Procurement Cost Savings: A Guide

The primary objective of any procurement department is to manage resources effectively, aiming for optimal cost savings.

To achieve these savings, it’s essential to clearly understand the costs involved and identify areas within procurement where savings can be realized.

Lucky for you, you’ve landed on our page!

Today, we’ll dive into the intricacies of procurement costs, highlight the importance of initiating cost savings in your procurement practices, and shed light on the positive impact these savings can have on your organization.

Before we wrap up, we’ll spotlight companies that have excelled in implementing effective cost-saving strategies in their procurement processes, providing valuable examples for you to follow.

So, stay with us as we explore procurement cost savings in detail.

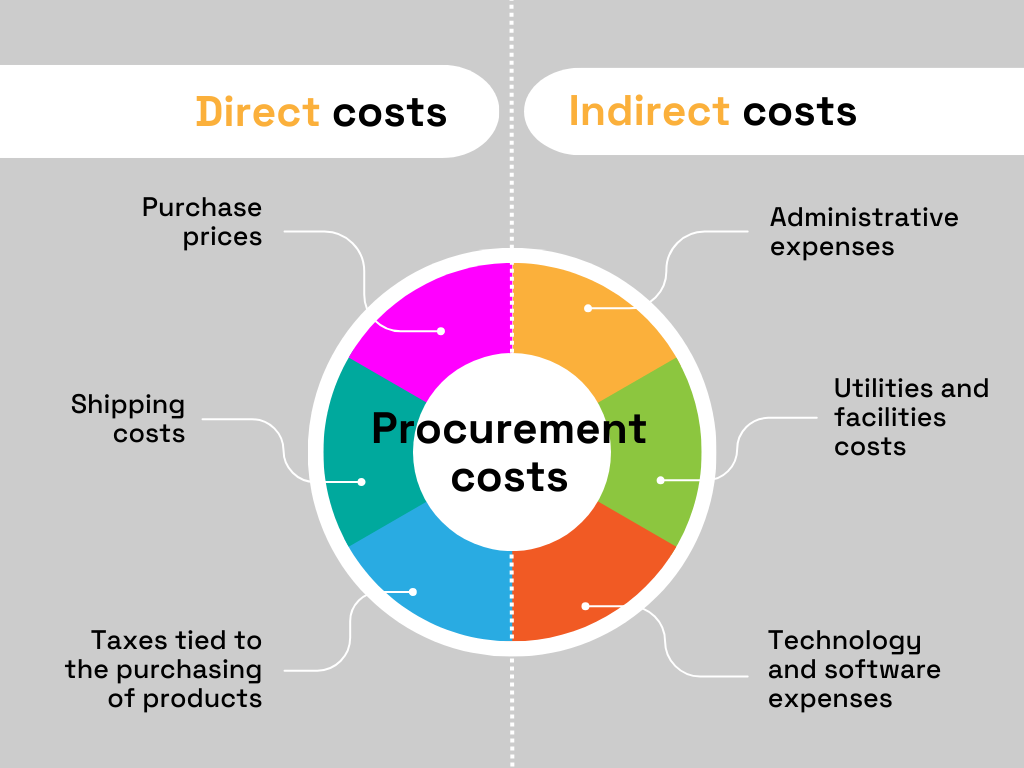

To initiate savings, you first need to understand different costs in procurement. These costs come in two primary forms: direct and indirect.

Direct costs are the expenses directly linked to obtaining the goods or services. These include purchase prices, shipping costs, and taxes tied to the purchasing of products.

Indirect costs, on the other hand, are more subtle, encompassing overheads like utilities or administrative expenses.

Take, for instance, the indirect cost of labor hours spent on manual purchase order management—essential for overall business operation but not tied directly to a specific product or service.

In essence, a comprehensive understanding of both direct and indirect expenses within your procurement is crucial.

Why?

Because identifying potential areas for savings becomes feasible only when you precisely understand where your funds go.

Source: Veridion

In this context, we can’t overstate the role of data analysis and data-driven decision-making.

When you analyze procurement data, you can understand your spending patterns more in-depth and quickly pinpoint where you can make adjustments to achieve cost savings, both in terms of direct and indirect costs.

For example, suppose you want to purchase a product for a lower price and reduce direct costs to achieve savings.

In that case, you can analyze historical data on purchases from a single supplier to see if there is an opportunity to renegotiate contracts with better prices.

Data can also discover bottlenecks in manually managing purchase orders and reveal that the process takes too much time.

Based on that insight, you can decide to automate the process to gain savings by reducing the costs of labor hours.

Such indirect costs are especially worth tracking as they can quickly accumulate and become extremely costly.

In summary, a clear understanding of procurement costs, coupled with data analysis, empowers you to identify areas to implement effective cost-saving strategies.

The areas where you can achieve the most substantial savings are the topic of our next section, so let’s continue there.

By now, we have explained procurement costs and acknowledged the importance of thoroughly understanding your procurement department’s spending.

In the following sections, we will explore the three most essential areas for cost savings—your suppliers, purchase demand, and total cost savings—and highlight how to achieve cost savings in these areas.

Let’s start with supplier cost savings.

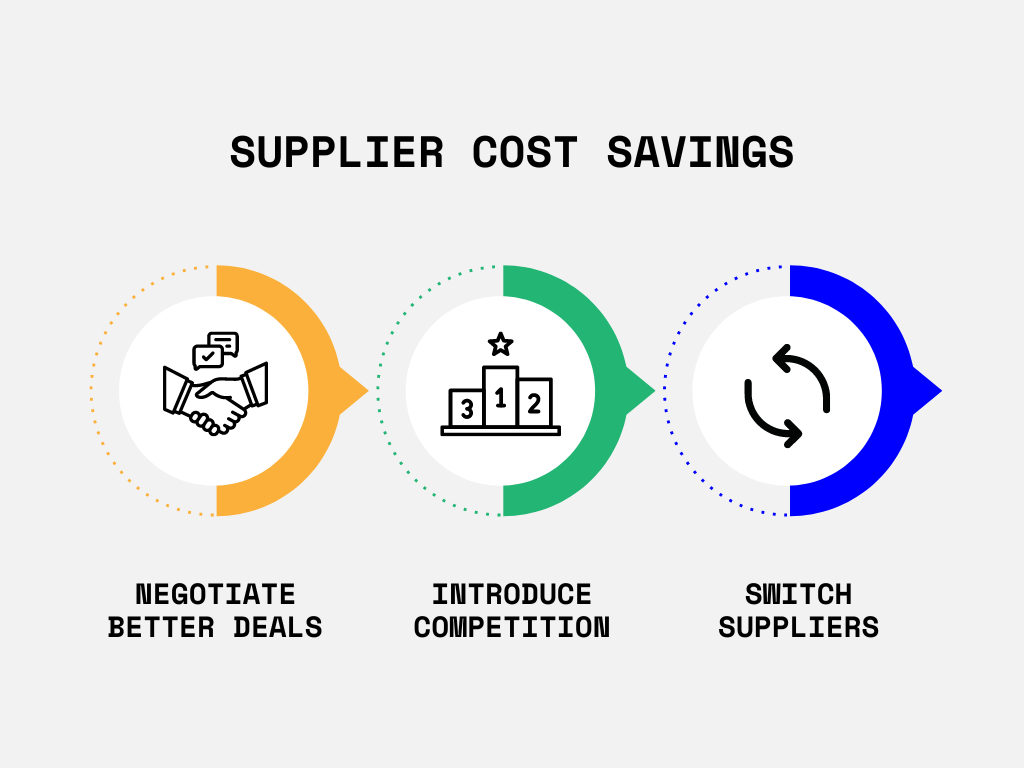

Realizing substantial cost savings through suppliers can be done by reevaluating existing relationships or considering new ones.

There are three practical approaches to achieving supplier cost savings, so let’s explore them one by one.

Source: Veridion

Starting with your current suppliers, it would be wise to reevaluate relationships with them to trim expenses.

You should review contracts with suppliers to avoid any spending leakage and perform continuous supplier assessments to see if they consistently deliver quality products on time.

Insights you get from these assessments can give you data-based ground for negotiating better prices, volume discounts, or loyalty incentives.

For example, you can negotiate a discount in return for early payment or increased order quantity.

Another effective way is to diversify the supplier base and introduce competition, giving you the leverage for better pricing and terms negotiation with current suppliers.

Supplier diversification is also an efficient risk mitigation strategy, which we will discuss later.

Lastly, if supplier assessments show that you don’t have suppliers that are reliable enough, you will be better off by considering replacing them.

However, manual supplier searches are time-intensive, with McKinsey noting that a sourcing professional spends over 40 hours on a single search. That is 40 hours of indirect cost spent on labor hours.

Illustration: Veridion / Data: McKinsey

Fortunately, there are better ways to streamline this process, and Veridion, our AI-powered supplier sourcing enabler, is just the right solution.

Veridion provides near real-time data on millions of global suppliers, allowing quick identification of those aligned with your standards without compromising quality.

Veridion’s complex search API integrates with your systems and yields accurate supplier data within minutes.

This data covers everything from firmographics to specific product details, certifications, and sustainability data.

A small sample of data points Veridion provides

The insights you get from it empower you to make informed decisions, enhance efficiency, and identify cost-saving opportunities in supplier relationships.

And since the search is done within minutes, you immediately reduce the indirect costs of labor hours.

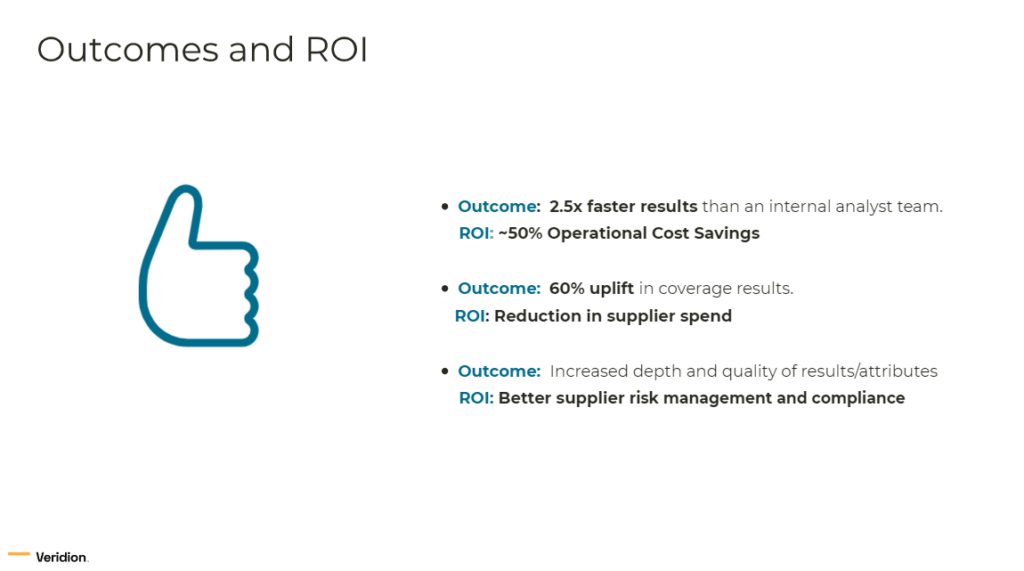

An example from a tier-one global management consultant company illustrates Veridion’s impact on cost savings.

The company in question had two analysts who needed two weeks each for supplier search—four weeks in total.

Veridion brought them results 2.5 times faster, which resulted in a 50% operational cost savings.

In addition, because of Veridion’s global coverage, the company was able to source optimal suppliers, further reducing spend and achieving savings.

Source: Veridion (ex Soleadify)

In conclusion, achieving cost savings through strategic supplier management, be it through renegotiation or efficient sourcing, is a valuable strategy for enhancing your bottom line.

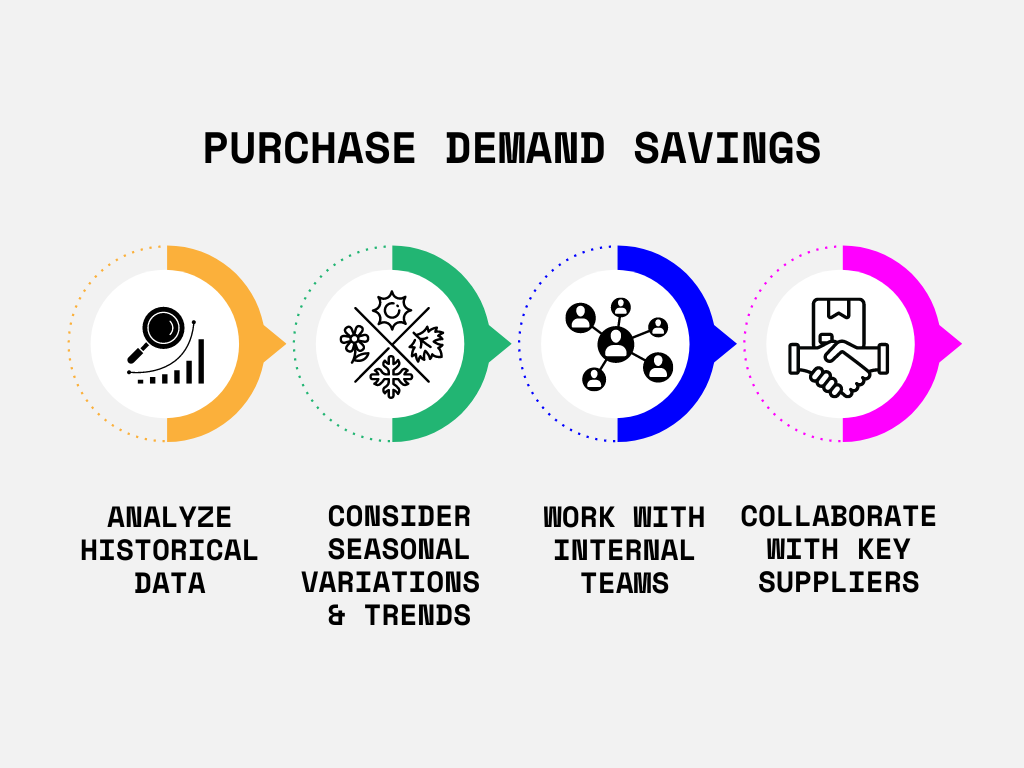

Another area where you can achieve substantial cost savings is managing purchasing demand, specifically by reducing unnecessary or excess spending and aligning procurement with actual needs.

But how can I precisely determine the required purchase quantity? What if I’m unable to meet customer demands and stock the products?

These are common questions and the driving factors behind why procurement teams often overstock their inventories, leading to high carrying costs.

Conversely, understocking presents its own set of negative consequences.

However, by avoiding both extremes, you can realize substantial cost savings. And the solution is accurate demand forecasting with the help of data.

Source: Veridion

For example, you can analyze your historical data to make informed predictions about future demand, taking into account seasonal variations, market trends, and other relevant factors.

Moreover, you can work closely with internal stakeholders, such as sales and marketing teams, to gather insights and collaborate on more accurate demand forecasts based on market intelligence.

Finally, it would be wise to collaborate with key suppliers and share forecasted demand information.

This would allow suppliers to optimize their production and inventory planning, fostering an improved strategic relationship with them.

Importantly, this also contributes to realizing long-term cost savings.

Bottom line, effective purchase demand forecasting presents a substantial opportunity for cost savings, particularly when you skillfully navigate the challenges of overstocking and understocking.

In pursuing cost savings, it’s crucial to shift your focus from merely slashing the upfront cost of a product to a more comprehensive strategy—total cost savings.

Total cost savings can be realized when you reduce the total cost of ownership, which encompasses all expenses tied to procuring products and services, such as costs associated with doing business, supply chain costs, and ownership costs.

Source: Veridion

Let’s focus on the costs of doing business for a moment.

The costs of doing business within procurement involve all operational expenses incurred throughout the procurement process.

This spans from supplier identification and negotiations to handling purchase orders and payments.

In other words, the costs of doing business are the costs of the entire lifecycle of your procurement-related activities.

Therefore, if you want to realize total cost savings, one way is to reduce the costs of doing business.

An impactful strategy to do this is integrating technology into procurement.

Procurement automation tools streamline and optimize various procurement processes, diminishing the need for time-consuming manual interventions and mitigating the risk of errors, which are both costly.

Moreover, technology enhances data accuracy and provides real-time insights, which empowers you to make informed decisions and identify additional cost-saving opportunities.

To summarize, leveraging technology in procurement accelerates processes and significantly reduces the costs associated with doing business.

By lowering the costs of doing business, there is a direct impact on total costs, ultimately leading to comprehensive total cost savings.

Now that we’ve pinpointed areas for potential procurement savings and how to begin, let’s see why it’s time to start saving in the first place.

In the following three sections, we will explain how procurement cost savings and strategic procurement practices contribute to the financial health and competitiveness of a company.

Cost savings in procurement have a direct and transformative impact on a company’s financial health.

In simple terms, when you reduce the costs of acquiring goods and services, more revenue becomes available as profit, thereby increasing your profit margins.

With increased profit and cash flow, you can avoid debts and allocate resources to invest in innovation or new infrastructure, further contributing to additional cost savings.

Therefore, cost savings not only improve short-term financial outcomes but also, when mastered, help you remain competitive in the market, attract investors, and sustain long-term growth.

Procurement cost savings empower companies with a newfound budgetary agility.

When procurement teams successfully identify and implement cost-saving measures, they create room for increased flexibility in budget allocation.

The funds you save can be redirected to areas that demand additional financial support. You can also invest in initiatives that can bring you even more profitability.

The resulting flexibility in the budget improves operational efficiency and positions the company to take advantage of new opportunities and effectively navigate challenges.

Strategic procurement practices, driven by the pursuit of cost savings, have an important role in mitigating risks.

One such practice involves diversifying the supplier base.

By consciously expanding the network of suppliers, you become less vulnerable to supply chain disruptions than you would be if you depended on a single supplier.

Thus, procurement cost savings extend beyond immediate financial gains, offering a strong shield against potential risks and enhancing the overall resilience of your organization.

In the end, let’s take a look at industry best practices for achieving cost savings.

We will focus on three of them while also bringing real-life examples from companies that have successfully implemented these strategies to realize significant cost savings.

Utilizing technology and automation is a foundational best practice for achieving efficient procurement cost savings.

Procurement automation tools and data analytics are instrumental in automating repetitive and time-consuming tasks, paving the way for substantial savings—an investment well justified.

Consider the case of Unilever, a multinational, fast-moving consumer goods company.

Unilever successfully implemented a digital procurement platform that offered comprehensive visibility into procurement for all stakeholders.

Through this platform, Unilever leverages artificial intelligence, data analytics, and automation to optimize sourcing decisions, reduce costs and risks, and foster supplier collaboration and innovation.

The transformative impact of this technology is evident in Unilever’s achievements—saving over €1 billion in annual procurement spend and attaining an impressive 100% visibility into its supplier base.

This success story underscores the tangible benefits of integrating technology and automation into procurement processes for enhanced efficiency and substantial cost savings.

Effectively diversifying suppliers, as we already mentioned today, is a strategic best practice for both risk mitigation and cost savings.

Johnson & Johnson, a prominent global healthcare leader, is an excellent example of this approach.

Since 1998, Johnson & Johnson has been proactive in implementing a supplier diversity program.

Source: Johnson & Johnson

Beyond this, the company places significant emphasis on cultivating robust relationships with its key suppliers.

By actively engaging with diverse suppliers and establishing strategic partnerships, Johnson & Johnson strengthens the resilience of its supply chain.

If one supplier faces challenges and disruptions, this doesn’t affect the company too much because they can rely on other suppliers and prevent additional expenses or financial losses.

This strategic diversification proved particularly crucial during the challenges posed by the COVID-19 pandemic.

What’s more, supplier diversification not only minimizes the impact of potential disruptions but also presents an opportunity to negotiate competitive terms with various suppliers.

This, in turn, contributes to a reduction in procurement costs and brings more savings.

Optimizing inventory systems is another best practice for achieving procurement cost savings, ensuring a balance between avoiding overstocking and understocking.

An effective approach in this regard is the implementation of just-in-time (JIT) inventory management systems.

Because materials are ordered after a customer orders a product, JIT minimizes the need for large inventories. In turn, this reduces holding costs associated with the storage, maintenance, and security of excess inventory.

Source: Veridion

Toyota, a trailblazer in JIT inventory management, continues to successfully utilize a just-in-time inventory system even today.

However, as Jamie Bonini, the president of the Toyota Production System Support Center, emphasizes, the success of this system hinges on establishing long-term partnerships with suppliers built on trust.

But such strategic partnerships not only facilitate the effectiveness of JIT—they are yet another best practice for realizing cost savings.

Namely, you can negotiate better deals with suppliers with whom you already have great relationships.

In a nutshell, adopting these best practices (and many others) is a comprehensive blueprint for businesses seeking to elevate their procurement strategies and achieve substantial cost savings.

Unilever, Toyota, and Johnson & Johnson are practical illustrations of the benefits that can be achieved by implementing these best practices in your procurement.

And that concludes our journey through procurement cost savings in this guide.

We started by defining procurement costs, delved into areas where savings are possible, and explored the benefits these savings bring to your organization.

In the end, we introduced best practices, citing examples of companies like Unilever, Johnson & Johnson, and Toyota that effectively leverage these strategies for increased cost savings.

We hope that this guide has provided a clear understanding of procurement cost savings and will prove valuable as you work towards realizing those savings in your procurement processes.

Best of luck with your procurement cost-saving endeavors!