Top 5 Challenges in Managing Supplier Relationships

Key Takeaways:

Have you ever walked away from a negotiation with a supplier feeling like you gave up too much?

Or, have you struggled to keep track of which suppliers consistently meet their commitments—and which don’t?

Managing supplier relationships is no easy task, yet it can make or break a business.

Done right, it helps control costs, prevent disruptions, and provide a competitive edge.

Done poorly, it exposes you to significant risks.

That’s why, in this article, we’ll explore the top five challenges businesses face in managing supplier relationships—and, more importantly, how to overcome them to keep your business thriving.

Sometimes, suppliers can be great at selling themselves—but once the contract is signed, how do you know they’re actually delivering on their promises?

Without proper tools and processes, you really can’t.

And this can lead to serious issues, such as unexpected declines in quality, delays, or cost increases.

In some cases, the consequences can be even more severe.

Take, for instance, the supplier of onions to McDonald’s, Taco Bell, KFC, and other major fast-food chains.

In 2024, the FDA recalled their onions after they were linked to an E. coli outbreak, which led to at least 49 people being infected, 10 others being hospitalized, and one older adult losing their life.

Source: Food Safety News

Meanwhile, McDonald’s was already facing lawsuits related to the issue.

So, what went wrong?

Further inspections uncovered that the supplier’s facilities were not up to standard at all.

Here’s just a portion of what FDA inspectors found:

“Production employees handling RTE produce and food contact surfaces were not observed using any of the handwashing sinks in the facility.”

Additionally, it was revealed that the sanitation chemical mixtures either exceeded maximum concentrations or lacked proper documentation for safe use.

But how can companies avoid situations like these?

The very first step is to define clear metrics for assessing supplier performance before the relationship even begins and share them with your suppliers.

By clearly outlining performance standards, you’re setting the stage for accountability.

When suppliers understand what’s expected of them—whether it’s quality benchmarks, compliance rates, or safety protocols—they are more likely to take ownership of their performance.

This way, you create a culture where suppliers know their actions have direct consequences.

However, Mark Hermans, Managing Director at PwC, warns not to track all possible metrics at once.

Instead, choose those that matter to you the most.

Illustration: Veridion / Quote: Supply Chain Dive

For example, if cost efficiency is your top priority at the moment, focus on TCO or purchase price variance.

Or, if you’re looking to minimize risk, monitor your suppliers’ compliance rates or financial stability score.

There’s no need to get overwhelmed with an avalanche of data when you can track only those metrics that are relevant to your operations.

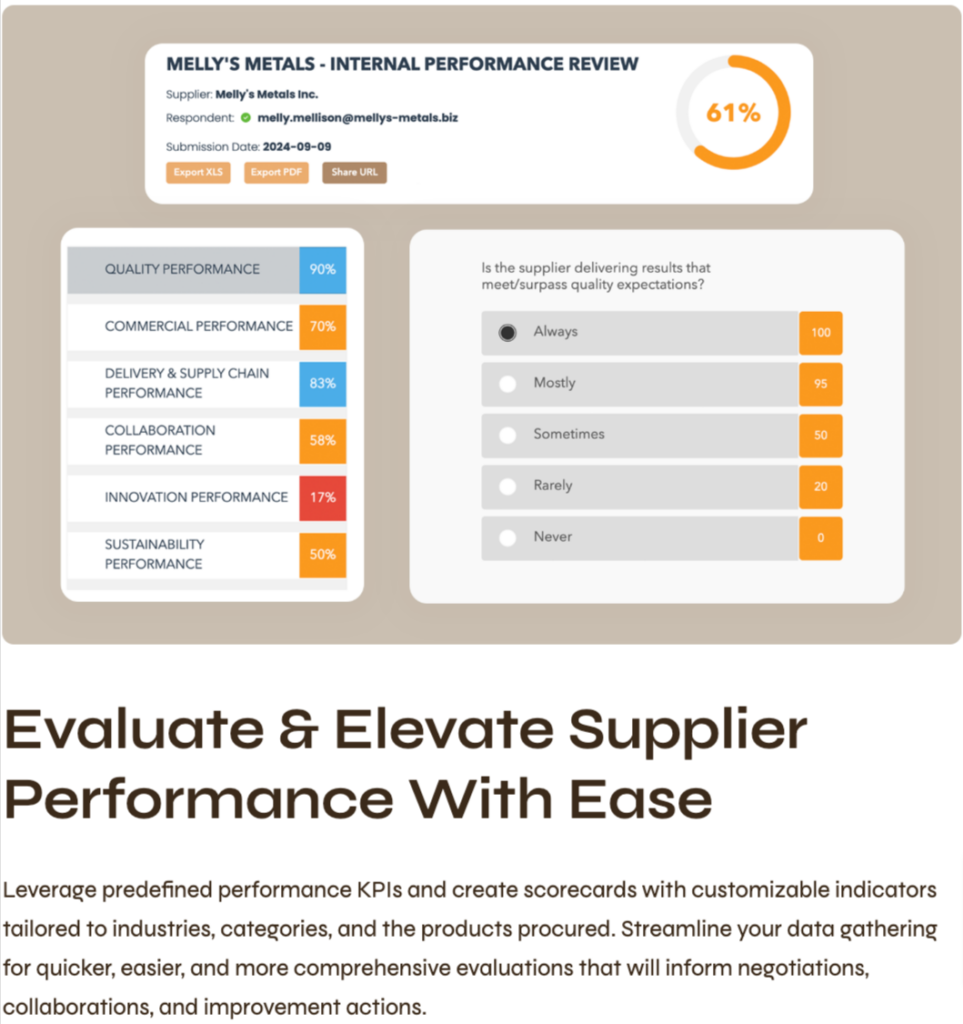

And to streamline and simplify this process even further, consider using Supplier Relationship Management (SRM) software.

These platforms centralize all that valuable supplier information, making it easier to monitor and manage relationships.

As shown below, they usually offer supplier scorecards, which automatically score vendors based on the KPIs you previously defined.

Source: Kodiak Hub

This approach worked perfectly for HL Display, a provider of merchandising and store communication solutions.

They used SRM software to consolidate data across multiple ERP systems, spreadsheets, notes, and emails, which allowed them to finally use those insights efficiently.

As a result, they significantly reduced the time required for supplier self-assessments, says Sunny Yang, Group Purchasing Director at HL Display:

“With our [old system], it took us 8-10 months to have our most important suppliers finish their self-assessments. With [our new SRM], we managed to get the same work done in 3 weeks.”

Tracking supplier performance doesn’t have to be that complex after all.

All you need is to set clear expectations from the beginning, leverage data effectively, and use the right tools.

Given the complexity of supply chains and supplier landscapes, buyers often struggle to communicate with all their key partners regularly and openly.

And suppliers notice it.

The 2024 HICX survey shows that 98% of suppliers believe communication with their clients needs improvement, while 48% report difficulties in resolving queries with their most important customers.

Illustration: Veridion / Data: HICX

Why does this matter?

Well, because poor communication can easily lead to misunderstandings, weakened trust, and operational disruptions.

Rivian, an American electric vehicle manufacturer, experienced this firsthand.

In 2024, due to a miscommunication with a supplier, Rivian lost access to a crucial component—copper windings used in its electric vehicle motors.

Meanwhile, the supplier redirected its production to other clients, leaving Rivian scrambling to find alternatives at a significantly higher cost.

Source: Drive Tesla

Ultimately, Rivian had to revise its annual production forecast downward by 18%, now expecting to produce between 47,000 and 49,000 vehicles.

Imagine the lost revenue, the production delays, and the frustration of trying to fix a preventable issue.

The best thing you can do to avoid incidents like these is to hold regular meetings with key vendors.

In fact, Melanie DiSalvo, founder of the fashion startup consultancy, virtue + vice, strongly recommends holding these meetings in person:

Illustration: Veridion / Quote: Shopify

According to her, face-to-face interactions are the best way to build strong relationships, establish trust, and possibly unlock preferential treatment or special favors down the line.

But meetings alone won’t cut it.

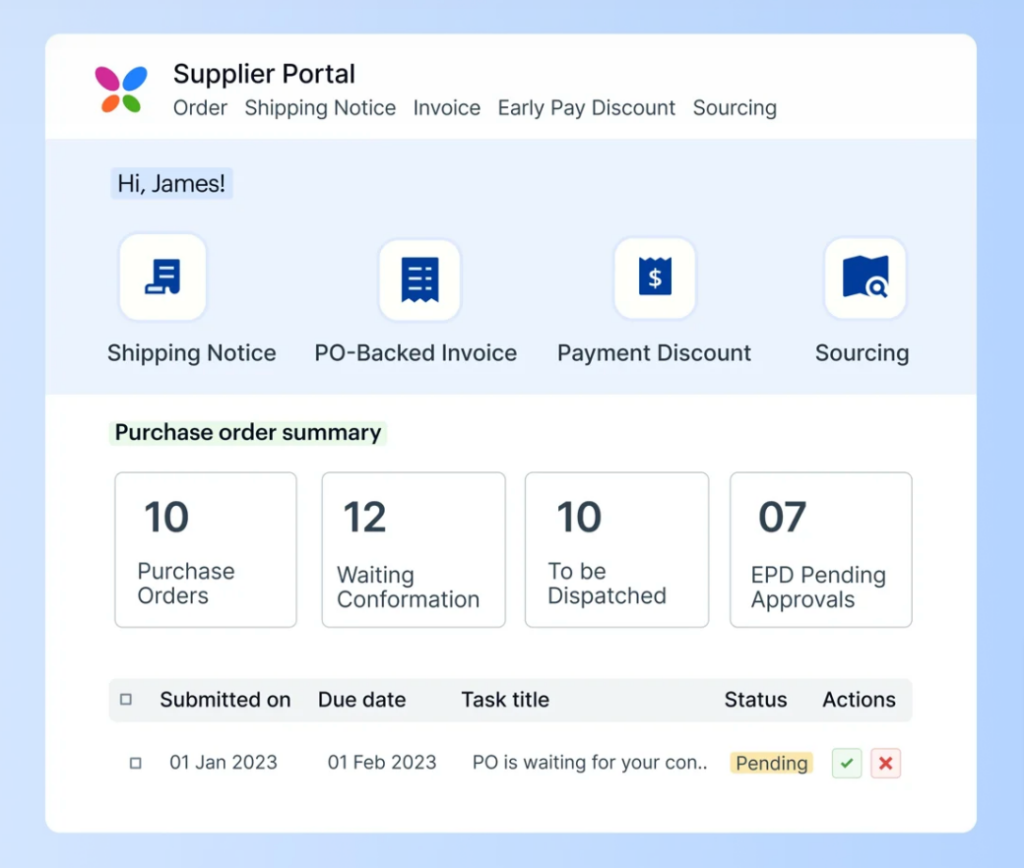

You also need a reliable system for consistent, documented day-to-day communication, like supplier portals.

A supplier portal is an online platform that serves as a centralized space where suppliers and buyers can access and manage business information, documents, orders, and transactions.

You can see an example of one such platform below:

Source: Kissflow

These portals typically offer robust features for tracking goods received, outstanding invoices, cleared payments, purchase history, etc., which considerably reduces the risk of errors.

Overall, when you combine frequent meetings with such communication tools, you’re preventing supply chain disasters and strengthening relationships at the same time.

In today’s volatile and highly competitive market, that’s certainly something you can’t afford to ignore.

Buyers and suppliers often have different priorities.

Buyers want the best price and quality, while suppliers want to maximize profits and secure favorable terms.

This misalignment can make it challenging to reach agreements, potentially wasting time and straining the buyer-supplier relationship.

For instance, if you become too rigid and focus solely on your own interests, you risk coming across as a bully—just as Laura Ashley, the interior design and clothing retailer, did in 2013.

Source: The Telegraph

As it turns out, despite reporting a 9% profit increase, the company still demanded a 10% discount from a supplier, which was met with heavy criticism.

However, Sean Anglim, Laura Ashley’s COO, defended the company, saying this was all done to stay competitive with rivals:

“I don’t think it was wrong to ask for an immediate discount. We need to be competitive on price.”

In situations like these, it’s hard to tell who’s right, which makes negotiations so tricky.

That’s why it’s so important to try to find a balance that benefits both sides.

Talk to your suppliers, understand their own needs and concerns, and avoid any manipulative tactics.

Nicolas Walden from The Hackett Group fully supports this collaborative, mutually beneficial approach.

Illustration: Veridion / Quote: Procurement Magazine

The best thing to do to ensure both sides feel like winners is to keep the terms and contracts somewhat flexible.

After all, market conditions constantly change so it’s not a bad idea to build a mechanism into the contract that addresses unplanned situations.

That way, both parties can feel protected should something go wrong.

Another way to achieve flexibility is to allow your partners to fulfill their responsibilities as they see fit.

Henry Stannard, Head of Strategy and Value Creation at Coalesce Capital, a private equity firm focused on investing in business services companies, explains how to do so:

Illustration: Veridion / Quote: Racounteur

He gives an example of incentivizing a facilities management provider to meet specific cleanliness standards instead of merely stating the number of cleaning sessions required.

And that’s how you ensure negotiations go smoothly, helping both parties meet their obligations in a way that works for them.

As a result, everyone’s expectations are met, relationships are strengthened, and nobody leaves the negotiation table disappointed.

Rules, regulations, market conditions, and supplier capabilities are constantly changing, making it difficult to proactively identify risks.

And if you can’t see the problems coming, how can you stop them?

The 2024 Supply Wisdom survey shows just how widespread this issue is.

Shockingly, 62% of businesses admit they don’t have full confidence that their risk monitoring programs meet contractual and regulatory standards.

Moreover, supplier evaluations take an excessive amount of time, with 35% of companies spending 5-6 weeks on a single assessment.

Illustration: Veridion / Data: Supply Wisdom

Yes, risk management is both time-consuming and complex.

Still, it’s absolutely vital.

Without it, you face numerous challenges, from lost revenue to operational disruptions.

Consider the case of Ineos Automotive Ltd, a British manufacturer of off-road vehicles.

In 2024, the company was forced to pause production of its popular vehicle models due to a supplier’s financial troubles.

Source: Carscoops

Since this was a supplier of a very important trim part, the plant had to be shut down for several months, leading to significant financial losses.

To mitigate such risks, companies need reliable, up-to-date supplier data to stay ahead of potential disruptions.

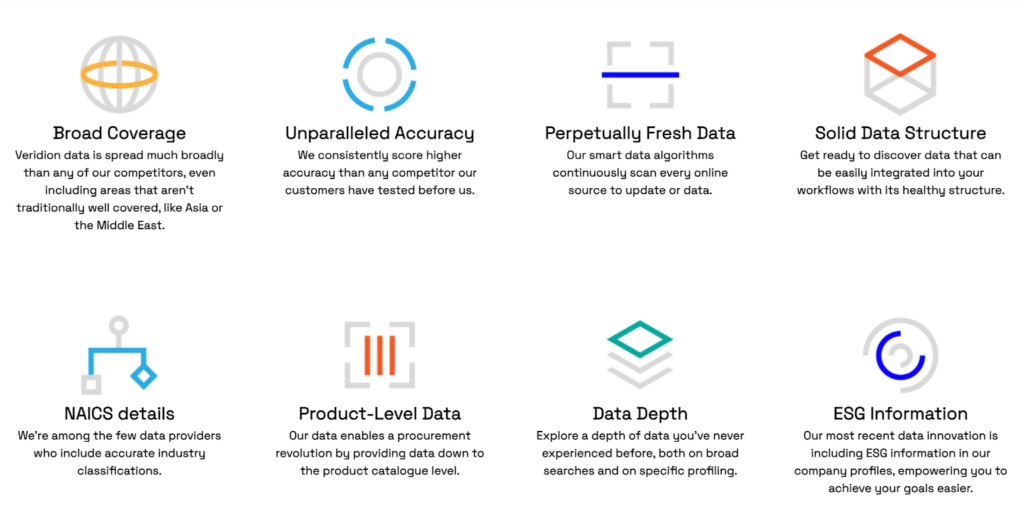

This is where business intelligence platforms like Veridion come in.

Veridion’s AI-managed database, covering over 120 million businesses, offers all the necessary information to efficiently pre-qualify new vendors and monitor existing ones.

Source: Veridion

The best part?

Our data is updated every week so that you can identify emerging risks within your supplier base in real time.

Plus, with our real-time alerts, it’s even easier to proactively respond to changes, mitigating potential disruptions before they impact your organization.

When it comes to risk data, Veridion covers a wide range of categories, some of which you can see outlined below:

Source: Veridion

With our unparalleled coverage and precision, you’re always in the know about your supplier landscape, keeping your operations agile, resilient, and disruption-free.

Managing risks isn’t so difficult after all if you have reliable data on your side.

Implementing sustainable and ethical practices often comes with higher costs, which some suppliers may resist or pass on to you as a buyer.

Additionally, suppliers are often reluctant to provide insights into their internal processes, which are needed to verify their ESG performance.

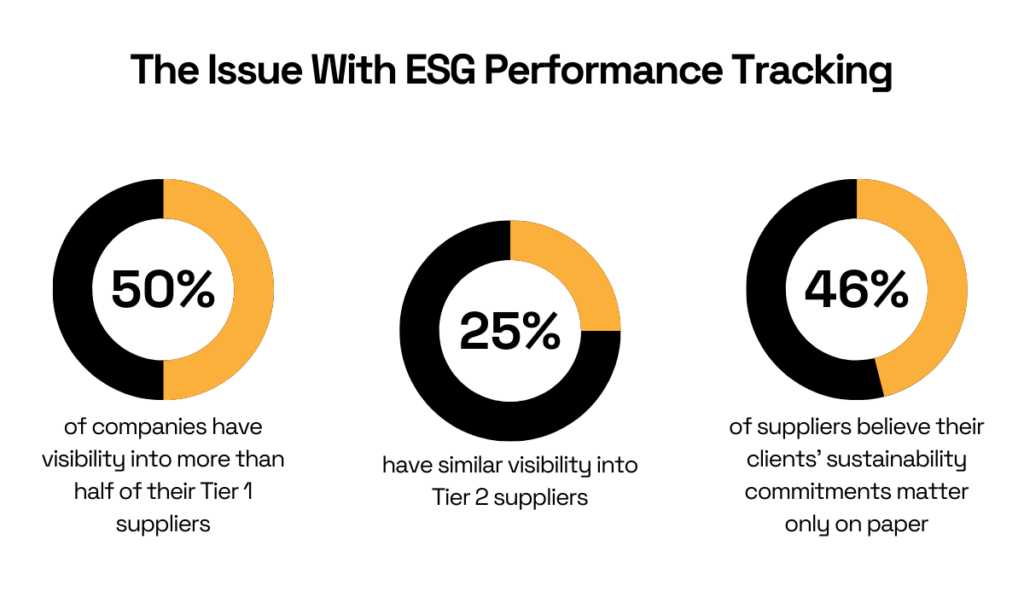

The 2024 EcoVadis survey highlights just how challenging it is for companies to monitor their supply chains in this regard.

It reveals that only a small number of companies have visibility into more than half of their Tier 1 and Tier 2 suppliers.

And an even more concerning finding is that 46% of suppliers believe their customers’ sustainability commitments matter “only on paper.”

Illustration: Veridion / Data: EcoVadis

This suggests a disconnect in trust, perception, or consistency when prioritizing ESG standards in buyer-supplier relationships.

The problem is this: if your suppliers engage in unethical practices like child labor or environmental harm, it can severely damage your organization.

For instance, in 2022, a Hyundai and Kia parts supplier was fined for child labor violations after authorities found children as young as 13 working at their plant.

While regulators did not accuse Hyundai or Kia of direct wrongdoing, scandals like this can still impact a company’s reputation in a very negative way.

Source: Reuters

Not to mention that supplier shutdowns due to regulatory violations can disrupt your own operations, too.

So, how do you protect your business from similar issues and ensure your suppliers are compliant with relevant ESG standards?

One step in the right direction is creating a Supplier Code of Conduct—a document that sets clear expectations for labor practices, environmental impact, and ethical behavior.

Companies like Bombardier, a Canadian business jet manufacturer, make these publicly available to ensure all partners know exactly what’s expected of them from the get-go.

In these documents, they outline all their standards in great detail, including areas such as:

That said, one document alone won’t protect you completely from ESG violations, especially if you lack visibility into supplier operations.

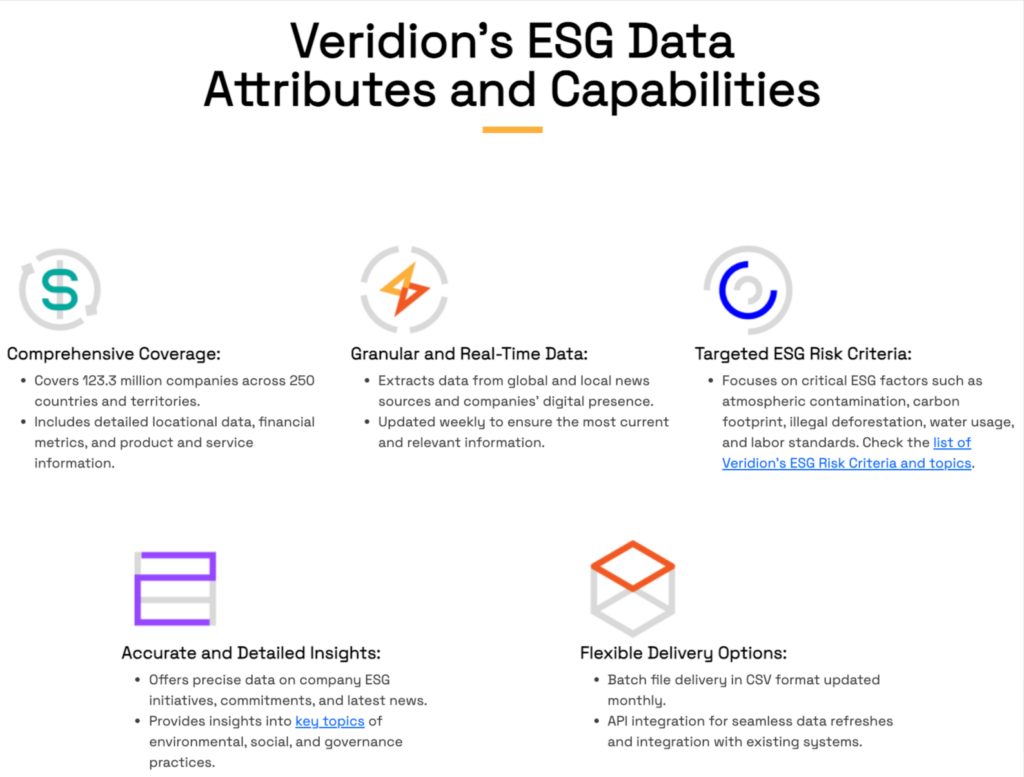

Here, supplier data platforms such as our Veridion emerge as a perfect solution once again.

Source: Veridion

In addition to financial, company, and product data, Veridion provides insights into the ESG performance of your partners as well.

Below is Veridion’s ESG taxonomy overview:

Source: Veridion

With this level of transparency, nothing slips through the cracks so you can finally ensure your partners align with your values and won’t become liabilities down the line.

That is—if you use this data to regularly evaluate supplier sustainability practices.

If managing supplier relationships feels like a constant uphill battle, full of miscommunication, misinformation, and a lack of understanding, know that you’re not alone.

These challenges are all too common.

Unfortunately, they often escalate into serious problems like strained relationships, operational disruptions, and even lost profits.

But there’s a way to turn things around.

It all starts with reliable, timely, and accurate supplier data.

With the right insights in hand, you can negotiate more strategically, mitigate risks, track supplier performance, and maintain strong, mutually beneficial partnerships.

It’s a win on all fronts.