Streamlining Supplier Onboarding: A Complete Guide

Proper supplier onboarding sets the foundation for smooth, reliable, and long-term partnerships. But let’s be honest, it can be a headache.

The process is often slow, repetitive, and, if not managed well, risky. For example, verification gaps or miscommunications can create compliance risks and delay your operations.

So, streamlining the process is key, especially for procurement teams that juggle multiple suppliers at the same time, have complex workflows, and need to navigate strict regulations.

In this post, we’ll break down how to simplify supplier onboarding, share real-world examples, and highlight tools that make it easier.

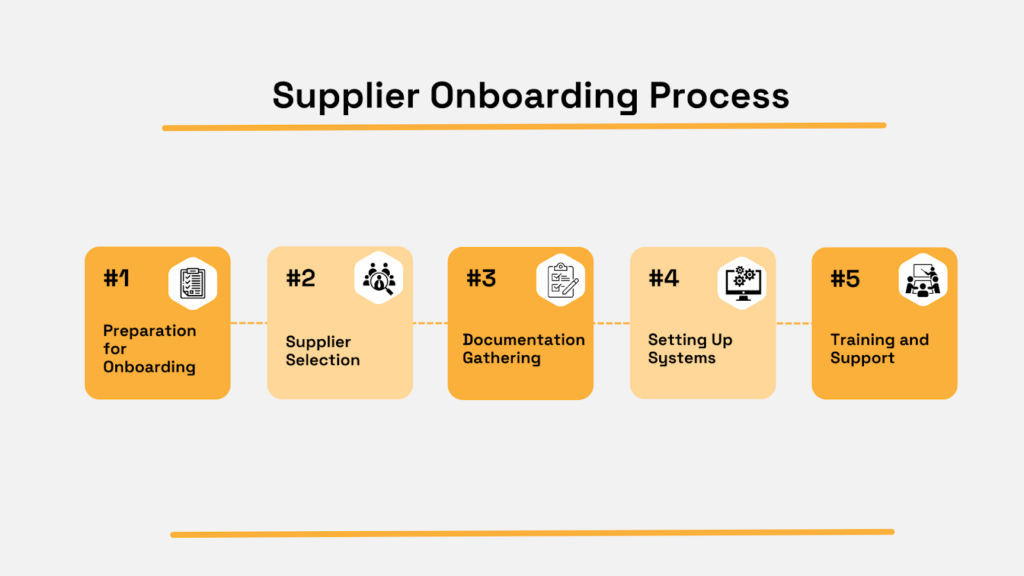

We define supplier onboarding as not only familiarizing suppliers with your processes but also planning, selecting, and vetting them thoroughly.

Doing so has many benefits for both the sourcing company and suppliers.

Illustration: Veridion

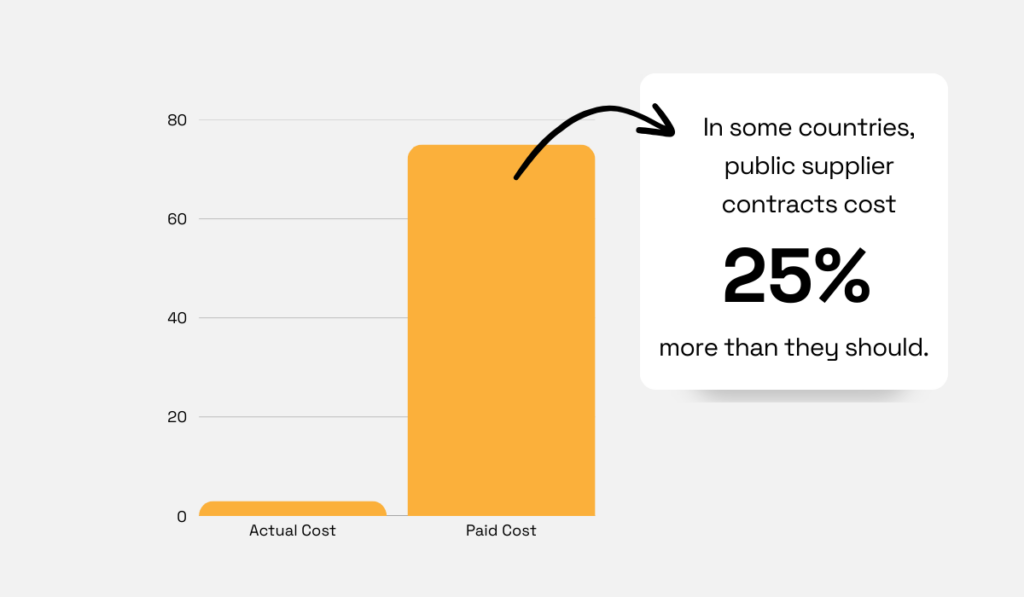

For one, proper onboarding ensures you’re not unintentionally paying more than you should.

In some Southeast European countries, for example, about 90% of public supplier contracts cost 25% more than necessary.

Illustration: Veridion / Data: SELDI

One potential reason for that is that companies often choose suppliers they discover easily.

Many fail to look into alternative options and properly compare suppliers against internal criteria.

This limits their ability to optimize spending.

Proper onboarding mitigates this issue by ensuring you have a well-defined set of criteria and stick to finding suppliers that meet them.

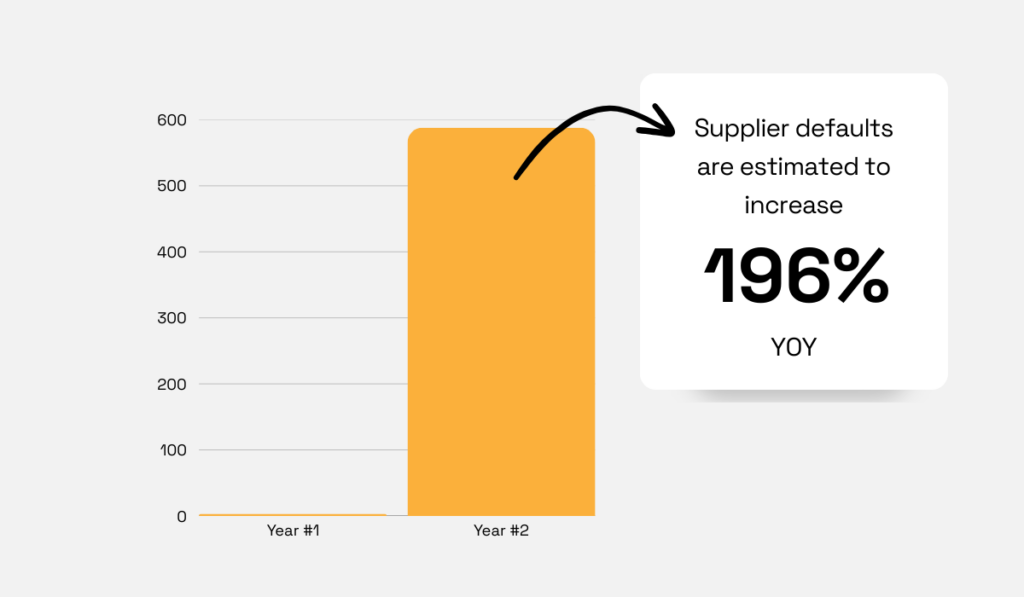

Another benefit for companies is minimizing disruptions.

According to a 2022 study, the annual cost of supply chain disruptions averages around $182 million.

Additionally, supplier defaults are estimated to grow 196% year-over-year, making disruptions only more likely in the future.

Illustration: Veridion / Data: Rapid Ratings

Proper vetting and selection, two crucial parts of onboarding, significantly reduce these risks.

Onboarding itself helps minimize other risks, too, especially those related to compliance and (un)ethical business practices.

For example, H&M faced significant backlash in 2020 over allegations of using cotton sourced from forced labor in China’s Xinjiang region.

Source: BBC

The company subsequently tried to distance itself from China, further angering Chinese consumers alongside Western critics.

As a result, the brand lost customer trust and experienced a significant drop in sales, especially in China.

Again, well-structured supplier onboarding can help you avoid such PR nightmares, but also keep your business truly ethical.

However, onboarding doesn’t just benefit sourcing organizations, but suppliers as well.

Here are a few ways how:

Though very beneficial, supplier onboarding is not without challenges.

The truth is, a lot of things can go wrong when onboarding your suppliers.

Many things can hinder progress and quickly turn into a major headache.

Anders Lillevik, ex-CPO at Fannie Mae and Webster Bank, agrees. He explicitly states that “supplier onboarding can be a nightmare” in procurement:

Illustration: Veridion / Quote: LinkedIn

But knowing which obstacles to watch out for can help you eliminate them.

Based on what we’ve observed throughout the years, companies primarily face challenges related to three areas: data accuracy, communication, and system integration.

Illustration: Veridion

When it comes to data, inaccuracies can occur on both sides and negatively impact the process.

For example, suppliers may provide incorrect or incomplete information, such as outdated tax IDs or compliance documentation, while buyer companies may hold outdated supplier profiles. Both scenarios delay verification and approval.

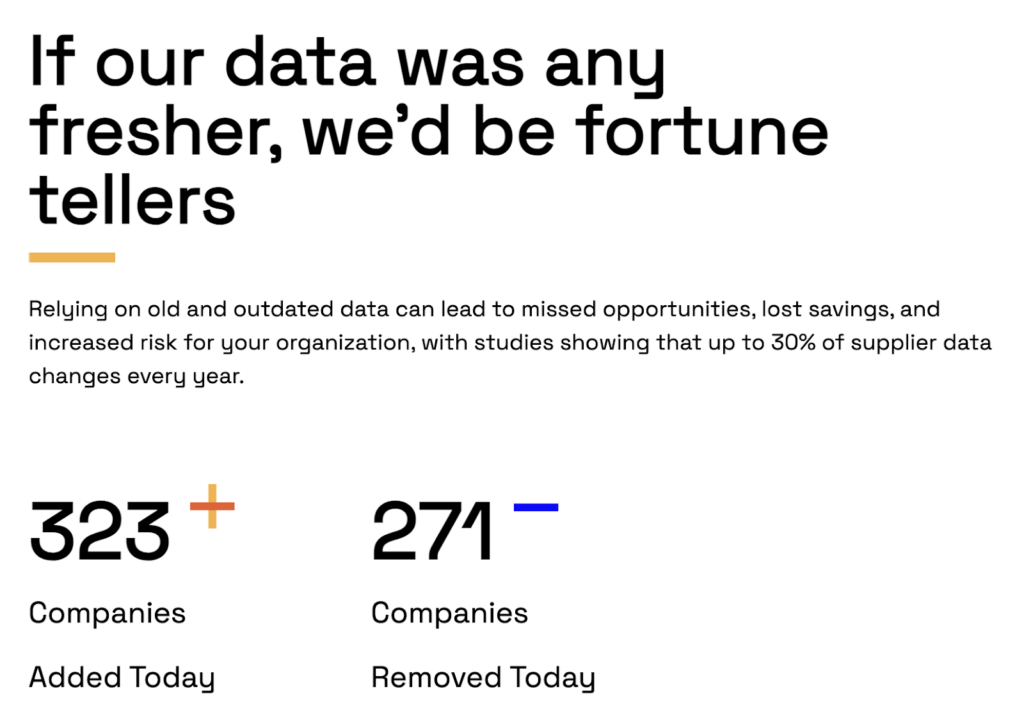

One way to overcome this challenge is to use an advanced data service like Veridion.

Our system continually browses the internet updating company data as it changes, equipping sourcing teams with the most accurate information.

Source: Veridion

Another challenge to stay ahead of is poor communication and slow response times, which can lead to further delays.

Some ways to overcome this are to use centralized communication platforms and set clear expectations from the get-go.

Unfortunately, even when supplier data is accurate and communication streamlined, poor system integration can still create bottlenecks.

To enhance it, consider conducting system training sessions as a part of onboarding, and using API-first solutions that allow smooth integration with existing systems.

Now that you know how supplier onboarding can benefit both sides, as well as the obstacles to watch out for, you’re probably ready to start mapping out your process.

To do so, you can follow these step-by-step instructions.

The first step is to define clear goals and expectations for onboarding.

Here are some questions to consider:

Answering these and other relevant questions will help you structure your onboarding process, but also establish clear selection criteria (step 2).

Additionally, you’ll get more insight into who should be involved in the onboarding process and how.

When deciding on internal stakeholders, there are three key things to consider: who can make decisions, who has relevant expertise, and who will be directly involved in managing supplier relationships.

Illustration: Veridion

Consider all three to define stakeholders and assign roles.

Next, establish clear selection and approval criteria. This will help everyone involved operate within the same framework and work toward the same goals.

We can generally divide the selection criteria into three major categories:

Which specific qualifications, capabilities, and values to prioritize is up to you. But this generalized overview may help you decide:

| Qualifications | Capabilities | Alignment with Company Goals |

|---|---|---|

| Industry certifications and standards met | Ability to scale production to meet demand | Commitment to sustainability and environmental practices |

| Relevant experience in the specific field | Access to advanced technology and infrastructure | Shared values regarding ethical labor practices |

| Proven track record of reliability and consistency | Demonstrated expertise in specialized solutions | Willingness to engage in long-term partnerships |

Of course, there is no one-size-fits-all solution. You’ll always need to consider your unique needs, as well as general trends.

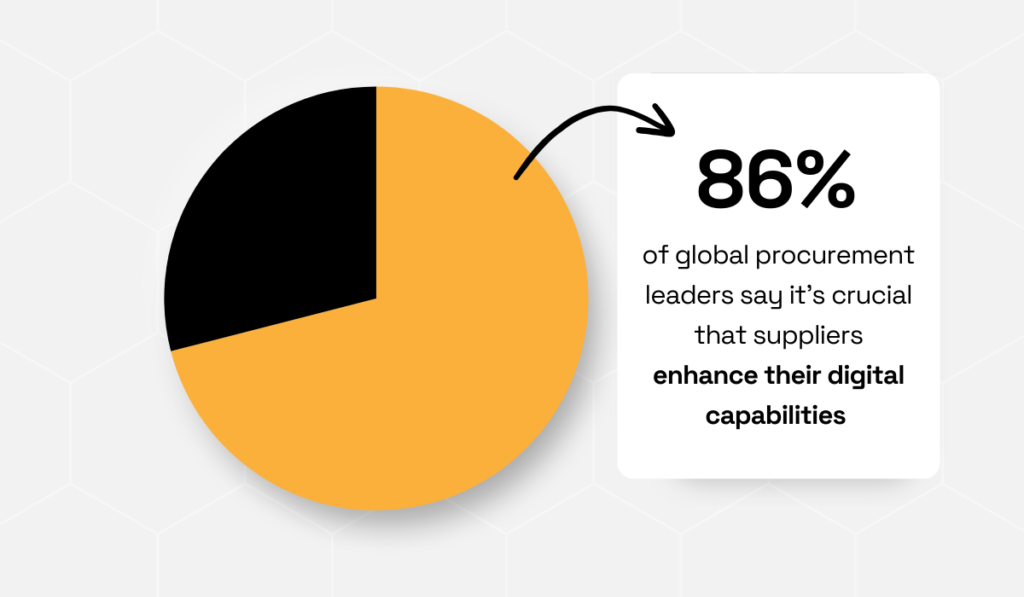

For example, supply chain digitization has steadily grown in the last decade, and will become only more important in the future.

That’s why, according to ProcureTech’s research, 86% of surveyed procurement leaders consider good digital capabilities essential when selecting suppliers.

Illustration: Veridion / Data: ProcureTech

The bottom line is: consider all the various tasks you’ll need your suppliers to handle, including admin work, and how you want them to go about it in advance.

This will help you set criteria that work.

Additionally, having clear requirements is essential for properly conducting due diligence.

This takes us to the next step.

The third step is collecting and verifying documentation that helps ensure suppliers adhere to legal, regulatory, and company-specific compliance standards.

Again, the exact documentation to assess will depend on your previously set criteria.

However, here’s a general overview of some key records:

| Qualifications | Capabilities | Alignment with Company Goals |

|---|---|---|

| Certifications and licenses | Capacity and production reports | Sustainability policies |

| Financial records | Technical specifications | CSR reports |

| Compliance documentation | Quality management systems | Strategic partnerships records |

Ask your suppliers to provide this documentation and assess it carefully with relevant stakeholders.

This could include compliance officers, legal advisors, or sustainability experts, depending on the documentation type.

Once a supplier is approved, the next step is integrating them into your procurement and Enterprise Resource Planning (ERP) systems.

This ensures seamless transactions, data consistency, and compliance.

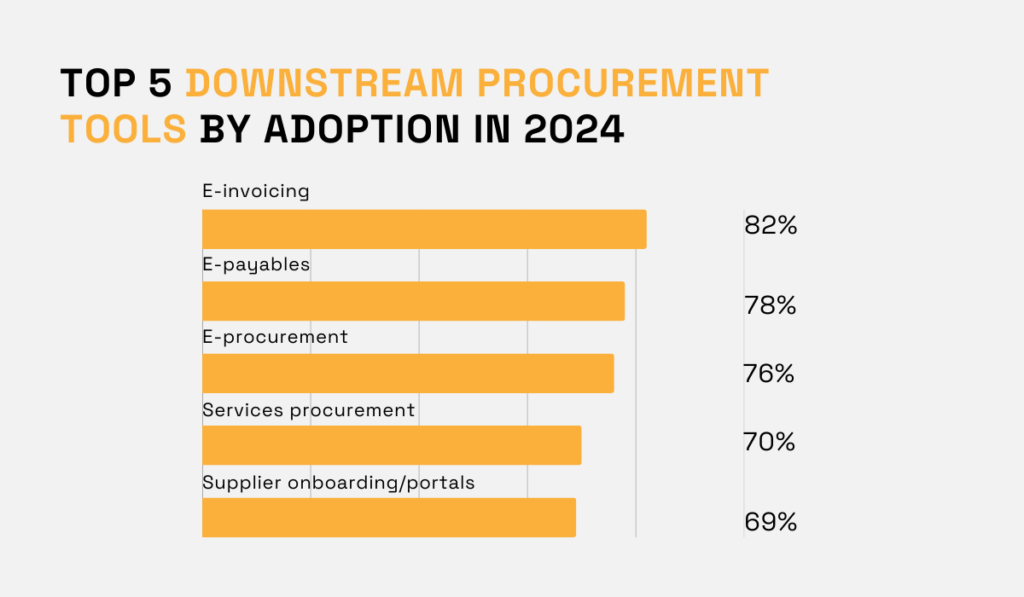

In fact, all leading organizations already have digitally enabled supplier onboarding, together with invoicing, payments, and financing solutions.

Supplier onboarding systems/portals were among the 5 most widely adopted downstream procurement tools in 2024 according to the Hackett Group’s CPO Agenda.

Illustration: Veridion / Data: The Hackett Group

Start by creating supplier profiles in your system, including payment details, contract terms, and compliance documents.

Next, provide suppliers with access to necessary tools or platforms, such as procurement portals, invoicing systems, or self-service dashboards.

Though adoption may take some time initially, it will significantly reduce manual work and improve efficiency in the long run.

To make this happen, though, make sure you provide appropriate training and support.

Successful supplier onboarding doesn’t end once a supplier is integrated into your systems. To ensure smooth collaboration, you should also provide training and ongoing support.

Start by offering training sessions or resources that familiarize suppliers with your company’s processes, standards, and expectations.

Depending on your needs, this could include guidelines on:

Amin Mirfakhraie, Director of Global Business Development at Advanced Horizon Markets, a company specializing in import/export and technology, emphasizes that walking the suppliers through your platform is key to ensuring adoption.

He finds guides particularly useful, especially when they contain step-by-step instructions and screenshots:

Illustration: Veridion / Quote: LinkedIn

Finally, ongoing communication with suppliers and their employees is imperative if you’re looking to build stable, long-term relationships.

So, the last step is establishing clear communication channels for ongoing support. You can consider assigning a dedicated contact person or scheduling regular check-ins.

Ensure that suppliers can quickly resolve issues and get the support they need when they need it.

Supplier onboarding can be a slow, paperwork-heavy process. The right technology can cut down manual work and accelerate it.

Specialized software solutions can streamline every aspect of supplier management, especially ongoing data management and communication:

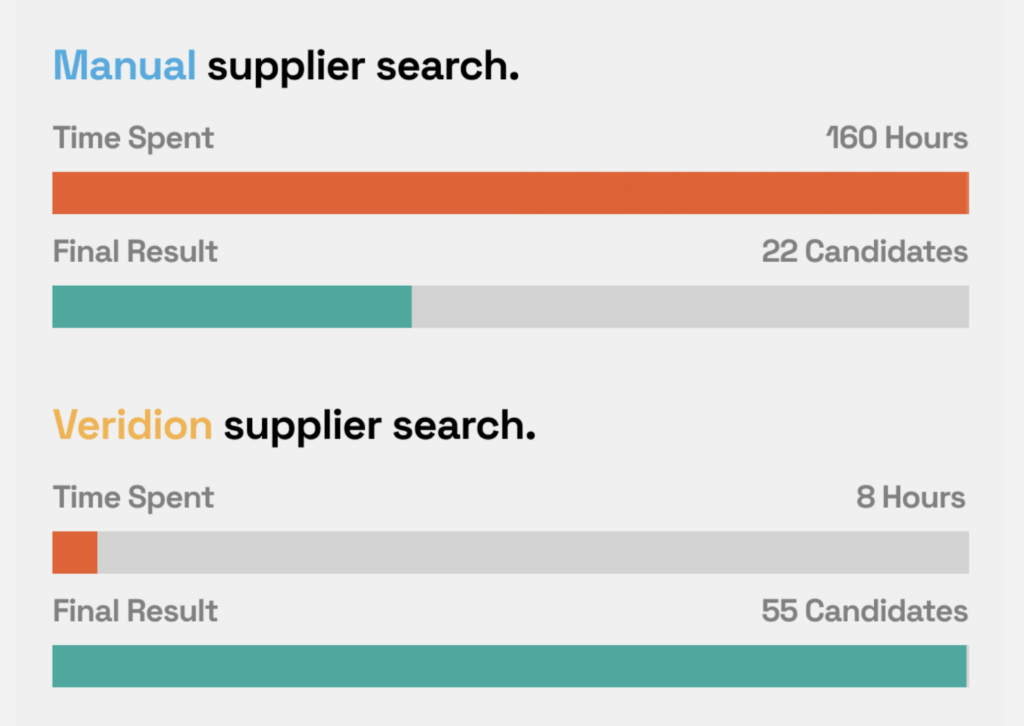

Data services like Veridion help you find suppliers more quickly by giving you access to a global supplier database, enriched with the data you need to make informed decisions.

Source: Veridion

This accelerates supplier discovery and ensures you’re selecting the right partners based on specific criteria.

Vendor self-service portals like Ariba Supplier Portal and Coupa Supplier Portal enable suppliers to submit documents, track approvals, and check updates independently.

This reduces back-and-forth emails and administrative overhead.

SAP Ariba also offers a comprehensive supplier management module that allows suppliers to manage all aspects of their relationship with you—from invoices to compliance documentation.

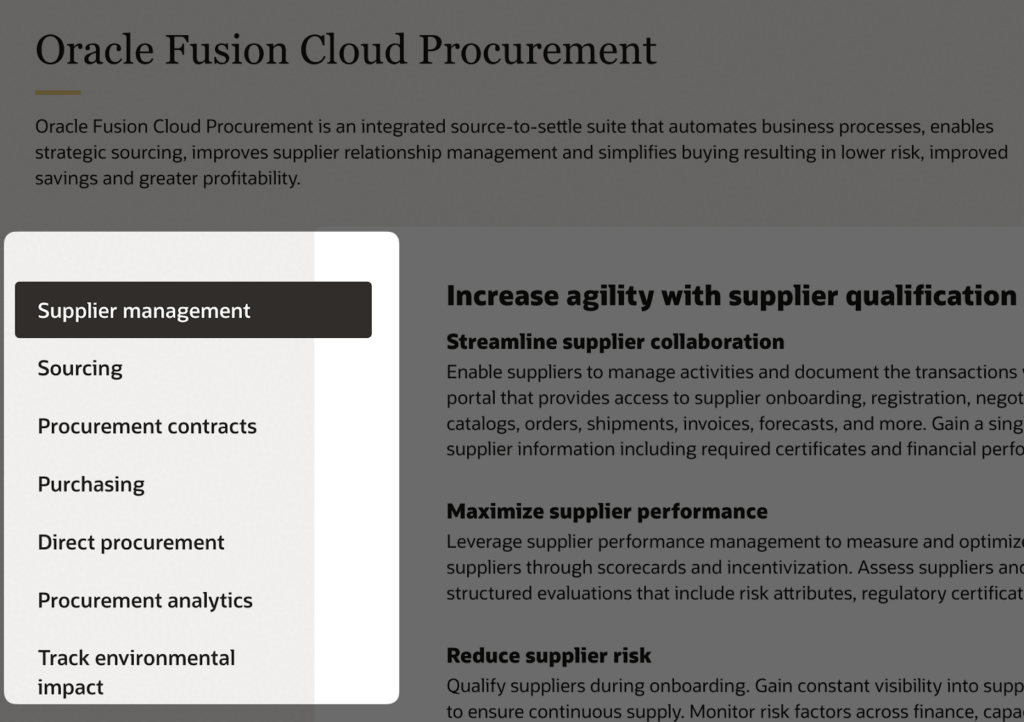

Procurement or ERP software like Oracle Procurement Cloud syncs supplier data with purchasing workflows for seamless transactions.

These tools integrate supplier information directly into your procurement process, making the entire workflow—from sourcing to payment—more efficient and reducing the chances of errors.

Source: Oracle

Similarly, Zycus and Jaggaer automate repetitive tasks like data entry, compliance checks, and contract approvals.

They provide centralized dashboards where procurement teams can monitor supplier performance, track risk factors, and ensure that compliance standards are met.

Remember, tools are your friends. With the right ones in place, you’ll get relevant stakeholders on board more quickly.

More and more companies are realizing just how important it is to properly onboard suppliers, with some prioritizing systems that enable timely data exchanges.

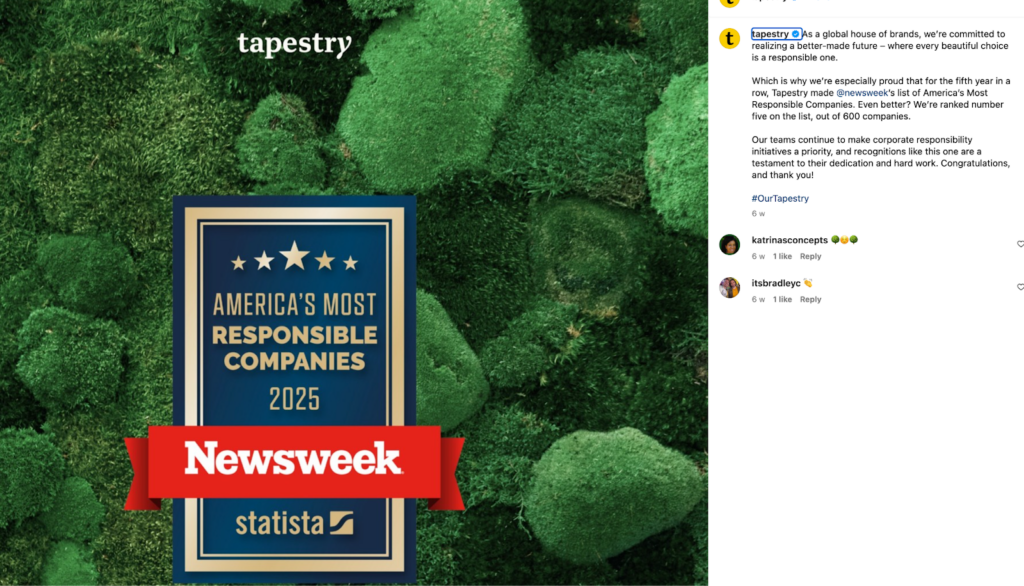

One example is Tapestry, a luxury fashion holding company that aims to trace the origins of 95% of its raw materials using a traceability platform.

Through a collaborative platform suppliers can share their data directly without overburdening Tapestry’s internal teams.

They also host supplier sessions, and training programs, and gather feedback.

This shows how working closely with suppliers, especially in the beginning, is crucial.

Source: @Tapestry

Adidas, on the other hand, serves as an example of a company with strict selection criteria, strong communication channels, and ongoing supplier support.

The company provides training sessions for suppliers after they’re onboarded, and has established various grievance channels.

As a result, satisfaction rates related to complaint resolution have risen from 39% in 2019 to 77% in 2022.

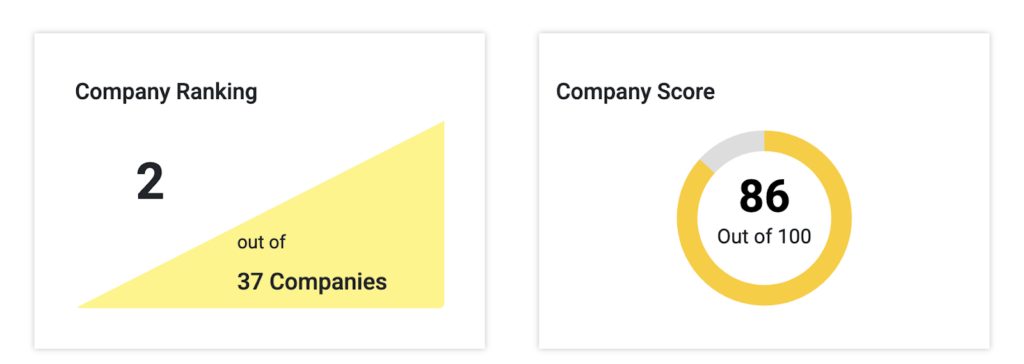

KnowTheChain also rated Adidas 2nd out of 37 companies for its disclosure of forced labor policies and practices.

Source: KnowTheChain

Ongoing support and close collaboration can help companies improve supplier relationships, transparency, and their own reputation.

Supplier onboarding is crucial for building strong, long-term partnerships, but when it’s slow and inefficient, it can create unnecessary risks and delays.

By leveraging a proven structure, improving communication, and using the right tools, you can make your processes better.

But you don’t have to do it all at once. Even small improvements can make a big difference.

Start by identifying gaps in your current approach, whether it’s better verification, clearer expectations, or automation. Then, consider how to make these processes just 1% better.

Sounds good? We think so. Good luck!