5 Challenges of Implementing Supplier Intelligence

Key Takeaways:

Implementing supplier intelligence into your procurement operations sounds great. But then you start hitting the roadblocks.

Messy data, pushback from teams, and non-cooperative suppliers can stall progress before you even get started.

Yet, without supplier intelligence, you’re flying blind on costs, risks, and performance.

What’s standing in your way?

Let’s break down the five biggest challenges and how to overcome them.

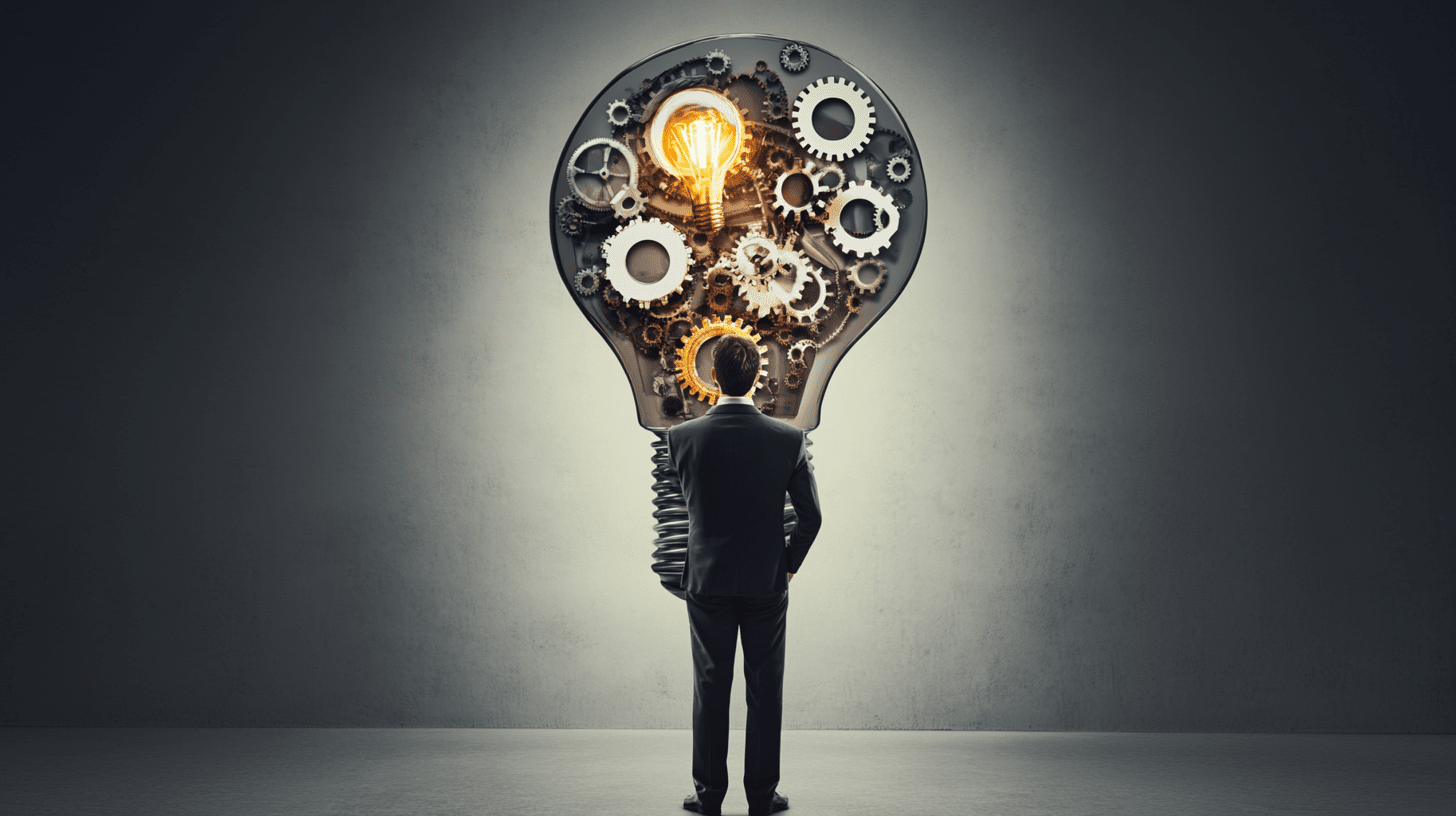

Procurement has a data problem.

That’s what SpendHQ concluded after surveying 181 procurement professionals.

Out of all respondents, only 28% said they trust the data they present to stakeholders.

The rest, roughly three-quarters, said they doubt the accuracy of their procurement data and wouldn’t rely on it to make strategic decisions.

For most, the biggest issue is the inability to refresh their data regularly.

Illustration: Veridion / Data: SpendHQ

Many rely on expired or incomplete data, which only creates more confusion and leads to overly confident, misinformed decisions.

This problem becomes even more evident when you zoom in specifically on supplier data.

Why?

Because many companies still rely on their suppliers to manage and supply their own data, so they ultimately end up with inconsistent, incomplete, and out-of-date information.

This creates further issues for procurement and other stakeholders.

Some of the most challenging ones include:

Some believe the only way to overcome this challenge is by automating supplier data management.

Patrice Tiolet, the organization director and CIO at Groupe Perret, is one of them.

He highlights that supplier data is increasingly sourced from multiple data streams while also facing tighter regulatory oversight.

So, managing supplier data manually may no longer make sense, even for smaller companies.

Illustration: Veridion / Quote: LinkedIn

Automation allows you to trust your data more, streamline procurement, and reduce the risk of errors, all while spending less time on mundane tasks.

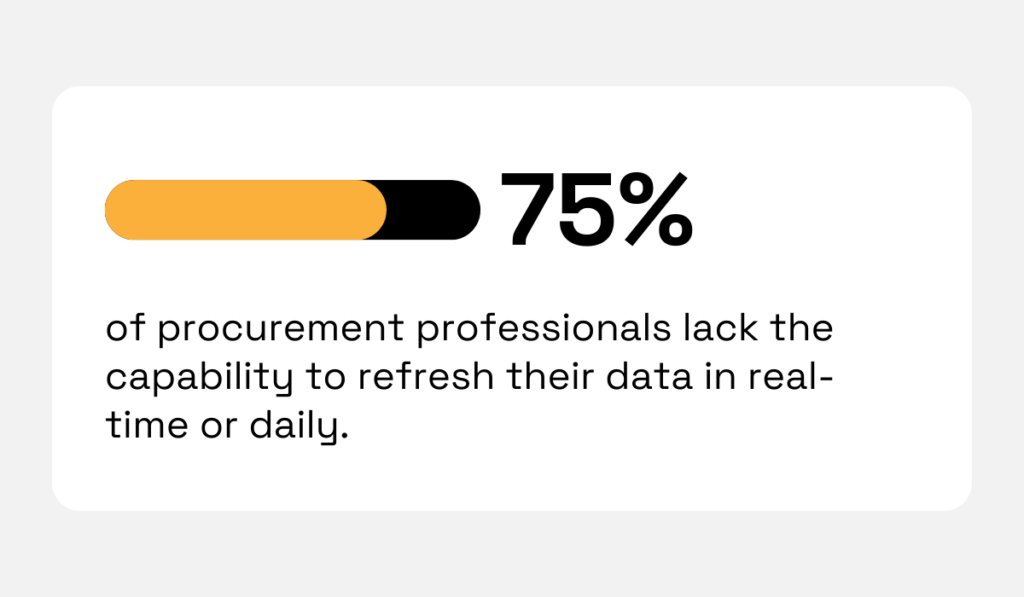

That’s where DaaS (data-as-service) solutions like Veridion come in.

They can automate almost all supplier data management processes, including the most important ones: data quality checks and data integration.

So, instead of relying on suppliers or internal teams to provide and check data, Veridion lets you automate these tasks with data validation and enrichment tools.

Veridion’s supplier data is automatically updated every week, so you can be sure that you’re making all the important decisions based on the freshest, most accurate data.

Source: Veridion

In short, one of the best ways to solve data quality issues is to use solutions that automate data validation and consolidation.

That way, you don’t have to worry about supply chain efficiency or compliance. Both are well taken care of, and often even more effective than when handled manually.

As mentioned, many companies rely on suppliers to self-report or provide their own data.

This is problematic for many reasons, but let’s focus on one of the main ones: the lack of consistency.

Think about it:

If suppliers are the ones providing their own data, chances are that they’re using different systems, file formats, and reporting structures to do so.

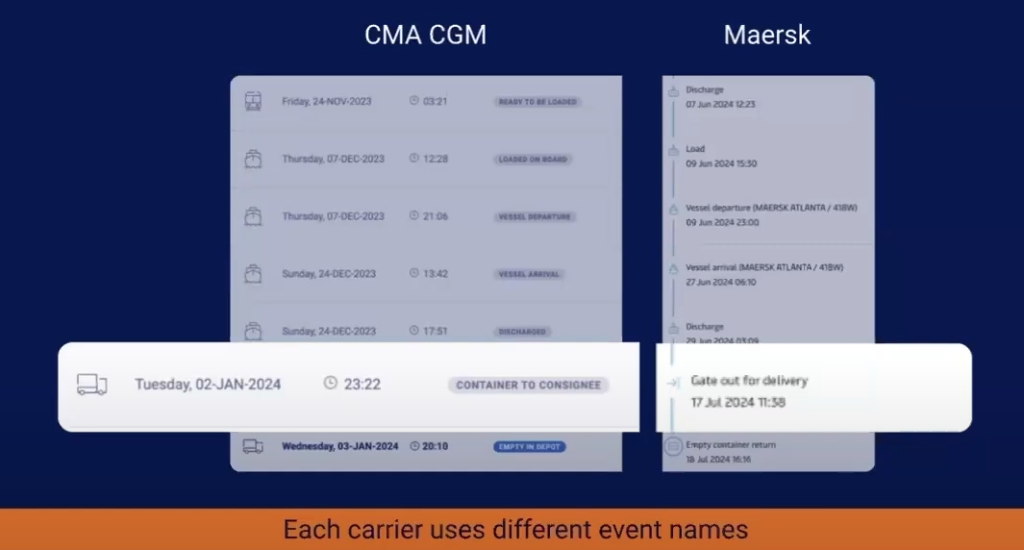

Take a look at the example below, where two carriers use different event names to describe the same event:

Source: Windward on YouTube

Simply put, without standardization, it becomes difficult to ensure consistency across all data sets.

This means you can’t easily analyze your supplier base, compare suppliers, or gain any kind of actionable insights.

But here’s the real irony: though many companies rely on non-standardized data, most are well aware that this exposes them to risks.

A Tealbook survey confirms this.

It has revealed that a staggering 93% of procurement and supply chain leaders had experienced the adverse effects of misinformation about their suppliers first-hand.

Yet, leaders like Matt Palackdharry, Founder of the SaaS startup consultancy Kinetic Talents, know that supplier data is essential for effective procurement.

Illustration: Veridion / Quote: TealBook

So, how can companies resolve this discrepancy: understanding the importance of accurate, standardized supplier data, yet still relying on inconsistent and fragmented information that exposes them to significant risks?

The solution would be for companies to either stop relying on suppliers to report their own data or at least ensure they can standardize the data themselves more easily.

This means establishing clear data reporting guidelines that all suppliers should adhere to and using standardized reporting formats.

One way to go about it is to provide suppliers with fillable templates.

This will ensure that the same data is always found in the same places, making it easier to process by both humans and machines.

Alternatively, you can use advanced analytics tools that normalize and consolidate data across multiple sources.

That way, your data is comparable, actionable, and actually helps you make better decisions.

Finding the right supplier intelligence tools can be difficult.

But getting the intended users to actually use them or leverage them to their full potential?

That’s often even more challenging.

There are many reasons why employees are resistant to new tools.

Some fear they could lose their jobs to technology.

Others feel they don’t have an adequate understanding of the tools or haven’t received proper training that would allow them to use them.

And some believe that new technology will only add more tasks to their never-ending to-do lists and see more disadvantages than benefits.

So many reasons not to adopt new tech, right?

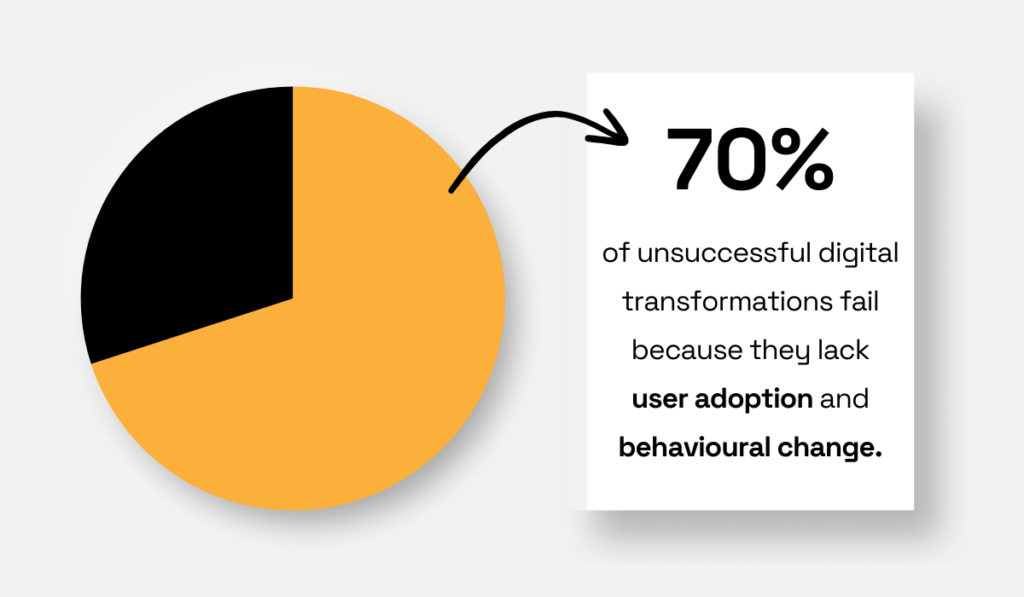

It’s no wonder, then, that the majority of digital transformations that don’t generate adequate ROI fail because of adoption-related issues.

Illustration: Veridion / Data: PwC

Without user buy-in, even the most advanced supplier intelligence systems will fail.

If employees do not adapt to the change, organizations risk investing in tools that end up underutilized and only wasting resources.

One SaaS report, for example, estimates that companies don’t use over 52% of software licenses they purchase.

The result is an annual waste of $20.9 million across companies of all sizes.

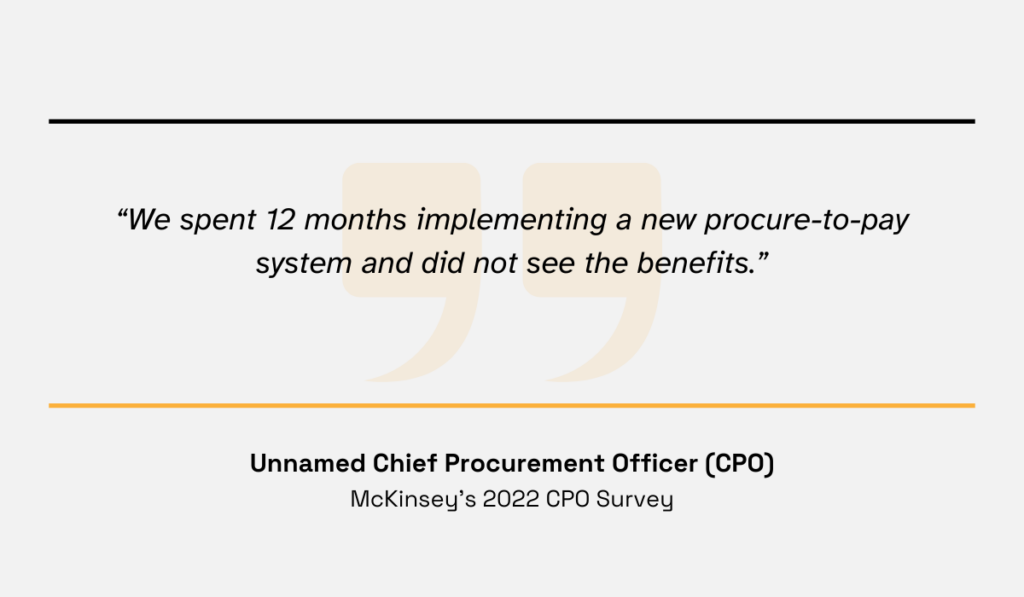

McKinsey’s 2022 CPO Survey also revealed that many CPOs are not happy with their digitization efforts.

Some CPOs have shared stories of painful software rollouts with minimal ROI:

Illustration: Veridion / Quote: McKinsey

To put it simply, system underutilization takes you back to square one:

Your team will still evaluate suppliers and manage risk inefficiently, mainly by relying on supplier self-reports and manual checks.

To avoid this scenario, procurement teams should couple new supplier intelligence tools with structured employee training programs.

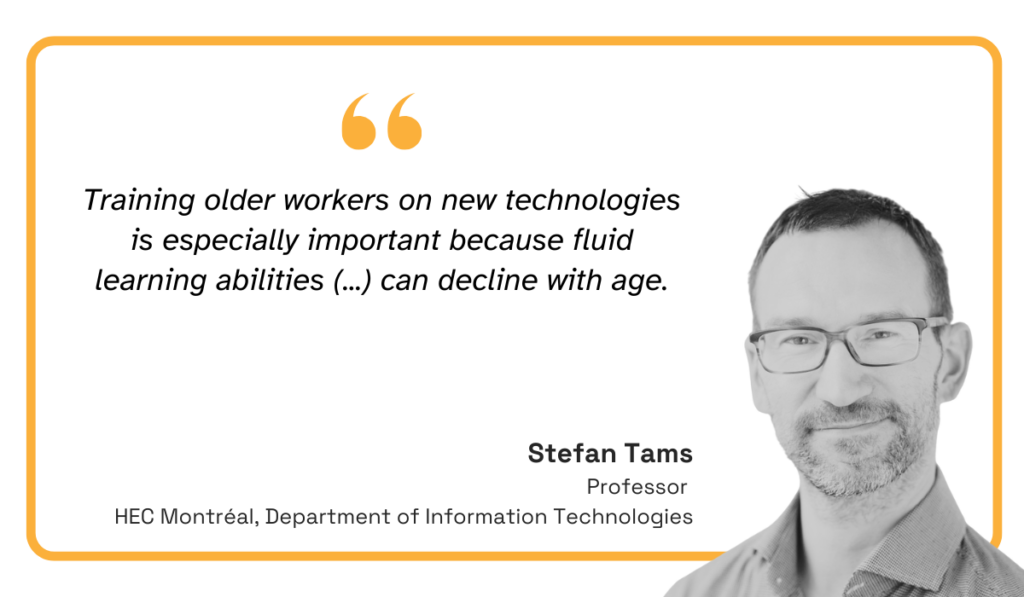

Though group training is a good start, you should also consider that different employees have different skill sets and needs.

Some may require more instructions than others, and this can especially be the case for older team members.

As the professor at HEC Montréal’s Department of Information Technologies, Stefan Tams, explains, we become less able to pick up new skills without prior context as we get older.

Illustration: Veridion / Quote: CIO Dive

In any case, it is important to adopt a user-centric mindset.

Think about what type of training your team members would benefit from the most.

How hands-on or theoretical should it be? Should you also support them after the tool goes live? If so, how?

And how can leadership encourage them to adopt new processes?

Answering these questions is the first step to successful, large-scale adoption.

Perhaps you might feel that internal buy-in is not the main challenge, especially when the real roadblocks stem from working with suppliers.

So, let us acknowledge that, indeed, supplier cooperation—or lack thereof—can present another obstacle to getting and implementing supplier intelligence in your operations.

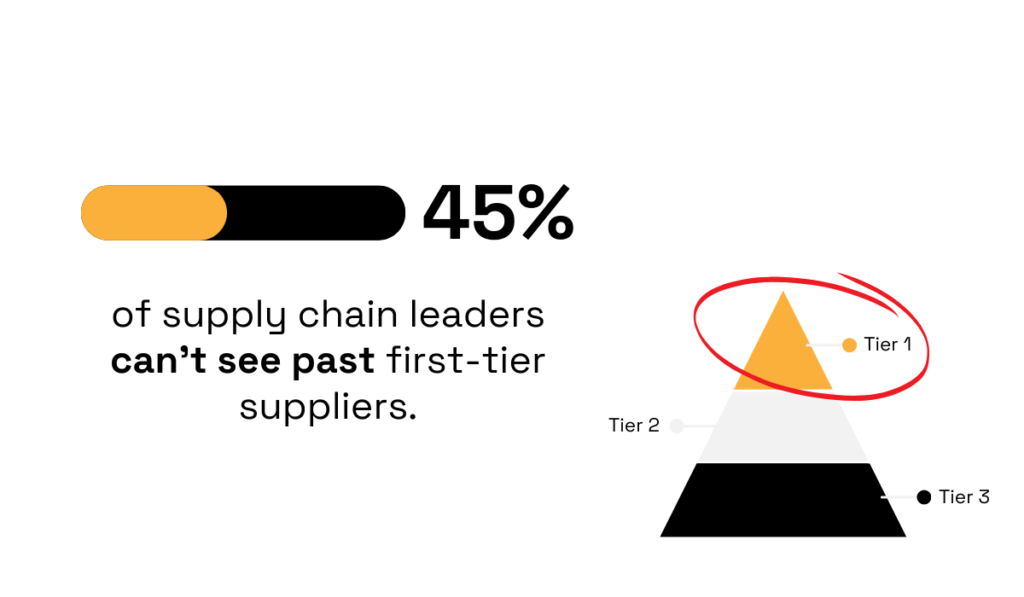

McKinsey’s 2022 survey shows that 45% of supply chain leaders have little to no visibility into their upstream supply chain or can’t see beyond first-tier suppliers.

And, in many cases, this is caused by a lack of supplier collaboration.

Illustration: Veridion / Data: McKinsey

Suppliers may avoid actively sharing their data with you for various reasons:

Some see it as just one more thing to do, but of lower priority than internally-requested tasks.

Others are reluctant to share performance metrics, pricing, and other sensitive information due to concerns about transparency or competitive advantage.

Then there’s also the possibility that some of them are hiding something they don’t want you to know about.

In such cases, you aren’t just risking supply chain disruptions and delays.

You’re also exposing yourself to potential reputational damage, legal and compliance issues, and, ultimately, financial losses.

Take Uniqlo, a Fast Retailing-owned brand, as an example.

In 2021, customs seized their shipment of cotton shirts because they failed to provide “clear and convincing evidence” that there was no forced labor involved in the production.

Source: Business Insider

The company presented certificates of origin for the items, but CBP did not accept this as sufficient proof.

Fast Retailing later clarified that CBP didn’t find any proof of forced labor in their supply chain.

But the burden of proof wasn’t on CBP.

It was on the company, and they didn’t have sufficient supplier data to prove otherwise.

The lesson?

Your company is solely responsible for verifying sourcing practices and having the data to back up your claims.

So, to avoid internal, legal, and reputational issues, you must have visibility over your suppliers.

Get them to cooperate by building strong relationships based on trust.

Clear expectations, proactive communication, and mutually beneficial incentives will encourage transparency.

Try to emphasize the benefits of actively sharing data and improving collaboration, especially better forecasting and reduced risks for both sides.

Implementing supplier intelligence requires significant investment in software, integration, and employee training.

And many procurement teams struggle to justify these costs to stakeholders.

Some fail to present the benefits of implementation. Others deal with leadership burned by previous bad experiences, especially budget overruns.

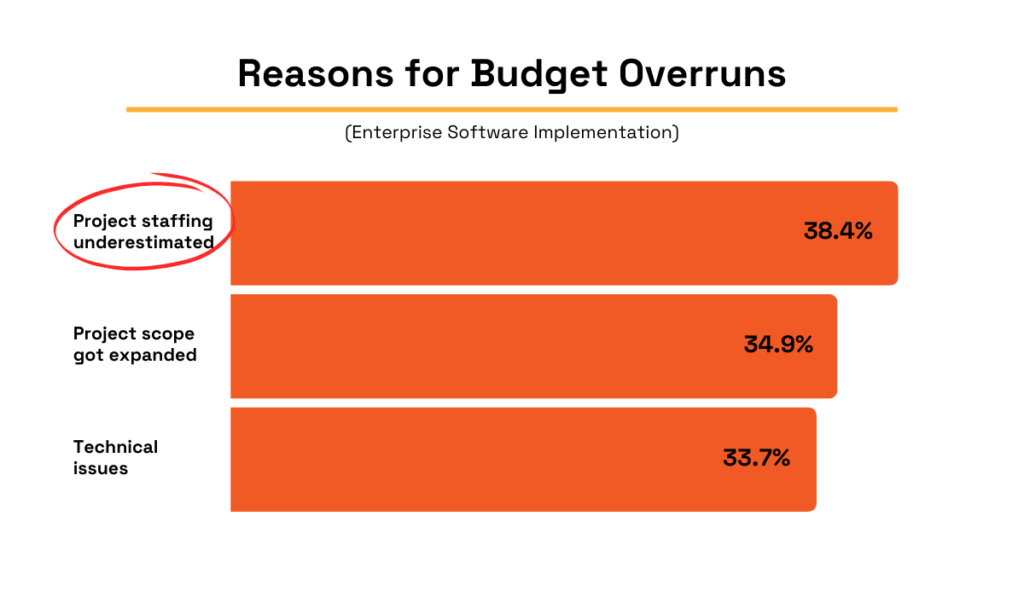

The 2023 ERP Report illustrates just how often software implementation exceeds budgets, with 47% of enterprises reporting they had previously experienced budget overruns.

Most commonly, budgets blow up because companies underestimate the necessary internal resources, ignore scope creep, and don’t plan for hidden technical complexities.

Illustration: Veridion / Data: Panorama Consulting Group

So, after a series of similar experiences, it’s not surprising that leadership often becomes more wary of implementing new solutions.

Budget overruns are not the only culprit, though.

Poor cost assessments can also lead to choosing less effective solutions that don’t fully support procurement goals and, therefore, yield low ROI.

They can also cause teams to abandon projects mid-way, after they realize the full cost of implementation.

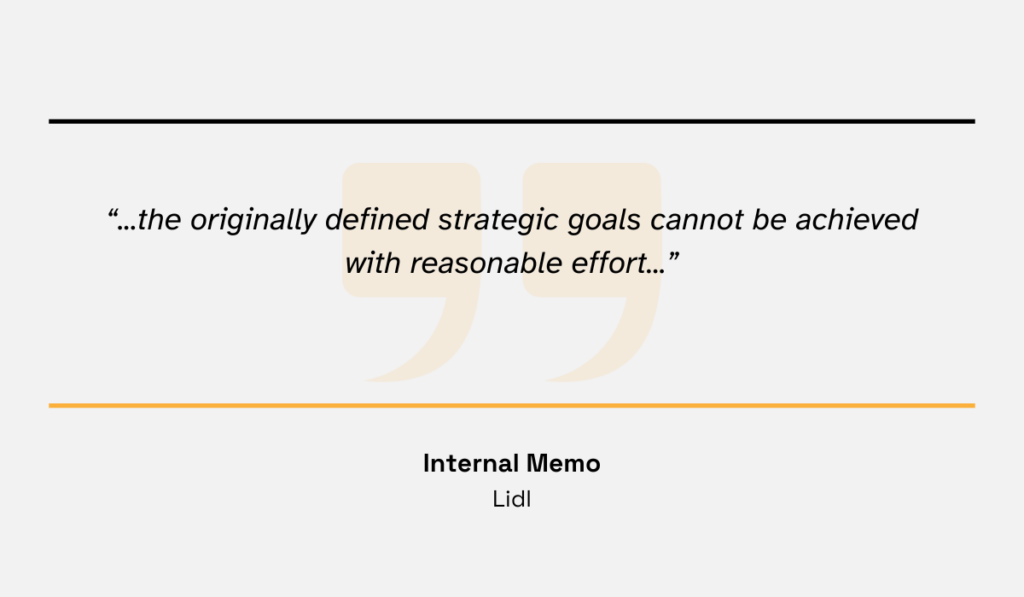

This happens even to those with the deepest of pockets.

Lidl, for example, pulled the plug on a €500M SAP project after already sinking millions into it, upon realizing they’d need to spend even more to make it work.

Illustration: Veridion / Quote: Henrico Dolfing

So, don’t underestimate the impact of proper cost planning.

Without it, you risk paying unnecessarily high costs with little to no benefits.

The first step is conducting a thorough cost-benefit analysis.

First, consider the full cost of implementation, not just software costs.

Integration, data cleaning, and user training are often what push projects over budget.

When it comes to the benefits, start by considering all appropriate use cases and pinpoint the ones most valuable to your company.

However, even after a comprehensive analysis, you may still not have the full picture of the potential costs.

Many of them become clear only after you begin implementation.

So, consider coupling thorough analyses with a phased implementation approach.

This will help you understand the software and the necessary requirements better, demonstrate early value, and justify the investment to leadership before fully committing to potentially unsuitable software.

No major change comes without challenges, and implementing supplier intelligence is no different.

But with the right approach, you can overcome these obstacles and build a more efficient, data-driven procurement process.

Now that you know which challenges to watch out for, you have everything you need to eliminate, or at least minimize them in advance.

Focus on improving data quality, aligning internal teams, and planning ahead, and you’ll be on the right track to making supplier intelligence a valuable asset in your procurement strategy.

Small, steady improvements are the way to go!