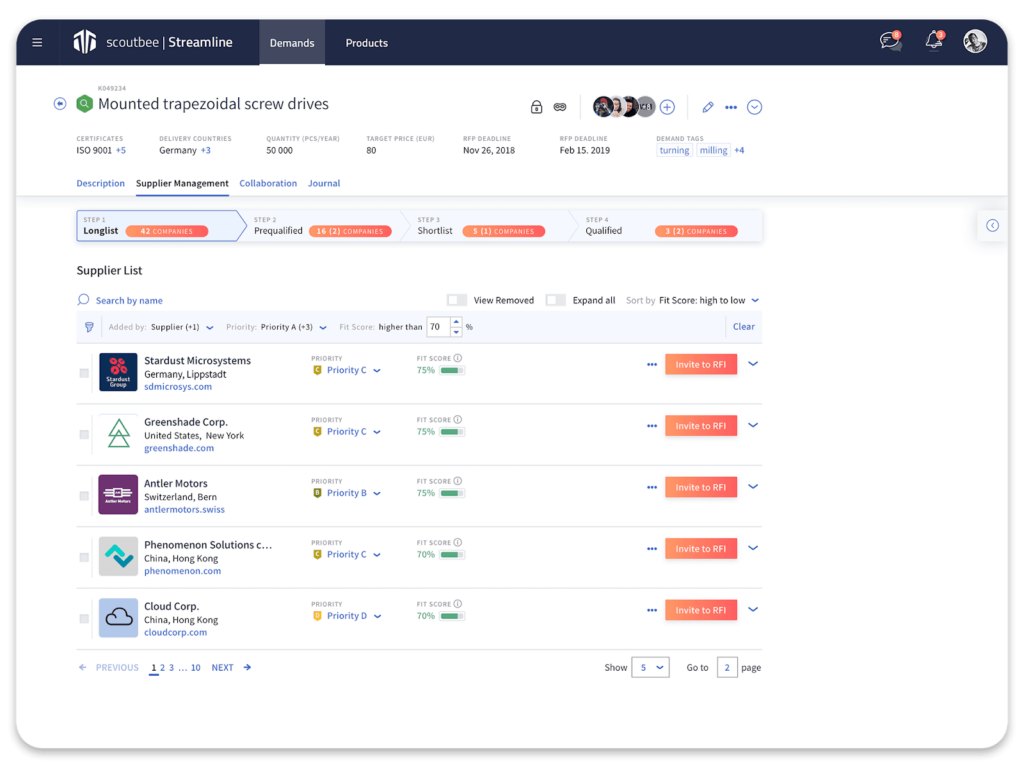

So, Audi opted for a technology-driven solution—Scoutbee.

Source: Scoutbee

Scoutbee is an AI-powered digital platform that streamlines the process of finding, evaluating, and onboarding new suppliers.

It promises to accelerate the Request for Proposal (RFP) process and all related activities.

Now while Scoutbee’s supplier database of 14 million suppliers is smaller compared to platforms like Veridion, it’s still a valuable resource for identifying potential partners.

In fact, in Audi AG’s case, this platform helped significantly speed up the sourcing process, progressing from the initial stage to supplier proposals in just seven weeks.

Illustration: Veridion / Data: Tech Prospect

Using Scoutbee’s AI features, Audi screened 180 times more suppliers in a fraction of the time, completing the entire discovery process in just six hours.

This resulted in significant efficiency gains, proving the power of AI-driven supplier discovery—even in niche markets.

For a strong example of supplier management and relationship building, look no further than Nike, a company that needs no introduction.

Nike’s supplier-related practices center on three key pillars:

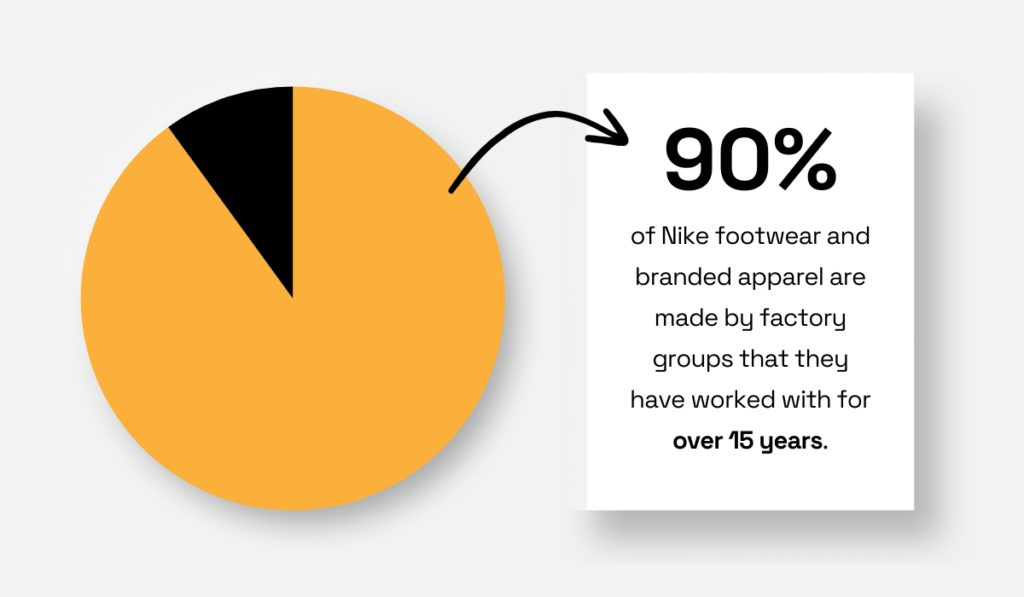

Nike outsources 100% of its footwear and apparel manufacturing to independent suppliers.

While this is great for cutting costs, it comes with potential risks, like ensuring that suppliers are reliable and provide high-quality products.

To ensure quality and reliability, Nike uses supplier scorecards to evaluate performance on quality, delivery, cost, and sustainability.

These scorecards guide both initial supplier selection and ongoing assessments, reinforcing Nike’s long-term commitment to strong supplier partnerships.

This approach makes sense, given that most of Nike’s products come from well-established relationships built over time.

Illustration: Veridion / Source: Nike

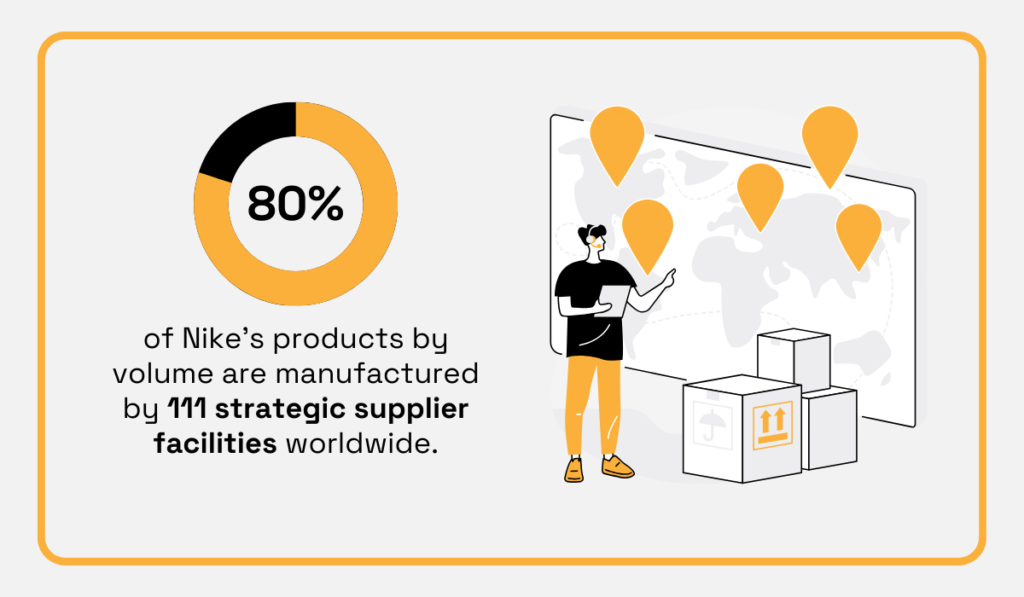

But, even with such strong suppliers, outsourcing all their manufacturing comes with inherent risks.

Disruptions at any point in the supply chain, whether due to supplier-specific issues or broader market forces, can significantly impact production and delivery.

Nike mitigates these risks from the outset by diversifying its supplier base.

In fact, 111 supplier facilities are responsible for the majority of Nike’s production.

Illustration: Veridion / Source: Nike

This strategic approach ensures no single factory dominates production, maintaining flexibility and resilience in the supply chain.

Also, not being overly reliant on any one site means Nike is less vulnerable to unpredictable occurrences and supply chain disruptions.

But it’s not just diversification that’s on Nike’s agenda.

Nike treats suppliers as strategic partners and is heavily involved in broadening its supplier base to include more diverse suppliers.

Nike’s diversity initiative contributes to greater inclusion and also brings more creative and innovative solutions to greatly support Nike’s growth.

Source: Nike

Plus, Nike offers its Diverse Supplier Development Program, or “Academy,” designed to amplify and accelerate the capabilities of diverse suppliers to grow in their relationship with Nike.

This academy ultimately provides all the necessary resources and network access to ensure the suppliers enrolled are set up for success.

So, Nike isn’t just looking for vendors.

Nike is actively involved in the growth of its suppliers, ensuring they create a mutually beneficial partnership.

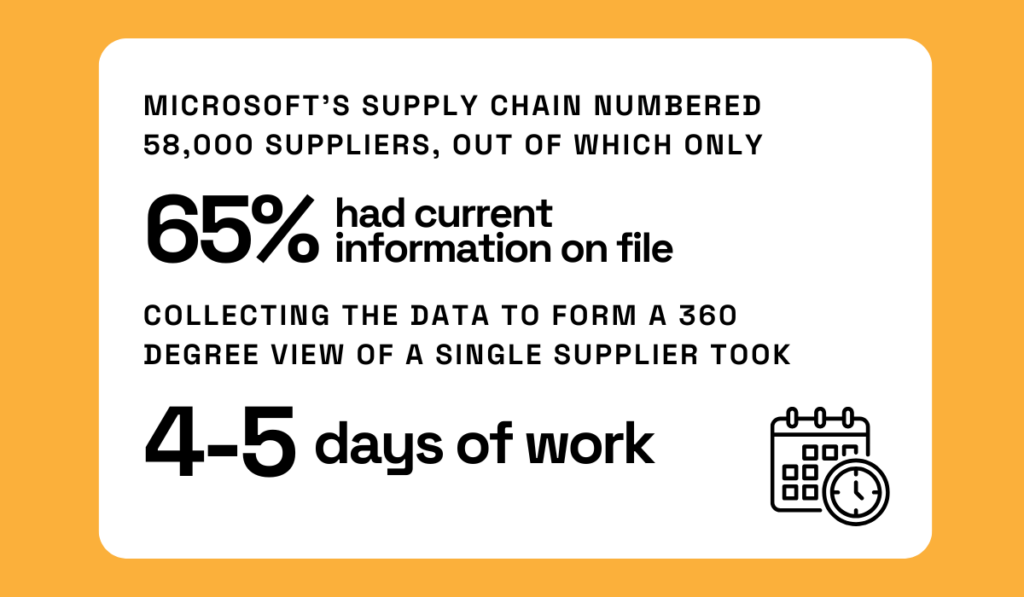

Microsoft’s supply chain is vast, encompassing a network of 58,000 suppliers.

These suppliers primarily support its two key business segments, Personal Computing and Intelligent Cloud, which generate two-thirds of Microsoft’s revenue.

But, this extensive supplier base presented a significant challenge in managing and maintaining this complex network.

The primary issue stemmed from the decentralized nature of Microsoft’s supplier data, which was spread across ten different databases and tools.

Accessing and using this data was a tedious and inefficient process, with no guarantee that you’re even working with current information.

Illustration: Veridion / Data: Microsoft

Clearly, these inefficiencies hindered effective supplier management and put the supplier data accuracy into question.

Even worse, this complexity negatively impacted the suppliers themselves.

The sheer number of tools Microsoft used created confusion for suppliers regarding how and where to interact with the company.

This sentiment is echoed by Suchit Shah, a senior procurement operations manager at Microsoft.

Illustration: Veridion / Quote: Microsoft

Consequently, suppliers frequently missed compliance deadlines and failed to provide critical data, occasionally leading Microsoft to end collaborations.

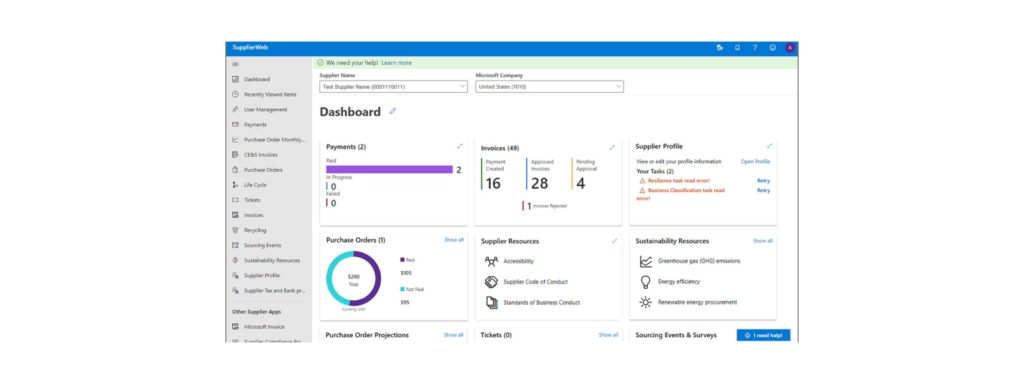

To address these challenges, Microsoft developed SupplierWeb, a centralized platform to streamline supplier interactions and data management.

Source: Microsoft

Designed as a self-service portal, SupplierWeb empowered suppliers to easily manage and update their own data, view their transactions, and access support through a digital assistant.

Microsoft also introduced ProcureWeb to address internal supplier management challenges.

This tool enabled internal users to efficiently search for suppliers based on specific criteria, such as areas of expertise, experience level, or diversity rating.

The results were transformative.

Suppliers benefited from a simplified and more efficient interaction process, while procurement teams gained access to accurate, centralized supplier data, leading to improved decision-making and stronger supplier relationships.

To summarize, by simplifying and centralizing their systems, Microsoft empowered both their internal teams and their external partners, fostering a more robust and collaborative supply chain ecosystem.

Finally, let’s examine a case study highlighting the challenges and opportunities of breaking into a new supplier market.

We’ll be looking at Heidelberger Druckmaschinen AG, a leading manufacturer of printing presses and related equipment.

Heidelberger’s challenge involved sourcing a rare cast metal part made from an uncommon aluminum bronze alloy for one of their printing machines.

Previously, Heidelberger relied on a single supplier for this specialized part.

But, supply bottlenecks and the need to reduce costs prompted the company to seek alternative vendors.

Specifically, Heidelberg wanted to diversify its supplier base and explore foreign markets, building on the positive experiences they already had with suppliers from Germany and Europe.

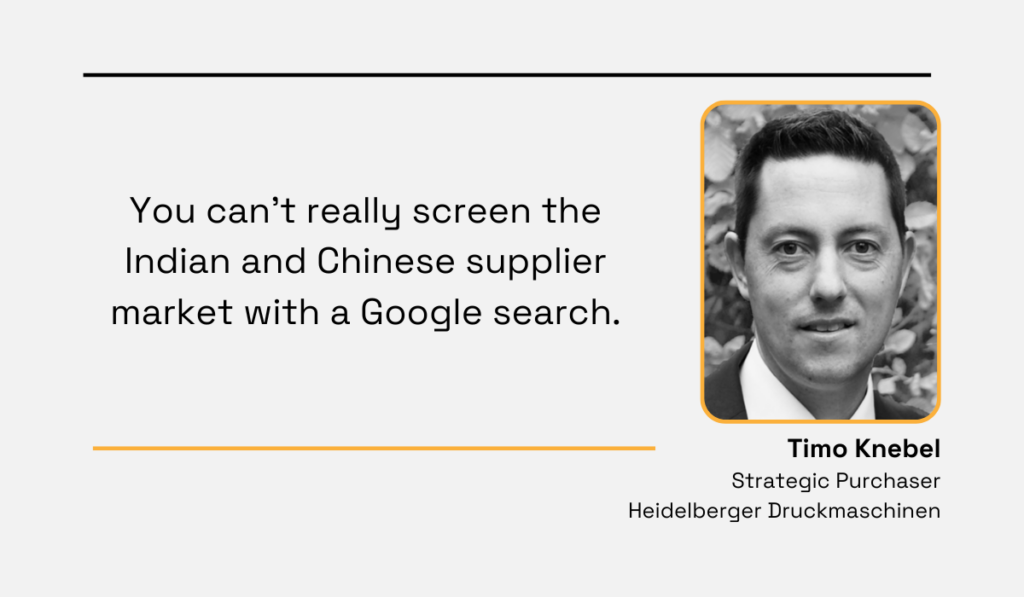

This pursuit, however, presented significant challenges, some of which are shown below:

Source: Veridion

The main problem was sifting through numerous supplier websites in foreign languages, often with questionable credibility and information accuracy.

Identifying reliable suppliers under these conditions is inherently difficult and introduces significant risks, including potential quality issues, communication barriers, and logistical complexities.

Due to these challenges, Timo Knebel, a strategic purchaser at Heidelberger, noted that manual supplier searches were simply not feasible.

Illustration: Veridion / Quote: Procurement Leaders

He further explains that the unreliable information on foreign websites made it unsuitable for informed decision-making.

To address this, Heidelberger turned to Scoutbee’s AI-driven supplier search capabilities.

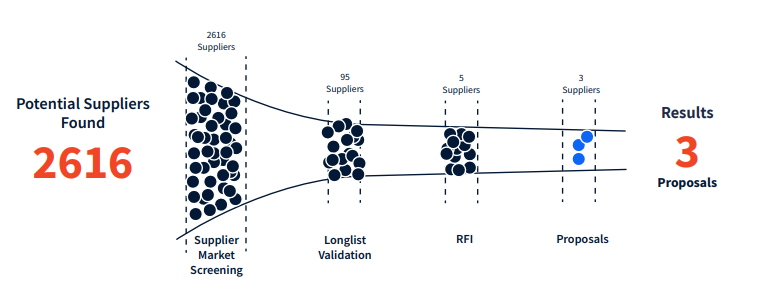

Using Scoutbee, they identified 2,616 potential suppliers in their initial market screening.

And, after a validation and Request for Information (RFI) process, Heidelberger received three promising proposals, all within ten weeks of the initial search.

Source: Procurement Leaders

So, compared to manual supplier sourcing, Scoutbee helped find four times the number of suppliers, with a 50% RFI response rate.

As Knebel points out, Scoutbee enabled them to prequalify these foreign suppliers and focus on the factories with a great enough trust score.

Ultimately, this entire process resulted in 25% cost savings for the company and demonstrates how the right supplier discovery platforms can be essential for breaking into new and foreign markets.

Supplier discovery and management are evolving, and these real examples show just how much impact the right tools and processes can have.

From PepsiCo’s smart sourcing to Nike’s supplier partnerships and Microsoft’s data centralization, we see a common theme: efficiency, adaptability, and innovation.

Hopefully, this article gave you valuable insights into modern procurement strategies and has inspired you to follow by example.