What Is Procurement Automation?

Procurement automation is not just another industry buzzword.

Instead, it’s a boundary-pushing strategy that uses technology to streamline the procurement process.

And if you’re wondering what exactly procurement automation is and why you need it, we’ll break it down for you in this article.

Then, we will discuss the pitfalls of the old-school manual procurement process that many are still clinging to (much to their disadvantage).

After that, we’ll show you the reasons why jumping onto the automation bandwagon isn’t just a modern business trend but truly a necessity.

So, let’s get into it.

Imagine procuring necessary supplies with fewer errors at a faster pace.

Procurement automation is all that and more because it uses technology to automate many procurement processes, cutting down on human intervention.

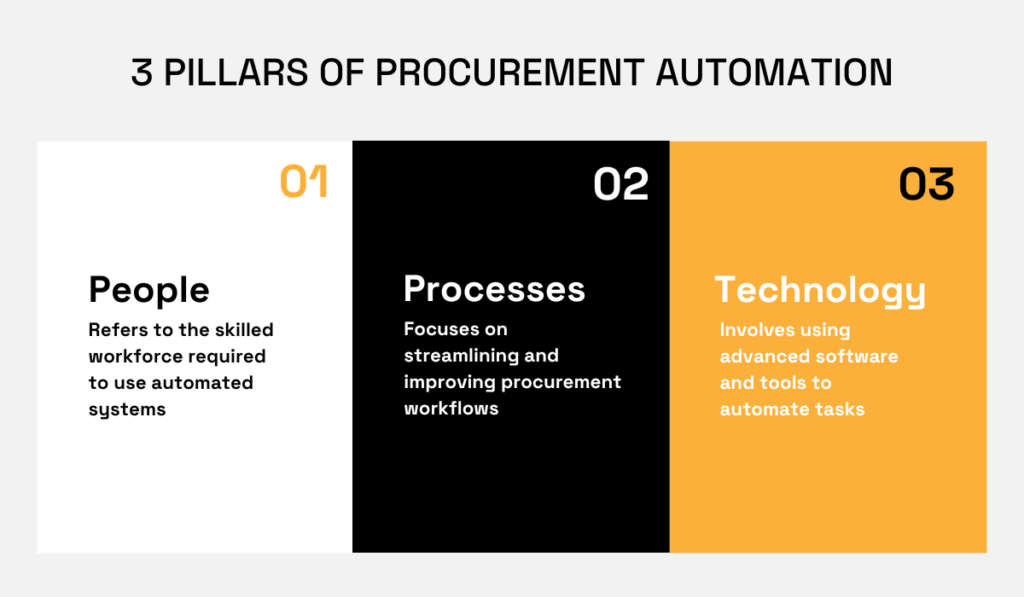

Understanding procurement automation might seem daunting, so let’s simplify it by focusing on its three core pillars: people, processes, and technology.

Source: Veridion

Since people are the ones who’ll be using any software you introduce, it’s vital that everyone understands and actively promotes the positive effects and objectives of automation.

This is a good time to debunk a prevailing myth: automation doesn’t signify a reduction in jobs, as is often feared.

On the contrary, it reduces the boredom of repetitive tasks, enabling teams to redirect their skills where they matter the most—the areas that truly call for human intelligence and creativity.

Take sourcing professionals, for example.

No longer bound by the boring work of managing paperwork, they can now better focus on the more important roles, like taking care of supplier relationships.

Undoubtedly, the greatest strength of procurement automation lies in its ability to streamline Processes, the second crucial pillar here.

Just take a look at the Levvel Research survey, identifying the key pain points of manual procurement in the image below.

It shows that most bottlenecks are process-related.

Source: Levvel

Those process issues can be:

All these process-related hurdles can now be smartly tackled with software solutions that drive automation.

This brings us to technology, the last pillar of this procurement automation. In other words, various digital tools designed purposefully to automate procurement processes.

Together, these three pillars form the indispensable foundation of procurement automation.

Businesses are already recognizing the bounty of benefits automation brings to the table.

In fact, Deloitte’s 2023 survey hints at this shift, revealing that 72% of chief procurement officers mark digital transformation as one of their top priorities.

We’ll look into some of the reasons why that might be the case in the following sections.

People are creatures of habit. And we all appreciate a good, reliable service that has stood the test of time.

It’s comforting, it’s familiar, and we know it works—just like manual procurement has worked for businesses for decades.

However, in light of recent technological advancements, it’s become evident that manual procurement has limitations that might be slowing companies down.

That’s why, in the following sections, we will reveal the biggest disadvantages of manual procurement.

Before we start dissecting how manual processes prolong procurement cycles, we should first touch upon the steps that constitute every such cycle.

As shown in the image below, procurement consists of steps such as identifying the need for products or services, selecting suppliers, administering contracts, managing purchase orders, approving invoices, and ultimately, processing payments and keeping records.

Source: Simfoni

Each step is crucial, forming a chain that leads to an effective procurement operation.

Now, how much would it take to navigate through this cycle manually?

Imagine skimming through a big stack of paper-based invoices or comparing prices across suppliers manually.

Done that way, each step of the process becomes time-consuming. As a result, you end up with a very long purchase cycle that interferes with business operations and stops overall efficiency.

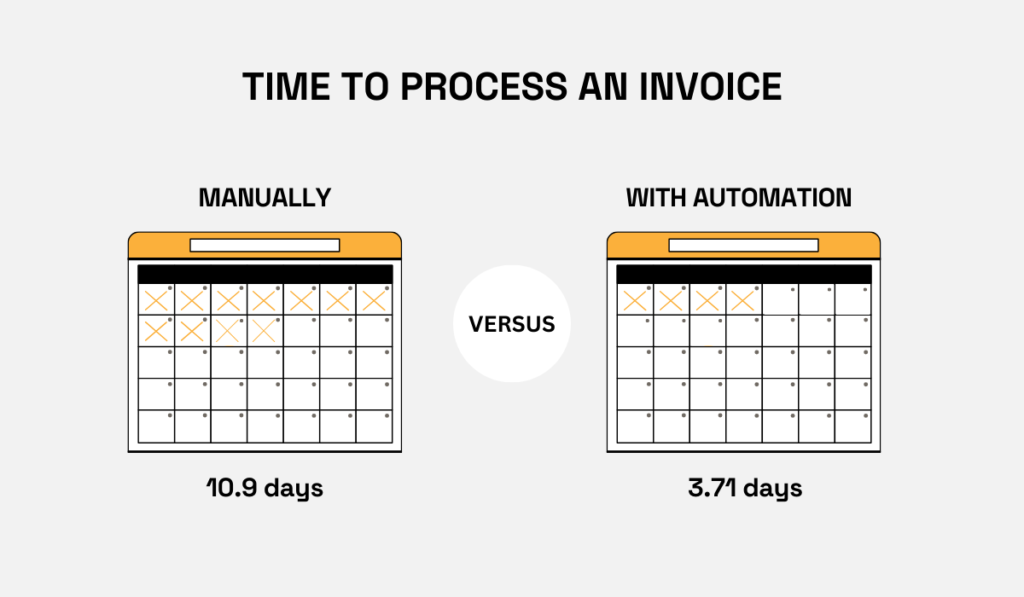

Take invoice processing, for instance. As the Ardent State of ePayables 2022 report showed us, processing a single invoice manually takes an average of 10.9 days.

An automated system cuts this duration down to just 3.71 days.

Illustration: Veridion / Data: Ardent

Thanks to automation, savings of 7 days are gained at just one step of the cycle.

If you extend this efficiency to other steps, you can easily understand the possibility of time savings that automation brings to the overall procurement cycle.

This is important because long procurement cycles present many hurdles for a company’s bottom line.

As the process draws out, price fluctuations can come into play, jeopardizing the cost benefits you secured in the first place.

Considering these aspects, it’s fair to say that this is a major drawback that automation can rectify.

Manual procurement cycles can, unfortunately, become a breeding ground for errors.

Each part of procurement has its unique set of requirements, and trying to manage everything manually leaves room for human error.

Would you believe that almost 90% of Excel spreadsheets, which are central to many manual processes, contain formula inaccuracies?

It’s not all that surprising when you consider the mental strain people face when juggling a lot of data entry, often during long hours and under the pressure of tight deadlines.

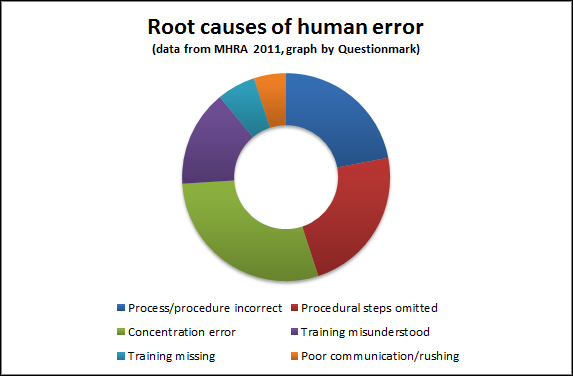

However, errors can also stem from incorrect processes or imperfect procedures.

Add to this the possibility of misconceptions arising from concentration errors, not enough training, poor communication, or hurried work—which are all recognized as root causes of human errors—and you have a recipe for a lot of mistakes.

Source: SAP Community

Common mistakes like copying wrong numbers, misreading figures, or misunderstanding terms can have serious consequences.

From unexpected surpluses to supply shortages and even delivery of incorrect goods, the impact can be far-reaching.

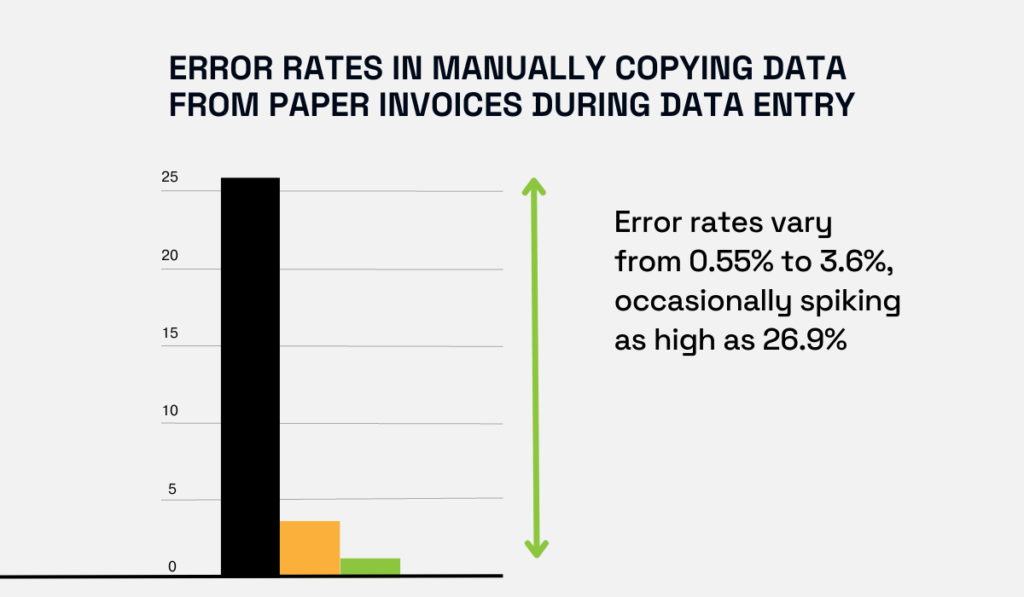

For instance, when you manually transfer data from paper invoices, the possibility of data entry errors rises.

The typical error rates can vary between 0.55% and 3.6%, but in some cases, they’ve been recorded as high as 26.9%.

Illustration: Veridion / Data: Springer

It’s not just about the existing errors, either.

Identifying and fixing these mistakes manually adds another layer of difficulties—it could stretch the already long procurement cycles.

So, while there’s no denying the value of human effort, it can sometimes create roadblocks in the process.

One of the most significant drawbacks of manual procurement lies in the greater risk of uncontrolled expenses.

In a manual procurement process, every order, every invoice, and every single payment requires hands-on attention.

This method, though traditional, is highly time-consuming and allows no real-time visibility into spending.

When you can’t see what’s happening until after the fact, the whole process is vulnerable to accidental spending.

One part of uncontrolled spending is maverick spending, a term for unauthorized purchases that bypass a company’s procurement guidelines.

According to research by the Chartered Institute of Procurement & Supply (CIPS), unchecked maverick spending can account for as much as 80 percent of a company’s total spending.

Illustration: Veridion / Data: CIPS

The Hackett Group’s Maverick Spend Report further elaborates on how this type of spending comes with a hefty price tag.

Decreased sourcing savings, weakened control over procurement due to fragmented spending, and increased supply-base risk are just some of the consequences.

Source: The Hackett Group

Plus, with unapproved suppliers in the mix, you can expect potential quality, service, compliance, and other supplier-related issues.

In other words, in the absence of automated processes, regulations are much harder to enforce, and maverick spending tends to thrive.

Without clear visibility into where the money is going, companies can find themselves facing budget overruns, often catching them off guard.

From evaluating current suppliers to assessing contracts, supplier management lays the foundation for a successful procurement process.

By neglecting it, you’re on course for cost overruns and missed opportunities.

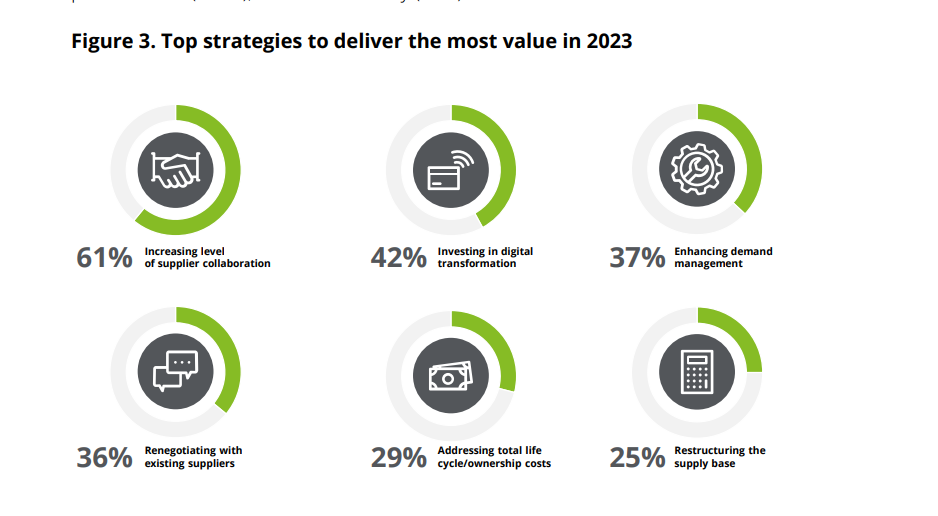

That’s why it’s no surprise that increasing the level of supplier collaboration emerged as one of the top strategies for improving procurement in 2023.

Source: Deloitte

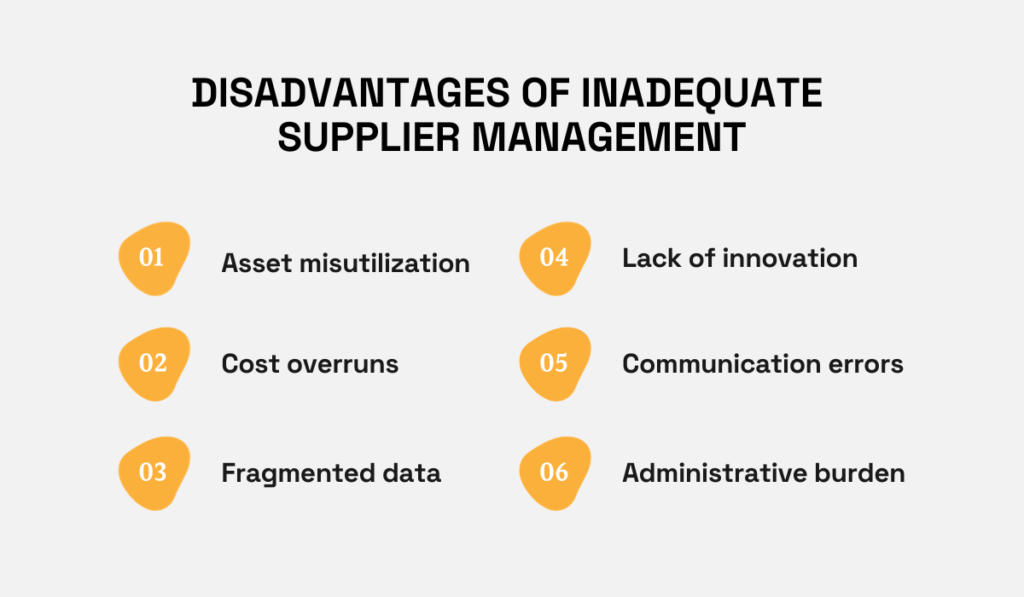

But why is inadequate manual supplier management so detrimental?

Well, manual procurement systems inevitably lead to fragmented, inconsistent data, making it challenging to track supplier performance and analyze procurement activities accurately.

In such a scenario, opportunities to negotiate better terms, ensure compliance, or improve service levels might slip through unnoticed.

Source: Veridion

Effective supplier management goes beyond just cost savings.

It also involves building strong partnerships with suppliers that can lead to innovation and increased value for the company.

For instance, harnessing the ideas, expertise, and technologies of your suppliers might lead to new product developments or process improvements that would have otherwise remained untapped.

Sadly, manual procurement often gets in the way of achieving these benefits.

Instead of fostering collaborative relationships or structuring supplier management, it often leaves the procurement teams bogged down with administrative tasks.

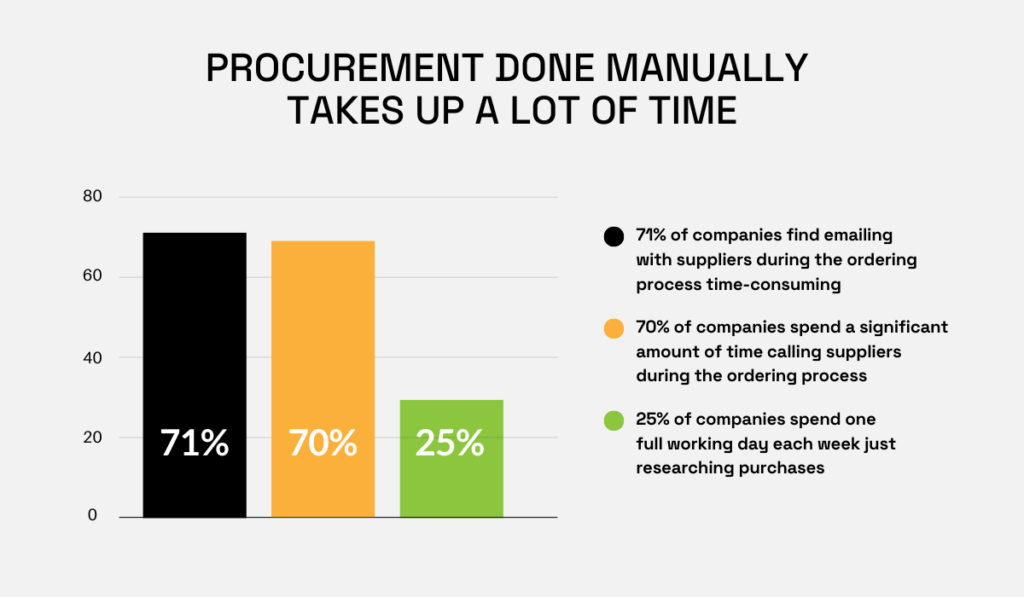

The consequences of not leveraging automation in procurement can be seen in regular, day-to-day operations.

Probrand and CIPS report paints an accurate state of affairs.

The report details that 25% of companies spend one day of each week—an entire working day—solely on researching purchases. But that’s not it.

Illustration: Veridion / Data: Probrand and CIPS

Dealing with suppliers during the ordering process has turned out to be a time-consuming process, too—71% and 70% of companies shared that they spent a fair bit of their time emailing and calling, respectively.

Most businesses admitted they are burdened by additional responsibilities like tracking orders, checking prices and stock, processing orders, and dealing with returns or mistakes.

Looking at the manual procurement process from this angle, it’s obviously draining on time, heavy on costs, and inefficient.

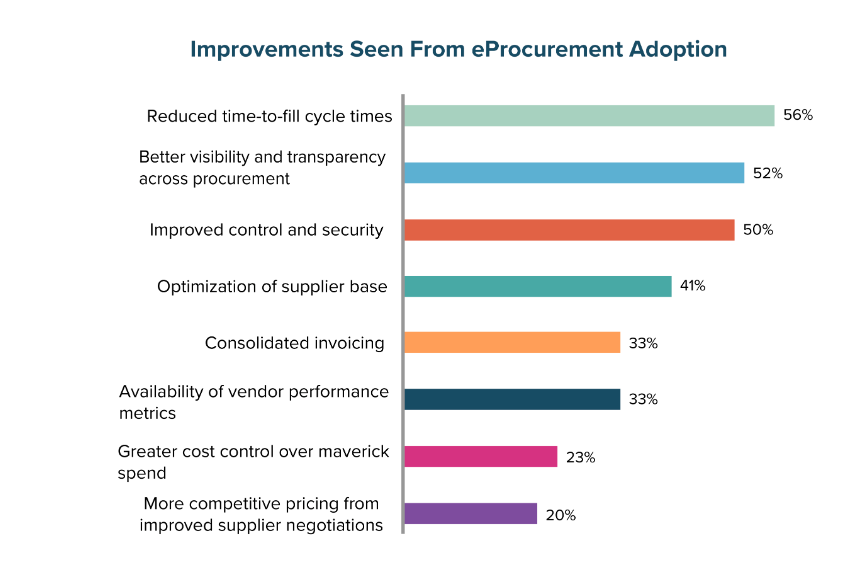

As we can see in the chart below, automation boasts various benefits, such as shorter cycle times, more transparency, and improved security.

Source: Levvel

Digital procurement also optimizes the supplier base, streamlines invoicing, provides a better view of expenditures and offers opportunities for more competitive pricing through improved supplier discovery enablement.

In essence, it addresses and rectifies all the drawbacks we outlined in the prior sections.

Therefore, failure to digitize procurement processes won’t be a minor hiccup—it would affect the overall business and decrease your competitive advantage.

Here’s an uplifting fact: you can automate almost every single stage of your procurement.

Let’s see how exactly.

In recent years, sourcing, an essential element of the procurement process, has experienced a notable rise in automation capabilities.

A driving force behind automated sourcing is undoubtedly the progression of technology.

Impressively, artificial intelligence (AI) driven algorithms are now capable of analyzing extensive datasets.

This feature enables the discovery of potential suppliers and even allows for searching on very specific parameters.

To illustrate this, let’s examine our own tool, Veridion.

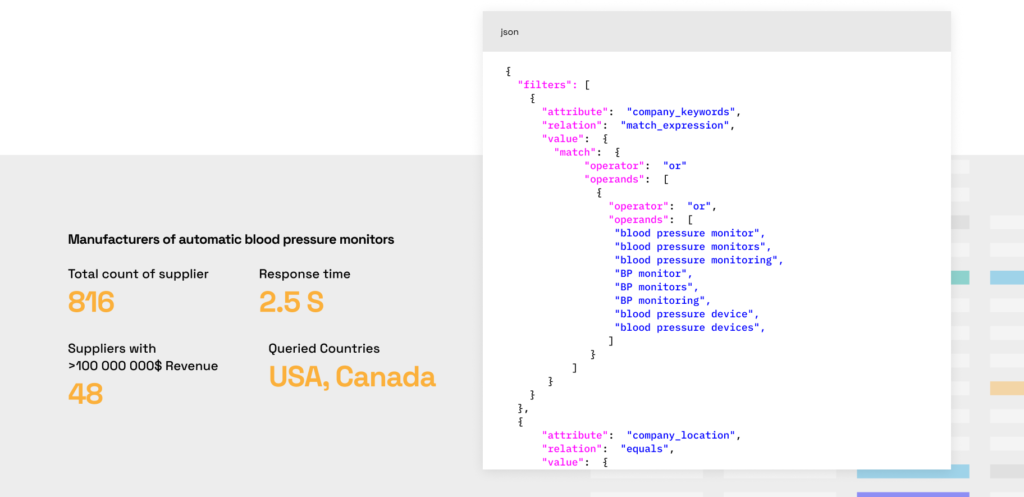

Imagine that you need to find suppliers for blood pressure monitors operating in the USA and Canada with revenues exceeding $100 million.

With Veridion, you can do that simply by specifying search parameters.

As demonstrated in the image below, within just 2.5 seconds, Veridion efficiently discovered 48 matching suppliers.

Source: Veridion

No doubt, manual methods of sourcing these suppliers would have consumed a considerable amount more time—far surpassing the mere 2.5 seconds it took with Veridion.

From this example, we can see that the advantages of automation in sourcing extend beyond mere time savings. Automation also provides access to new information. In this case, an extensive pool of suppliers.

Veridion contains information on over 80 million suppliers spread across 230 countries—a database that is updated weekly for maximum accuracy and can be combed through using sophisticated search API.

Source: Veridion

The bottom line?

Obtaining such a massive amount of supplier data would be almost impossible.

However, thanks to automation, supplier discovery and evaluation becomes faster, more precise, and undoubtedly more intelligent.

The purchasing stage also consists of many individual steps.

After finding the preferred supplier, going through RFx phase and purchase requisitions, procurement specialists create a purchase request and, subsequently, a detailed purchase order that specifies the products or services, agreed pricing, delivery dates, and payment conditions.

Then, the supplier provides an invoice and the procurement team verifies that the invoice aligns with the purchase order and that pricing is spot-on.

Source: Veridion

Tackling these steps manually can become quite a tangled, time-consuming endeavor.

Take the purchase requisition, for instance. Typically, it goes through numerous approval stages, considerably slowing progress.

Many departments like legal, management, and finance might need to validate contracts and approve expenses.

Luckily, automation significantly accelerates these multistage approvals by sending notifications and alerting approvers to respond quickly and minimize potential delays.

Additionally, it simplifies the entire process by offering standardized digital forms equipped with rules to prevent missing or incomplete information.

The same approach can be applied to other parts of the purchasing stage, making automation a great solution to streamline the often intricate and burdensome purchasing processes.

The payment stage marks the final step of the procurement process, where dealing with invoices and settling payments to suppliers become the primary focus.

Following a thorough review and approval by the procurement team, the invoice is forwarded to the accounts payable department to make the final payment.

An image below aptly illustrates this process–the last step of the payment stage involves recording and archiving the settled invoice.

Source: Veridion

Now, we all know handling a pile of paperwork can turn into a challenge, especially when managed manually.

The challenge can be anything from inaccurate data entries and lost invoices to delayed payments.

The good news is that procurement automation presents a viable solution by digitizing the entire process.

It enables electronic documentation handling and establishes a centralized, easily accessible database containing all relevant information.

And automating accounts payable brings many benefits.

If you, for example, look at Levvel’s 2020 Payables Insight Report, you’ll notice that the benefits that accounts payable automation brings to the table are manifold.

Source: Levvel

Companies using automation in this state have faster approval cycles and increased employee productivity.

Apart from these direct impacts, there are several long-term and strategic advantages, such as better supplier relationships, simplified audits, and decreased fraud and duplicate payments.

Moreover, a study focusing on small to medium-sized companies reported a distinct uplift in procurement efficiency following the implementation of automation.

The results were startling– there was a 60% reduction in lost invoices, a 59% fall in delayed payment approvals, and a 55% decrease in lost receipts.

Taking all this into consideration, it’s safe to say that automation not only leads to a quicker and smoother payment process but also to a more accurate and cost-effective one.

There you have it—an overview of what procurement automation is, why it’s important, and how it represents progress compared to traditional manual procurement methods.

As you can see, sticking to manual processes simply isn’t sustainable anymore.

It results in slowdowns, opens room for human error, and makes companies less competitive than those already adopting automation.

Remember, procurement automation isn’t merely a passing trend—it’s the future.

That’s why the sooner you set forth on the automation journey, the sooner you’ll reap its benefits.