Vendor Concentration Risk: 6 Challenges of High Supplier Concentration

Relying on fewer suppliers is often touted as beneficial for companies.

After all, it leads to cost savings and makes procurement processes simpler and more streamlined, right?

While this is often true, supplier concentration also has its downsides.

In this article, we’ll explore six hidden dangers of high supplier concentration and suggest how to reduce these risks and maintain a resilient supply chain.

Let’s dig in.

When a company relies heavily on a small number of suppliers, any disruption to those suppliers can create a significant ripple effect on the company’s operations.

In recent years, many companies have consolidated their supplier base to streamline procurement and gain volume discounts.

However, this strategy can backfire if a critical supplier faces disruptions, exposing the company to substantial risks.

For example, in 2018, a fire at a key supplier’s factory forced Ford to halt production of its best-selling F-150 pickup truck.

Source: NPR

In the words of Abhay Vadhavkar, Ford’s director at that time, the supplier affected by the fire:

“…is the only supplier in North America that has the ability to supply this product at the volume Ford requires. You don’t have multiple suppliers for a complicated part like this one. You have specialty manufacturers because it’s more efficient.”

Michelle Krebs, executive analyst for Autotrader, highlights how this trend in the automotive industry has contributed to increased disruption risks:

Illustration: Veridion / Quote: Detroit Free Press

This massive effect arises when companies—like Ford in our example—have few or no alternative suppliers to replace the affected supplier.

More specifically, such companies face a higher risk of severe consequences when disruptions occur, including:

So, what can companies do to decrease the odds of such disruptions?

Two key actions include building higher backup inventory levels and establishing greater supplier redundancies.

For example, while other automakers were also affected by the fire at that facility, GM was able to avoid production shutdowns by proactively identifying and engaging alternative suppliers.

To recap, while relying on a few key suppliers can make supply chains more efficient, it also makes them less adaptable and more vulnerable to disruptions.

To effectively manage these risks, companies must recognize the inherent tradeoffs between supply chain efficiency and flexibility—and strive to achieve a balanced approach.

Another issue for companies with high supplier concentration is that they lose leverage in negotiations.

This means that suppliers may have more power to increase prices, especially if they know your company has limited or no alternatives.

Knowing they have leverage, they also might impose stricter payment terms, lower quality standards, or less flexible delivery schedules.

In such cases, your first impulse may be to find a new supplier.

But you can’t do that without viable alternatives.

This is exactly the issue Apple has with its key supplier of 5G modems, Qualcomm, which continues to leverage its near-monopoly position to raise prices.

Source: Wccftech

To address this longstanding issue, Apple began developing its own custom 5G modems.

By reducing its reliance on Qualcomm over the long term, Apple aims to decrease its vulnerability to price increases and supply limitations from a single supplier.

This strategy can also serve as a model for other companies looking to limit supplier overdependency.

Of course, not all companies have the resources to develop internal production capabilities to replace a key supplier.

So, what can you do if that’s the case?

Simple: you need to diversify your supply base.

This involves identifying alternative suppliers who can provide similar products or services at competitive prices.

The easiest way to find them is by using supplier discovery tools like our Veridion.

Source: Veridion

Veridion gives you access to a global, AI-powered database of suppliers that’s updated on a weekly basis and currently features over 120 million companies.

With Veridion’s natural language search, you can find any supplier with an active online presence in seconds.

Source: Veridion on YouTube

This way, you can gradually expand your supplier network, reduce dependency on any single supplier, and strengthen your negotiating leverage.

Other longer-term tactics to prevent price hikes and other unfavorable changes from key suppliers include:

However, there may be times when a supplier increases prices or changes terms, and none of the options we’ve discussed are feasible.

In these cases, consider formally asking the supplier to justify the price increase or any other change.

This helps determine whether their request is reasonable or excessive.

It also gives you a chance to use historical data and benchmarks to prepare a counteroffer and negotiate better terms.

While these strategies can help manage supplier demands, diversification remains a key strategy for increasing your negotiating power.

By building a broader supplier base, you reduce dependency and gain the leverage needed to maintain stable, favorable terms over time.

Picture this: you’re working with a single for the procurement of an essential product, and you couldn’t be happier about it.

That is until suddenly, their quality deteriorates.

Because you don’t have alternative suppliers readily available, the impact of your supplier’s quality control or operational issues is bound to be severe.

This is exactly what Boeing has been dealing with.

They faced a major operational disruption when Spirit AeroSystems, their primary supplier of fuselages, started experiencing manufacturing defects.

This caused delays in the production and delivery of a large number of Boeing’s 737 Max planes.

Source: AP News

This example illustrates how a disruption from a single key supplier can cascade through the supply chain when supplier concentration is high.

So, what can you do to avoid disruptions related to a supplier’s quality control?

As discussed, diversifying your supply base by engaging multiple suppliers helps reduce dependency on a single source, which is crucial when quality issues arise.

After additional suppliers for the same products or components are identified and onboarded, you will have alternatives if quality issues arise with one supplier.

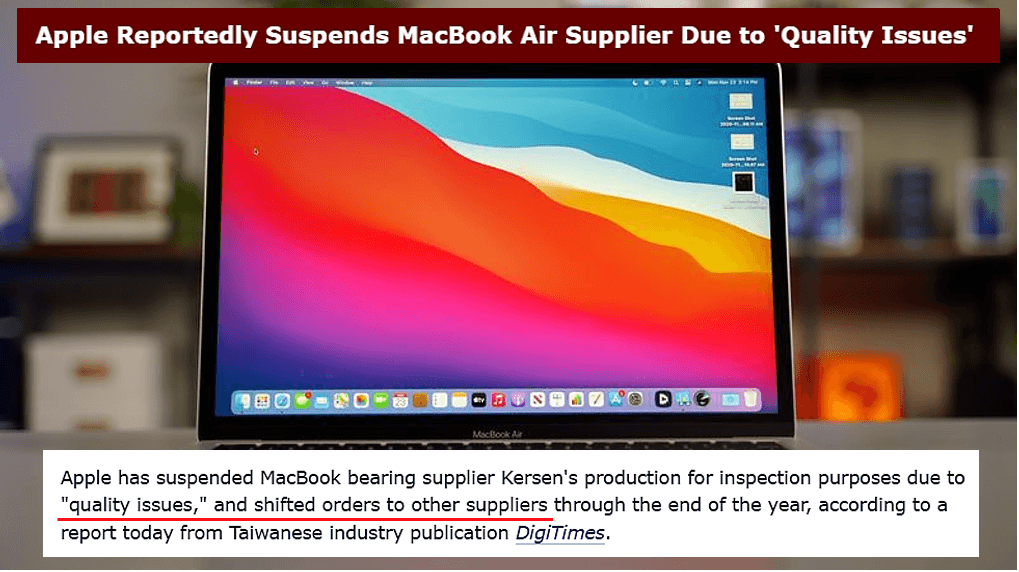

That’s exactly what what Apple did when one of its suppliers faced quality issues.

Source: MacRumors

Apple’s actions illustrate the advantage of having multiple suppliers for the same or similar products, components, or materials.

If one supplier experiences quality control problems, others can step in to fulfill orders, ensuring business continuity and minimizing disruptions.

That’s why it’s common for companies—especially in sectors like manufacturing and retail—to maintain two or three backup suppliers.

These suppliers are often engaged by the company to deliver other products or components.

This approach keeps them familiar with the company’s needs and quality standards, ensuring they can step in quickly if required.

Large corporations are also increasingly leveraging technology, such as the supplier discovery tools we mentioned, to identify and pre-qualify backup suppliers.

This allows them to quickly engage alternative sources during disruptions, enhancing their supply chain resilience.

Overall, building a diverse and well-prepared supplier base mitigates risks associated with quality control issues and strengthens your company’s resilience to unexpected disruptions.

When a company is highly dependent on a single or limited group of suppliers, it risks being bound to the supplier’s product development roadmap.

This roadmap usually reflects the supplier’s overall market strategy and the demands of their largest customer segments, rather than the unique needs of any single client.

For instance, a supplier may prioritize certain product features or innovations that appeal to broader markets.

This may not seem like an issue—at least not until they stop aligning with your company’s specific strategic requirements.

This misalignment can then lead to challenges in differentiation.

Why?

Because your company will lack the flexibility to introduce tailored features that could offer competitive advantages.

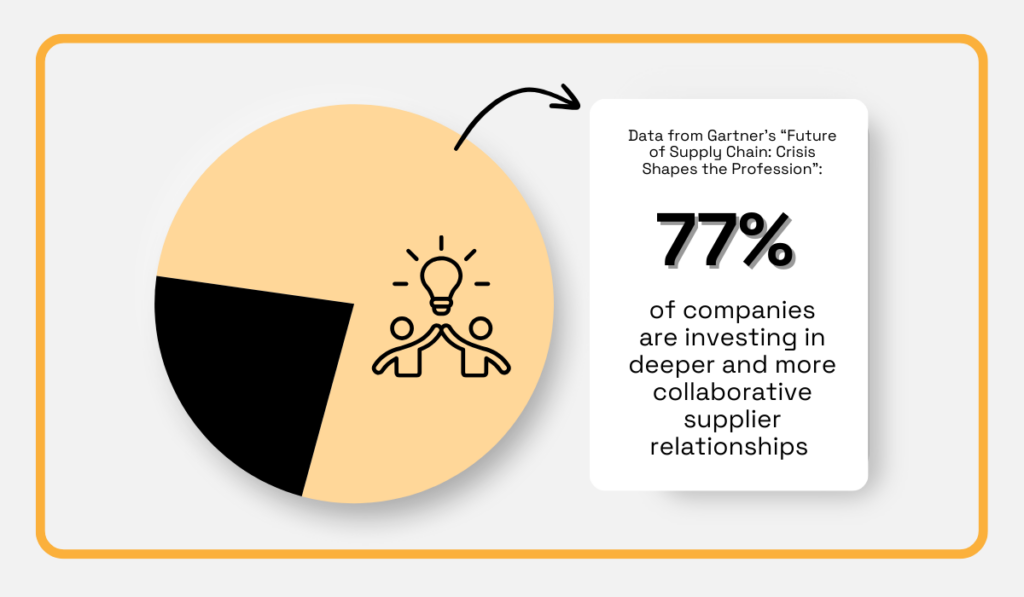

To mitigate this, companies are increasingly recognizing the value of fostering close supplier partnerships, as shown by findings from Gartner’s report:

Illustration: Veridion / Data: Gartner

Investing in deeper, collaborative supplier relationships can help ensure that your suppliers’ development priorities align more closely with your own.

This approach also fosters open, ongoing communication about your future needs, enabling early identification of any potential gaps.

Another effective strategy is to establish joint development agreements, which create a formal framework for both parties to collaborate on product innovations.

For instance, P&G entered into such an agreement with its supplier, Dow Chemical.

Together, they created a novel process for reusing hard-to-recycle waste in consumer packaging.

Source: Packaging Dive

This collaboration allowed P&G to align its sustainability goals with Dow’s expertise in material science, ensuring that both parties pursued shared objectives in product development.

Overall, diversifying your supplier base by including smaller, more specialized suppliers can provide access to niche solutions that larger, market-driven suppliers may not offer.

This approach will allow your company to stay adaptable and responsive to specific customer needs, without being limited by the development priorities of a single supplier.

This risk of high supplier concentration is similar to the one we just discussed.

In this case, however, a dominant supplier may not invest in new technologies or innovate quickly enough for your company to keep pace with market trends.

This misalignment can be especially challenging in fast-paced industries, where access to cutting-edge tools or processes is vital for maintaining a competitive edge.

To address this, companies can diversify their supplier network to include vendors with strong innovation pipelines.

So, where should you look to find such suppliers?

Typically, smaller, specialized suppliers or startups often focus on emerging technologies and may be more open to collaborating on tailored solutions.

Consider this example:

Source: The EV Report

Establishing such partnerships or co-development agreements with technology-forward suppliers can help your company stay aligned with the latest market advancements.

Additionally, you should consider fostering a collaborative environment with suppliers through initiatives like technology roadmaps or innovation workshops.

By sharing your company’s goals and challenges, you can encourage suppliers to prioritize relevant technological advancements that enable effective future collaboration.

While some would argue that fewer suppliers mean fewer regulatory risks, the opposite can often be true.

Relying on a limited set of suppliers can actually increase your exposure to compliance and ethical risks.

How so?

Because it ties your company more closely to those suppliers’ practices.

This overreliance can also limit your ability to pivot away from a supplier embroiled in controversy.

If a supplier fails to meet regulatory standards—such as safety, labor, or environmental requirements—you as the buyer are often bound to face legal, financial, or reputational repercussions.

A notable example is the UK fashion brand Boohoo, which faced major backlash when one of its Leicester-based suppliers was accused of modern slavery.

Source: The Guardian

This incident led to Boohoo shares dropping by 18%, retailers leaving the brand, and the US authorities considering an import ban.

Despite this, the company struggled to sever ties with that supplier due to their established relationship and reliance on their production capabilities.

This example illustrates how a company’s dependency on a specific supplier can increase its exposure to regulatory risks.

It also shows that, even in developed countries like the UK, suppliers are not immune to profit chasing at the expense of workers or the environment.

These issues can be even more pronounced in countries with poor labor practices or low environmental standards.

Luckily, these risks can be mitigated by proactively identifying regulatory issues when selecting suppliers and continuously monitoring changes in their business activity.

This is again where Veridion can help.

Source: Veridion

Whether you’re choosing a new supplier or monitoring existing ones, Veridion will alert you about potential regulatory risks, helping you address them before they escalate.

Other proactive steps you can consider taking to minimize regulatory risks include:

Overall, addressing regulatory risks in today’s globalized world is increasingly complex.

But, diversifying suppliers can help minimize the impact if such risks materialize.

Beyond that, mitigation requires a proactive approach that combines advanced tools for supplier selection and monitoring with consistent enforcement of compliance standards.

As we’ve shown time and time again in this article, the dangers of high supplier concentration are significant.

They can impact everything, from your supply chain resilience to regulatory compliance.

While focusing on a few key suppliers can streamline processes and reduce costs, it can also expose your company to disruptions, limited negotiation power, and quality issues.

Conversely, diversifying your supplier network, implementing proactive risk management strategies, and leveraging technology help ensure a balanced, resilient supply chain.

So, if you have any doubts about whether reducing your dependence on a single or few suppliers is worth it, we hope this article helps answer this question for you.