5 Mistakes to Avoid During Supplier Onboarding

Key Takeaways:

While many organizations invest heavily in sourcing and negotiation, onboarding often gets rushed or overlooked.

Yet onboarding has a significant impact on supplier performance and operational resilience.

Are you guilty of relying on manual data exchange or neglecting ongoing supplier collaboration?

In this article, we’ll explore these and other supplier onboarding mistakes that can quietly sabotage projects, partnerships, and profitability, as well as show you how you can avoid making them.

Integrating new suppliers into your system has to be done methodically, following clearly defined requirements and workflows.

When it’s not, confusion spreads across the organization, supplier activation gets delayed, and you’re looking at major data inconsistencies.

No two onboarding processes will be exactly the same, but a lack of alignment on basic standards creates operational friction.

Procurement, finance, and legal teams wind up with conflicting expectations.

Worst of all, inefficient and error-prone processes erode supplier relationships right from the start.

HICX’s 2021 survey reveals that strong supplier relationships require clear, reliable communication and business processes.

Illustration: Veridion / Data: HICX

Organizations know this, and onboarding is the first test of that dedication.

Your company should consistently standardize at least five areas throughout the supplier onboarding process, including:

At the same time, these standards need to leave room for flexibility.

Would it make sense to apply identical onboarding steps to both a local subcontractor and a multinational vendor?

No, since it’s inefficient and creates unnecessary work for everyone involved.

A recent HICX report reinforces this, stating that 60% of suppliers believe they’re forced to deal with too much administration just to work with buyers.

Illustration: Veridion / Data: HICX

The key is ensuring clarity on what you’re asking for—and why.

In other words, design your workflows around specific supplier segments, ensuring each requirement is relevant to the supplier’s role, size, and risk profile.

This will improve accuracy, reduce supplier frustration, and eliminate irrelevant data collection.

Unstandardized onboarding also compromises supplier data management.

Without firm standards, information inevitably gets scattered across spreadsheets, emails, and isolated systems, leading to errors, duplicates, and missing records.

And as your supplier base grows, these issues quickly multiply.

However, streamlined and centralized onboarding processes help you avoid duplication and ensure consistency.

Cyril Law, Director of Technology and Data Engineering at Engine Transformation, recalls overseeing three data centres that sourced IT equipment from three different suppliers, with fragmented records in each location.

His solution?

Investing in standardized processes that centralize and clean supplier data.

Illustration: Veridion / Quote: HICX

The bottom line is that unstandardized processes lead to duplication and inconsistency.

Meanwhile, consistent data collection, coupled with segmentation strategies and clear workflows, lays the groundwork for supplier relationships that scale without additional complexity.

Rushing the onboarding process might deliver short-term gains, but it often creates more problems than it solves.

When deadlines loom and procurement teams are under pressure to onboard suppliers quickly, it’s tempting to prioritize speed over thoroughness.

This usually leads to incomplete supplier records, missing documentation, and misaligned expectations that can easily disrupt operations further down the line.

According to TealBook, most organizations experience the consequences of poor supplier data, with nearly half encountering these issues regularly.

Illustration: Veridion / Data: TealBook

These consequences might seem minor until you miss a critical delivery because a supplier wasn’t properly briefed on your requirements.

A rushed onboarding process can throw your supply chain off balance, but there are also more subtle risks.

For instance, if suppliers aren’t clear on service-level agreements (SLAs), payment terms, or compliance standards, tensions can build before any actual work begins.

As Oliver Chapman, CEO at procurement firm OCI Group, notes, it’s common for suppliers to be bounced between departments while trying to resolve basic onboarding errors.

Illustration: Veridion / Quote: HICX

Still, the bigger issue is the operational drag this creates.

Procurement teams end up spending valuable hours fixing avoidable mistakes while new suppliers wait in the pipeline, creating a cycle of delays and inefficiencies.

At its core, this issue highlights a deeper operational flaw of processes built around reacting to pressure rather than preventing problems.

Get the fundamentals right, and you’ll build a streamlined, fast-track protocol that incorporates essential checks to slow things down and avoid bigger issues later on.

Treating due diligence like a simple checkbox exercise exposes your organization to significant, yet avoidable risks.

On the other hand, proper supplier vetting allows you to confirm a supplier’s financial health, legal standing, operational capacity, and reputation before any agreements are finalized.

Without this, companies risk onboarding partners who are unreliable, non-compliant, or simply unable to scale with their needs.

Such mistakes can lead to financial losses, reputational damage, or even regulatory penalties.

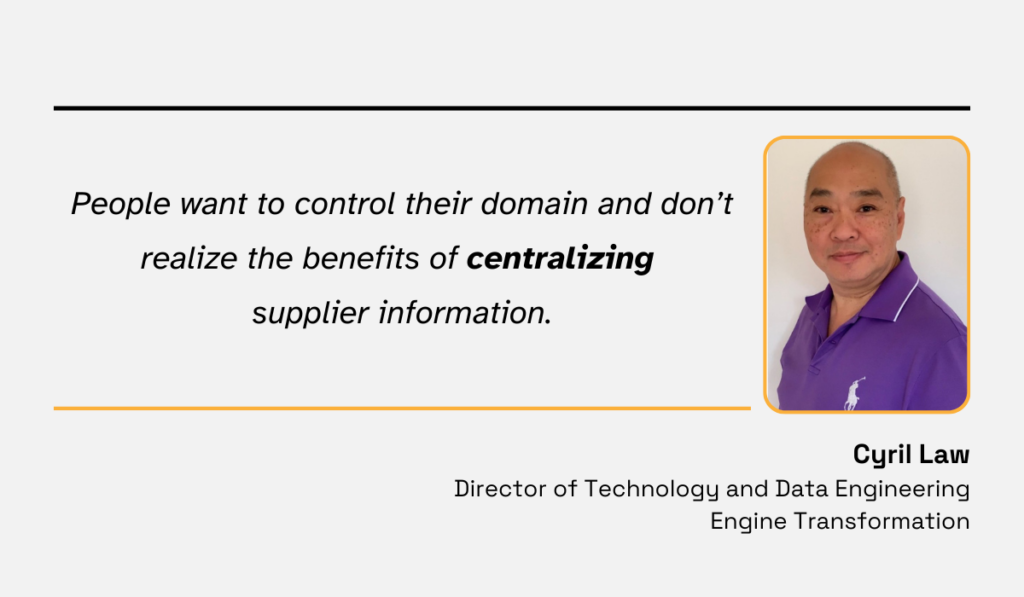

The consequences of overlooking due diligence are well-documented.

A notable example is the case of Pharmally Pharmaceutical Corporation during the COVID-19 pandemic.

The Philippine government awarded the company substantial contracts for medical supplies, only for it to emerge that Pharmally had limited capital, no track record, and weak operational infrastructure.

The fallout included Senate investigations, public outcry, and lasting reputational damage for all parties involved.

Source: Inquirer

But most of all, the case highlighted the dangers of bypassing proper due diligence, especially during emergencies where expedited processes might be misused.

While this was an extreme scenario, it’s easy to see how similar mistakes could occur under everyday business pressures, from tight deadlines to enticing cost savings.

These may prompt companies to cut corners, but thorough vetting should remain non-negotiable.

That includes verifying financial stability, business credentials, regulatory compliance, and reputational standing, supported by current and trustworthy data.

However, many procurement teams still rely on information that’s outdated, incomplete, or difficult to verify.

Sayan Debroy, Smart Cube VP and Head of Supplier Risk Intelligence at WNS Procurement, warns that much of the supplier data companies rely on for risk assessments is already obsolete by the time it’s reviewed.

Illustration: Veridion / Quote: Supply Chain Digital

For instance, suppliers might submit outdated compliance documentation or incorrect tax IDs, while buyer organizations may hold old supplier profiles in their systems.

Add to that the challenges of accessing reliable global data, and the problem grows more complex, delaying onboarding and increasing exposure to risk.

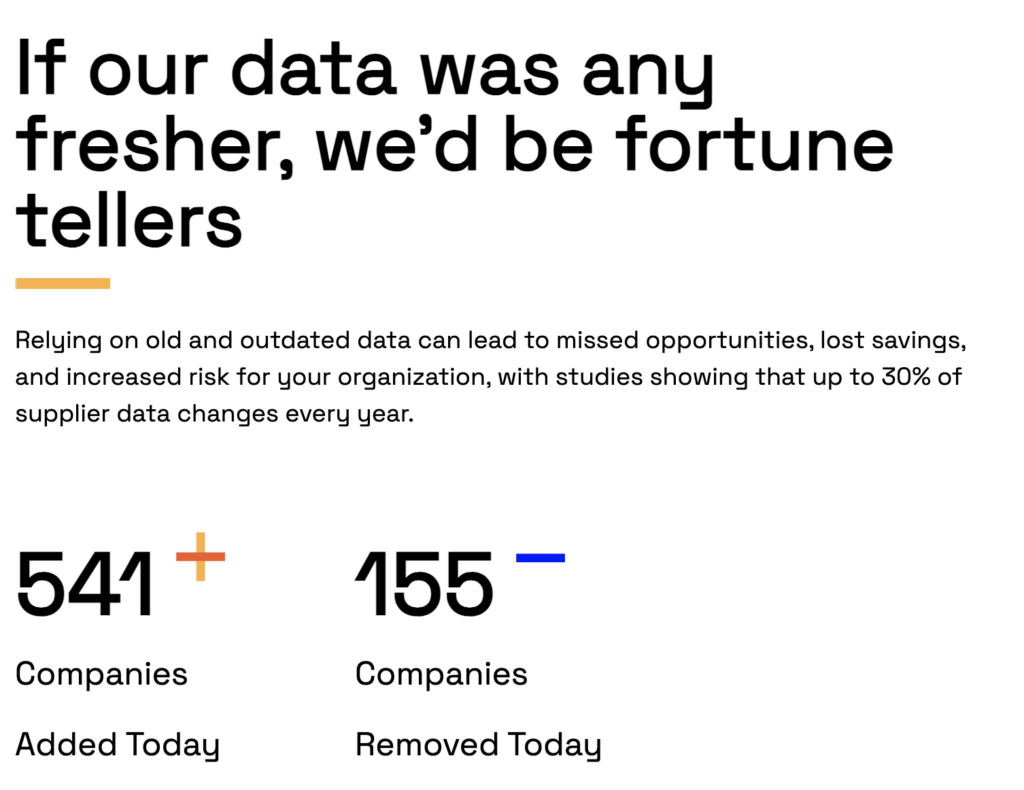

Fortunately, this is where dedicated data providers like Veridion step in.

Veridion maintains detailed, weekly-updated profiles on over 120 million global suppliers, with AI bots continuously monitoring for risk indicators like financial instability, ESG violations, or regulatory issues.

Source: Veridion

Customizable alerts ensure procurement teams are notified instantly of material changes, helping you safeguard onboarding and ongoing supplier relationships.

But whether you integrate specialized risk platforms or not, remember that the short-term convenience of sidelining supplier due diligence is never worth the long-term cost.

Keeping in mind the risks of non-compliance, inaccuracies, and disruption, relying solely on manual onboarding methods simply doesn’t cut it anymore.

The increased potential for human error, data silos, and slower turnaround times makes manual processes an expensive liability in modern supply chains.

It’s no secret that Excel has long been the backbone of supply chain operations.

As one Reddit user puts it, spreadsheets are so widespread that it feels like they’re holding the global supply chain together.

Source: Reddit

But while this comment highlights Excel’s importance in procurement, it also exposes a critical vulnerability.

Spreadsheets and email threads lack automation, leave data scattered, and open your business up to delays and costly mistakes.

A single error in a contact record, tax ID, or bank detail can trigger payment issues, compliance breaches, and supplier disputes.

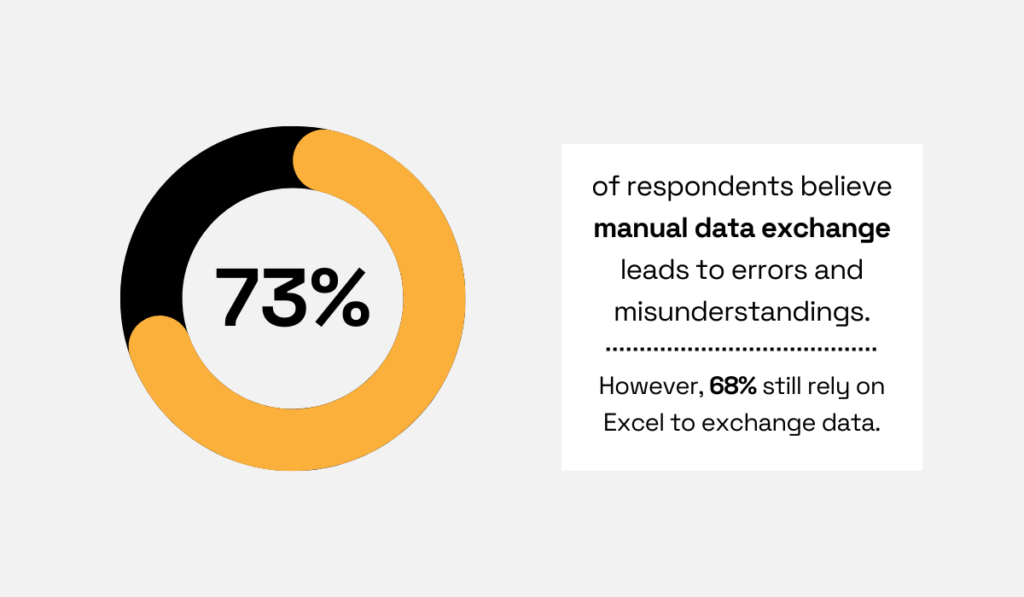

The problem is widely recognized: 73% of procurement leaders acknowledge that manual data exchange is a major issue.

And yet, nearly as many organizations still rely on spreadsheets for key processes, including supplier onboarding.

Illustration: Veridion / Data: XPLM

That might have worked years ago, but today’s supply chains involve complex webs of international suppliers.

Therefore, without centralized, automated onboarding systems, organizations can’t keep up with real-time supplier data, risk profiles, and compliance statuses.

Freshworks, a cloud-based SaaS company, experienced this firsthand.

Sheel Patel, the company’s Head of Strategic Sourcing & Procurement, recalls how supplier onboarding requests were handled via email until they joined hands with supplier management solution Graphite Connect.

Illustration: Veridion / Quote: Graphite Connect

By moving onboarding workflows to Graphite Connect and integrating it with Freshworks’ ERP system, processes that previously took four to six weeks could be completed in one.

Naturally, accelerated processes also meant faster project launches, earlier access to reliable supplier data, and lower administrative burden.

While manual processes cause you to fall behind, automation delivers reliability at scale, keeping your procurement team in control and connected to supplier performance.

Many organizations treat supplier onboarding as a one-and-done process, but nothing could be further from the truth.

Developing strong onboarding workflows is a critical first step, but sustaining supplier engagement and compliance requires continuous support.

Without ongoing supplier enablement, your suppliers are more likely to become disconnected from your processes, leading to missed deadlines, inaccuracies, and friction.

Consider a scenario where a supplier is onboarded with no follow-up.

Six months later, a minor change to your invoicing process stalls their payment, which results in delayed deliveries, frustrated stakeholders, and a strained relationship.

And the worst part is, the entire situation could have been avoided with a timely update.

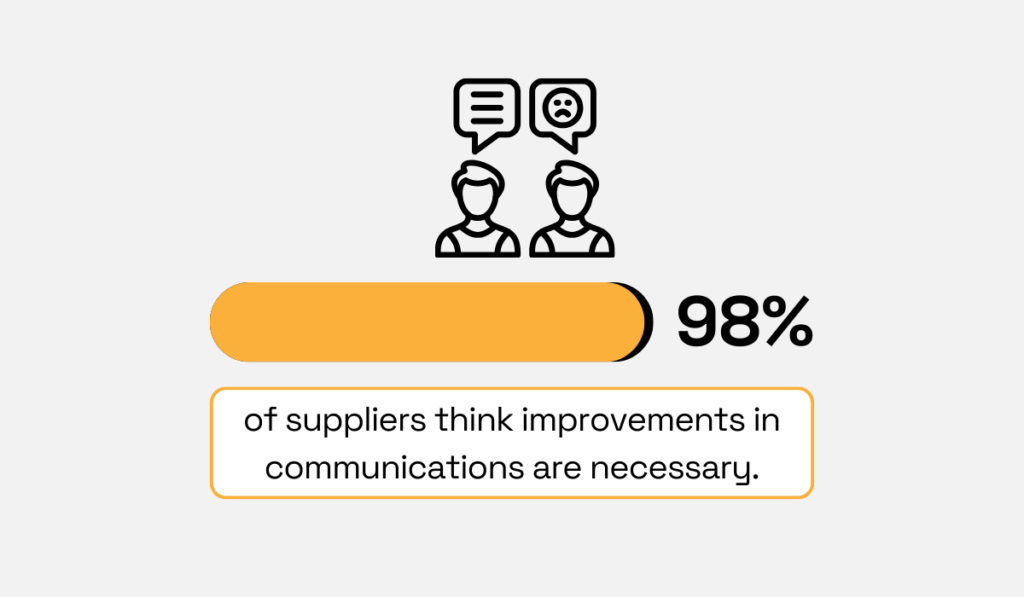

Research underscores this issue, with nearly all surveyed suppliers stating that communication with buyers needs improvement.

Illustration: Veridion / Data: HICX

Continuous supplier enablement hinges on two essentials: access to training and intuitive, easy-to-use systems.

Suppliers won’t collaborate smoothly if they feel left to fend for themselves.

Providing relevant training that covers compliance, quality control, invoicing procedures, and procurement tools equips them to navigate your expectations and processes effectively.

At the same time, technology should act as an enabler, not a barrier.

Too often, multiple logins, clunky interfaces, or scattered information hubs frustrate suppliers and discourage interaction.

In fact, roughly one-third of suppliers say the best way to improve buyer-supplier relationships is to make it easier to find key information and receive timely support.

Illustration: Veridion / Data: HICX

To keep suppliers engaged, organizations need to track supplier activity, gather feedback, and refine processes based on how suppliers actually use portals and tools.

Practical features like invoice tracking, order status dashboards, and document libraries keep suppliers returning, thereby ensuring that your data is as current as it can be.

Michael Van Keulen, longtime CPO and industry practice leader at Coupa, also underscores the need for versatile features.

Illustration: Veridion / Quote: Procurement Magazine

Nevertheless, enablement isn’t just about technology.

The key lies in building an experience that makes it easy and worthwhile for suppliers to stay connected.

Ultimately, this also creates a safeguard against operational disruption and unreliable supplier data.

Supplier onboarding ensures you’ve ticked off several administrative boxes, but it’s much more than that.

It’s the foundation for reliable data, clear communication, and operational control.

When companies neglect this process or rush it, they risk fragmented supplier records, delays, compliance issues, and damaged supplier relationships.

And in a procurement environment where data accuracy and supplier collaboration directly impact business performance, these mistakes aren’t minor oversights.

They’re entirely avoidable liabilities.

By recognizing and addressing these pitfalls, you’re poised to build stronger supplier partnerships, streamline operations, and ensure the data consistency needed to stay ahead and make smarter decisions.