Top 7 Tips for Successful Supplier Vetting

Having reliable and reputable suppliers is essential for efficient procurement, consistent product quality, and resilient supply chains.

And this is exactly why thorough supplier vetting is so important.

It helps you identify and select trustworthy partners from the start, minimizing risks down the line and building sustainable supply networks.

So, if you’re looking to improve your supplier vetting process, you’ve come to the right place.

This article will give you seven practical tips for vetting and ultimately selecting the best suppliers for your business.

Let’s dive in!

First off, it’s crucial to establish a structured process for supplier vetting.

While evaluating suppliers on a case-by-case basis might work in certain situations, a well-defined process is essential for maintaining objectivity and consistency.

This means evaluating all potential suppliers against the same criteria, ensuring a fair and unbiased selection process.

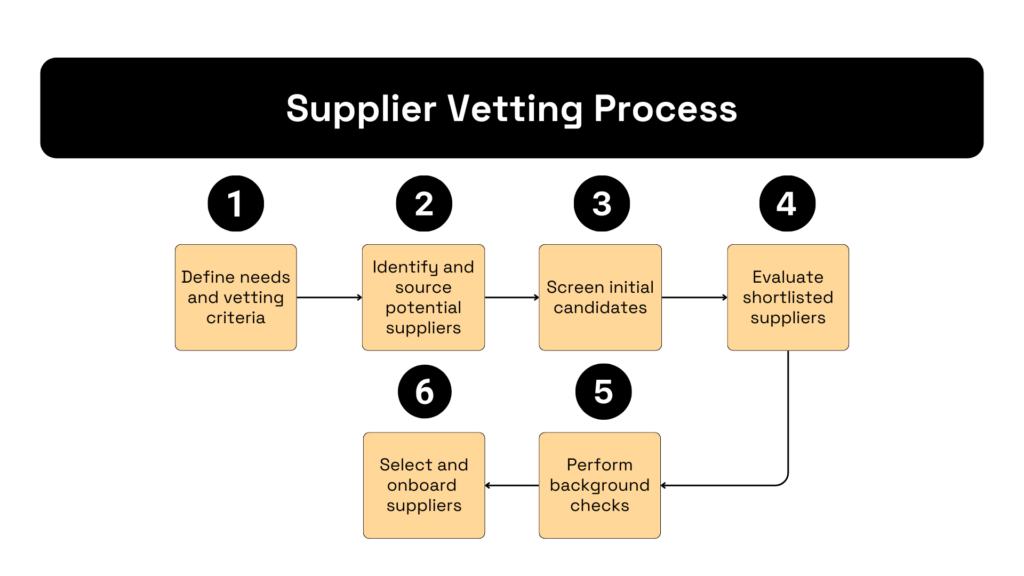

The first step in creating a standardized vetting process is outlining the general steps, as you can see below.

Source: Veridion

This process begins with clearly defining your organization’s needs and expectations.

Along with defining your needs, you also need to establish clear criteria for the vetting process itself.

These criteria could include factors such as price, quality, delivery time, reliability, financial stability, and more.

After defining your needs and criteria, you can start narrowing down your list.

As the list narrows, you can move on to using scorecards in order to evaluate the remaining suppliers across a broader range of criteria.

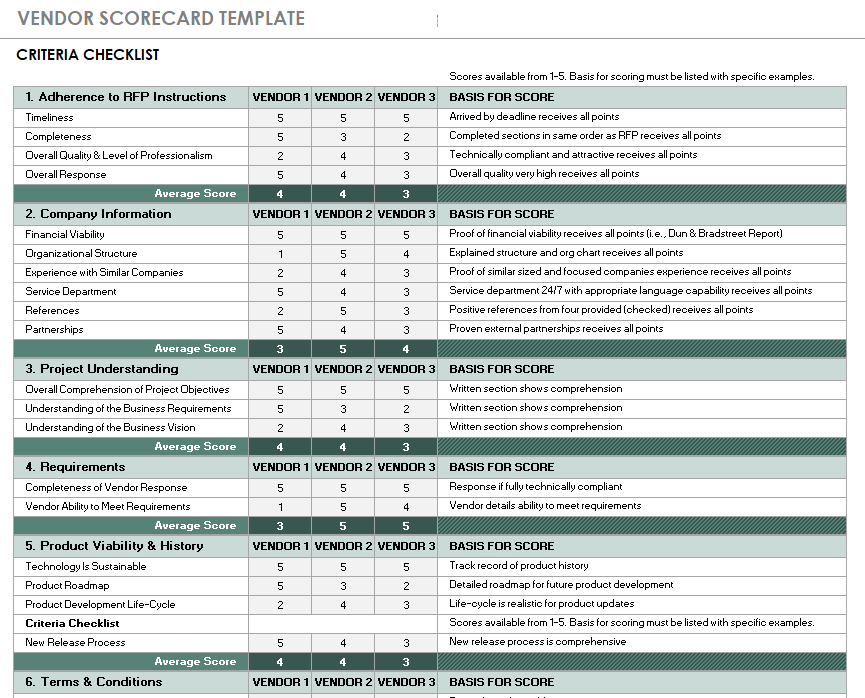

Supplier selection scorecards are helpful because they provide a structured way to evaluate suppliers, allowing you to assign scores to different aspects of supplier profiles.

Take a look at an example scorecard below.

Source: Smartsheet

Scoring in these scorecards can be done using numerical scales (e.g., 1-5) or qualitative assessments (e.g., excellent, good, fair, poor), with each criterion weighted based on its importance to your organization.

By objectively comparing scores across all potential suppliers, you can identify those with the highest average scores.

What’s more, you can identify suppliers with close average scores to serve as backup options.

All in all, a standardized vetting process provides structure, consistency, and objectivity to your supplier selection.

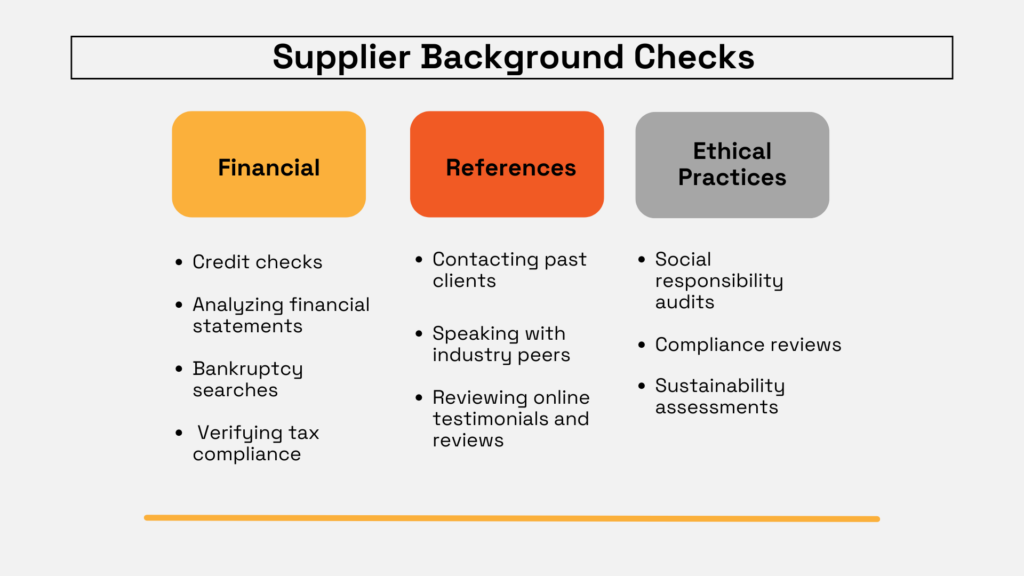

A crucial component of the vetting process is conducting thorough background checks on potential suppliers.

Typically, these checks are best performed on a shortlist of suppliers.

In a way, they act as a final layer of due diligence, confirming your initial supplier assessments and uncovering any potential issues.

These background checks can cover various aspects of a supplier’s profile, including their financial stability, customer references, and ethical practices.

Source: Veridion

However, gathering all the necessary information for this process can be challenging.

One effective method is checking supplier references.

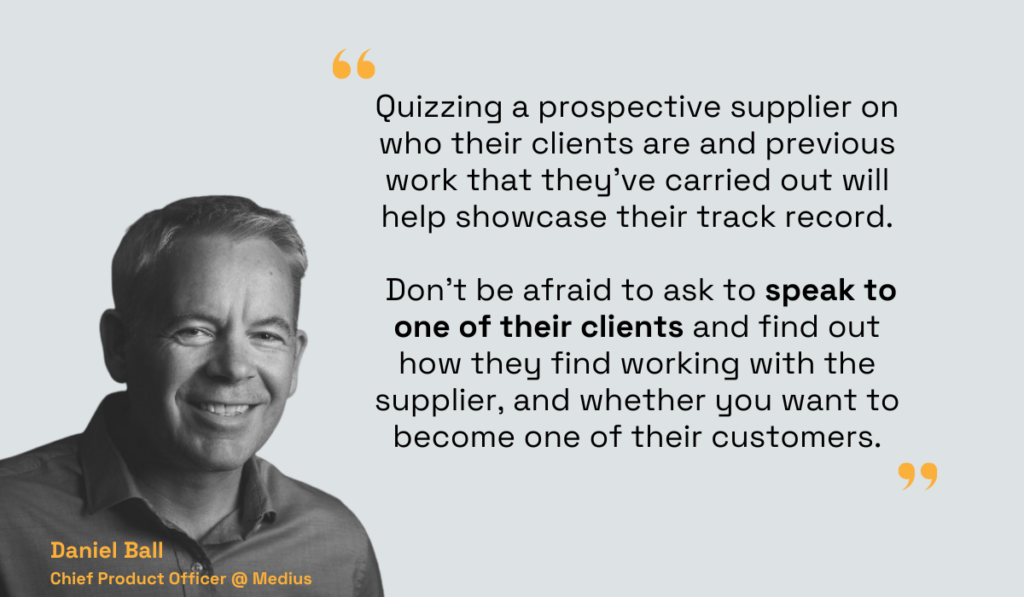

Daniel Ball, CPO of Medius, emphasizes the importance of contacting potential suppliers’ past clients to gain insights into their track record.

Illustration: Veridion / Quote: Supply Chain Digital

When speaking with past or current clients, you can inquire about:

Then, you can combine these insights with data from a supplier intelligence platform like Veridion.

Source: Veridion

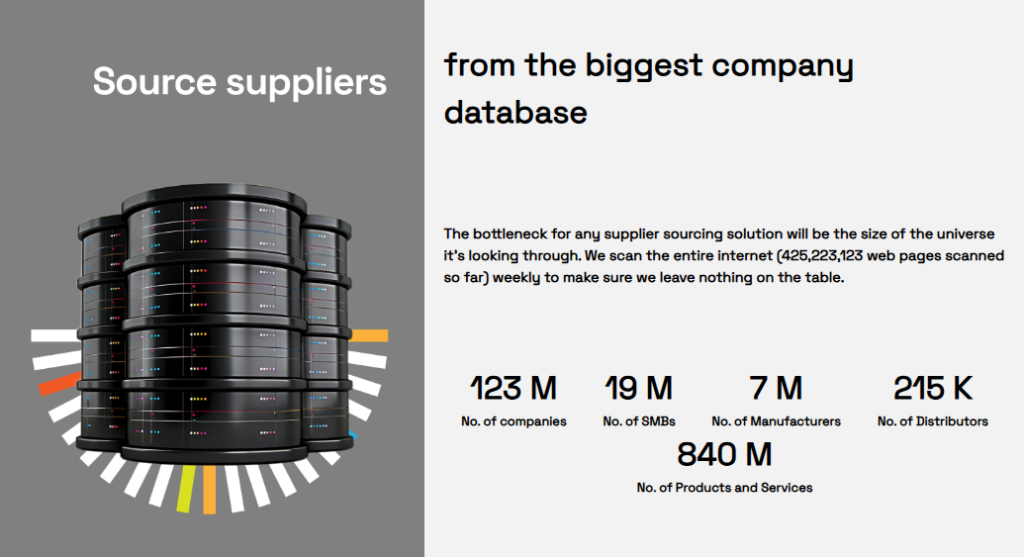

With a database of over 120 million companies, Veridion provides access to key information such as the following:

And, with our Supplier Discovery service, vetting and finding the right suppliers is straightforward, using natural language search queries.

Check out the demo video below for a closer look at how it works.

Source: Veridion

On top of that, our Match and Enrich service allows you to enhance your company’s existing supplier profiles with the latest information, making sure you have accurate and recent data to work with.

Overall, by combining traditional methods like reference checks with the power of platforms like Veridion, you can gather all the necessary data to conduct thorough and effective background checks.

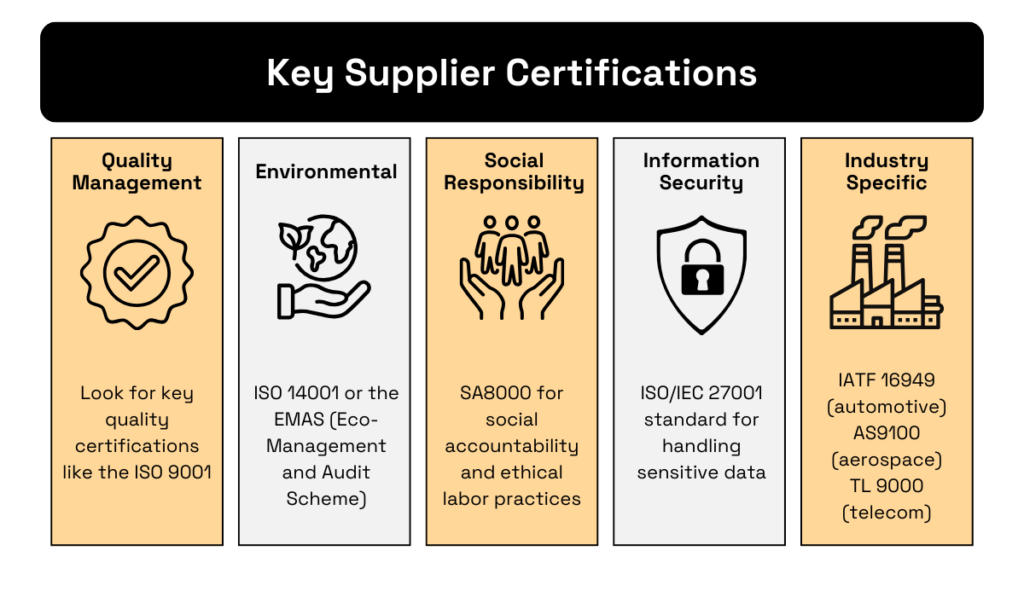

Quality and safety are paramount considerations during supplier vetting, and checking certifications is a crucial step in this process.

The specific certifications you need will depend on your industry and requirements.

Generally speaking, though, you may want to consider some of the categories outlined below.

Source: Veridion

Quality certifications, such as ISO 9001 are one of the first things to look for, as this provides assurance that the supplier has established quality processes.

When it comes to working in a specific industry, look for quality certifications that apply to that field, like the IATF 16949 for the automotive field or AS9100 for aerospace.

It’s always a positive sign when suppliers openly display their valid quality certifications.

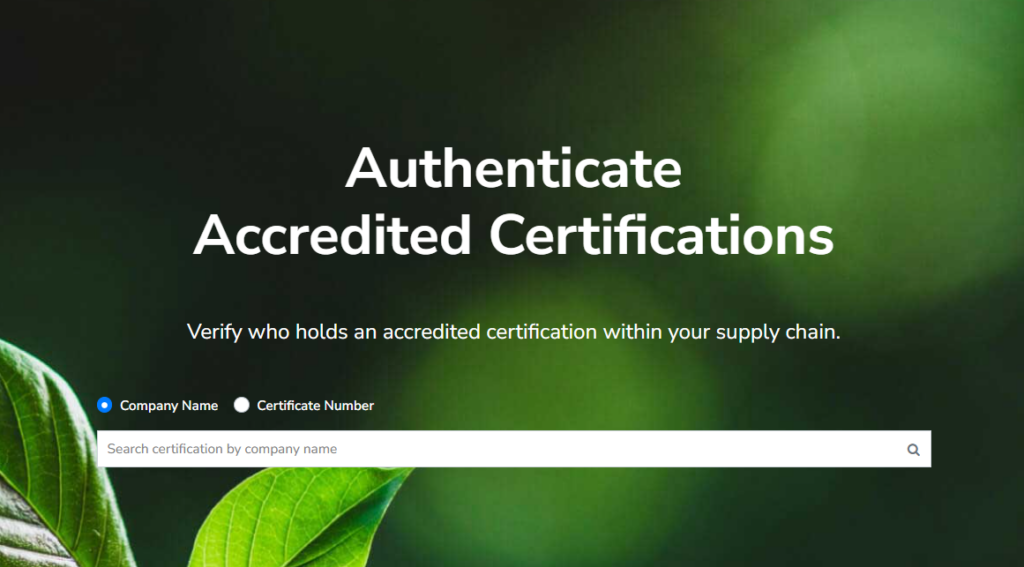

However, when that’s not the case, platforms like IAF CertSearch offer searchable databases of companies and their certifications for validation purposes.

Source: IAF

Also, don’t overlook certifications related to sustainability, environmental responsibility, and social responsibility (ESG).

Ensuring your suppliers align with your organization’s values and ethical commitments is crucial, as it prevents potential reputational and financial damages.

For example, consider the case of Lululemon and the allegations of forced labor within their supply chain.

Source: Freedomunited

With an increasing number of countries implementing modern slavery regulations, ensuring your suppliers adhere to ethical labor practices is non-negotiable.

In summary, verifying certifications is vital in ensuring supplier quality, safety, and ethical practices.

So, don’t rely solely on a supplier’s claims—utilize your available resources and independently verify certifications to make informed decisions.

Now, let’s shift our focus to assessing a supplier’s production capabilities.

This crucial evaluation is best performed early in the vetting process and helps ensure that a potential supplier can consistently meet your company’s demand for goods or services.

Some key criteria to look for are illustrated below.

Source: Veridion

Among these, production capacity, workforce size, and technological infrastructure are particularly important, as they directly impact a supplier’s ability to meet your current and future needs.

More specifically, when evaluating a supplier’s production capacity, several aspects come into play, as shown below.

| Type | Metric | Implication |

|---|---|---|

| Manufacturing Capacity | Units produced per time period (e.g., widgets per hour, tons per day) | Directly affects order fulfillment speed and volume. |

| Warehouse Capacity | Storage space (e.g., square footage, cubic meters, pallet spaces) | Influences inventory management, production continuity, and order fulfillment speed. |

| Transport Capacity | Volume or weight of goods that can be transported (e.g., tons per truckload) | Impacts delivery speed, logistics costs, and overall supply chain efficiency. |

| Labor Capacity | Available labor hours or number of skilled workers | Determines production flexibility, responsiveness to demand changes, and potential for scaling operations. |

It’s important to remember that, even if a supplier has adequate manufacturing capacity, limitations in other areas—such as warehousing or transportation—can still create bottlenecks and delays.

Also, it’s vital to consider not just current capabilities, but also factor in changing demands.

Your needs may change over time, and your suppliers need to be adaptable enough to accommodate growth or fluctuations in demand.

For example, if a supplier is currently operating at 60% capacity, this might seem positive, but it could indicate underlying issues or inefficiencies.

Conversely, a supplier operating at 80% capacity may struggle to meet increased demand if your business expands, potentially leading to supply delays and disruptions.

Therefore, you should vet suppliers not only for their current production capabilities but also for their scalability and ability to adapt to changing demands.

Look for suppliers who have a track record of scaling their operations effectively and who demonstrate a willingness to invest in future growth.

This proactive approach will help ensure a reliable and adaptable supply chain—both now and in the future.

Before finalizing a supplier partnership, even if they appear to meet your demand requirements, you must thoroughly assess their production quality.

This is essential for maintaining the quality of your own products or services and, in turn, protecting your brand reputation and customer satisfaction.

For this reason, conducting on-site quality audits during the vetting process is crucial.

These audits involve visiting the supplier’s facilities to assess various aspects of their operations.

This includes production processes, quality control measures, equipment maintenance, and employee training.

And while everything may look well on the surface, you also want to go one level deeper and get product samples.

While obtaining representative samples for a product can be time-consuming, involving back-and-forth communication with suppliers, the effort is well worth it.

Jim Kennemer, Founder of Cosmo Sourcing, elaborates on this.

Illustration: Veridion / Quote: Cosmo Sourcing

After all, robust quality audits and sample checks can ultimately save you significant costs in the long run.

They help prevent costly product recalls due to defects and minimize the need for rework or returns.

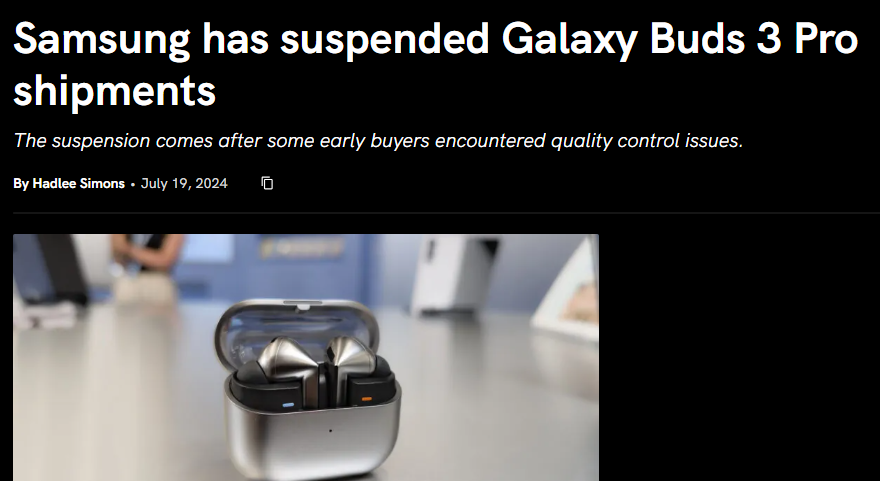

Consider Samsung’s example.

In early 2024, they suspended shipments of their Galaxy Buds 3 due to multiple quality problems, including easily torn ear tips.

Source: Android Authority

This incident further added to the list of Samsung’s history of quality control challenges, including overheating and ignitable phones, as well as issues with their foldable phone.

Thorough supplier vetting, including rigorous quality audits, could potentially identify and address these issues before they impact consumers, preventing reputational damage and financial losses.

In other words, never underestimate the importance of quality audits and sample checks in the supplier vetting process—they can be a lifesaver in the long run.

Supply chain risk assessments identify potential disruptions or vulnerabilities that could impact the flow of goods or services from your suppliers.

These assessments are crucial for proactively mitigating potential problems and building a more resilient supply chain.

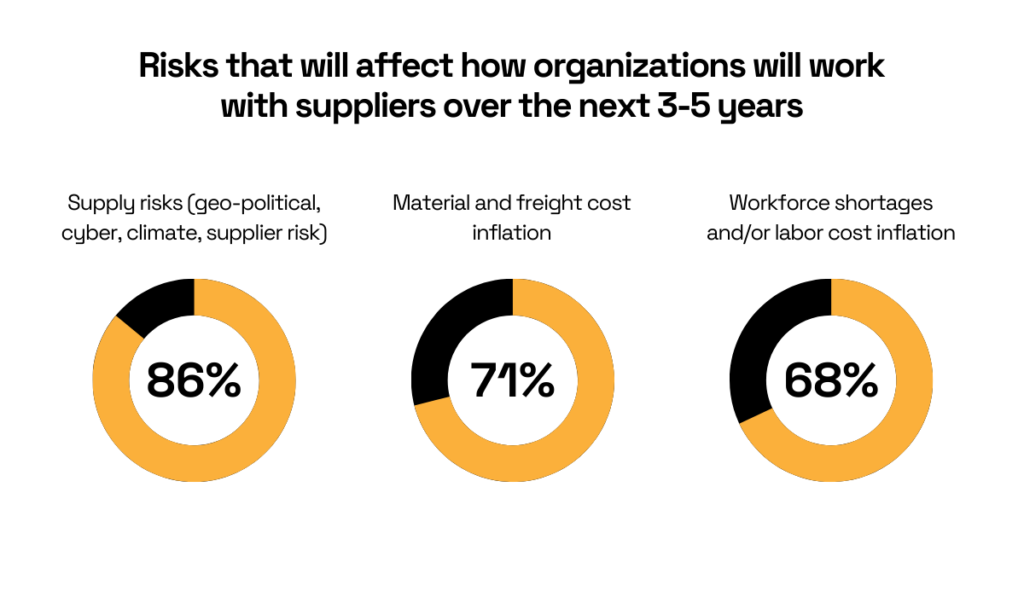

A KPMG study of over 400 C-suite and SVP/VP executives in procurement and outsourcing companies revealed valuable insights into supply chain risks.

When asked about the risks they anticipated being the most affected by in the next 3-5 years, the results were as follows:

Illustration: Veridion / Data: KPMG

As you can see, supply risks, along with cost inflation and workforce shortages, were the top concerns.

Your vetting process should address these risks by evaluating suppliers’ resilience to potential disruptions.

This includes assessing their financial stability, geopolitical situation, and mitigation strategies for various risk factors.

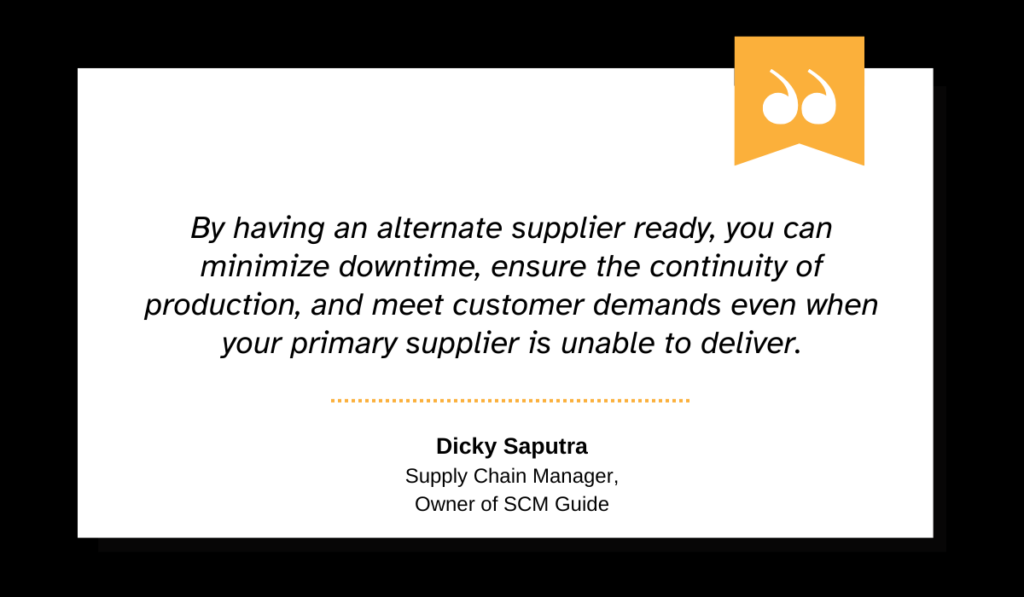

But, another key strategy to keep in mind is supplier base diversification.

So, to reduce your reliance on any single supplier, consider vetting and establishing relationships with backup suppliers.

While backup suppliers are typically utilized only in exceptional circumstances, they are indispensable for maintaining smooth operations during disruptions.

Dicky Saputra, supply chain manager and owner of SCM Guide, agrees.

Illustration: Veridion / Quote: SCM Guide

A thorough supplier vetting process helps identify the best backup suppliers—those most closely aligned with your primary suppliers in terms of capabilities and offerings.

And, having these pre-vetted backup suppliers in place allows for a swift transition in case of unforeseen circumstances with your primary supplier.

Ultimately, by proactively identifying and mitigating potential disruptions, you can build a more resilient and reliable supply chain, safeguarding your business from unforeseen challenges.

Finally, supplier vetting provides a great opportunity to discuss and negotiate pricing and payment terms early on.

Comparing costs from different suppliers is undoubtedly a key part of the vetting process, helping you identify the most cost-effective options.

However, focusing solely on the initial price tag can be misleading.

Often, costs are evaluated superficially, leading to the selection of the cheapest supplier without considering other critical factors.

As Jared Haw, VP of Revenue Ops at OpenBOM, points out, this can be a costly mistake:

“Suppliers looking to offer attractively low costs often reduce their expenses by using inferior materials, employing less skilled labor, or cutting corners in the manufacturing process. These compromises can lead to defective or substandard products that fail to meet the quality expectations set by both the company and its customers.”

Fortunately, a thorough supplier vetting process addresses many of the issues he highlights.

By assessing production quality, workforce data, and manufacturing processes, combined with a careful analysis of costs, you gain a more comprehensive understanding of the true value each supplier offers.

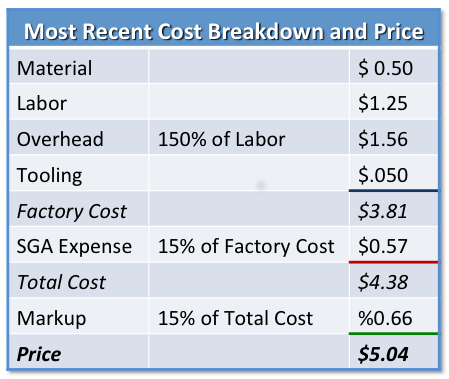

This can also involve creating a detailed cost breakdown of the products or services offered by each supplier.

Consider the example cost breakdown below.

Source: ME

This breakdown can reveal valuable insights.

For example, it can highlight whether a supplier is applying a disproportionately large markup compared to their costs, or if a higher price is justified by the use of higher-quality materials or more skilled labor.

In the end, this data can allow for more informed negotiations and help you identify suppliers who offer genuine value for money.

We examined seven critical aspects of supplier vetting, including thorough planning, proactive risk management, and assessments of certifications, production capabilities, costs, and overall supplier quality.

Hopefully, you now have a clearer understanding of how crucial they are for establishing a robust and reliable supply chain.

By applying the tips we shared to your own vetting process, you can strengthen your procurement operations and build stronger, more collaborative relationships with the right vendors.

In turn, these proactive vetting practices will ultimately serve as a valuable investment in your long-term procurement success.