A Quick Guide to Procurement Performance Management

Managing procurement performance isn’t just about acquiring goods and services at the best price possible.

Instead, it focuses on pinpointing strengths and weaknesses within your processes and activities in order to ensure smooth operations—from procurement initiation to completion.

In this guide, we’ll explore the fundamentals of this important concept, as well as delve into some of the best practices, real-world examples, and actionable strategies to help you streamline your own procurement procedures.

Let’s start with the basics.

Procurement Performance Management (PPM) refers to the continuous monitoring, measurement, evaluation, and optimization of effectiveness and spend across all procurement activities within an organization, such as:

The primary objective of PPM is to ensure the procurement department operates at peak efficiency at all times, leveraging its resources and processes to minimize potential risks and achieve the consistency and reliability of its supply inputs.

In short, well-managed procurement performance directly translates to better outcomes for both the procurement teams and companies as a whole.

In fact, Nicolas Walden, associate principal at the Hackett Group, says that effective procurement has never before played such an important role in company success.

Illustration: Veridion / Quote: Procurement Mag

It serves as the foundation for business resilience amidst market volatility and concerns like raw material shortages and inflation, which are currently at the forefront of everyone’s minds.

That’s why now is the right moment for procurement professionals to look for ways to elevate their performance and embrace innovation—a goal attainable only through a robust framework for procurement performance management.

PPM is far more complex than many might assume.

It consists of many different activities, all of which have the same goal: to optimize the procurement process and unlock the team’s strategic objectives.

Let’s dissect each of them.

The well-known adage “You can’t manage what you can’t measure” rings particularly true when it comes to procurement performance.

After all, to be able to improve your PPM down the line, you need to begin by gauging how well you’re doing right now.

So, to efficiently track your procurement performance, there are three steps you need to take.

For starters, define clear objectives that align with the company’s goals, budget, and organizational structure.

They should also adhere to the SMART framework, which you can see outlined in the image below.

Source: Veridion

In the simplest of terms, the SMART criteria help ensure that whatever you’ve set out to achieve, is actually achievable.

As such, this framework is a valuable tool in any manager’s toolkit.

Next, establish relevant KPIs to track your performance against these objectives.

In procurement, KPIs typically fall into three broad categories: cost management, supplier management, and process efficiency. Here’s a breakdown of the KPIs within each category:

| COST MANAGEMENT | SUPPLIER MANAGEMENT | PROCESS EFFICIENCY |

| Cost savings | Supplier availability | Procurement cycle time |

| Cost avoidance | Supplier compliance rate | Vendor rejection rate |

| Procurement ROI | Supplier quality | Emergency purchase ratio |

| Spend under management | Supplier defect rate | Purchase order accuracy |

Once goals and KPIs are defined, the only thing that’s left to do is to regularly monitor and analyze your actual performance against these established parameters and standards.

This ongoing assessment will tell you whether you’re meeting your objectives or if there’s room for improvement after all.

Given just how much supplier-buyer relationships influence procurement performance, establishing and nurturing strong partnerships with suppliers should be considered one of the top priorities of PPM.

Reliable and strategic alliances are always good news for procurement, unlocking a treasure trove of benefits, including:

When it comes to improving relationships with suppliers, technology can be a great ally.

Supplier management platforms, for example, help streamline all processes related to supplier management, from onboarding to ongoing performance assessment.

They centralize relevant documentation, generate reports on supplier quality, and take care of risk analysis, saving you a lot of time in the process.

Consequently, manual, error-prone, and time-intensive tasks are eliminated, allowing you to focus on matters only humans can handle, such as building rapport and trust with suppliers, understanding mutual long-term objectives, or managing negotiation and conflict resolution.

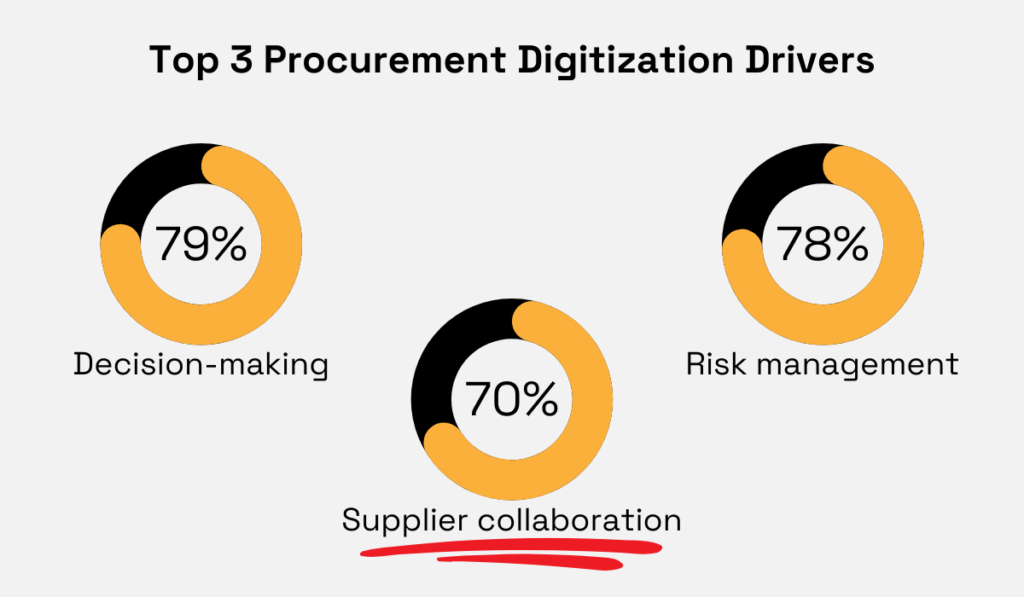

The importance of technology in boosting these crucial relationships is further supported by ProcureTech’s survey on digital adoption in procurement.

Illustration: Veridion / Data: ProcureTech

As you can see, supplier collaboration improvement ranks among the top three drivers for digitization, alongside decision-making and risk management.

All in all, if you aim to take your procurement performance to another level, look no further than your suppliers.

They are the key that unlocks better product quality, cost savings, reliability, and competitive advantage.

Procurement is a risky business, no two ways about that.

Risk can manifest in various forms, such as supply chain disruptions, supplier bankruptcies, material shortages, or even fraud within the company, all of which can severely impact businesses as a whole.

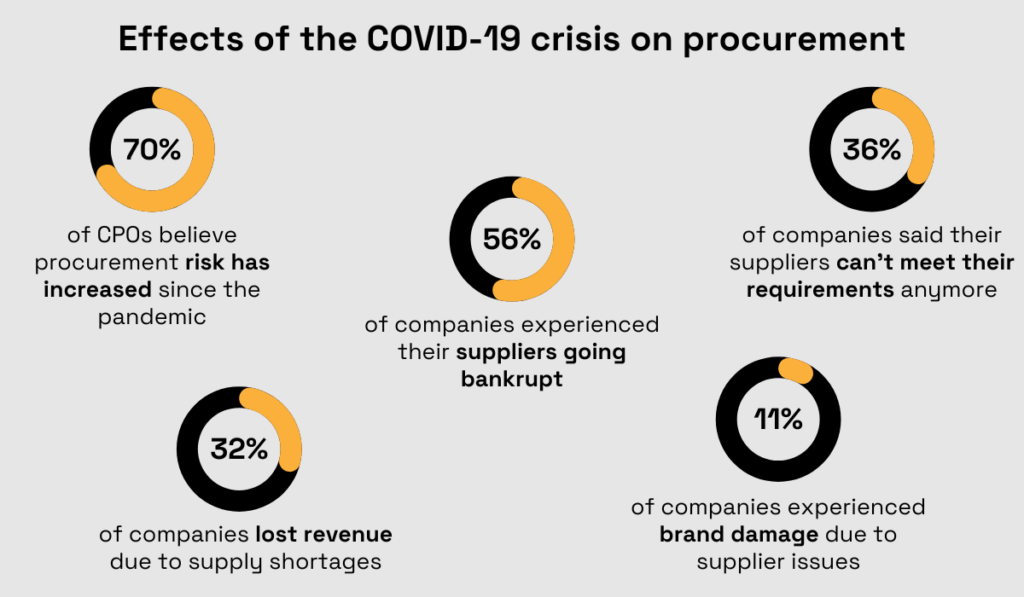

The COVID-19 crisis is a prime example in this context, serving as a valuable lesson in the importance of contingency planning and risk management within the procurement function.

A 2021 Deloitte survey delves a bit deeper into the pandemic’s effect, revealing that 70% of CPOs perceive a considerable increase in risk since the virus’s onset.

Illustration: Veridion / Data: Deloitte

This risk affected both suppliers and buyers alike, harming their profitability, efficiency, and sometimes even reputation.

Therefore, it’s up to procurement to devise risk mitigation strategies to minimize the adverse effects of such problems on both procurement performance and overall business operations.

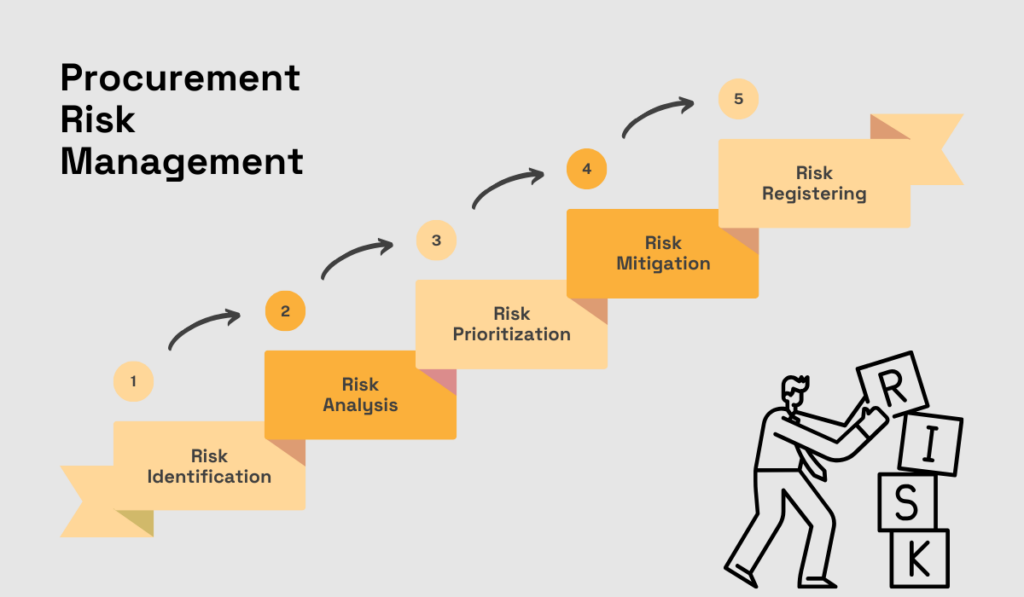

Presented below are five steps that can help you fortify your risk reduction efforts.

Source: Veridion

To demonstrate how exactly this framework works in real life, let’s address a common procurement problem—poor supplier performance—and explore how to mitigate it using the steps we outlined above.

| Risk Identification | You experience issues with late deliveries. Upon investigation, you realize the problems can be traced back to subpar supplier performance. |

| Risk Analysis | You analyze why supplier failure might occur. This could include factors such as financial instability, operational issues, market fluctuations, or legal challenges. |

| Risk Prioritization | Out of all the risks you deal with at the moment, you conclude this one should be prioritized, as it poses the greatest danger to your procurement operations. |

| Risk Mitigation | You start to implement strategies to mitigate the risk, such as diversifying the supplier base, developing contingency plans and alternative sourcing strategies, and conducting regular supplier assessments and audits |

| Risk Registering | You document any insights into what causes this problem, along with any best practices to help avoid it in the future. |

Ultimately, it’s undeniable that procurement will always be exposed to some risk, whether it comes from within the company itself, or from the outside world.

That’s why PPM needs to focus on developing systems that either prevent these issues or at least soften their blow, ensuring companies can continue operating smoothly without major disruptions.

Contract management is all about ensuring that both buyers and suppliers adhere to the agreed-upon contractual terms.

There are, in fact, many different phases to this process, including:

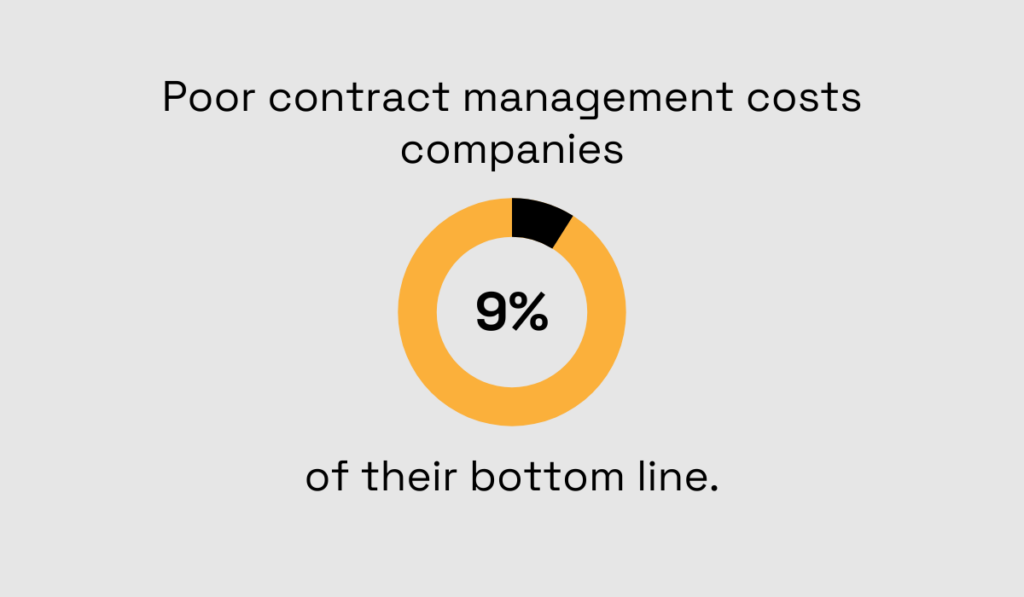

The inability to stay on top of these tasks can spell serious trouble for both procurement teams and companies overall.

As a matter of fact, research has already shown that poor contract management can cost businesses up to 9% of their bottom line.

Illustration: Veridion / Data: World Commerce & Contracting

This statistic alone should be enough to convince any CPO to start paying more attention to how they handle their contracts.

So, to bypass costly legal risks and prevent disputes that could damage your supplier relationships, consistently monitor contract performance using KPIs such as delivery schedules, pricing, service levels, contract cycle time, and renewal rates.

The primary objective here is to identify areas for improvement and proactively address potential issues before they escalate.

For instance, inadequate record-keeping and failure to document contract changes may be identified as the root cause of your product quality problems.

This realization can then inform your decision-making regarding strategies to improve this aspect, such as implementing version control, conducting regular audits, or establishing a centralized repository for storing all critical contracts.

Overall, contract management’s role in PPM cannot be overlooked.

Not only does it ensure adherence to contractual terms and conditions, thereby maximizing the value derived from the procurement process, but it also protects the company against risks such as delays, quality concerns, or non-compliance with regulatory standards.

Managing procurement performance is an ongoing endeavor, not a one-time task.

After all, market conditions and trends are constantly evolving, too.

How can you expect to keep pace with these changes and maintain a competitive advantage if you’re not on a constant lookout for innovative ways to improve?

Whether it’s embracing new technologies, eliminating inefficient practices, or implementing fresh organizational structures, promoting continuous improvement is a non-negotiable aspect of PPM success.

To cultivate a work environment where growth is a routine part of the job, consider looking into adopting a robust feedback system.

Source: LinkedIn

At the end of the day, every procurement task should serve as an opportunity to learn from mistakes and optimize procedures.

This can only be achieved through input from stakeholders, both within your team and from other departments.

For instance, feedback from warehouse operations regarding frequent stockouts or overstock situations may shed some light on challenges in inventory management.

This insight can then enable strategic improvements such as refining demand forecasting methods, adjusting inventory levels based on consumption patterns, and improving communication between procurement and inventory management teams to ensure timely replenishment.

The bottom line is this: without a commitment to progress, companies risk stagnation in this ever-evolving market.

This is where feedback comes in, a valuable tool that can help optimize processes, boost efficiency, and achieve sustainable success within the procurement function.

Now that we’ve covered which activities are involved in successful PPM, let’s explore what kind of advantages all these procedures bring to the table.

Through effective PPM, you become much better equipped to notice areas within the procurement function that may fall short of company expectations.

This may include identifying inefficient processes, bottlenecks, or opportunities to generate cost savings.

The truth is, efficient procurement can be a huge game-changer, sometimes in the most unexpected ways.

Consider Walmart’s case: In 2020, they implemented a procurement strategy that resulted in staggering annual savings of $60 million.

Remarkably, this wasn’t a result of a significant, costly overhaul.

Instead, it stemmed from optimizing their plastic shopping bag purchasing process, said their CFO, Brett Briggs.

And this isn’t the first time Walmart has saved money through savvy procurement choices.

In 2018, a seemingly minor change—replacing the floor wax used in their stores—saved them over $20 million annually.

Here’s Briggs’ comment about these amazing cost savings:

“Not only is the new wax cheaper, it’s also sturdier. It doesn’t need to be buffed as often, resulting in less spent on the actual buffing, as well as fuel for the machines. That one change in floor wax will save us over $20 million a year. […] These small differences can make a big difference to Walmart.”

This is precisely what PPM aims to accomplish: empowering your team to identify even the smallest yet impactful ways to drive value for the company.

Remember, there is always room for improvement.

You just need to be able to spot that opportunity.

Proper procurement performance management heavily relies on data that yields actionable insights into trends, patterns, and areas of underperforming.

This enables procurement professionals to make better-informed decisions regarding where to concentrate improvement efforts and how to allocate resources more efficiently.

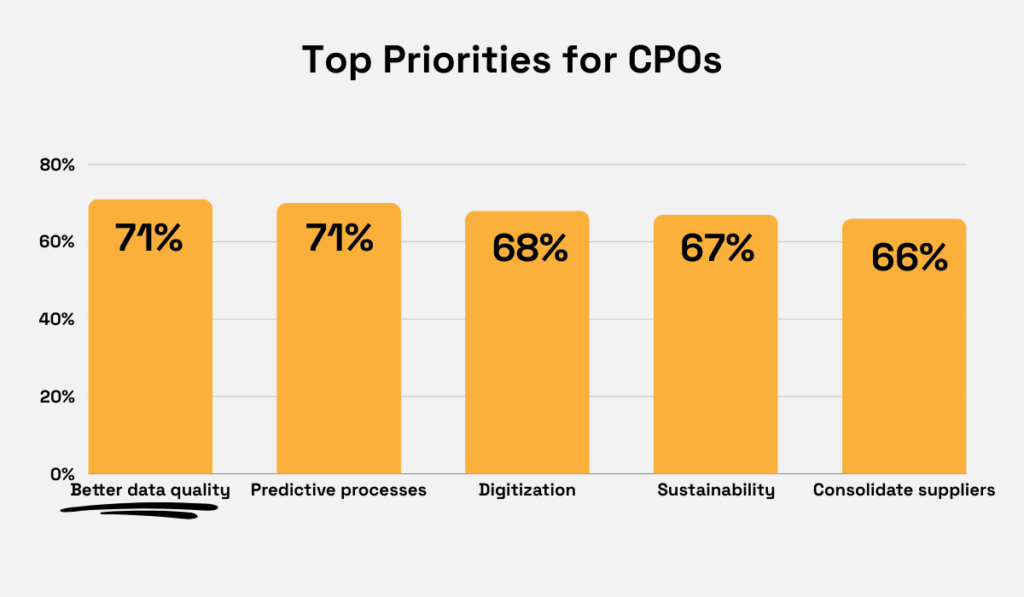

Consequently, it’s no surprise that surveys consistently indicate boosting data quality as the top priority among CPOs.

Illustration: Veridion / Data: Ivalua

They recognize that, in today’s landscape, high-quality data is indispensable for achieving success.

And if data indeed reigns supreme, then the sources of that data rightfully claim the throne.

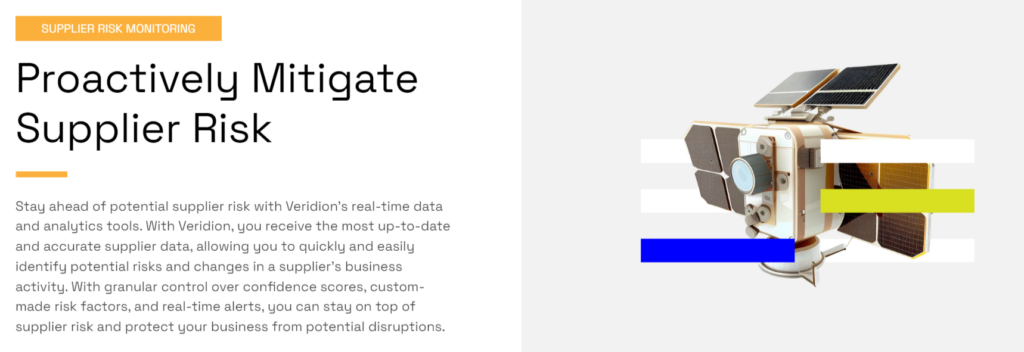

Consider Veridion, our own procurement market intelligence platform.

Veridion empowers its users to monitor supplier performance by enabling them to establish risk parameters for each supplier and receive alerts about any pertinent changes in their business operations.

Source: Veridion

That way, you always have a full picture of your supplier landscape, which enables you to take prompt corrective action in response to subpar performance or potential risks.

For instance, if any of your suppliers face issues like material shortage or bankruptcy, you’ll be immediately notified.

In conclusion, nothing can beat data-driven procurement.

It prepares you to tackle any problems that may come your way head-on, allowing you to mitigate their full impact and continue with your operations, disruption-free.

PPM provides visibility into various aspects of the supply chain, including supplier performance, sourcing strategies, and procurement processes, which in turn encourages accountability and fosters trust between procurement and suppliers.

Such transparency also often helps identify ethical and sustainability issues within the supply chain, allowing companies to address such concerns and drive positive change through responsible sourcing practices.

A great example of this is Unilever, which implements a sustainable procurement strategy that relies heavily on suppliers’ transparency.

As per their own website, they dedicate a lot of effort, time, and money to tracing the origin of the raw materials they use:

“Another area where our work will continue is the promotion of chain-of-custody transparency in our critical supply chains. We are making steady progress here, as our efforts in the palm oil sector demonstrate. Back in 2014, we began asking our palm oil suppliers to provide GPS coordinates for the mills that they source from. This gave us visibility on over 1,800 mills – around two-thirds of the total number of mills at the time.”

They also collaborate exclusively with suppliers aligned with their philosophy and goals, which ultimately leads to long-term partnerships that support sustainable business practices on both ends.

The lesson from Unilever’s model is the following: effective PPM and supply chain visibility sometimes go beyond conventional metrics of success, like cost savings or increased product quality.

Instead, they can serve as a catalyst for impactful change on a global scale.

Hopefully, this article has effectively demonstrated the importance of procurement performance management, not only for procurement departments themselves but also for companies as a whole.

As evidenced by the examples highlighted throughout the article, businesses that don’t neglect PPM are typically far better positioned for long-term success in today’s competitive and dynamic marketplace.

Overall, the key takeaway of this article is this: with the implementation of the right strategies and practices, the procurement function doesn’t have to be perceived as a mere cost center anymore.

Instead, it can be the true value-driving engine that fosters innovation, facilitates growth, and boosts resilience within the company.