Different Types of Cost Savings in Procurement

Successful procurement operations require a balance between effective resource management and maintaining a high level of quality of sourced goods.

This can be a challenging task, as it sometimes may seem like there is no way to save money without compromising anything.

However, this article is here to prove you otherwise.

Today, we are going to present you with several different types of cost savings in procurement, as well as share our best practical tips on how you can realize them in your organization.

So, let’s dive right into it.

The first type of cost savings you need to know about is price savings.

In simple terms, price savings are savings you can realize through effective negotiation with suppliers.

So, if you want to ensure that your organization consistently gets goods at the most favorable terms, building relationships with your suppliers and mastering the skill of negotiation is crucial.

Getting in touch with your suppliers—especially those you haven’t built a relationship with—and simply requesting a lower price is an approach that isn’t very likely to yield the desired result, and is considered to be outdated by many.

Nowadays, nurturing supplier relationships is the foundation for success in procurement, explains Mickey North Rizza, Group Vice-President for IDC’s Enterprise Software.

Illustration: Veridion / Quote: SupplyChainDigest

Furthermore, according to research conducted by HICX, 73% of suppliers are willing to go the extra mile for their customers of choice, i.e., those who show appreciation and treat them “as an extension of the organization.”

So, when you put effort into building strong relationships with your suppliers, you’re bound to reap benefits like special deals and more favorable payment terms, both of which ultimately lead to price savings.

But how do you begin discussing this with your suppliers?

For starters, bring data—both internal and external—to the table.

Take a look at your organization’s past purchasing patterns and the supplier’s performance.

Do you have the grounds to suggest a volume discount?

Are there any areas where the supplier falls short, that you could leverage to work out a lower price of goods?

Then, arm yourself with information about the current state of the market and competitor pricing.

How does your supplier’s pricing compare to that of their competitors?

Have there been any market changes that would warrant a lower price request?

Bring those findings to your suppliers and use them to make a case for yourself.

Illustration: Veridion / Quote: LinkedIn

Coming to a negotiation with concrete data shows your supplier that you’re making a request based on facts, and not out of a lack of respect and appreciation for their business.

The bottom line is: if you approach supplier negotiations with respect and armed with current and relevant data that supports your case, chances are, you’re going to realize the desired price savings.

Sometimes, however, there may be no room for negotiation of prices.

Maybe the suppliers you’re using are dealing with increasing costs of raw materials, or maybe there is a high demand for a specific good, therefore making the supplier less inclined to discuss a lower price with you.

Whatever the case may be, not all is lost, and there are other ways to realize cost savings.

One of the most straightforward ways to do so is through improving your supplier management.

Illustration: Veridion / Data: Zycus

It’s all about taking a step back and identifying what measures you and your procurement team need to take in order to get the most out of your supplier relationships.

Take a good look at your current supplier lineup.

Does each one of them genuinely bring something unique to the table, or is there a way for you to reduce the number of suppliers you work with?

For instance, if an automotive manufacturer is working with 10 different suppliers to get 10 different types of components, it might be a good idea to explore supplier consolidation.

Is there a supplier among those 10 that could provide them with multiple types of components without quality going down?

If so, that might be an option worth exploring.

Not only would the procurement team need to juggle fewer different suppliers, but this would also help them strengthen the relationships with the remaining, top-performing ones.

Christina Langley, Managing Director of procurement-focused recruiters Langley Search & Selection, explains that there is a trend toward vendor rationalization, driven by the desire for cost reduction.

She says that procurement teams are trying to minimize costs by:

But how do you avoid finding yourself in a situation where your organization works with an unnecessarily high number of suppliers in the first place?

Well, that is where taking a more strategic approach to procurement comes in.

Namely, if you thoroughly research all of your supplier options before making a commitment, you’re more likely to build long-term partnerships that carry cost-saving benefits.

This is a task that Veridion’s AI-powered tool can help you with.

Source: Veridion

Our AI-based machine-learning models rifle through billions of websites every week to provide you with the most recent information on more than 80 million companies worldwide.

That way, you can easily find the suppliers that perfectly match your criteria within seconds and be confident that you’re always getting the freshest data about them.

With Veridion, you can find the right suppliers the first time around and immediately start building relationships that will save your organization valuable time and resources.

Apart from looking at outside factors—i.e., your suppliers—consider looking inside your procurement department to identify cost savings opportunities.

Are your processes truly as efficient as they can be?

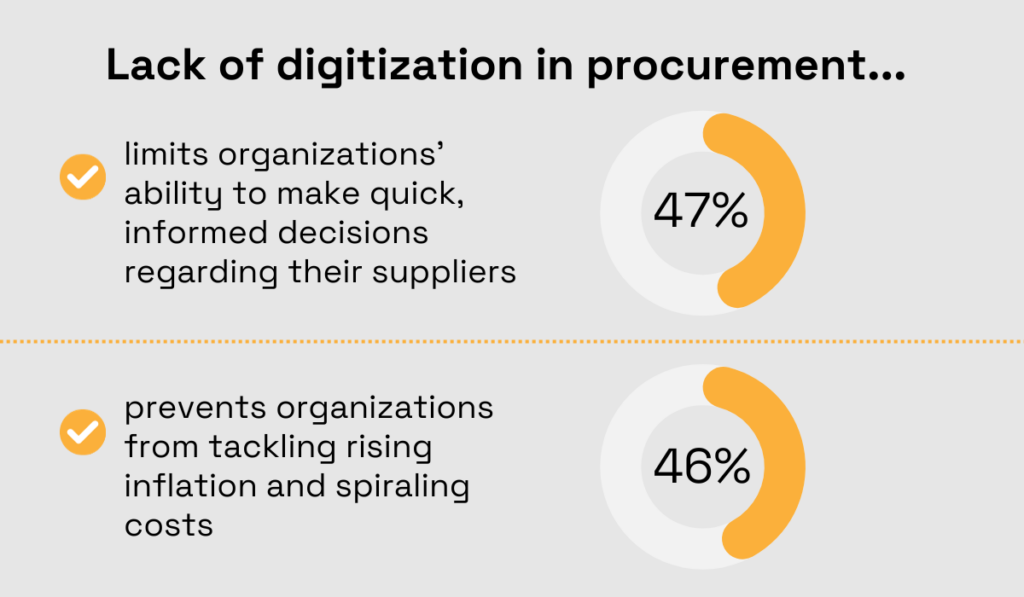

If there is a lack of digitization within your department, the answer is probably “No”.

And that is the case for 53% of procurement and supplier management processes according to Ivalua’s research.

Illustration: Veridion / Data: Ivalua

Alex Saric, a smart procurement expert at Ivalua, goes on to explain that organizations should start implementing automation tools more in order to combat the lack of digitization.

This reduces the need for procurement professionals to deal with low-value manual tasks and allows them to focus more of their efforts on strategic tasks that require human touch.

But how does this save your organization money?

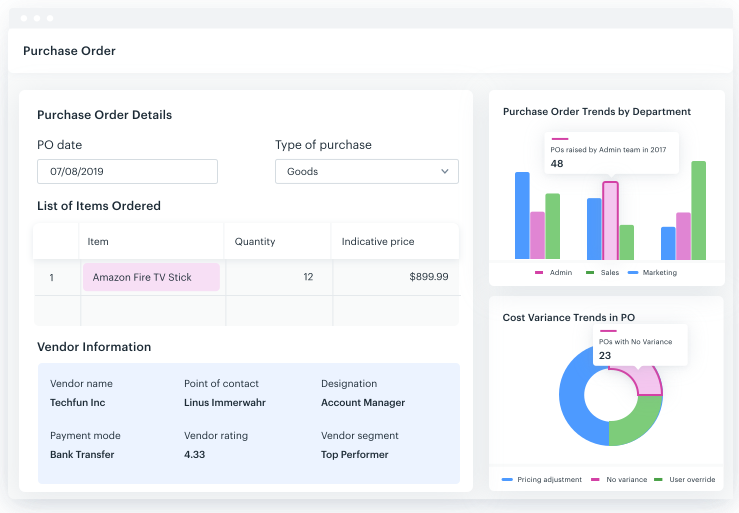

Consider, for example, the process of manually creating a purchase order.

As we’re sure you already know, the process is time-consuming, comes with a lot of manual data entry, and carries a high risk of human error.

Every moment your procurement team spends manually extracting the information needed to create the purchase order, waiting for the order to be passed around to various stakeholders for approval, and fixing mistakes that easily could have been avoided, is a moment in which the organization is losing money.

Conversely, if you invest in automating these processes, all of these pitfalls can be mitigated.

Source: Kissflow

Yes, such software is going to require an initial investment, but it is also going to streamline the purchase order process and prevent costly errors.

On top of that, various kinds of software solutions your procurement team can use can serve as a central database that enables data-driven decision-making.

You can use them to track spending patterns, prevent expensive overstocking, and use the data and analytics to more efficiently identify additional cost-saving opportunities.

So, if you feel like there is room for your procurement processes to become more efficient, digitization might be the way to go.

Your team will have space to focus on more value-added tasks, and your organization will save money, so everybody wins.

Another way to realize cost savings in procurement is through proper demand management.

But what is demand management?

Let’s take a look at how the Chief Procurement Officer of the Swedish telecommunications company Telia, Nicolas Passaquin, defines it.

Illustration: Veridion / Quote: LinkedIn

Successfully anticipating demand, improving your supply chain operations, and realizing cost savings in the process is no easy feat.

However, it can be achieved with the help of fresh, accurate data and collaboration with internal and external stakeholders.

Using both internal and external data helps your procurement team understand your organization’s needs and current market conditions, improving their ability to predict future demand accurately.

But simply looking at numbers won’t necessarily paint the entire picture of why your demand looks the way it does, and what can be done to achieve savings.

To get the full picture, you need to foster open communication and collaboration across different departments within your organization.

Rachel Dolan, Head of Procurement at Permanent TSB bank, shared that having the procurement department work with other departments on demand forecasting helped the company realize millions of euros in savings.

Illustration: Veridion / Quote: Efficio

Given that demand management involves demand forecasting, procurement, and inventory management, encouraging collaborative work between relevant departments can have a significant impact on your cost savings.

Sharing information prevents the creation of data silos and gives each relevant department the full picture of the situation within the organization.

Combined with information about broader market conditions, it becomes easier for them to source goods with more accuracy, thus achieving optimal inventory levels and avoiding costly overstocks.

Aside from that, collaboration helps in mitigating costly risks.

Let’s say that a supplier informs you about imminent disruptions in the supply chain that are bound to cause a delay in the delivery of goods.

If you foster collaboration and data exchange within your organization, this is the kind of information that is going to be relayed to your demand planning team.

They will then be able to develop a mitigation strategy that will ensure this kind of challenge doesn’t have a negative financial impact on the organization.

The total cost of ownership savings refers to the reduction of costs associated with the entire lifecycle of a product—from its acquisition, throughout its operation and maintenance, to its disposal.

These costs are often represented in the form of an iceberg, where the unit price, i.e., the initial purchase price of a single unit of the product, is only its tip.

Source: Veridion

While the costs that are below the surface often cannot be completely eliminated—after all, you have to store your goods somewhere—they can certainly be reduced.

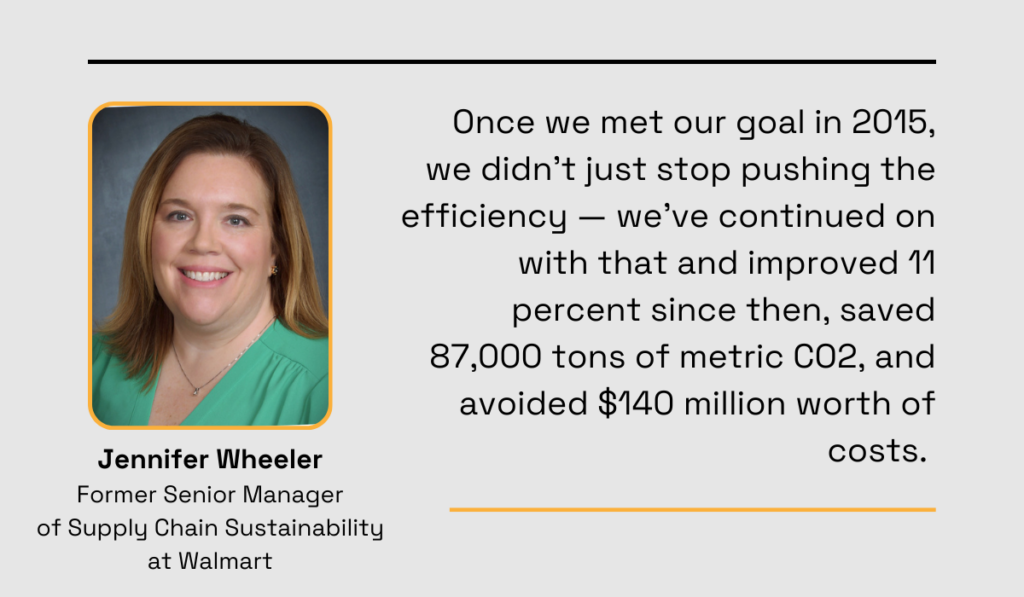

Take Walmart as an example.

Back in 2005, this multinational retailer made it their mission to improve their fleet’s fuel efficiency and save money on fuel costs by cutting diesel use.

They met their goal 10 years later, saved $1 billion in fuel costs by that point, and have since continued on that path.

Illustration: Veridion / Data: GreenBiz

This begs the question, what can your procurement department do to realize TCO savings?

You can start by selecting your suppliers based not only on their competitive price of goods, but also their reliability and the quality of their products.

Let’s say you were to procure heavy industrial machinery from a supplier whose quality isn’t on a high level.

More than likely, you’d experience equipment breakdowns that not only require costly repairs and maintenance, but also cause unnecessary and long downtimes.

By the time that piece of machinery reaches the end of its useful life, it might just turn out that all of the repairs and downtime cost you more than an initially more expensive machine would have.

Working with high-quality suppliers might drive higher initial costs, but the lower maintenance expenses and longer operational lifespan with less downtime are bound to contribute to your TCO savings.

Therefore, to achieve TCO savings, focus on the big picture when choosing your suppliers, and watch the long-term benefits happen.

From honing your procurement team’s negotiation skills for working out lower prices of goods and exploring supplier consolidation, to optimizing your processes through digitization and smart demand management, there are numerous ways in which you can increase your cost savings.

So, regardless of whether you decide to seek cost-saving opportunities outside of your organization or within, we hope that this article has empowered you to research your options and take the next step toward improving your procurement operations.