The 7 Steps of Procurement Performance Management

We could say that, although the ultimate goal of procurement departments hasn’t changed, their role certainly did.

Procurement is still focused on acquiring all the necessary goods and services a company needs to operate smoothly.

However, the tools and management skills required to achieve this have significantly evolved, giving rise to procurement performance management.

This strategic approach can help companies gain valuable insights, optimize costs, drive efficiency, and enhance supplier relationships.

In this article, we’ll explore the seven essential steps you should take to establish effective procurement performance management.

The first step your procurement team should take is to gather data relevant to your organization’s procurement performance.

This can include data on spending (within the procurement department and company-wide), supplier performance, contract compliance, and other relevant metrics.

Collecting and analyzing this data is crucial for understanding the current state of procurement operations and identifying areas for improvement.

So, how do you ensure that this process doesn’t take months of work and eat up a lot of your staff’s time?

With technology.

More specifically, this involves utilizing some type of procurement software to automate data collection and analysis.

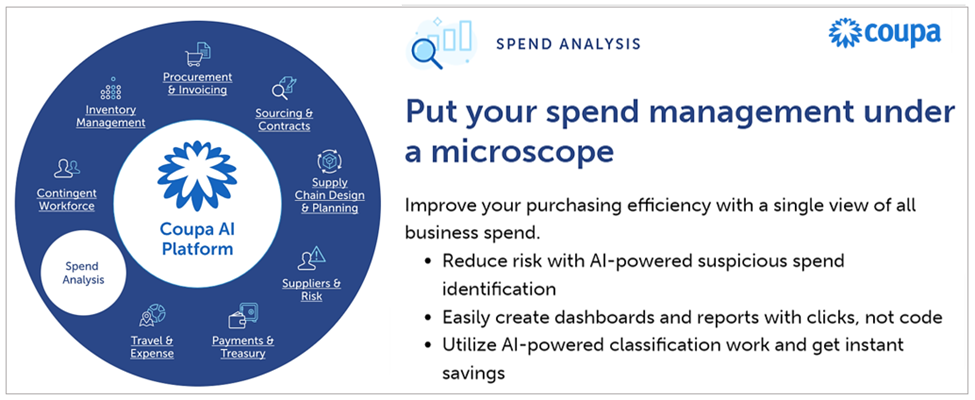

Here’s an example of one such solution.

Source: Coupa

As you can see, the features of this all-in-one procurement solution aim to cover all aspects of procurement operations, from which we fittingly highlighted spend analysis.

That’s because, once procurement data is gathered in one central location (cloud database), conducting a spend analysis will be crucial in identifying process-improving and cost-saving opportunities.

This data will come from internal sources, such as:

Now, the trick is also ensuring the internal data pulled from other systems is accurate.

Since internal data doesn’t exist in isolation and is often dependent on external data, you need to ensure that these systems pull data from reliable external sources.

For example, if we’re talking about supplier data, you want to know which supplier experiences changes in their business, closes shop, or anything else.

In such situations, you can rely on a solution like our Veridion.

Source: Veridion

By leveraging Veridion’s weekly updated, global supplier database with over 80 million companies and its advanced search functions, you can:

This will help when, based on the collected data, your team sets out to establish and track key performance indicators (KPIs) for the procurement department.

In other words, external data sources (market intelligence) will enable you to define benchmarks against which you can then regularly monitor your overall procurement performance.

To do that, you can utilize performance dashboards, reports, and analytics tools provided by the procurement solutions you selected.

These tools will enable you to not only efficiently gather data but also gain data-driven insights into various performance metrics, spending patterns, and market trends.

In turn, this will allow you to perform the next step on your procurement performance management journey, i.e., identify improvement opportunities.

Once collected, it’s time to analyze performance data.

This will help you identify areas where the procurement process may be falling short of objectives or where opportunities for improvement exist.

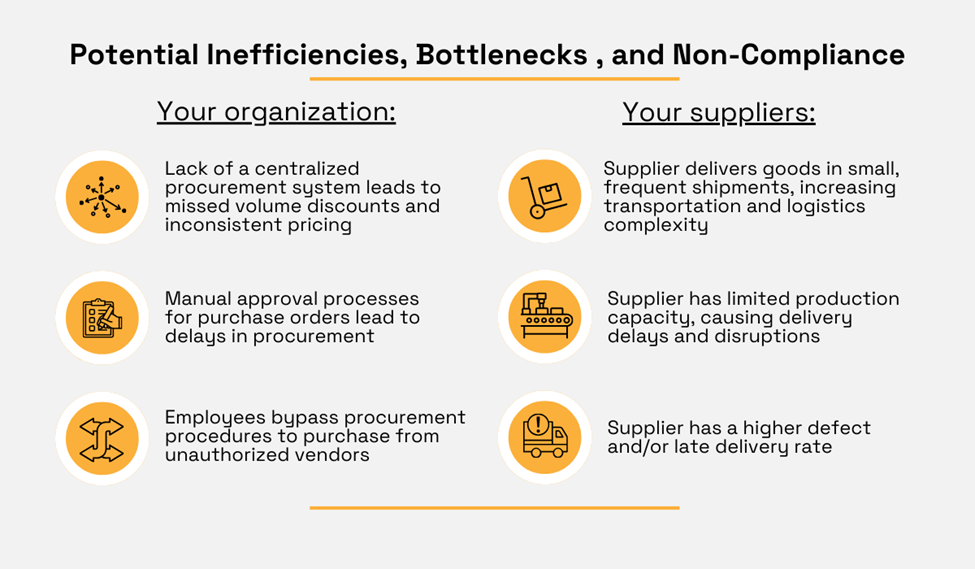

That could involve identifying inefficiencies, bottlenecks, and areas of non-compliance, as well as cost-saving opportunities.

The process should start with a comprehensive spend analysis of not only your procurement function but other company departments, too.

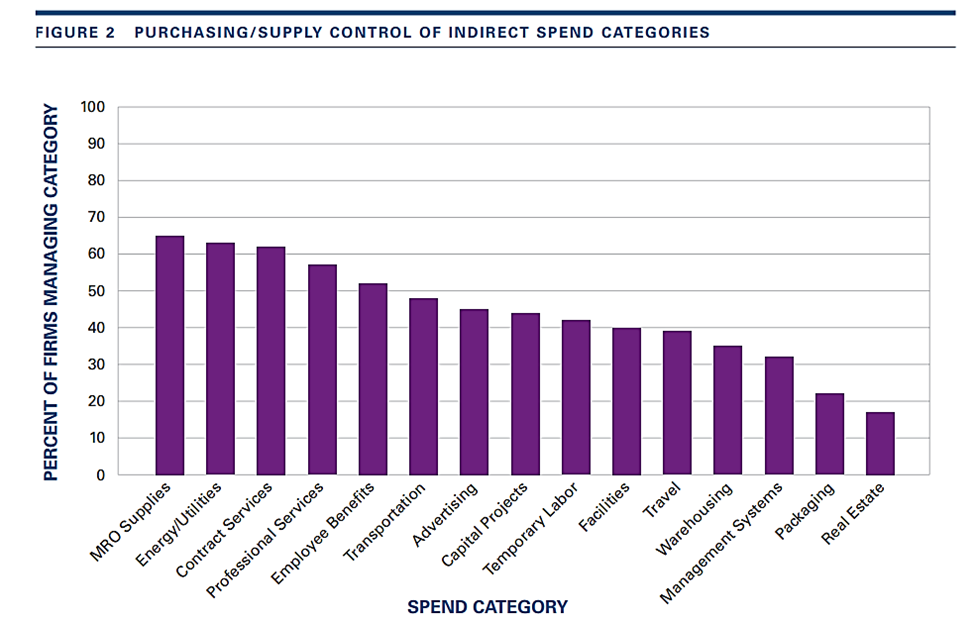

That’s because many improvement opportunities lie hidden in so-called indirect costs, i.e., those not controlled (incurred) by your procurement team but dispersed across your company’s different units or locations.

Below, you can see what cost categories are usually classified as indirect spend, along with the percentage of companies that empower procurement teams to handle them.

Source: Procurement Academy

Therefore, spend analysis should include both direct and indirect costs to provide a holistic view of procurement performance.

This can also help you determine what indirect costs could be consolidated by your procurement team.

For instance, you may find that different business units in your company procure office supplies or travel arrangements from various vendors at varying prices and contract terms.

By consolidating these expenses under one roof—your procurement department—you can improve both the efficiency and cost of such categories.

The same principle applies to those expenses already managed by procurement, i.e., direct costs.

Their analysis may also reveal inefficiencies or bottlenecks in procurement processes, as well as areas of internal and external non-compliance.

To illustrate, here are three examples of each.

Source: Veridion

Beyond a spend analysis, other actions you can take to identify improvement opportunities include:

Overall, analyzing your company’s direct and indirect spend and continuously monitoring performance metrics should allow you to find a range of improvement opportunities.

Now, it’s time to prioritize them.

Once your procurement team has identified in which areas improvements can be achieved, they should develop strategies and action plans to address the most beneficial ones first.

That way, you ensure that procurement efforts are focused on strategies that will deliver the most value for your organization.

These may involve process optimization, supplier development initiatives, technology upgrades, or other improvement initiatives.

Let’s say your team established that the manual processing of purchase orders is a bottleneck in the procurement process, leading to delays and errors.

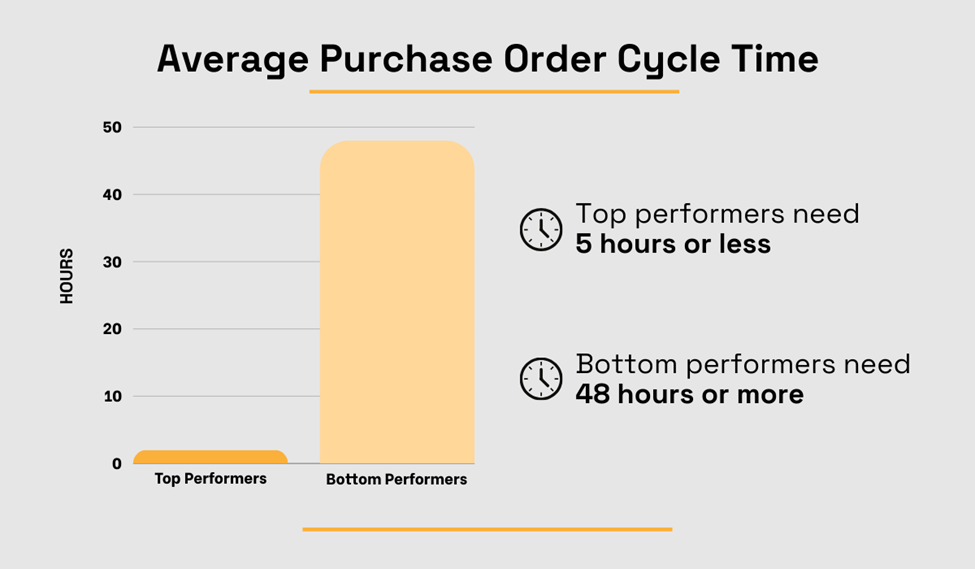

This is a common issue among procurement departments, as evidenced by the findings of the American Productivity and Quality Center (APQC).

As illustrated below, top-performing companies average five hours or less to process a purchase order internally and send it to their supplier.

Conversely, bottom-performing companies needed 48 hours or more.

Illustration: Veridion / Data: APQC

Given this benchmark, if your team calculated that the average PO cycle time is longer and that the majority of delays are caused by manual processes, these findings can be presented to company management as a reason to prioritize this high-value opportunity.

From there, the team can:

Next, they should research and evaluate different procurement automation solutions available on the market, considering factors such as features, scalability, cost-effectiveness, and compatibility with existing systems.

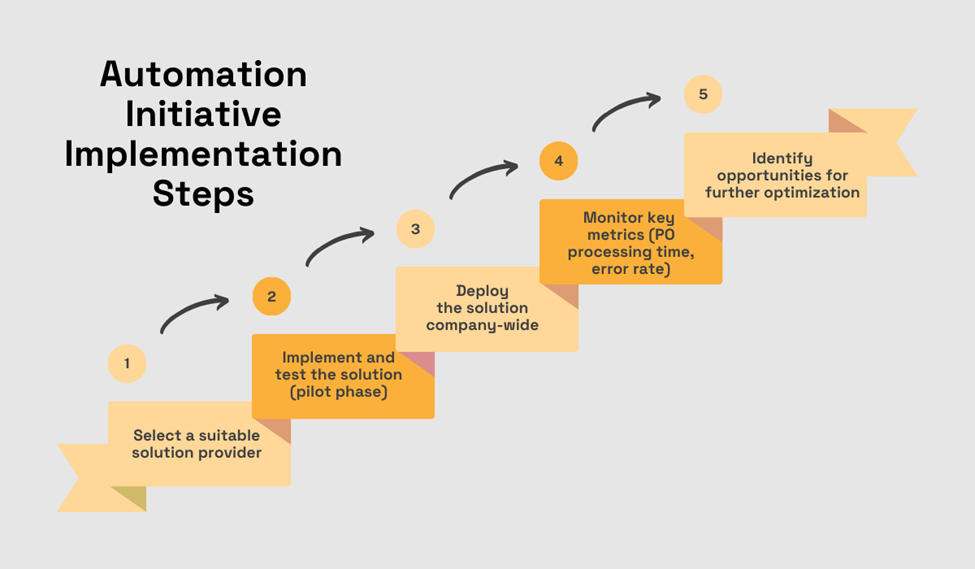

Now, they can move to other steps needed to implement this initiative, illustrated below:

Source: Veridion

Of course, other identified improvement initiatives, such as contract renegotiation with key suppliers, will have their own requirements and complexities.

Regardless, they should be prioritized based on their potential impact on cost savings, supplier relationships, and overall procurement performance.

As we’ll see, that’s where forecasting savings and collaborating across teams can help streamline the prioritization process and ensure alignment with strategic objectives, fostering a proactive approach to procurement performance management.

As we explained above, prioritizing improvement opportunities should begin by presenting a compelling case to company stakeholders.

That way, you can highlight the potential for significant contractual savings and emphasize the strategic benefits of optimization efforts.

More specifically, your procurement team should estimate and project potential cost savings and cost avoidance opportunities for each improvement initiative or strategy.

This process involves analyzing historical data, market trends, and supplier performance to forecast potential savings and inform budgeting and financial planning processes.

For example, your team might’ve identified opportunities to consolidate suppliers, negotiate volume discounts, or revise the agreed pricing.

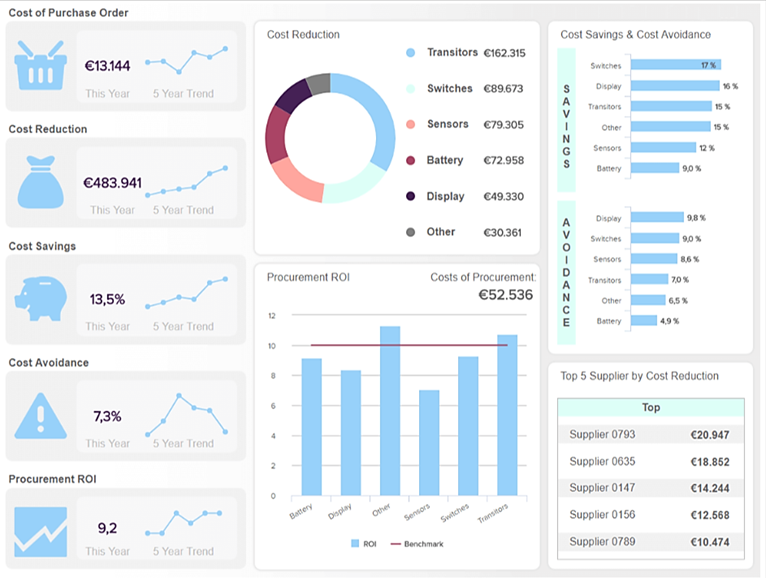

To accurately estimate savings from such initiatives, leveraging data analytics and predictive modeling tools is essential.

Source: Datapine

By utilizing such tools, the procurement department can analyze historical spending patterns, market pricing trends, and supplier performance data to forecast potential contractual savings in identified areas for improvement.

For instance, predictive modeling techniques can anticipate future price fluctuations and signal when early contract renewal should be pursued to secure more favorable terms.

In summary, presenting clear and compelling business cases supported by data-driven insights and quantifiable metrics will strengthen your team’s arguments and enhance credibility with company stakeholders.

For procurement performance management to be successful, the procurement team should foster collaboration and communication between their own and other departments or teams within the organization.

This involves sharing information and coordinating efforts to align procurement objectives with broader organizational goals.

Ideally, this process should result in enhanced visibility and transparency of procurement processes and factors that affect them, reduced data silos, increased innovation, and better risk management.

Simply put, there is no good substitute for efficient cross-departmental teamwork and communication.

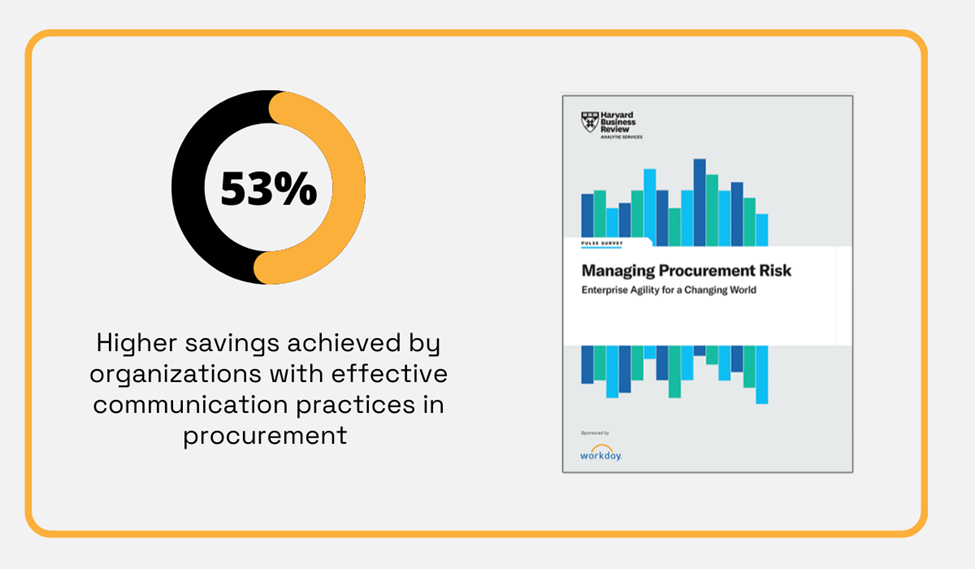

Namely, the Harvard Business Review study demonstrates that companies with effective communication practices in procurement achieve significantly better results.

Illustration: Veridion / Data: Workday

So, what can you do to establish effective collaboration across teams and improve your procurement performance?

Start by defining clear communication channels to ensure consistent communication between the procurement team and other departments.

To avoid confusion and facilitate collaboration, clearly outline the roles and responsibilities of each department in procurement initiatives.

In doing so, make sure to encourage open communication and information sharing to promote transparency and trust among departments.

For more demanding procurement initiatives, consider creating cross-functional teams comprising members from various departments tasked with tackling specific procurement challenges and fostering innovative solutions.

As employees from other departments may not be well-versed in procurement processes, consider organizing training sessions to promote a better understanding of the issues involved.

The suggested actions should enable you to establish effective collaboration and communication across different departments or teams, ultimately leading to improved procurement performance management.

Once procurement performance-enhancing initiatives are launched, it’s crucial for the procurement team to continuously monitor and evaluate their progress to ensure effectiveness, identify obstacles, and make timely adjustments.

Ongoing performance monitoring, coupled with stakeholder feedback, enables the team to refine established strategies and action plans and, if necessary, reassess their initial savings forecasts.

Here are some suggestions for effective progress monitoring:

For example, suppose your procurement team is implementing a supplier consolidation initiative to streamline vendor management and achieve cost savings.

In that case, relevant KPIs for measuring its progress could include KPIs illustrated below:

Source: Veridion

These KPIs can be monitored through regular data collection and analysis using procurement software tools.

For example, the KPI pertaining to the reduction in the total number of suppliers can be measured by calculating the percentage decrease over a predefined period.

That way, your procurement team can assess the success of consolidation efforts and identify opportunities for further streamlining supplier relationships.

Overall, monitoring progress based on quantifiable KPIs provides the procurement team with real-time visibility into the status of each initiative, enabling them to identify issues early and proactively manage risks.

Finally, those involved in improvement initiatives should regularly share performance results and progress reports with relevant stakeholders, including senior management, other procurement team members, and remaining key participants.

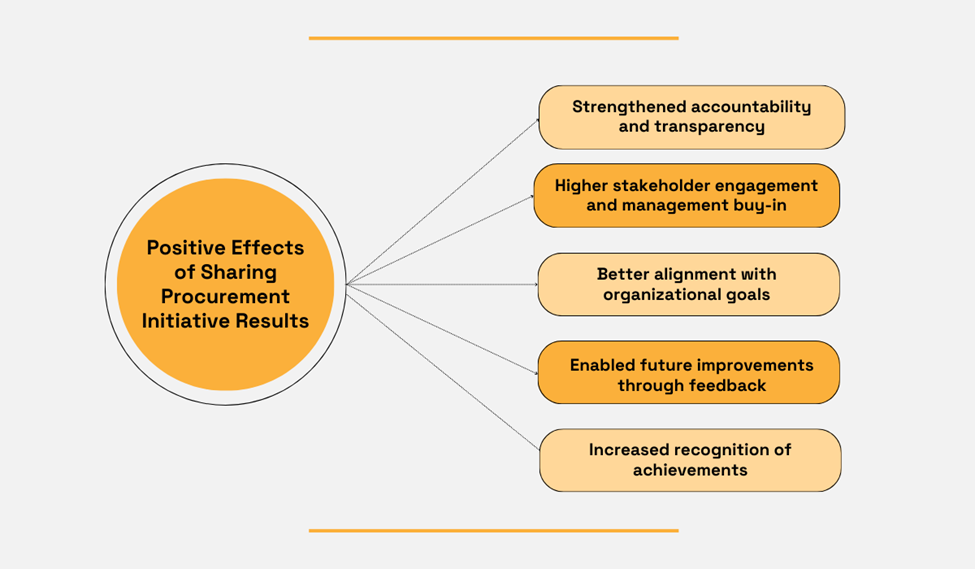

In addition to minimizing initiative implementation challenges, this will generate the following positive results:

Source: Veridion

Furthermore, when sharing the results, try to tailor communication to different stakeholders’ interests and their level of expertise.

You can also leverage storytelling to illustrate the impact of initiatives on the company’s productivity and profitability.

Ultimately, this will reinforce the value of investing in effective procurement performance management.

It is evident that effective procurement performance management is indispensable for companies striving to optimize costs, enhance efficiency, and strengthen supplier relationships.

By selecting the right tools and following the steps outlined in this article, your team can establish a systematic approach to procurement that drives continuous improvement and aligns with strategic objectives.

With proactive monitoring, strong collaboration, and a commitment to data-driven decision-making, your organization can unlock significant value and maintain a competitive edge in today’s dynamic marketplace.