Supplier Risk Management Process in 6 Steps

Companies rely on suppliers to operate effectively.

Yet, these suppliers also expose companies to various operational, financial, and compliance risks.

Those risks shouldn’t be ignored.

Instead, having a clear, step-by-step supplier risk management process is essential.

In this article, we’ll guide you through six actionable steps to create one.

It will help your team proactively manage supplier risks and ensure smoother operations for your company.

Supplier risk management isn’t just a procurement concern—it affects an entire organization, from finance to operations.

Engaging stakeholders early ensures everyone aligns on procurement goals, priorities, and acceptable risk levels.

This helps secure stakeholder buy-in and sufficient resources.

So, who are the key internal stakeholders in your risk management efforts?

While this varies between organizations, the following six categories are usually involved:

Source: Veridion

Senior management is vital for securing resources and setting strategic sourcing priorities.

The other involved departments provide valuable insights within their respective areas of expertise.

For instance, the operations department can highlight relevant risks related to supplier performance, such as delivery delays, capacity issues, and production bottlenecks.

The quality assurance (QA) department can define the required quality standards and quality control processes suppliers should adhere to while also flagging potential risks.

Similarly, the finance department can point out supplier-related financial risks your procurement team should watch out for, such as insolvency.

Overall, each department can draw attention to the most critical supplier risks in their domain.

Francesco Fulcoli, a financial expert, highlights two critical benefits of early stakeholder involvement in risk management:

Illustration: Veridion / Quote: LinkedIn

Engaging key stakeholders not only provides critical expertise but also strengthens collaboration and accountability throughout the supplier risk management process.

Therefore, your first step is to:

This last point may involve one-on-one interviews (typically with senior managers), workshops, surveys, or other methods.

Ultimately, close cross-departmental collaboration helps identify additional risks and aligns supplier risk management goals with broader objectives.

If your supplier data isn’t centralized yet, now is the time to consolidate it.

A central database makes accessing key supplier information straightforward.

It also ensures data consistency, eliminates duplication, and integrates various sources of supplier data seamlessly.

These functionalities are essential for effective supplier risk assessment and mitigation.

Without accurate and complete supplier data, your team might overlook significant risks, inefficiencies, and missed opportunities.

As Omera Khan, professor of supply chain management at the University of London, explains, that’s not something a lot of companies are aware of:

Illustration: Veridion / Quote: HICX

With Professor Khan highlighting the importance of having a central supplier database, let’s see how it can be created.

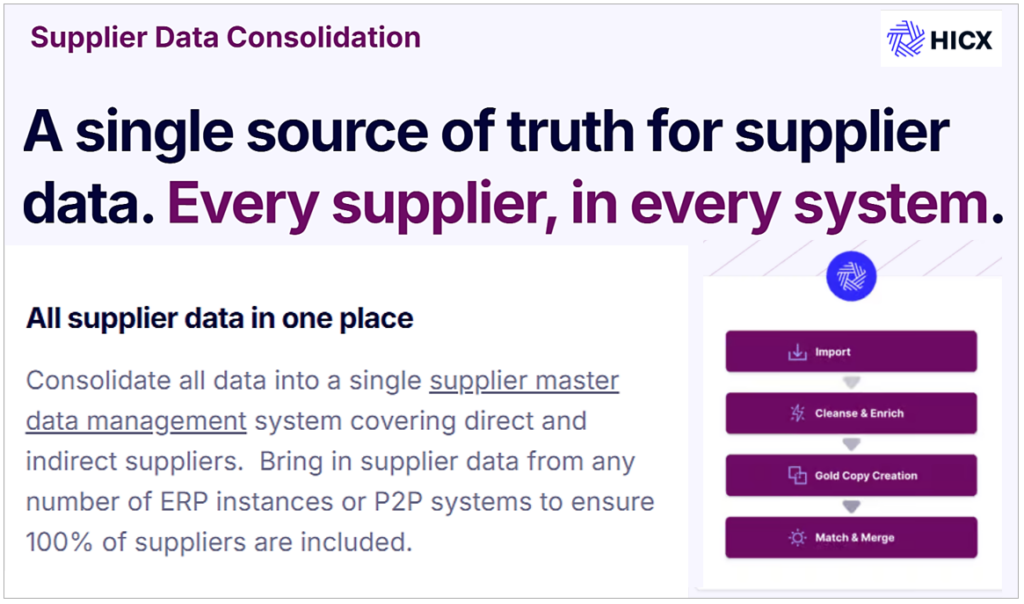

Since supplier data often resides in various platforms and ERP systems, the simplest solution is to use a tool designed to consolidate and integrate it.

Here’s an example.

Source: HICX

HICX enables companies to consolidate supplier information from various ERP and P2P systems into a single master data management system.

This involves identifying errors and filling in missing information as well as capabilities to match and merge supplier records.

Of course, other notable tools in the procurement and spend management space also provide robust solutions for centralizing all supplier data.

Examples include Coupa, SAP Ariba, Procurify, GEP Smart, and others.

Once your central database is established, consider integrating it with external, real-time data sources.

As to what supplier data you should collect, that’s what the next section is about.

The next step in supplier risk management is defining the specific information your team needs to gather.

Supplier data falls into two categories—internal and external—both critical for effective risk assessment.

Internal data sources typically include::

This data is usually contained in your company’s systems, such as procurement platforms, accounting software, and supplier relationship management (SRM) tools.

Of course, insights from internal data sources can take you only so far.

Real-time data from external sources is essential. Without it, your risk management process would fall short.

External sources typically include:

| Category | Details |

|---|---|

| Financial stability | Credit ratings, bankruptcy risks. |

| Market intelligence | Industry trends, competitive positioning, shifts in demand or supply dynamics, and reputational risks. |

| Regulatory compliance | ESG commitments, including ethical and labor practices. |

| Geopolitical risks | Trade disputes, sanctions, and political instability affecting supplier operations. |

External data helps identify risks that internal records might not reveal.

The easiest way to collect it is by leveraging tools that use AI-powered algorithms to scour the internet and gather the freshest info on the above categories.

One such tool is our own Veridion.

Source: Veridion

Veridion provides your team with access to a global database of supplier data, updated weekly, currently encompassing over 120 million companies worldwide.

Using Veridion, you can:

Integrating Veridion’s functionalities with your central supplier database allows your team to gain detailed insights about both current and potential suppliers.

Among other benefits, this is crucial for the next step—segmenting suppliers into risk categories.

Use internal and external data to group suppliers into risk levels such as high, medium, or low.

This segmentation helps allocate resources efficiently, prioritizing high-risk suppliers.

It also ensures that strategies are tailored to the specific needs of each supplier group, optimizing risk management efforts across the board.

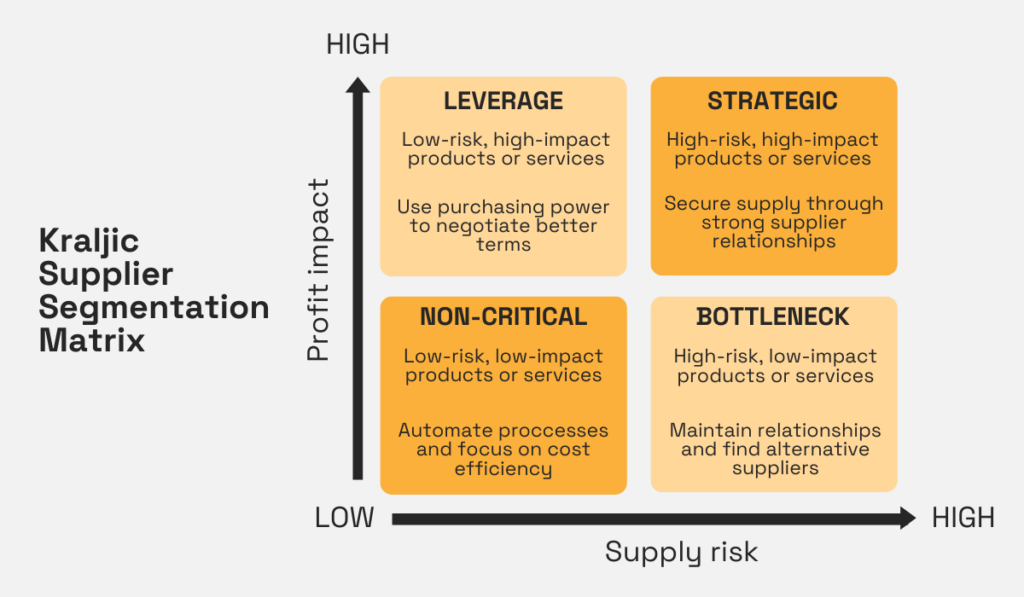

One widely adopted method for segmenting suppliers based on risk is the Kraljic matrix, which classifies suppliers according to two key factors: supply risk and profit impact.

Source: Veridion

This matrix segments suppliers into four categories, each with distinct risk levels and recommended management strategies.

Suppliers categorized as strategic and bottleneck are considered critical, as any disruption in their operations can have significant consequences for your supply chain.

These suppliers need careful monitoring and strong risk management strategies.

However, supplier segmentation is not always straightforward.

Companies may categorize suppliers differently based on factors like market conditions, geopolitical influences, or specific operational needs.

For instance, here’s how Volvo Cars segments its suppliers:

Illustration: Veridion / Quote: Volvo Cars

Volvo’s definition of critical suppliers is broader and considers more criteria than the generalized Kraljic matrix.

This ensures supplier risk segmentation accounts for a broader range of operational realities, such as unique supplier dependencies and strategic spending priorities, enabling them to focus their risk mitigation efforts where they are needed most.

Overall, the step of segmenting suppliers into risk categories provides your team with a clear, actionable roadmap for continuous and effective risk management.

Clearly, risk management is not a one-time task but an ongoing process.

Supplier risks can emerge due to various factors like market shifts, geopolitical tensions, natural disasters, or changes in supplier performance.

Therefore, regular updates and reassessments of supplier risk are essential.

The most effective way to stay informed is through close supplier relationships, which foster clear communication.

When suppliers can alert you to emerging issues, you can collaborate on contingency plans.

Yet, suppliers might not report issues, either to maintain the relationship or due to their own lack of awareness.

That’s why an objective third party is crucial for identifying changes in a supplier’s activities or their broader economic and political context.

In such a situation, Veridion’s supplier risk monitoring function can be invaluable.

Source: Veridion

Veridion allows you to define custom supplier risk factors.

When Veridion’s AI-driven bots detect one of these factors while scanning the web, you’ll receive an immediate alert.

You can also check data confidence scores to evaluate the accuracy and reliability of the information.

This way, you can monitor a spectrum of supplier risks, maintain accurate assessments, and make proactive decisions as risk levels change.

Risk data isn’t just about solving problems; it’s about anticipating and preventing them.

Analyzing supplier risk data helps your team spot issues before they escalate.

For example, if data indicates that a supplier operates in a politically unstable region, you can take that as an early warning sign.

With this insight, your procurement team can proactively mitigate such risks by diversifying to suppliers in more stable regions.

Similarly, being alerted to a supplier’s ESG non-compliance or controversies enables your team to quickly find alternative solutions.

To minimize such risks from the outset, it’s best to include ESG criteria when selecting new suppliers.

Source: Veridion

This proactive approach ensures alignment with your sustainability goals while reducing risks associated with supplier non-compliance.

It also demonstrates how incorporating real-time risk data enhances the risk management process by providing continuous updates and actionable insights.

With these capabilities, your team can transition from a reactive approach to a proactive, strategic one—ensuring resilience and stability in your supply chain.

Ultimately, proactive decision-making based on risk data strengthens your ability to adapt to evolving market dynamics and supports long-term business success.

We hope the six steps we outlined will help you refine your supplier risk management process.

This structured approach minimizes potential disruptions and supports strategic decision-making to enhance supply chain resilience and sustainability.

From early stakeholder involvement to leveraging real-time risk data, implementing these steps ensures a proactive and effective approach to managing supplier risks.

With the right tools and strategies in place, your organization can boost operational efficiency and create a solid foundation for sustained growth and innovation.