6 Benefits of Supplier Performance Management in Procurement

As the world around us grows more complex every day, so do the supply chains.

As a result, the ability to effectively select, monitor, evaluate, and collaborate with suppliers has become even more important for any company’s success.

These elements are unified under the umbrella of supplier performance management, which serves as the cornerstone of strategic procurement and offers a multitude of benefits that extend far beyond cost savings.

In this article, we’ll explore six key benefits of supplier performance management in procurement and how they empower organizations to excel in today’s competitive marketplace.

By monitoring and evaluating different aspects of supplier performance, companies can identify quality issues early on and take corrective actions to maintain their product or service quality standards.

Therefore, supplier performance management (SPM) helps ensure your suppliers consistently deliver products and services of the desired quality.

To achieve this, your company first needs to establish clear quality standards and benchmarks for components and materials provided by suppliers.

Then, it can use these criteria to assess whether a potential supplier fits your quality requirements or evaluate the performance of your current suppliers.

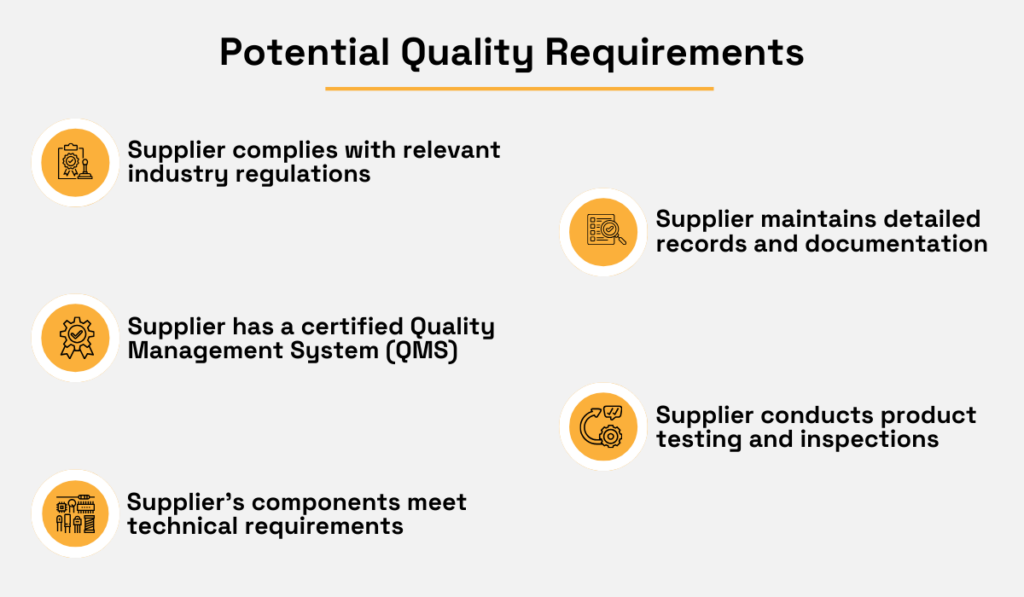

For example, a company producing electronics could set the following requirements for components it sources from suppliers to make its products:

Source: Veridion

Each of the above standards will help ensure that the components provided by suppliers meet the quality objectives and deliver value to customers, all while maintaining compliance with regulatory requirements and industry best practices.

For instance, detailed technical specifications ensure that the components align with the company’s product specifications and performance standards.

Similarly, QMS certification indicates that suppliers have established robust quality control processes and procedures, while testing and inspection requirements help identify and prevent defects, ensuring the quality of the final electronic devices.

In addition, the company in our example could define a set of quality-related key performance indicators (KPIs) as additional benchmarks for evaluating and monitoring supplier performance.

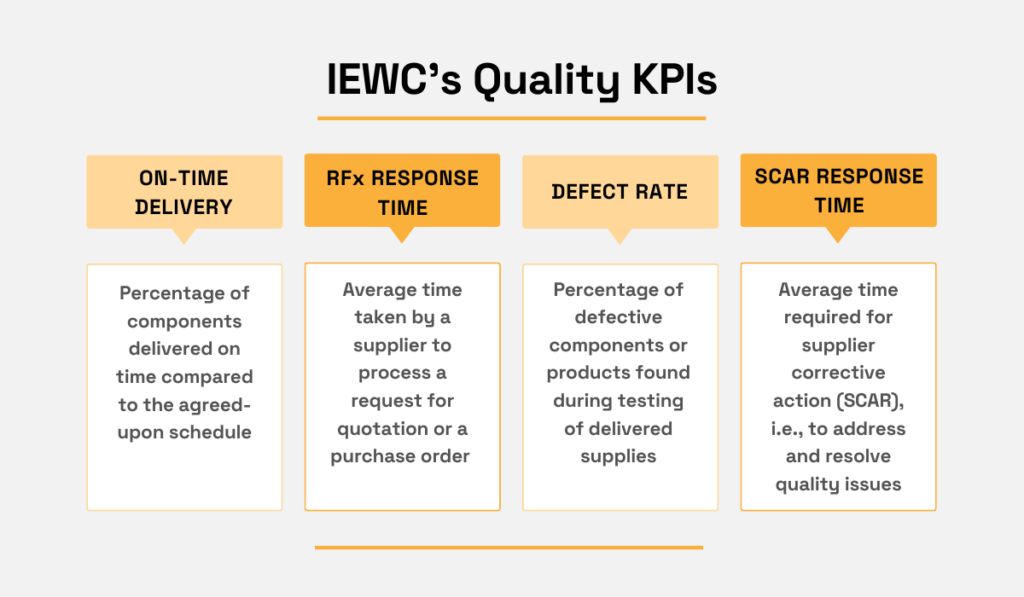

For example, IEWC, a global producer of electrical wires, cables, and other components, has a Supplier Quality Manual that sets out these four quality KPIs for its suppliers:

Illustration: Veridion / Data: IEWC

These KPIs complement the established quality requirements we mentioned by providing measurable metrics for evaluating suppliers in key performance areas, such as

By integrating them with quality-related KPIs, companies can achieve enhanced quality assurance, drive supplier accountability, and foster a culture of excellence across the supply chain.

Ultimately, this holistic approach sets the foundation for high product quality and customer satisfaction.

Supplier performance management enables procurement teams to effectively evaluate and manage suppliers based on their overall performance, capabilities, and alignment with business objectives.

As part of this process, companies often employ supplier segmentation, which involves categorizing suppliers into different groups or tiers based on specific criteria such as quality, reliability, and strategic importance.

This segmentation allows for targeted supplier relationship management and resource allocation.

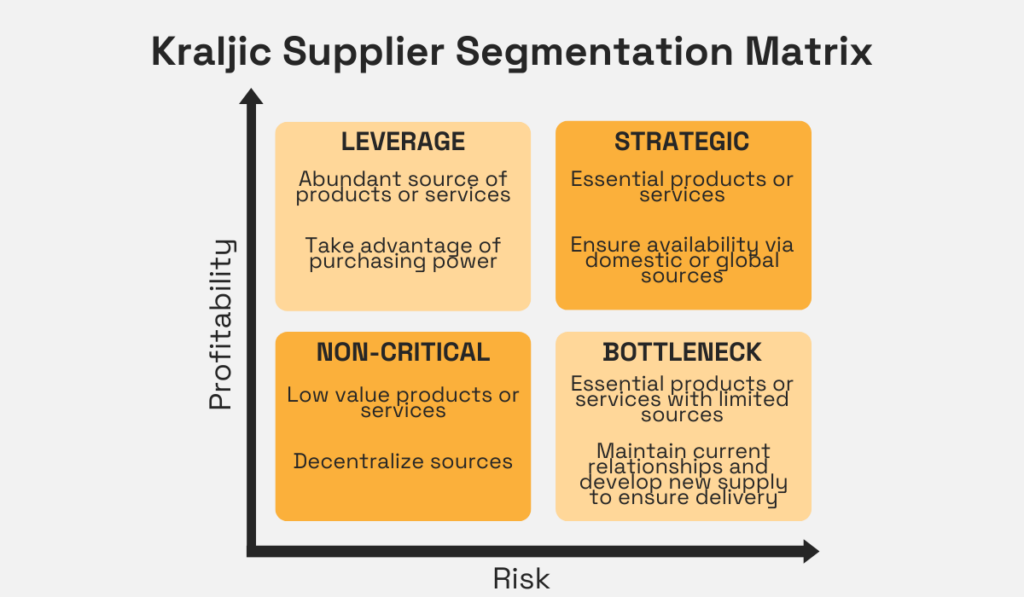

One well-known method for supplier segmentation is the Kraljic Supplier Segmentation Matrix, developed by Peter Kraljic in the 1980s.

Unlike some other segmentation approaches, this matrix ranks suppliers based on two key dimensions: supply risk and profit impact.

As illustrated, by applying this matrix to your suppliers, you can group them into four distinct categories.

Illustration: Veridion / Data: Smartsheet

For example, your “bottleneck” suppliers are those that provide products or services essential for your company’s operations that are not abundantly available on the market.

Due to their critical role in your supply chain, they pose high supply risk, but also substantially contribute to your company’s profits or competitive advantage.

Therefore, relationships with such suppliers should be prioritized and carefully nurtured.

At the same time, you should monitor the market for the emergence of new suppliers in this group, allowing you to:

To a degree, this also applies to your “strategic” suppliers.

As for suppliers grouped under the “leverage” and “non-critical” categories, they provide opportunities for leveraging your purchasing power or decentralizing sources.

In any case, efficiently implementing one of many possible supplier segmentation methodologies requires detailed information, preferably provided and regularly updated by each supplier.

However, given the possibility that suppliers may not always report risks, issues, or changes in their operations or market environment, it’s equally important to have access to external, up-to-date sources of supplier data.

For instance, our own tool, Veridion, can provide you with the most comprehensive and up-to-date database of supplier information.

Source: Veridion

Veridion consists of an AI-powered, weekly updated global supplier database and advanced search APIs.

Combined, they give you the freshest data for nearly 80 million companies, each covered by over 70 data points, including their product specifications, business locations, ESG compliance, and more.

As highlighted above, supplier data changes quickly, and working on outdated assumptions can negatively affect your company’s bottom line.

Conversely, having accurate data is crucial for effectively evaluating both current and prospective suppliers across a range of criteria.

For example, if you want to segment your suppliers into the Kraljic Matrix, you should first do extensive market research to determine the competitive landscape of each supplier so you can rank them accurately.

Once you have a comprehensive understanding of each supplier’s competitive position, you can effectively monitor their performance against predetermined criteria, ensuring alignment with your segmentation and ranking objectives.

This proactive approach not only enhances the accuracy of your supplier segmentation but also enables more informed decision-making and strategic supplier management.

To recap, leveraging comprehensive supplier data and robust monitoring mechanisms enables you to effectively segment and rank suppliers, empowering you to manage their performance, optimize relationships, and mitigate risks.

Supplier performance management is a vital tool for mitigating risks associated with suppliers, which can encompass a wide range of potential challenges in the supply chain.

From supply chain disruptions to quality defects, delivery delays, or financial instability, these risks can significantly impact your organization’s operations and bottom line.

However, by implementing effective supplier performance management practices, your team can proactively identify and address these risks before they escalate into major issues.

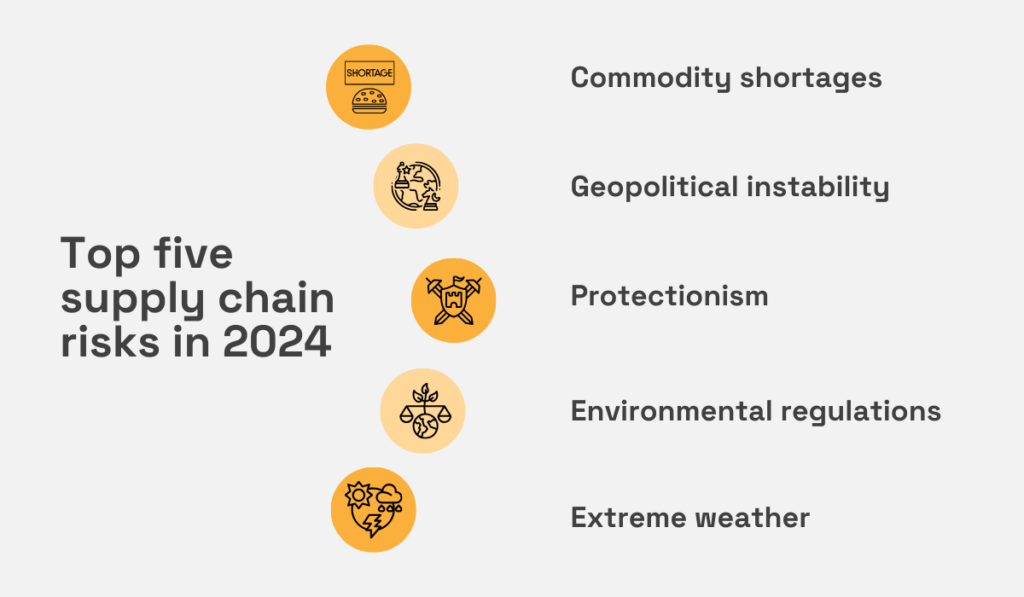

On that note, here are the top 5 supply chain risks to look out for in 2024 according to DHL:

Illustration: Veridion / Data: DHL

As mentioned, supplier performance management can play a crucial role in addressing or mitigating these specific supply chain risks.

For instance, closely monitoring supplier KPIs such as inventory levels, production capacity, and lead times can enable companies to identify potential shortages in key commodities early on.

With this insight, they can collaborate with suppliers to:

Likewise, you can monitor your suppliers’ production locations and evaluate the potential risks associated with geopolitical instability in those regions.

To do that, you can utilize real-time data and analytics tools that will scour the internet and alert you if one of your suppliers is faced with unfavorable political conditions in their home country, or perhaps countries where they have production facilities.

Source: Veridion

By being timely alerted to emerging geopolitical tensions, protectionism measures, or stricter environmental regulations, you can proactively seek alternative sourcing options or implement risk management strategies.

For example, you could see if your supplier’s facilities in other countries not affected by these disruptions have sufficient capacity to meet your demand, or could source from two suppliers instead of one (dual sourcing) to minimize their impact.

Similarly, by tracking and analyzing historical supplier performance data and identifying trends or patterns, you can refine risk assessment processes and develop more effective, data-driven risk mitigation strategies.

For instance, recurring issues identified with specific suppliers may prompt your organization to invest in additional supplier development initiatives or contingency planning measures to mitigate future risks.

As you can see, supplier performance management allows you to proactively address potential risks, enhance the resilience and reliability of your supply chains, and ultimately safeguard your operations from supplier-related disruptions.

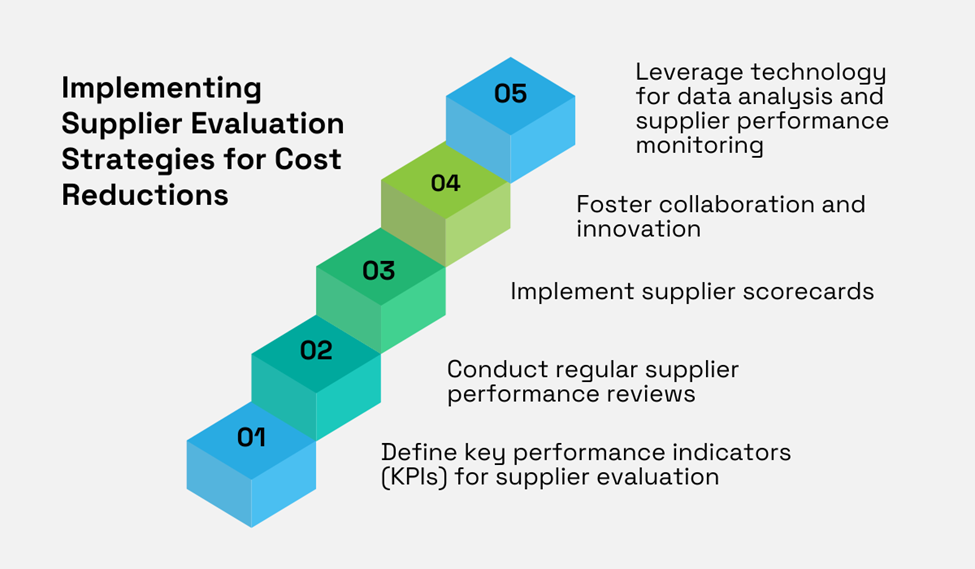

Supplier performance management is not only about ensuring quality and mitigating risks but also about promoting cost-saving initiatives within your organization.

By implementing effective performance management practices, your team can streamline procurement processes, optimize resource utilization, and drive efficiency across the supply chain.

For instance, by closely monitoring supplier performance metrics such as on-time delivery rates and product quality, you can identify areas for improvement and work collaboratively with suppliers to minimize errors and inefficiencies.

This can lead to significant cost savings by reducing waste, minimizing production downtime, avoiding potential miscommunications and delays, and lowering inventory carrying costs.

Of course, monitoring suppliers and evaluating opportunities for cost reductions is an ongoing, iterative process.

As such, it starts with defining KPIs for supplier evaluation and continues by regularly applying the other necessary tools and actions described below.

Illustration: Veridion / Data: Faster Capital

Let’s take supplier scorecards as an example.

Scorecards can be a valuable tool for assessing supplier performance against predefined metrics and benchmarks.

For instance, if a supplier consistently delivers products late or fails to meet quality standards, this can lead to increased production downtime, additional rush orders, and higher inventory carrying costs.

However, by capturing and documenting these performance issues in scorecards, you can:

Another aspect that promotes cost-saving is leveraging technology for data analysis and supplier performance monitoring.

Advanced analytics tools can help your procurement team analyze large volumes of supplier data in real time, track performance trends, and identify cost-saving tactics and challenges.

Overall, supplier performance management provides you with data-driven insights and helps make informed decisions to address issues, optimize processes, and implement continuous improvements, ultimately promoting cost savings.

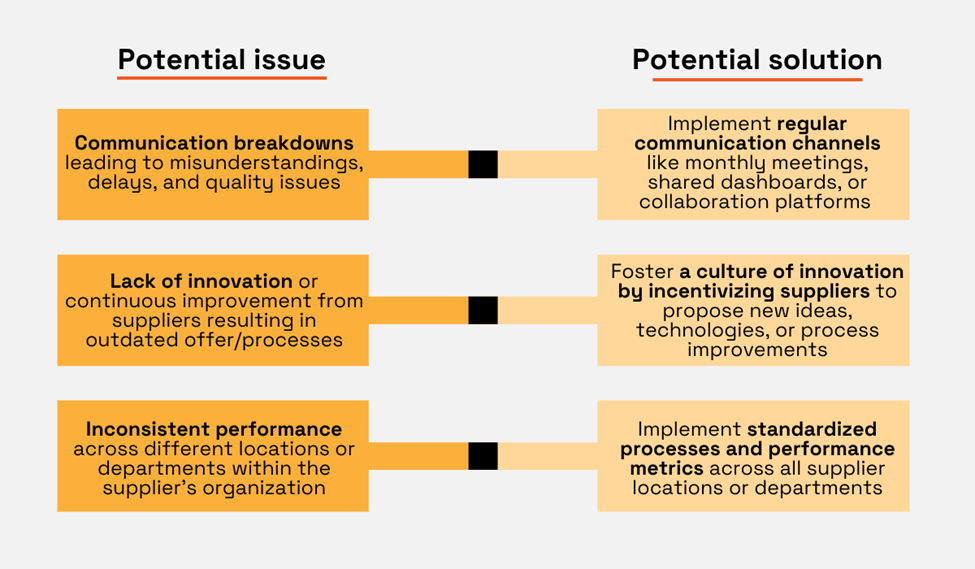

Another benefit of supplier performance management is that it fosters closer collaboration and partnerships between organizations and their suppliers.

Simply put, clear performance expectations and regular communication with suppliers allow organizations to address potential issues more effectively.

Poor communication and unfocused collaboration with suppliers can be managed in different ways depending on what the underlying issue is.

To illustrate, here are three typical supplier collaboration issues and their suggested solutions.

Source: Veridion

As you can see, by identifying and addressing communication breakdowns, fostering innovation, and standardizing processes, your organization can build stronger relationships with its suppliers and drive mutual success.

For example, a lack of innovation in a specific supplier’s product offer or production processes can be addressed through:

Again, monitoring supplier performance through KPIs enables you to identify potential issues and implement effective solutions, thereby not only strengthening collaboration with suppliers but also enhancing the overall efficiency and resilience of your supply chain.

So focus on continuous performance management, developing transparent communication channels, and sharing feedback.

This will allow your procurement team to efficiently encourage suppliers to innovate, develop new products or services, and contribute to improvement initiatives.

Effective supplier performance management helps safeguard your company’s reputation by ensuring that suppliers meet expectations for quality, reliability, and ethical conduct.

Otherwise, the failings of your suppliers can quickly become your own issues.

For instance, if one of your suppliers uses child labor, your company might suffer reputational damage when that fact comes out, even if management was unaware of this practice.

However, by vetting new suppliers before contracting them and continuously monitoring their performance regarding ethical business practices, you can protect your company’s reputation and maintain customer trust.

The same applies to your suppliers’ environmental, social, and governance (ESG) policies, such as adhering to environmental protection regulations not only set by their home country’s laws but your company’s standards as well.

Source: Veridion

By staying informed on any ESG issues related to your suppliers, you can react in time to prevent not only reputational damage but also legal consequences, financial penalties, and operational disruptions.

To recap, by prioritizing and monitoring ethical conduct in supplier relationships, your procurement team can mitigate risks and protect your company’s reputation in the marketplace.

It is evident that setting supplier performance indicators and continuously monitoring them is essential for companies aiming to optimize costs, enhance efficiency, and minimize risks.

Whether it improves your quality assurance processes, allows you to rank suppliers, or protects your company’s reputation, supplier performance management stands out as a critical tool for strategic procurement.

By utilizing the right analytics tools and methods, your procurement team can unlock the benefits outlined in this article, allowing you to make the most out of your supplier relationships.