5 Challenges of Supplier Onboarding and How to Overcome Them

Key Takeaways:

Supplier onboarding should be the start of a strong relationship, not a frustrating bottleneck.

Yet for many organizations, it’s exactly that.

Disconnected teams and systems, manual steps, and inconsistent data all drag out the process and create unnecessary risks.

In this article, we’ll explore five common supplier onboarding challenges and, more importantly, how you can solve them.

One of the main reasons supplier onboarding becomes lengthy and inefficient is fragmentation.

In many organizations, key departments—procurement, legal, finance, and compliance—manage onboarding independently, each using their own tools, timelines, and requirements.

Due to this, information often ends up scattered across spreadsheets, emails, and shared folders, while coordination between teams and management approvals is slow.

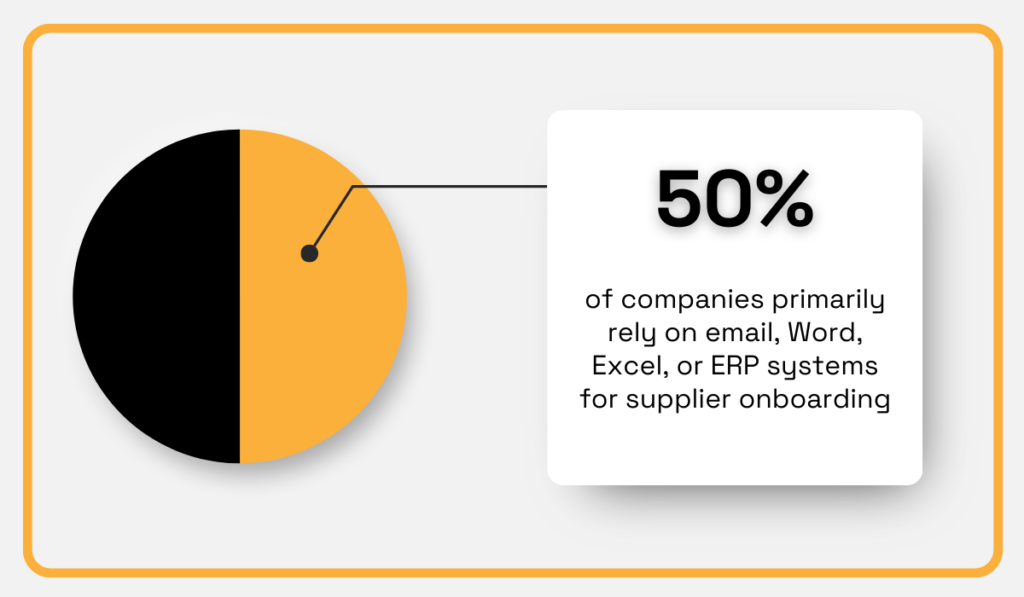

According to a recent study by The Hackett Group, at least 50% of companies still rely on email, Excel, Word, or ERP systems to manage supplier onboarding, highlighting just how common this issue is.

Illustration: Veridion / Data: HICX

Because these systems and workflows are rarely integrated, miscommunication, delays, and lost information quickly become the norm.

Manual steps only make the problem worse.

When teams have to chase down documents over email or manually update supplier records, it slows the process and increases the risk of errors.

Weeks can pass before a vendor is fully onboarded.

By then, procurement deadlines may be missed, supply chain operations disrupted, and critical projects delayed.

Anders Lillevik, CEO of Focal Point, highlights how manual processes further contaminate fragmented onboarding efforts:

Illustration: Veridion / Quote: LinkedIn

To address these issues, organizations need to standardize and streamline their supplier onboarding processes.

A good starting point is to develop a unified onboarding framework—one that clearly defines the steps, documentation, and approvals required across all departments.

Forming a cross-functional team to align expectations and reduce back-and-forth is just as critical.

This team can help establish consistent selection and onboarding criteria, avoid duplicated efforts, and ensure smoother coordination between legal, finance, procurement, and compliance.

To clarify roles and further reduce delays, many organizations use a RACI matrix—a simple tool that defines who is Responsible, Accountable, Consulted, and Informed at each step of the process.

Here’s an example tailored to supplier onboarding:

| Onboarding Step | Procurement | Legal | Finance | Compliance | IT |

| Define supplier requirements | R | C | C | C | I |

| Identify and evaluate supplier | R | C | C | C | I |

| Select supplier and request documentation | R | I | I | C | I |

| Review and approve legal documents/contracts | C | A/R | I | C | I |

| Validate tax, bank, and financial information | C | I | A/R | I | I |

| Perform compliance checks (sanctions, ESG, etc.) | I | C | I | A/R | I |

| Set up supplier in ERP and procurement systems | C | I | C | I | A/R |

| Communicate onboarding completion to supplier | A/R | I | I | I | C |

Of course, this is just a generic example—your supplier onboarding RACI should be tailored to your company’s structure, workflows, and risk profile.

The key to preventing fragmentation is ensuring that every stakeholder understands their role, has access to the right information, and communicates openly across teams.

While fragmentation—caused by poor coordination, data silos, and manual processes—is a major challenge on its own, it’s often compounded by the other onboarding issues we’ll explore.

Poor-quality supplier data remains one of the most persistent barriers to efficient onboarding.

Inaccurate, outdated, or incomplete records delay evaluations and approvals, introduce compliance risks, and often create unnecessary back-and-forth between internal teams and vendors.

Much of this stems from manual data entry, the absence of real-time verification, and overreliance on self-reported information—all of which compromise data accuracy from the start.

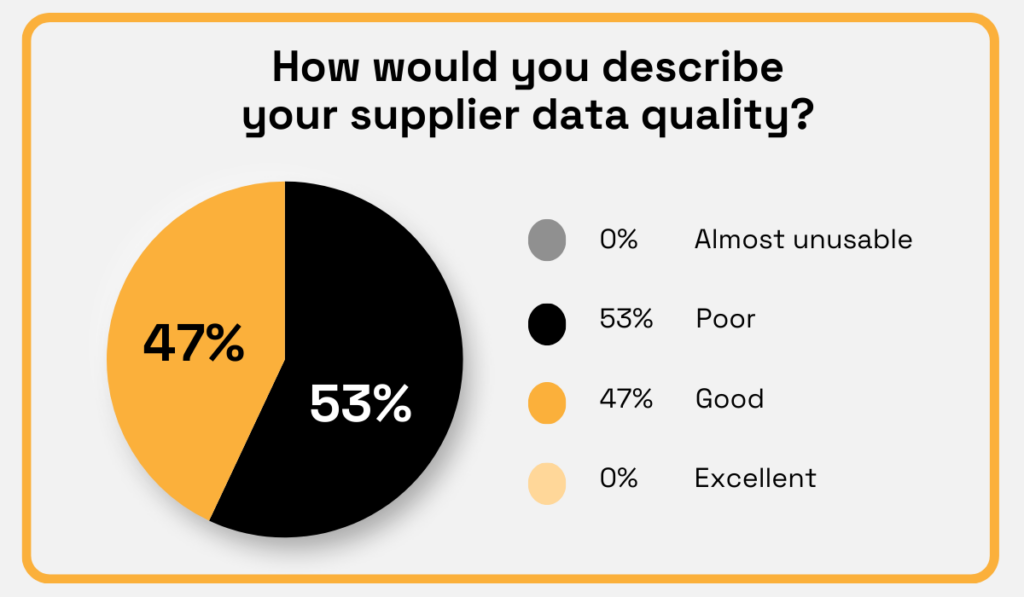

A 2025 TealBook survey underscores the scale of the issue.

53% of procurement professionals rate their supplier data as poor, and none consider it excellent.

Illustration: Veridion / Data: TealBook

But the impact of poor supplier data goes far beyond administrative delays.

Misinformation can result in onboarding high-risk vendors, overlooking compliance requirements, or misallocating critical resources.

Omera Khan, Professor of Supply Chain Management at the University of London, notes that too few organizations recognize the actual cost of incomplete, outdated, or low-quality supplier data.

She continues:

Illustration: Veridion / Quote: HICX

And these vulnerabilities can be effectively mitigated during onboarding, when understood broadly to include supplier discovery, evaluation, and selection.

Effective supplier data management starts with standardized data collection practices and reliable verification workflows.

That means enforcing validation rules at the point of entry, automating document checks, and flagging inconsistencies early—before they snowball into bigger issues.

After all, relying solely on self-reported supplier data is risky.

Why?

Because vendors may omit or misrepresent key details to secure your business.

That’s why external data verification is essential.

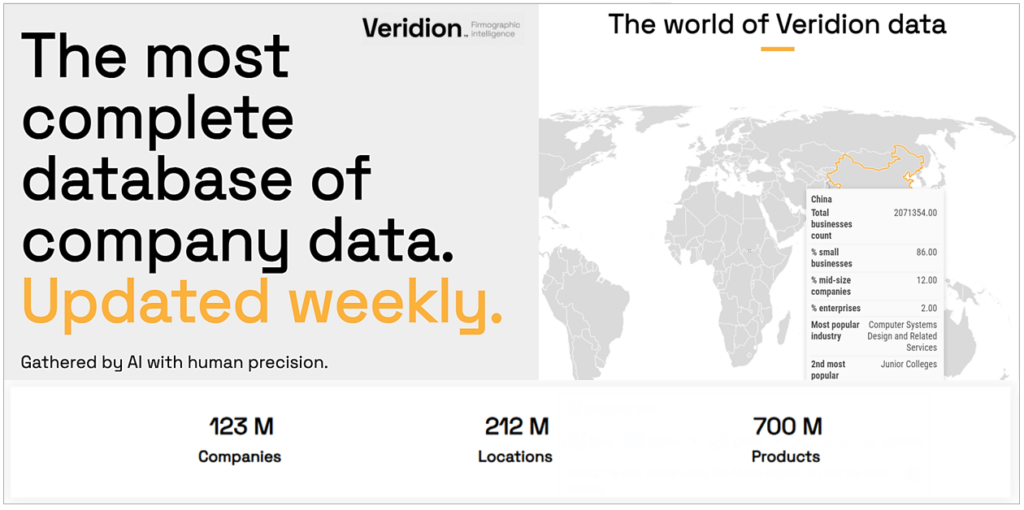

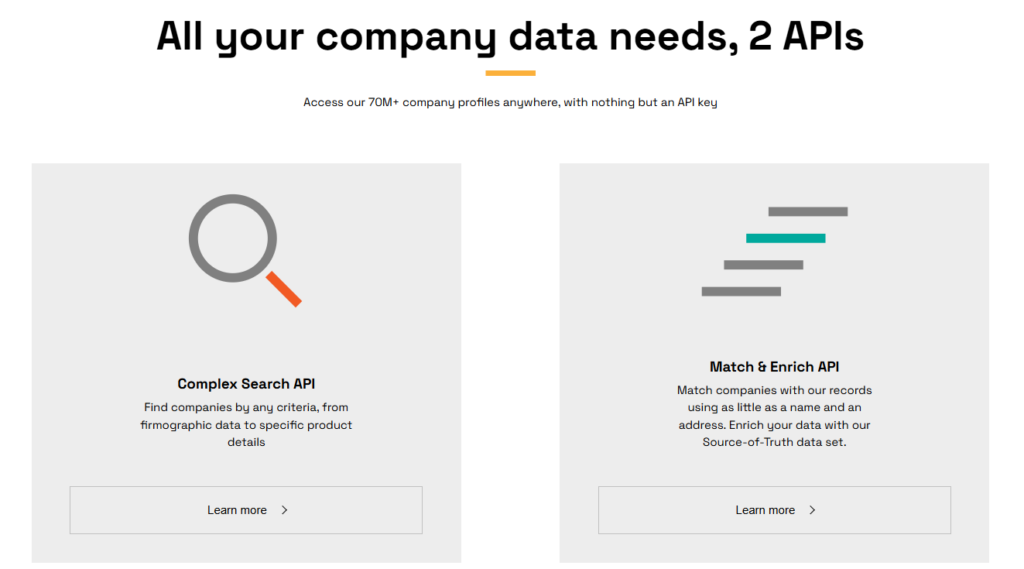

Tools like our data engine, Veridion, automate this process by continuously enriching and validating supplier profiles using external sources and AI-driven data verification.

Source: Veridion

Veridion continuously updates its database of over 123 million companies across 250 geographies, giving teams access to the most current and accurate supplier information.

This significantly accelerates the early stages of onboarding, helping teams quickly identify suppliers that meet their criteria and cutting down manual search time by over 90%.

Beyond fast supplier discovery, your team can:

Overall, standardized data collection practices—combined with real-time verification and enrichment tools—help ensure that supplier data remains complete, current, and reliable throughout the onboarding process.

But even the best data won’t deliver results if your internal systems and onboarding workflows remain disconnected and siloed.

That brings us to the next common challenge.

Disconnected systems are one of the biggest roadblocks to smooth supplier onboarding.

When supplier data is scattered across ERP platforms, procurement tools, legal systems, and spreadsheets, it becomes nearly impossible to get a single, reliable view.

Critical information is often missed, duplicated, or outdated, and teams waste valuable time manually reconciling records.

Worse still, onboarding steps fall through the cracks because no single system tracks the full process.

Without integration, even routine updates can cause confusion or delays, undermining both compliance and efficiency from the outset.

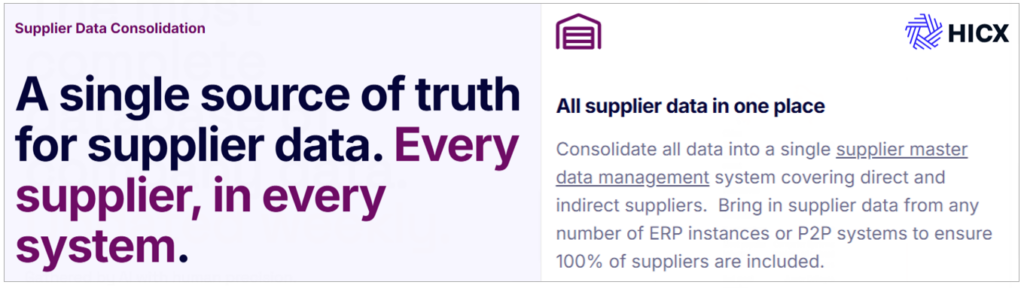

That’s why consolidating supplier data from all systems into one central platform—like the HICX supplier master data management solution does—is key.

Source: HICX

Establishing a master supplier database is essential not just for onboarding but also for ongoing performance monitoring and relationship management.

To get the most out of it, this database needs to connect with your existing systems and tools.

That’s where middleware and API-based integrations come in.

Middleware acts as a bridge between disparate systems—ERP, procurement, contract management, etc., allowing them to exchange data and functions.

APIs, often used by middleware, offer a somewhat simpler route to real-time syncing between your supplier master and other platforms.

This ensures updates are automatically reflected across systems and reduces the risk of errors or delays.

For instance, Veridion can be integrated with your existing onboarding tools through APIs that let you search for suppliers and enrich profiles.

Source: Veridion

Generally, integrating your systems is the most effective way to prevent fragmentation and eliminate manual workarounds during onboarding.

Whether through middleware or direct APIs, syncing platforms ensures that supplier data remains consistent, complete, and actionable across the board.

This not only streamlines onboarding but also creates a solid foundation for managing compliance requirements.

Ensuring supplier compliance is one of the most demanding aspects of onboarding.

This is especially the case when you’re working with hundreds or even thousands of vendors across different regions and categories.

From verifying certifications and licenses to conducting background checks and confirming ethical practices, requirements vary widely depending on the supplier’s type and location.

With so many moving parts, it’s easy for something to fall through the cracks—especially if your onboarding process already suffers from the issues discussed earlier.

And when that happens, the consequences can be serious, exposing your company to legal, financial, and reputational risks.

As Albert Kim, VP of Talent at Checkr, puts it:

Illustration: Veridion / Quote: Softr

This highlights why managing compliance isn’t just a legal formality—it’s a core part of effective supplier onboarding and lifecycle management.

To mitigate reputational, financial, and regulatory risks, companies need structured processes for collecting, verifying, and tracking compliance documents right from the start.

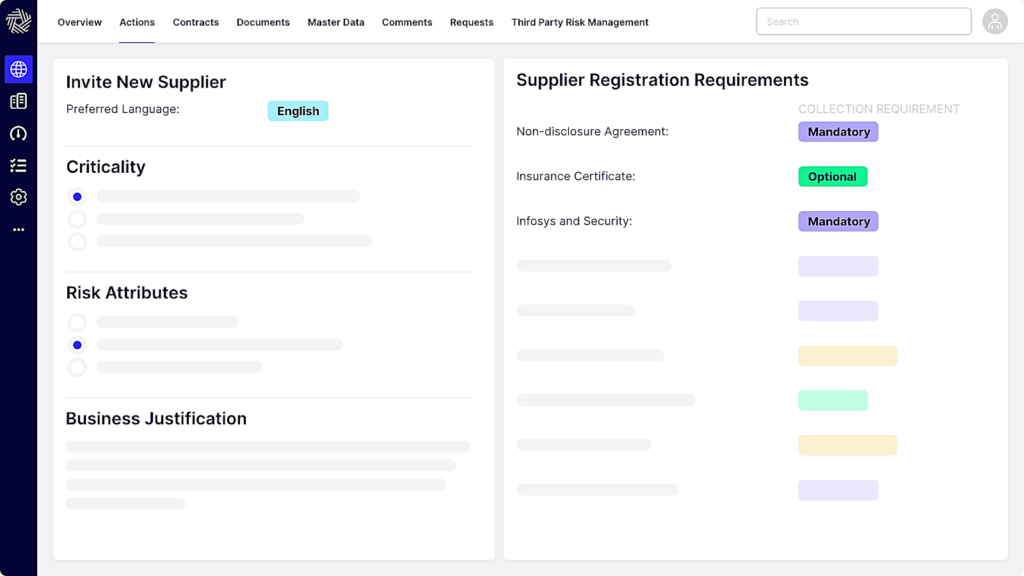

The most effective way to do this is with an onboarding platform that includes built-in compliance tracking.

Centralized dashboards ensure nothing gets overlooked and give procurement, legal, and risk teams shared visibility into each supplier’s onboarding progress.

Such tools also allow you to embed required checks directly into onboarding workflows, automate follow-ups, and enable self-service onboarding for faster processing.

Source: HICX

Even better, onboarding tools allow you to automate expiry reminders and approval workflows, helping prevent many last-minute scrambles.

However, as we’ve already discussed, compliance risk doesn’t end once a supplier is onboarded.

Certifications expire, regulations shift, and suppliers may alter their operations, introducing new risks at any stage of the relationship.

That’s why it’s just as important to monitor compliance post-onboarding, using integrated systems and third-party, real-time data platforms to flag issues early and stay ahead of potential problems.

Now, let’s look at another pain point for both internal teams and suppliers—limited visibility into the onboarding process.

One of the biggest frustrations for both internal teams and suppliers is not knowing where things stand.

When onboarding steps are scattered across emails, spreadsheets, and siloed tools, it’s hard to track progress, follow up, or even know what’s missing.

Suppliers are left guessing, while internal teams waste time chasing updates and approvals.

The root of the issue?

A lack of transparency and consistency in the onboarding workflow.

Depending on the company’s size, urgency, or systems involved, supplier onboarding timelines can range from a few minutes to several months.

As one Reddit commenter put it:

Source: Reddit

This kind of variability is exactly why companies should aim for greater standardization and visibility of the onboarding process.

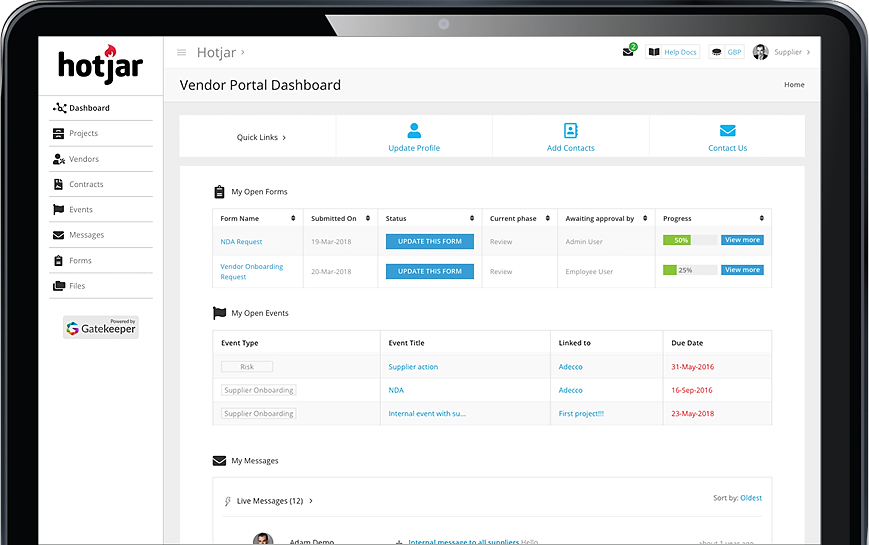

Beyond an integrated supplier database, one of the most effective ways to do that is by providing suppliers with a self-service onboarding portal.

These portals let suppliers track their own progress, upload required documents, and see which steps are pending—all without endless email threads or manual nudges.

Internally, teams get real-time status updates and fewer delays, while suppliers enjoy a smoother, more transparent experience from day one.

Source: Gatekeeper

Of course, even the best self-service portal isn’t a silver bullet.

Suppliers may still miss onboarding steps or lose track of what’s next, especially without timely reminders or clear instructions.

That’s why it helps to automate status updates and centralize communication in one place.

Whether through a shared dashboard, in-platform messaging, or integrated collaboration tools, centralizing interactions minimizes onboarding delays and confusion.

As Cache Merrill, Founder of the custom software development company Zibtek, notes, streamlined systems and automated workflows can make all the difference.

Illustration: Veridion / Quote: Softr

As highlighted, streamlined onboarding processes and centralized communication can significantly improve visibility and reduce delays.

With automated workflows, transparent tracking, and ideally self-service portals, teams stay aligned, suppliers stay informed, and the entire onboarding process runs smoothly.

Ultimately, this clarity helps eliminate friction, making the process faster and more efficient for everyone involved.

So, supplier onboarding is clearly a foundational process that affects everything from compliance to efficiency.

By addressing the common challenges we covered with the right systems and workflows, your team can streamline onboarding, reduce risk, and build stronger supplier relationships.

A smarter, faster, and more transparent onboarding experience benefits all parties involved—and sets the tone for long-term success.