Supplier Location Intelligence: Why It Matters

Key Takeaways:

Most supplier intelligence discussions and applications focus on cost, quality, and risk, leaving location data overlooked.

However, knowing exactly where suppliers operate unlocks valuable insights that can reshape your decision-making, strengthen compliance, and more.

From managing disruptions to aligning with ESG goals, supplier location intelligence enhances nearly every aspect of supply chain management.

In this article, we’ll break down why it matters and how it can deliver results.

Supplier location intelligence plays a critical role in creating cost-efficient and resilient logistics operations.

Businesses need access to up-to-date, granular information about all operational, warehouse, and production sites tied to their suppliers, and not just head offices.

This way, they can significantly improve route planning, reduce delivery times, and lower transportation costs.

Knowing supplier location intelligence contributes to cost and time efficiency.

This is particularly important in a global supply environment where unpredictability is constant.

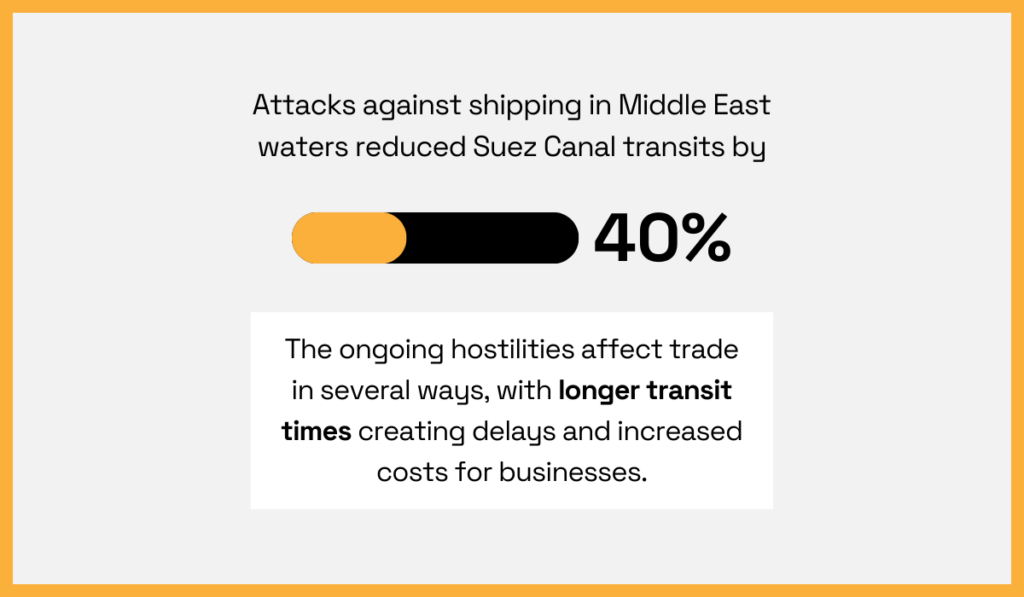

For example, in early 2024, security threats in Middle Eastern waters caused a severe drop in Suez Canal transits, with some estimations citing a 40% drop in traffic.

Illustration: Veridion / Data: Allianz Commercial

As a result, many companies were forced to divert ships via the Cape of Good Hope, adding over 3,000 nautical miles (5,500 km) and roughly 10 days to delivery times.

The Suez Canal situation is yet to be fully resolved, but it serves to highlight a broader point: companies need to maintain real-time awareness of supplier locations and regional risks.

Otherwise, they risk missing critical route adjustments entirely.

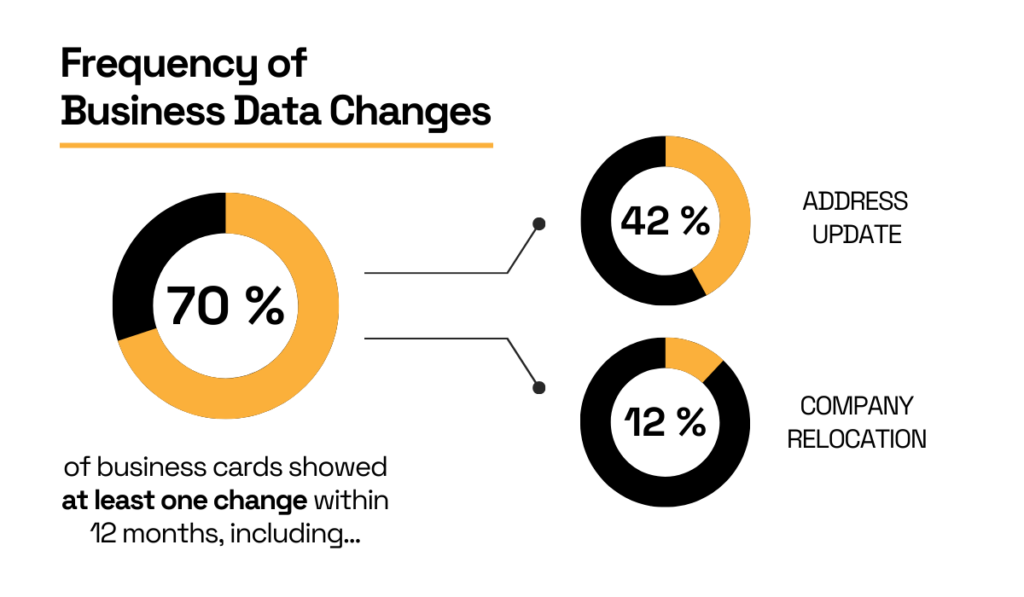

And while major incidents draw attention, quieter location changes happen far more often than most businesses realize.

According to Industry Select, roughly 70% of business professionals across multiple industries reported one or more location-related changes on their business cards in a single year.

Illustration: Veridion / Data: Industry Select

Without regular data updates, supply chains risk relying on outdated routes or failing to spot better regional alternatives—both of which can lead to:

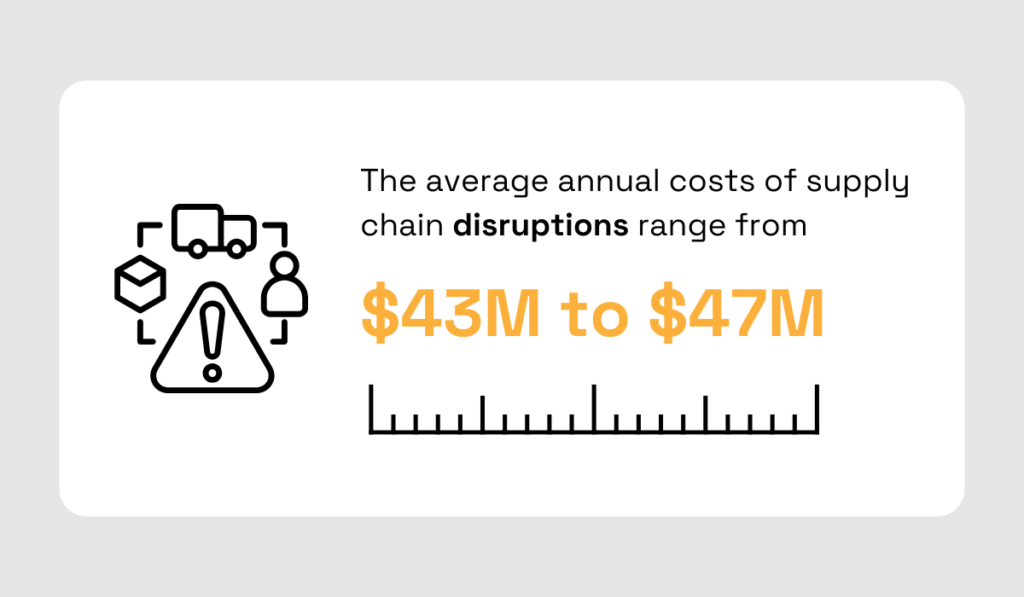

The costs of such disruption are considerable, with the average annual amount ranging from $43 to $47 million.

Illustration: Veridion / Data: Interos

Fortunately, having precise supplier location data mitigates these risks in several ways outlined below:

| Accurate lead time predictions | Knowing exact supplier locations enables more precise estimations of delivery times based on distance and regional logistics conditions. |

| Optimized multi-stop and consolidation planning | Understanding suppliers’ proximity to each other and distribution centers supports more efficient route planning. |

| Dynamic rerouting around disruptions | Supplier location intelligence helps supply chain systems quickly identify alternative routes in case of disruptions. |

Ultimately, supplier location intelligence strengthens logistics efficiency by turning static supply routes into dynamic, responsive networks that protect organizations while keeping customers satisfied.

Supplier location intelligence is essential for identifying and managing location-specific risks that could disrupt supply chains.

Without full visibility into where suppliers operate, companies risk being caught off guard by natural disasters, political instability, infrastructural issues, or regulatory changes affecting specific regions.

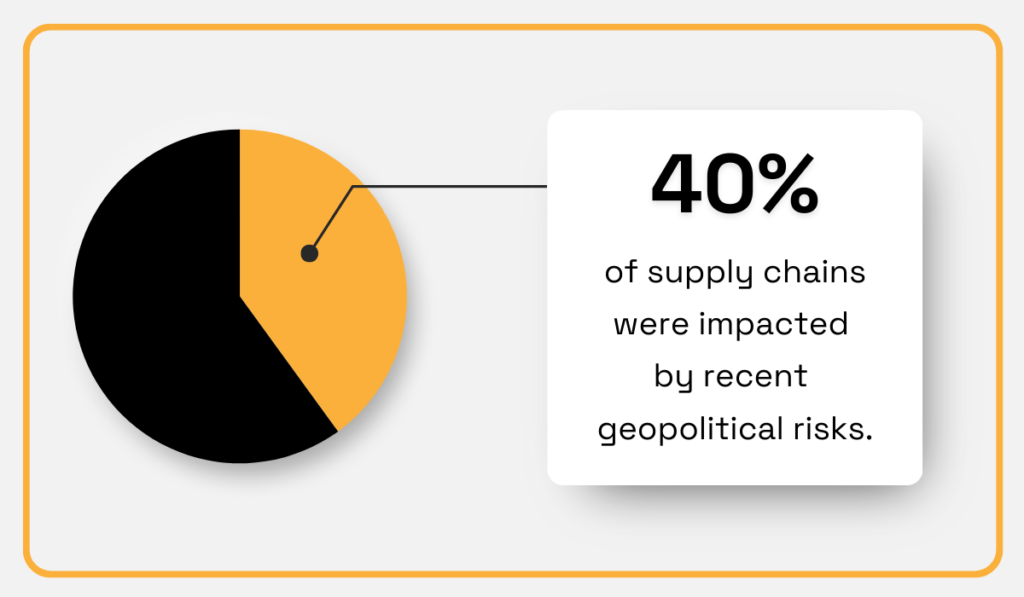

The risk landscape is continuously evolving, with recent data from Gartner showing that 40% of supply chains were impacted by geopolitical risks alone.

Illustration: Veridion / Data: Gartner

While 60% of survey respondents either met their performance expectations or exceeded them, more than a few were caught off guard.

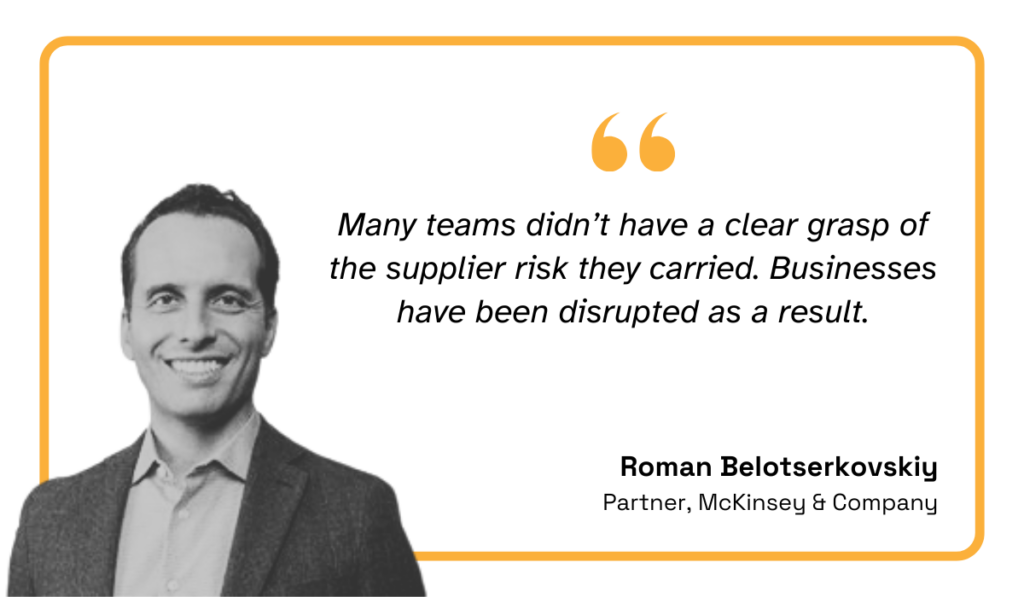

Roman Belotserkovskiy, one of McKinsey & Company’s partners, notes that, in many cases, relying on long-standing partnerships meant lacking awareness of the supplier risks.

Illustration: Veridion / Quote: Economist Impact

In other words, organizations need to do a much better job of understanding and measuring supplier risk to build resilient supply chains.

Some of the key strategies for achieving this include shifting to localized sourcing and investing in vigilant third-party risk management and advanced analytics.

Source: Veridion

Knowing the precise location of every supplier facility is a big part of this because it allows procurement and risk teams to monitor region-specific threats in real time and act early.

Companies increasingly recognize that supply chain resilience requires a different approach rooted in leveraging fresh supplier data.

Supplier location intelligence supports faster, better-informed decisions, whether it’s rerouting shipments, securing backup suppliers, or adjusting inventory buffers.

As Gartner’s Chris Audet sums it up, it’s time for businesses to move away from one-off supplier checks and embrace iterative and ongoing supplier risk monitoring.

Illustration: Veridion / Quote: Gartner

Ultimately, supplier location intelligence is a critical enabler of this shift.

It allows businesses to map exposures, prioritize stable regions, and build risk mitigation strategies that adapt to changing conditions.

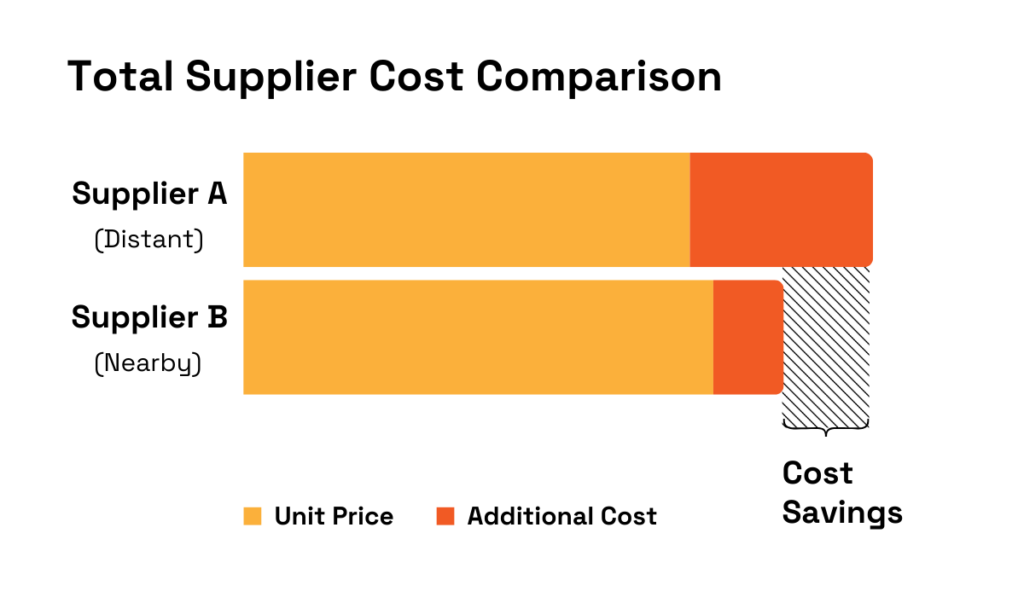

Supplier location intelligence directly enhances cost analysis by providing the granular data you need to uncover the true, end-to-end cost of sourcing decisions.

Procurement teams must account for much more than suppliers’ unit price, from local duties and transportation fees to delivery lead times, all of which can vary significantly based on location.

This has become especially important in today’s environment of sustained price volatility.

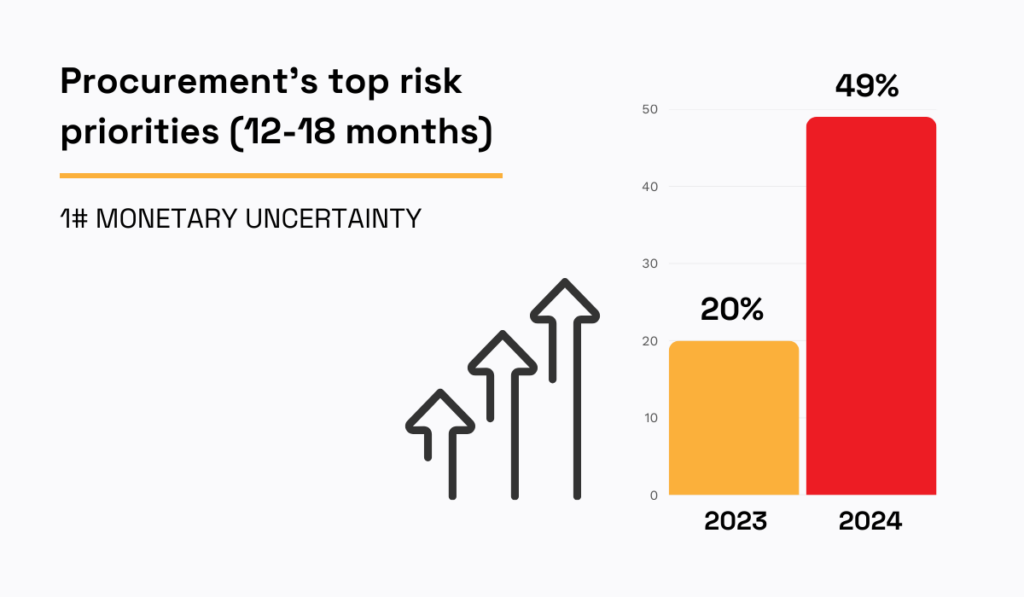

A recent Economist Impact study revealed that monetary uncertainty emerged as procurement’s top organizational risk over the next 12–18 months.

Illustration: Veridion / Data: Economist Impact

This is more than double the previous year’s figure, and it reflects a lasting shift in relative prices for critical commodities and services.

As Raquel Pittella Cancado, CPO of Arcelor Mittal Brasil, explains, the challenge is no longer about inflation itself but understanding new, long-term pricing patterns that directly shape sourcing strategy and competitiveness.

Illustration: Veridion / Quote: Economist Impact

In this context, supplier location intelligence plays a crucial, often overlooked role in strengthening cost analysis.

Mapping detailed supplier locations allows your organization to factor in variables beyond the supplier’s quoted price, such as:

These hidden or fluctuating costs can materially affect margins, especially in contexts where trade routes are disrupted or political flare-ups lead to increased costs.

For example, a supplier offering the lowest per-unit cost might ultimately be more expensive once port fees, last-mile delivery rates, or cross-border duties are considered.

Source: Veridion

Having accurate, location-specific data enables procurement teams to calculate total landed costs while highlighting opportunities for regional consolidation or nearshoring.

To put it differently, supplier location insights can reduce exposure to currency fluctuations and volatile freight rates by revealing the true cost behind every transaction.

Instead of relying on fixed assumptions, your procurement team gains a clearer understanding of the operational realities attached to each location, which helps elevate sourcing from price-chasing to strategic cost control.

Relying on supplier location intelligence helps businesses track sourcing regulations, trade restrictions, and sustainability reporting at a granular, location-specific level.

Maintaining regulatory compliance requires insight into all locations where your suppliers operate.

If your organization only knows about registered HQ and main facilities, you’re at risk of unknowingly breaching legal and ethical standards.

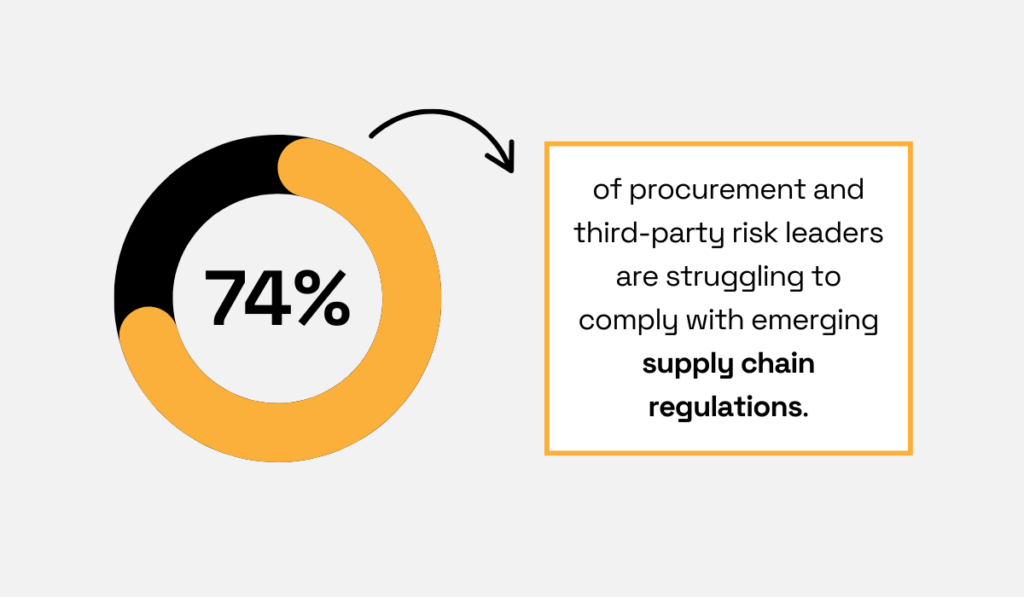

And this isn’t a niche problem either.

According to Interos, 74% of procurement and third-party risk leaders are currently struggling to keep up with emerging supply chain regulations.

Illustration: Veridion / Data: Interos

This level of insight is especially critical when dealing with high-risk regions like China’s Xinjiang province, where forced labor concerns continue to draw international scrutiny.

Just like the previous year, the U.S. Department of Homeland Security has expanded the Uyghur Forced Labor Prevention Act (UFLPA) Entity List, leading to broader detentions of shipments that are linked to the region.

Source: Politico

But of course, organizations need to be vigilant about more than just labor rights, with regulatory compliance spanning environmental, financial, and geopolitical restrictions as well.

Having verified, up-to-date location data helps businesses quickly identify suppliers operating in restricted or sensitive areas, ensuring they stay ahead of potential violations.

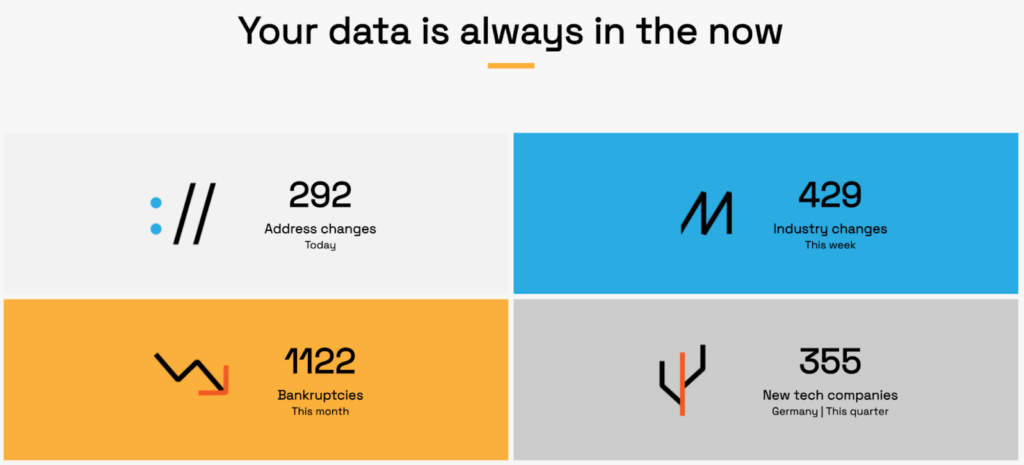

This is where Veridion stands out.

As one of the leading platforms for supplier intelligence, Veridion delivers real-time access to:

This vast database, covering nearly 130 million suppliers globally, ensures that every operational change is captured and made immediately available to you.

Source: Veridion

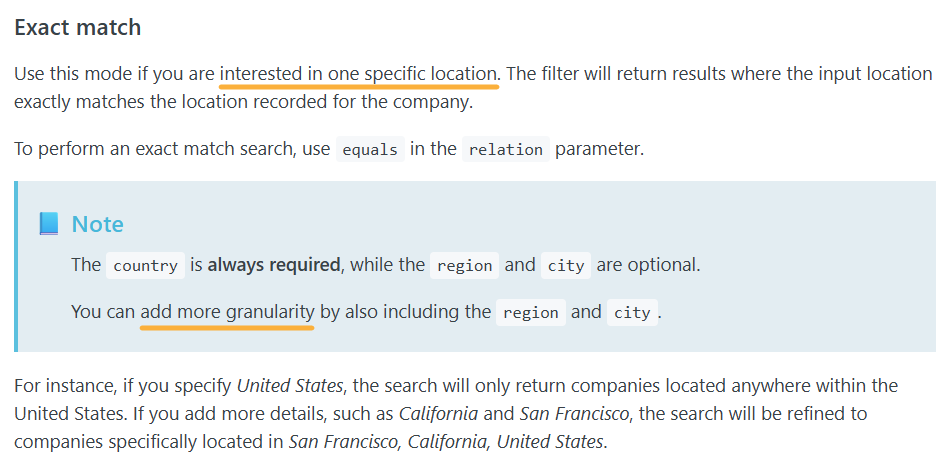

Teams can explore this global, weekly updated database using our search engine Scout or by integrating search functions into their procurement tools via APIs.

For example, your team can use the company location filter that narrows search results to precise geographic areas, down to the city level.

It also identifies secondary locations such as warehouses, branch offices, and manufacturing sites.

Source: Veridion

Most importantly, Veridion distinguishes each address by type, so businesses know whether it’s a corporate HQ, a production site, or a third-party fulfillment center.

This level of data precision allows organizations to confidently verify supplier operations, meet evolving regulatory demands, and proactively manage compliance risk across their entire supply base.

In short, accurate, location-level supplier data will do more than strengthen your regulatory compliance—it refines your control over your entire supplier management strategy.

Supplier location intelligence is becoming a vital tool for advancing corporate sustainability goals.

It’s simple: knowing all about your suppliers and their facilities enables businesses to more accurately evaluate environmental and social impacts across their entire supply chain.

Right now, unreliable supplier data ranks among the top five procurement challenges, with 17.6% of procurement leaders recognizing it as such.

Illustration: Veridion / Data: Tealbook

Although Tealbook’s report doesn’t go into specifics, ESG data remains one of the hardest to access and verify.

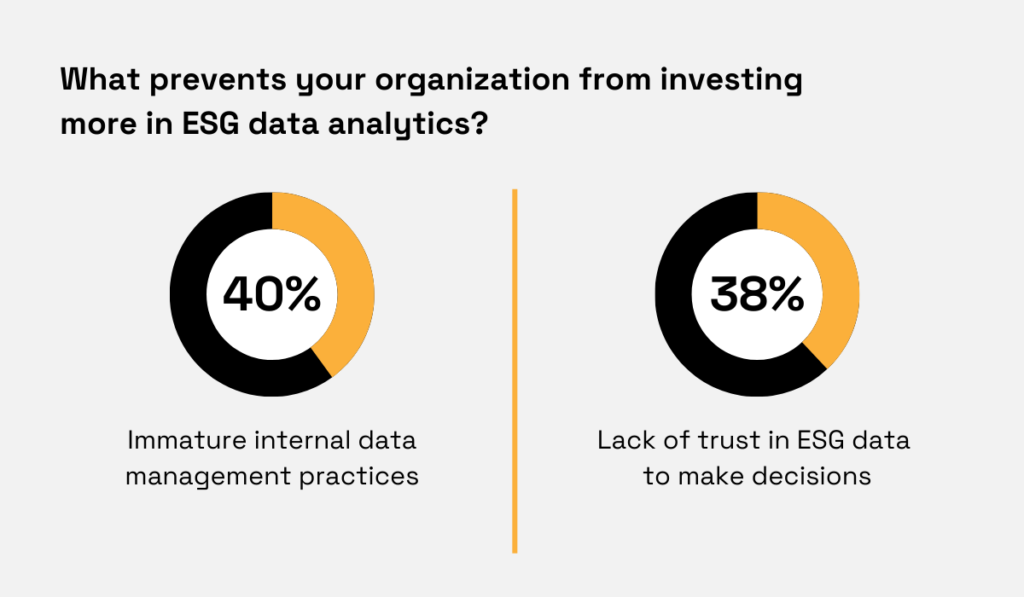

This is backed by a 2022 Dun & Bradstreet research, which highlights that 40% of organizations hesitate to invest further in ESG data analytics due to weak internal data management, while 38% cite a lack of trust in ESG data for decision-making.

Illustration: Veridion / Data: D&B

It’s clear that the existing challenges undermine both ESG reporting integrity and the execution of the entire sustainability strategy.

So, how does location intelligence figure into all this?

Priyanka Sud, Chief Manager of Sustainability at Siemens Limited, emphasizes the need to look beyond direct suppliers to understand the full ESG impact.

Illustration: Veridion / Quote: LinkedIn

As a result, understanding and navigating these complexities becomes paramount, and doing so is much easier with supplier location intelligence.

Knowing where your suppliers operate and how those locations influence your sustainability footprint enables procurement and sustainability teams to:

This is particularly valuable for spotting high-risk locations tied to unethical labor practices, heavy emissions, or poor environmental oversight.

However, the benefits go beyond risk detection.

Location data supports supplier development initiatives by creating a practical foundation for aligning your supplier base with ESG frameworks like GHG Protocol Scope 3, as well as ongoing performance tracking.

In short, location intelligence turns ESG goals from theory into actionable, measurable outcomes, which in turn helps you close the gap between commitments and actual impact.

Organizations that know precisely where suppliers store, manufacture, or dispatch goods are in a better position to align supply with market demand, reduce overstock, and avoid costly delays.

Granular supplier location data is a powerful asset for improving demand forecasting accuracy, even more so in volatile, fast-moving markets.

Therefore, firms need to carefully analyze their specific needs and circumstances when choosing suppliers.

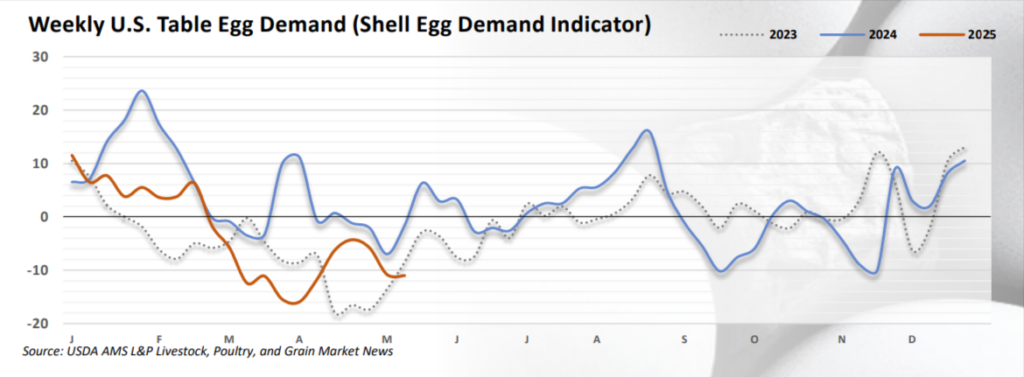

Consider the recent fluctuations in U.S. egg prices.

After months of surging demand, rapid changes in both supply availability and regional logistics led to a sudden price drop.

Source: USDA

In situations like this, businesses equipped with accurate, real-time supplier location data are far better positioned to pivot, identify alternate sourcing options nearby, and reroute supply chains before competitors react.

It’s a clear reminder that market movements aren’t just about volume—they’re also about where stock is stored and how quickly it can reach critical markets.

Tim Warner, VP of Insights and Analytics at PepsiCo, notes that today’s supply chains demand far more than traditional insights provide.

Illustration: Veridion / Quote: Financial Times

Incorporating location intelligence into demand planning models closes that gap.

By analyzing both historical and live location data, your team can spot regional demand patterns, anticipate trends, and make proactive inventory adjustments.

And if a particular area shows signs of a seasonal sales spike, they can coordinate with nearby suppliers and distribution hubs to prepare.

Of course, not every surge can be predicted.

Viral marketing campaigns and unexpected trends, like the TikTok feta cheese recipe that sparked a nationwide shortage, will inevitably catch businesses off guard.

Source: Fox 5 New York

The sudden surge in demand left many suppliers out of stock.

Saxelby Cheesemongers’ co-owner Anne Saxelby recalled that their distributor couldn’t fulfill the order and, to add insult to injury, simply forwarded them the viral video behind the shortage.

Illustration: Veridion / Quote: Fox 5 New York

Businesses with access to detailed supplier location data could have quickly identified nearby alternatives, rerouted deliveries, and mobilized backup inventory to keep up.

The bottom line is this: location intelligence helps supply chains stay nimble in day-to-day operations and recover faster in the face of unpredictable demand.

Ready to make location data part of your operations?

Nowadays, there’s no talking about modern supply chains without addressing resilience, just as there’s no market landscape without volatility.

In these fixed, yet ever-changing circumstances, reliable real-time data is one of your most valuable assets.

Supplier location intelligence gives your organization the visibility you need to navigate disruptions, meet regulatory demands, and plan with greater confidence.

Explore what location data can do for your business, and integrate it into your supplier management strategy today—you’ll boost efficiency and have fewer blind spots while gaining a competitive edge over your peers.