Procurement Performance: What You Need to Know

Procurement plays an important role in business operations, facilitating the acquisition of goods and services from suppliers while ensuring optimal value for money.

That’s why maintaining peak performance within procurement teams is paramount.

The most effective way to achieve that?

Procurement performance analysis.

That’s precisely the topic we’ll be covering today.

We’ll explore all the ins and outs of procurement performance, explain what it exactly is, how to measure it, and outline the factors that influence it.

Armed with these insights, you’ll be more than well-prepared to assess and elevate your own procurement performance to new heights.

Let’s get started.

Procurement performance refers to the measurement and evaluation of the efficiency of a company’s procurement processes and activities.

Its main purpose is to ensure that the services or goods being procured meet the company’s expectations and requirements.

This makes it a vital aspect of general business operations, helping businesses use their resources more wisely and obtain goods on time, all while adhering to budget constraints and maintaining product quality.

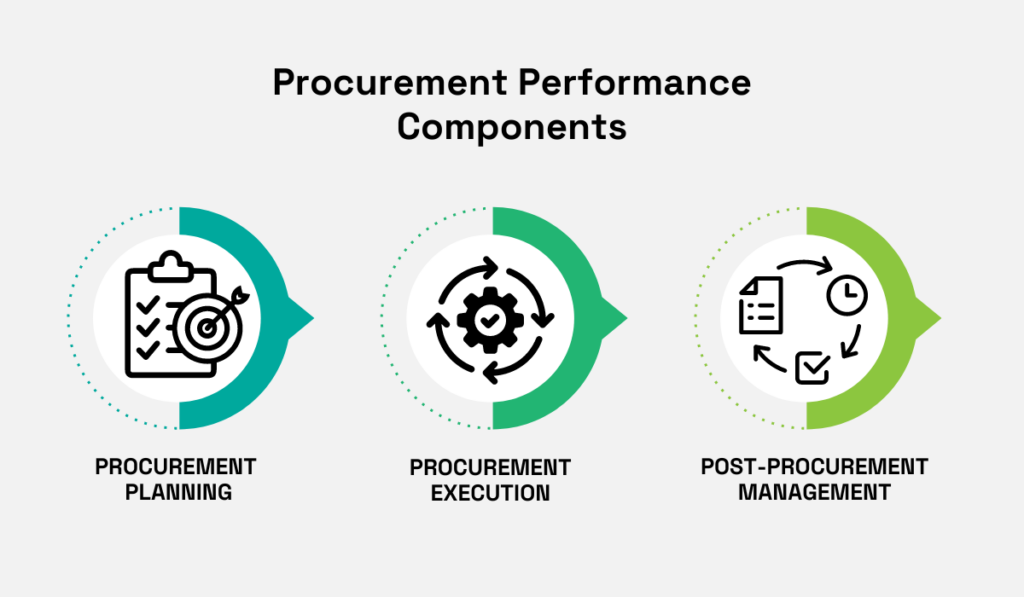

Procurement performance consists of three key components, depicted in the illustration below.

Source: Veridion

Planning is all about identifying company needs, determining the procurement timeframe, and selecting reliable suppliers capable of delivering what you need, when you need it.

Execution is, then, the core of procurement—it’s the actual buying of the goods or services.

This component can be further broken into 4 steps:

Finally, post-procurement management mainly revolves around resolving any issues that may have arisen during the process and confirming that the objectives of the procurement are actually met.

So, overall, procurement performance evaluates all aspects of procurement and serves as a reflection of how successfully it was executed.

As such, it’s a helpful tool for further evolving and high-tuning your procurement efforts.

Measuring and tracking procurement performance is simply a must if your goal is to improve your procurement process, there’s no doubt about it.

By doing so, you can:

In short, evaluating performance directly translates to better procurement management, which is good news for the entire company, and not just the procurement department itself.

By stepping up your procurement game, you can improve product quality, boost your company’s reputation, and save money.

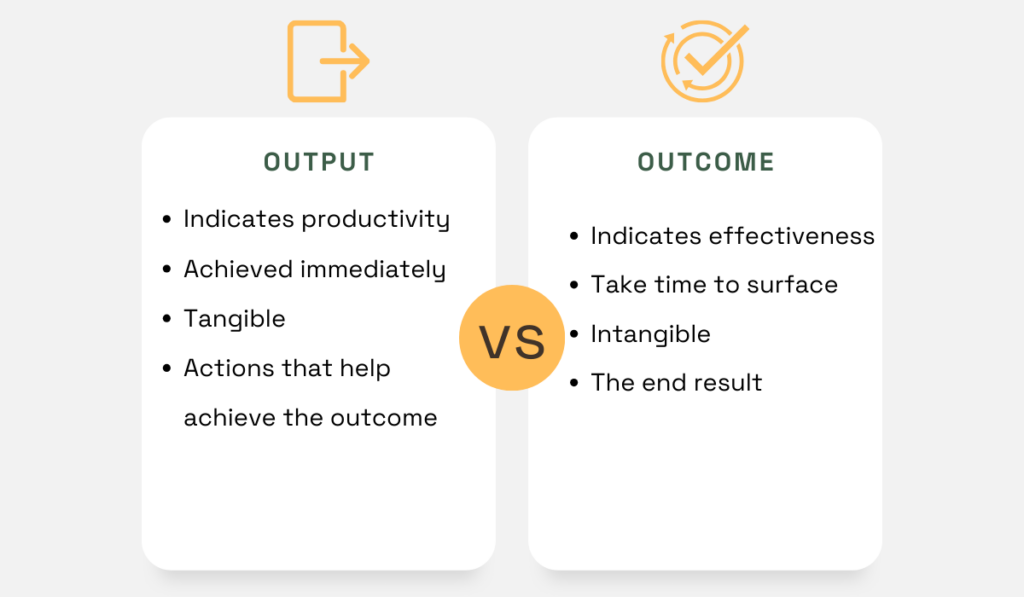

Here, we should also note that procurement performance evaluates both the output and outcomes of procurement, giving you a full picture of how well you’re doing.

Source: Veridion

Output refers to tangible and measurable goods produced as a result of the procurement process, such as management plans, invoices, or contracts.

Analyzing output tells you where you stand productivity-wise.

For example, low output can be a sign of inadequate procurement management, potentially leading to decreased business profitability.

Outcomes, on the other hand, are broader and encompass the overall results achieved from procurement activities.

Essentially, positive outcomes indicate that the procurement team is obtaining the goods and services that meet the company’s requirements and expectations.

So, in the simplest of terms, measuring procurement performance is important because it tells you whether or not you are where you need to be in terms of efficiency, and helps illuminate areas for improvement.

These findings play a major role in the overall success of a business as they can then be used to refine procurement processes and pinpoint cost-saving opportunities.

But, how exactly do you measure procurement performance?

There are, in fact, a couple of steps involved in this process, so let’s dissect each one.

First and foremost, it’s important to establish specific goals and objectives aligned with the company’s own business strategy, organizational structure, size, location, and budget.

Make sure, however, that these goals adhere to the SMART criteria, which you can see outlined below.

Source: Veridion

Sticking to these parameters when setting goals and KPIs ensures they are genuinely attainable, clear, and meaningful.

There’s really no room for guesswork and uncertainties when trying to accurately measure your procurement performance.

In any case, the KPIs will be your point of reference for comparison.

If you notice a deviation from the standards that you’ve set, it will be your sign to stop, reevaluate what you’re doing, and look for solutions to get you back on track.

Now, what are some KPIs used to evaluate procurement performance?

While cost savings are often prioritized in this context, focusing solely on them doesn’t really give you a full picture.

Instead, consider analyzing cost savings along with some of the following KPIs:

Remember, the deeper you go into procurement performance analysis, the better you’ll able to understand, manage, and, ultimately, improve your procurement process.

Next, you need to collect relevant data to compare it to the established KPIs.

Some data you’ll have to take into consideration includes:

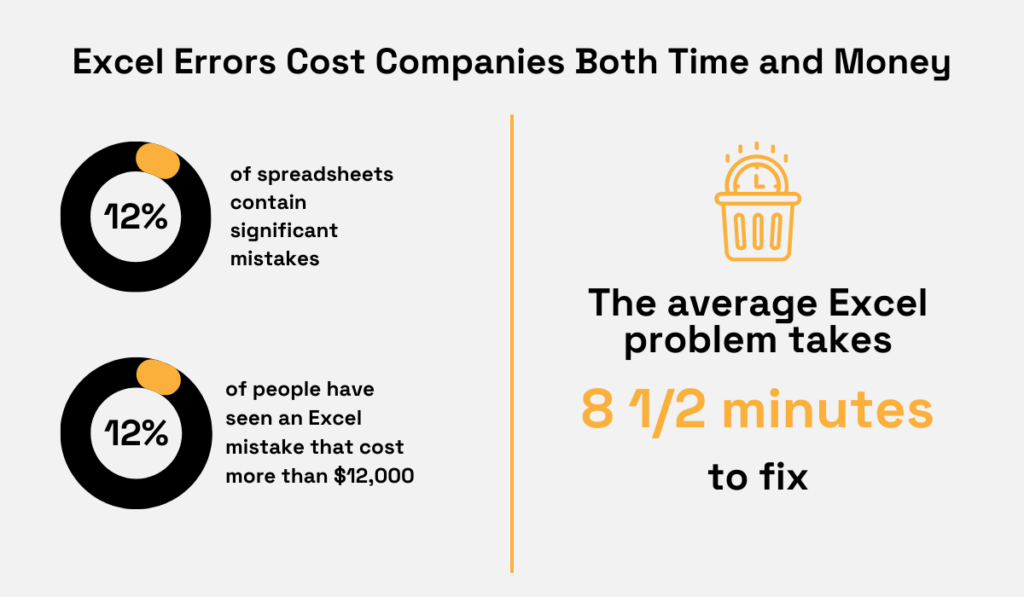

The biggest challenge you’ll encounter when gathering this data will be ensuring its accuracy, especially if you collect it through outdated methods like, for example, Excel sheets.

Surveys consistently show that Excel isn’t as reliable of a tool for this task, with its users often making mistakes that cost companies both time and money.

Illustration: Veridion / Data: Acuity Training

After all, much of the data entered into Excel sheets relies on manual input, which makes human error inevitable.

So if you’d rather steer clear of unreliable information and gain a clear insight into your performance, better look into automated alternatives.

There are now a plethora of software solutions for different aspects of procurement that automatically compile relevant data for you.

This ensures that your data is not only precise but also complete and up-to-date at all times.

Take Veridion for example, a procurement market intelligence solution that helps you monitor your suppliers’ performance.

It lets you create custom-made risk factors for your suppliers and alerts you if it detects any relevant changes in their business activities.

Source: Veridion

If one of them, for instance, faces material sourcing issues, you’ll immediately know about it.

Considering just how much your suppliers’ performance can impact your overall procurement performance, having such a tool as your secret weapon can be a complete game-changer.

The bottom line is this: data gathering may not always be as easy as it sounds, but it’s still vital to do this step right.

Otherwise, you’ll miss the opportunity to gain the insight needed to take your procurement process to the next level.

To unlock the full potential of the data you’ve collected, compare it against industry benchmarks or your own historical data.

This will help you:

Mélani Flores, a senior procurement advisor, probably summarized the importance of benchmarking the best:

Illustration: Veridion / Quote: The Procurement Magazine

In essence, benchmarking acts as a catalyst for growth and success, shedding light on your current achievements as well as untapped potential.

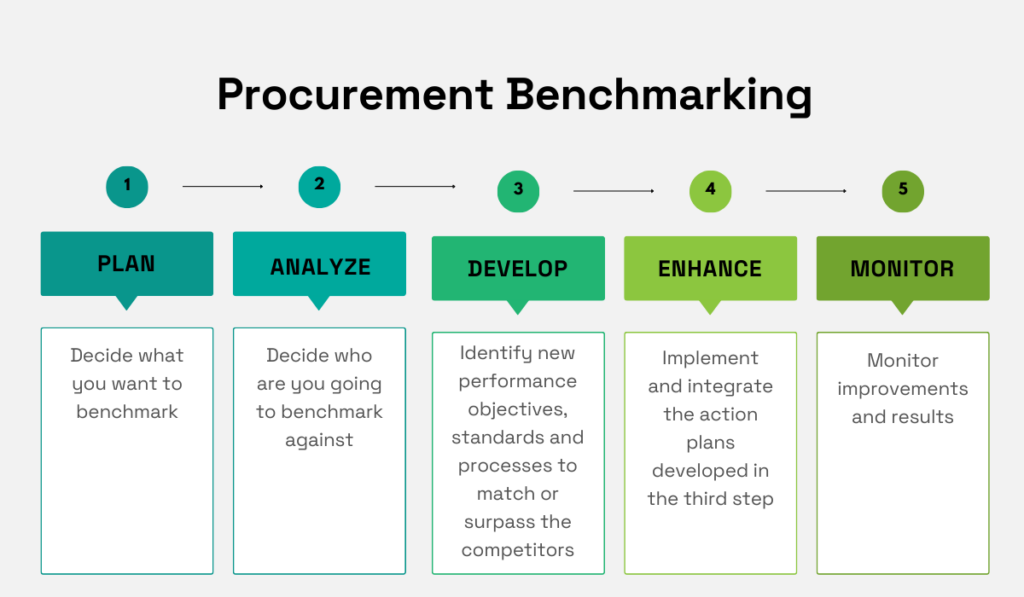

The benchmarking process typically unfolds in five steps, highlighted in the image below.

Source: Veridion

It’s important to emphasize, however, that this isn’t a one-off task, particularly in today’s volatile market landscape.

Instead, regular benchmarking is non-negotiable.

It enables you to stay on top of the industry trends and market dynamics, in turn facilitating the continuous improvement of your procurement processes.

We have already briefly touched upon the fact that unreliable suppliers can significantly undermine your overall procurement performance.

Francisco Javier Castellanos Aviña, a consulting manager at GEP Worldwide, succinctly summarized why this is the case.

Source: LinkedIn

Poor supplier performance can impact your procurement processes not only by causing delays in operations due to late deliveries but also by providing subpar products, leading to a myriad of issues like compliance and legal risks, reputational damage, or increased costs.

Not to mention the strain this puts on your relationship with the supplier, potentially affecting all future business transactions.

That’s why regular supplier reviews are a must.

They can be done using performance scorecards, such as the one from Just Analytics you can see below.

Source: Just Analytics

This scorecard tracks and evaluates your suppliers through predetermined KPIs that focus on different aspects of their performance.

Unsure about which KPIs to include in your own scorecard?

Consider the following:

Ultimately, achieving and maintaining outstanding procurement performance depends heavily on the quality of your suppliers.

Frequent evaluations can, therefore, be extremely valuable when it comes to ensuring your procurement department keeps pace with the organization’s needs and goals, fostering a symbiotic relationship between you and your suppliers.

Besides measuring, it’s crucial to consider the various factors that influence procurement performance, especially if your goal is to improve it.

Keep in mind that each of the following elements has the potential to either make or break your procurement endeavors.

Let’s see how.

In the world of procurement, the quality of the supplier-buyer relationship can either be a gateway to excellent procurement performance or the road to disaster.

If you manage to create collaborative and strategic partnerships with reliable suppliers, you stand to benefit on four different fronts:

Take, for instance, the partnership between Jabil, a global manufacturing company headquartered in St Petersburg, Florida, USA, and Vishay, their supplier of passive components and semiconductors.

According to Jabil’s own website, their supplier’s insights are extremely valuable when they plan for the future:

“Vishay advises Jabil on where we may want to upgrade components to provide lower cost and more readily available components. This helps us weather disruptions and better serve our customers when the market tightens up, like in the case of component shortages and COVID-19.”

Vishay informs them about the latest trends and newest technology so that they are always in the loop and able to adapt to market changes.

Another example of a successful partnership comes from the automotive industry.

Jeffrey Morrison, General Motors’ VP of global purchasing and supply chain, says it was precisely their suppliers who eased their transition into electric car production.

Illustration: Veridion / Quote: The Detroit News

Through effective communication and teamwork, he says, they were able to bypass interruptions in procurement as well as production and continue their work without hiccups.

These examples perfectly illustrate that the power of a good buyer-supplier relationship should never be underestimated.

Such collaborations can significantly help businesses unlock not only their procurement goals, but financial, operational, and strategic ones as well.

The market is an unpredictable force that can profoundly influence your procurement performance in multiple ways, including:

The occurrence of just one of these factors can set off a chain reaction, wreaking havoc on both suppliers and buyers alike.

A case in point is Volta Trucks, an electric truck manufacturer, which declared bankruptcy in August 2023 following the collapse of their battery supplier, Proterra.

Gareth Joyce, CEO of Proterra, said that, despite having a great product, the market’s volatility still managed to cause their downfall.

Illustration: Veridion / Quote: Autoweek

Their bankruptcy triggered a ripple effect that eventually reached Volta Trucks as well.

It significantly impacted the procurement department’s plans and “negatively affected their ability to raise sufficient capital in an already challenging capital-raising environment for electric vehicle players.”

What can be learned from this cautionary example is the importance of keeping your finger on the market’s pulse at all times.

Failure to keep pace with market dynamics and adjust your strategy accordingly can severely undermine procurement performance and, ultimately, harm the entire company.

It’s no secret that implementing appropriate technology to automate various processes can significantly boost performance across all aspects of business operations, and procurement is no exception.

Procurement automation tools such as

can speed up your day-to-day activities, provide real-time, accurate data, facilitate collaboration with suppliers, and ultimately, improve your overall efficiency.

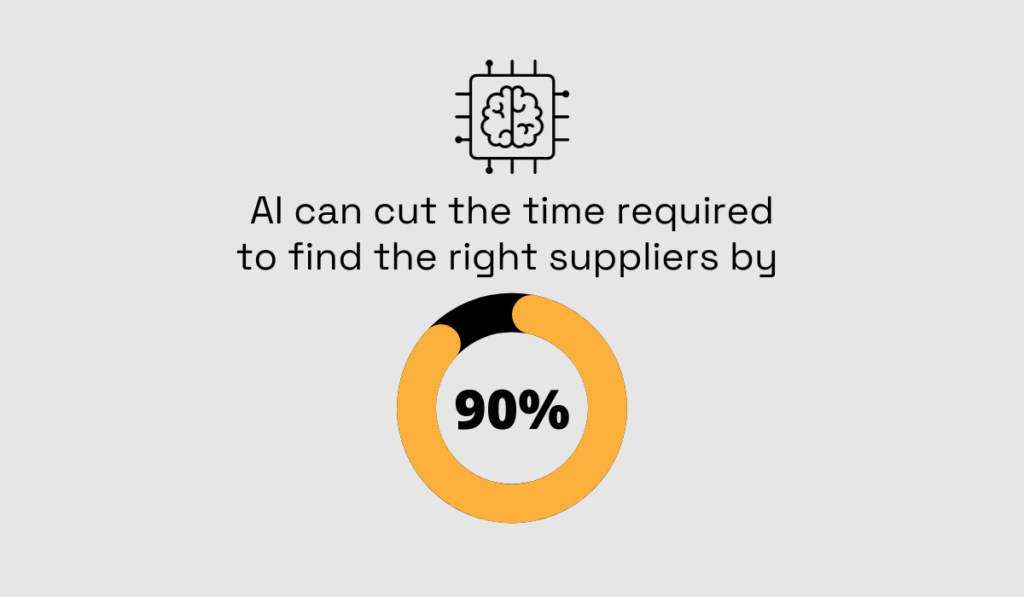

For instance, research by McKinsey indicates that, with the right sourcing tools, you can reduce supplier sourcing time by 90% or more—a remarkable efficiency boost.

Illustration: Veridion / Data: McKinsey & Company

Why spend hours upon hours looking for the right supplier when the software can do it in minutes?

Another example is leveraging AI and machine learning to analyze data from suppliers, markets, and internal processes to identify and mitigate risks.

According to Nickolas Walden, associate principal from the Hackett Group, this significantly increases both time and cost savings:

“Artificial intelligence tools with powerful analytical capabilities are perfect to ingest, review, analyse, and bring to our attention the most important topics – sort of like finding that metaphorical needle in the haystack. For humans to perform the equivalent would unfeasibly require many more resources.”

At the end of the day, there’s no denying that automation is the key to optimizing procurement performance.

That’s why we see the steady growth of the procurement software market size.

The benefits are too significant to ignore, and industry professionals are increasingly catching on to the fact that the tech is reshaping the landscape of procurement.

All in all, there’s more to evaluating procurement performance than it initially meets the eye.

With a multitude of KPIs to track and a plethora of influencing factors, the task may even seem daunting.

Still, worry not. Integrating performance monitoring into your routine processes will eventually become second nature.

Plus, implementing some of the software solutions mentioned in the article can streamline this task even further.

So, monitor, analyze, and strive for improvement. Soon enough, you’ll witness a noticeable boost in your procurement performance.