5 Best Practices for Supplier Lifecycle Management

Key Takeaways

Supplier lifecycle management or SLM provides a framework for managing every aspect of suppliers’ involvement with your organization.

When implemented successfully, it helps enhance supplier performance, mitigate risks, and drive significant business value.

However, even seasoned procurement professionals find it challenging to handle the whole lifecycle of their suppliers properly.

This is largely due to its complex, interconnected processes—without a structured approach, teams often struggle to stay consistent and maximize supplier value.

To help you lay the groundwork for ongoing success, we’ll explore five best practices.

Let’s dive right in.

Effective supplier management begins with well-defined supplier selection criteria.

Organizations without standardized, clear criteria for evaluating potential suppliers risk numerous inefficiencies and loss of value down the road.

Think about it.

Quick onboarding or savvy relationship management will hardly matter if you make the wrong pick initially.

Luckily, the odds of choosing an unreliable supplier are much lower when you’ve established guiding criteria for the supplier selection stage.

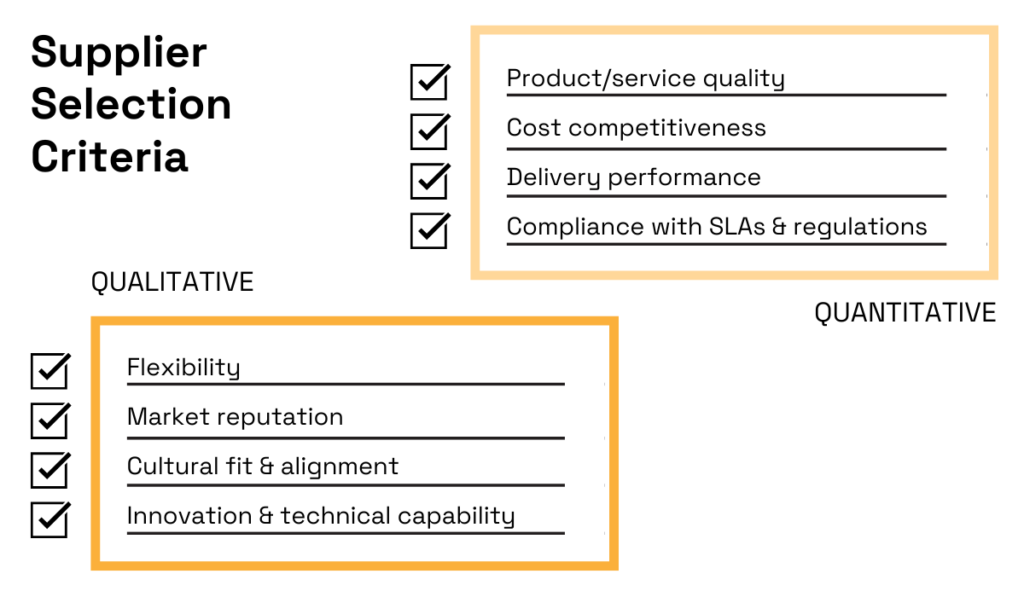

Each organization has unique needs, but the essential supplier selection criteria revolve around quality, cost, and overall performance.

These measurable criteria should always be balanced with other factors such as the supplier’s cultural fit, reputation, and innovation capabilities.

Source: Veridion

In doing so, you’ll ensure a holistic evaluation of each supplier that promises alignment with your strategic goals and brings long-term value to the organization.

For an increasing number of organizations, this means focusing on sustainable procurement and ESG criteria.

Ongoing conversations and a bulk of research confirm this.

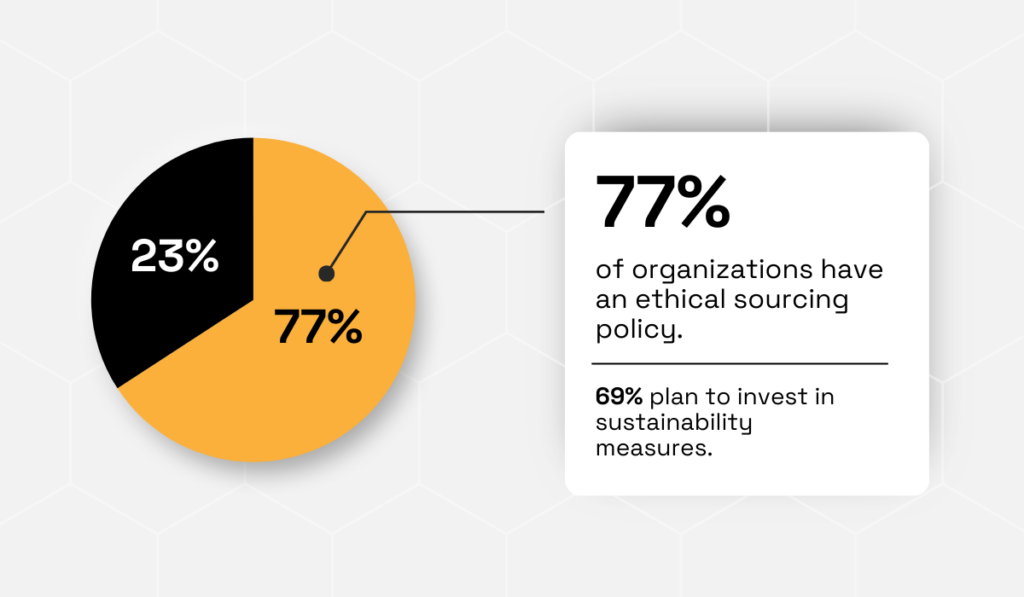

The 2024 CIPS Global State of Procurement & Supply report reveals that 77% of surveyed organizations already have ethical sourcing policies in place.

Illustration: Veridion / Data: CIPS & GEP

Moreover, with demand for sustainable goods and services climbing, and ever-stricter regulations on the horizon, the majority is ready to invest in new sustainability measures.

Not all of these link to SLM, but supplier sustainability evaluations are one such example and a critical element of promoting responsible sourcing.

Of course, prioritizing suppliers with a strong ESG record is difficult without access to the right data.

Collecting ESG data typically involves conducting surveys and audits or verifying compliance through third-party certifications.

Business data platforms are particularly suited for collecting and analyzing ESG data because they aggregate information from multiple sources and provide real-time updates.

Leading platforms like Veridion offer unparalleled coverage of ESG data, as illustrated in this image.

Source: Veridion

Veridion’s taxonomy delves deep into environmental considerations such as water usage or effects on protected regions, but also captures labor rights, wage disparity, and corporate ethics.

The bottom line is that your selection criteria stay aligned with your needs—that way it becomes the stepping stone for effective supplier lifecycle management.

Investing in a comprehensive onboarding process has an immediate effect on your overall supplier lifecycle management.

On the surface, this may seem like a pretty bold statement.

That’s because many professionals make the mistake of seeing onboarding as simply collecting supplier information and assessing compliance.

In reality, a smooth onboarding process helps you integrate the supplier into your system, setting the tone for the entire relationship.

HICX’s Former Chief Marketing Officer, Anthony Payne, agrees with that.

Illustration: Veridion / Quote: HICX on Youtube

Laying these foundations, as Payne calls them, means introducing mechanisms that facilitate clear communication and collaboration with your suppliers.

As such, the onboarding process should ensure that the supplier is familiar with key requirements and processes, as well as all the terms and conditions of the relationship.

This includes, among others:

When suppliers know what is expected of them upfront, you’re nipping several issues in the bud, and avoiding confusion or discontentment.

In other words, streamlining the onboarding process will set your suppliers up for success while preventing potentially costly issues down the road.

A big part of this is providing adequate training and resources to help suppliers align with compliance and company standards.

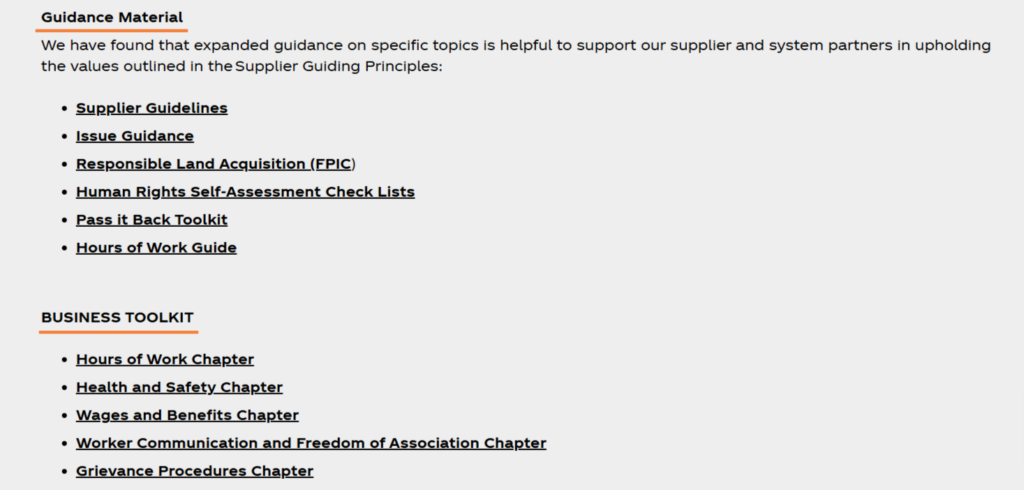

Large organizations like the Coca-Cola Company typically provide a variety of resources and toolkits that aim to ensure alignment with the company’s core values and standards.

Source: Coca-Cola Company

In addition to outlining relationship dealbreakers, these and similar resources support further supplier development.

Crafting tailored onboarding processes also helps organizations strike the right balance between being thorough and efficient.

Different sources indicate that supplier onboarding is a time-consuming process, with HICX experts stating that it can take up to 50 days to onboard high-risk suppliers, without accounting for a risk assessment.

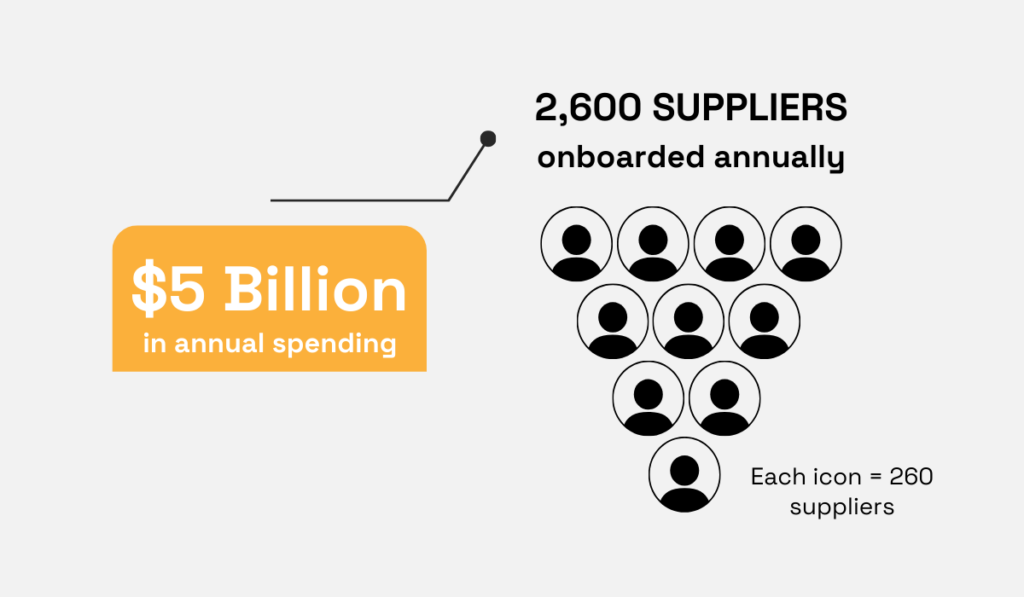

To put things into perspective, a mid-size company with $5 billion in annual spending onboards an average of 2,600 suppliers per year.

Illustration: Veridion / Source: HICX on Youtube

So the big question is, how do you manage risks while efficiently onboarding new suppliers?

One proven solution is adopting dedicated automation software.

The cloud content management platform Box recently partnered with the TPRM software provider Certa to tackle several pain points, including long onboarding cycle times.

Linda Chuan, Box’s Chief Procurement Officer, explains that adopting Certa’s tool proved to be a game changer, helping the company reduce its onboarding cycle times by nearly 80%.

Illustration: Veridion / Quote: Certa

Box’s procurement team could now request and handle multiple approval requests simultaneously, ensuring an equally comprehensive, but much more efficient approach.

Overall, a structured and transparent onboarding process is a vital part of supplier lifecycle management, and streamlining it is now easier than ever.

Maintaining high supplier standards rests on continuously monitoring both key performance indicators and service level agreements.

By keeping track of KPIs and SLAs, organizations are in a better position to review and evaluate individual supplier relationships to ensure that each connection delivers maximum ROI.

For instance, conducting regular performance reviews creates the basis for constructive feedback, which in turn helps you address any supplier issues early on.

Performance reviews provide you with objective data. And the benefits of that go beyond mapping inefficiencies.

Wayne Lewis, the Sector Head of Procurement at Imagile Professional Services, highlights that a data-driven approach to supplier management dictates future procurement decisions.

Illustration: Veridion / Quote: HICX

So, is supplier data critical for steady performance management and SLM in general?

The truth is that establishing monitoring processes requires two things:

Procurement experts engaged in digital transformation efforts urge companies to rely on data analytics to enhance this and other processes further.

Data plays an essential role in identifying trends and performance gaps, uncovering potential risks proactively, and making better decisions overall.

Simply put, you’re looking at better supplier visibility, reduced costs, and fewer risks.

Source: Veridion

On the practical side of things, you’re probably wondering how often you need to conduct these assessments.

Performance reviews and check-ins are typically done on a quarterly basis, but here is another key thing to consider.

Not all your suppliers are equally important to your operations.

This is exactly why companies take the time to segment suppliers and pinpoint priority relationships.

Suppliers who have the biggest impact on your supply chain demand the most attention.

What’s more, by giving feedback to them, you’re also impacting your Tier-2 and Tier-3 suppliers.

As one unnamed Senior Procurement Director for a Healthcare company points out:

The smart move is to educate your own suppliers and create a ripple effect down the supply chain. It can’t be your task to talk to Tier-2 or Tier-3. None of us have the resources to do so.

With this strategy, you might achieve such a ripple effect and ensure excellence across your entire supply chain.

In conclusion, it’s not uncommon for organizations to define KPIs and SLAs without introducing mechanisms for regular monitoring.

However, taking the time to monitor your suppliers’ performance contributes to your entire supplier lifecycle management process, making it more efficient and streamlined.

Strong relationships turn suppliers into partners.

So it’s no wonder fostering strong supplier relationships is another core supplier lifecycle management practice.

Strong supplier relationships are beneficial in several ways, driving performance, innovation, and ensuring better alignment with strategic goals.

All of that provides companies with a competitive edge in the market.

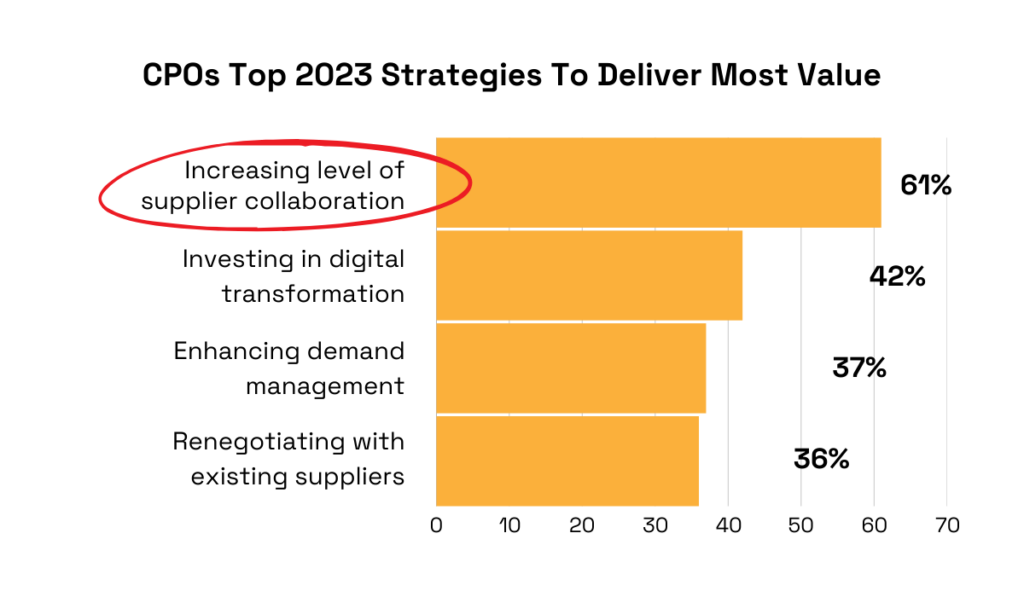

Considering these benefits, it’s no wonder that increasing supplier collaboration emerged as a top procurement strategy in 2023, ahead of digital transformation and demand management.

Illustration: Veridion / Data: Deloitte

Building trust paves the way for long-term collaboration, which can lead to better deals and “preferred buyer” status.

But these and similar perks are only one aspect of investing in strong supplier relationships.

The more important part is innovation born of long-term partnerships.

However, deepening the existing relationships requires concrete action.

One way you can do this is by engaging in strategic discussions, enabling your suppliers to stay up to speed with your plans and take a more active role in bringing them to life.

Suppliers who feel like integral stakeholders in the company’s success are more open to co-developing products or participating in pilot programs and initiatives.

Nevertheless, additional incentives are always welcome.

Almost a decade ago, the fuel and oil giant Caltex Australia introduced a new procurement strategy rooted in supplier relationship management.

One novelty was a supplier innovation program propelling new initiatives among suppliers and awarding them if and when they contributed to real business improvement.

For example, suppliers like Baker Hughes played a role in improving Caltex’s plant processes and output—as such, they were among the first to receive the company’s ‘Trailblaze Award’.

Johanne Rossi, procurement leader who pioneered Caltex’s strategy, explains that the goal was to move beyond cost reduction and put more focus on key suppliers’ capabilities.

Illustration: Veridion / Quote: State of Flux

Naturally, this shift didn’t happen overnight.

The company initially focused its efforts on 15 key suppliers and cost optimization.

Only later were they in a position to create an environment that would foster collaboration and drive creativity.

Remember: Caltex is hardly the only example.

Leading companies across various industries engage with their suppliers to enhance performance and maintain a competitive edge—there’s no reason why you shouldn’t do so either.

Risk management is an integral part of SLM, making regular risk assessments a must.

Identifying and assessing supplier risks helps organizations avoid financial instability and compliance issues, and counter supply chain disruptions.

This is all the more important given that the supplier risk landscape is continuously evolving, prompting procurement leaders to call for more resilient and flexible supply chains.

However, staying agile depends on several factors, including overall risk visibility.

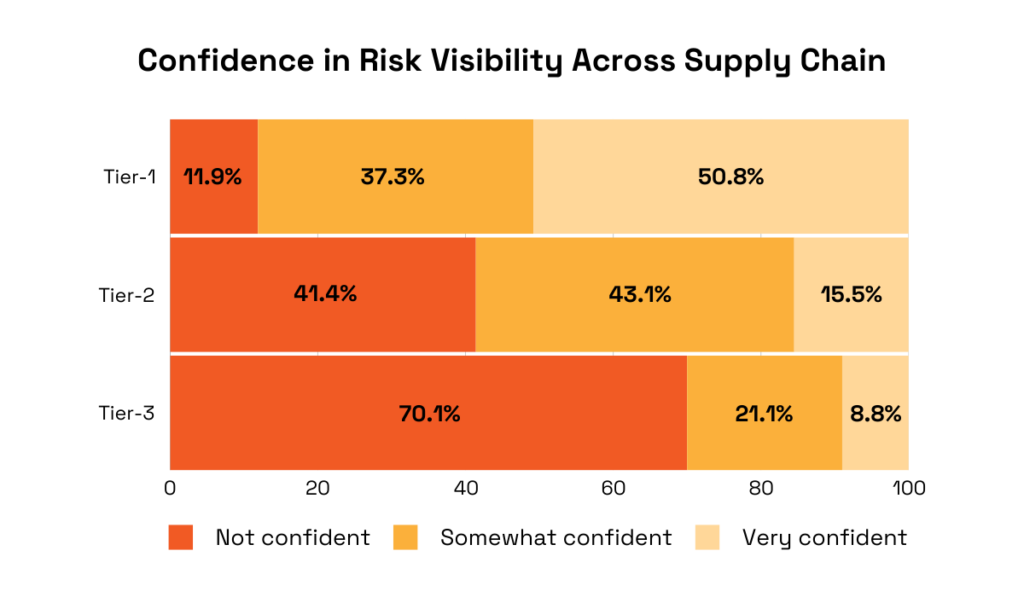

A recent study by Procurement Leaders and GEP suggests that organizations are not too confident about knowing which suppliers may pose a threat to their supply chains.

Namely, findings show that while Tier-1 supplier risks are monitored carefully, contributing to high confidence levels, there is a noticeable drop among Tier-2 and Tier-3 suppliers.

Illustration: Veridion / Data: Procurement Leaders & GEP

In light of these uncertainties, organizations are turning to different supplier risk management strategies.

For instance, developing contingency plans requires you to assess specific supplier-related risks and establish crisis communication channels, but some common measures include:

Moreover, companies are increasingly relying on supplier risk management software, monitoring tools, and similar technologies to be more aware of supplier risks.

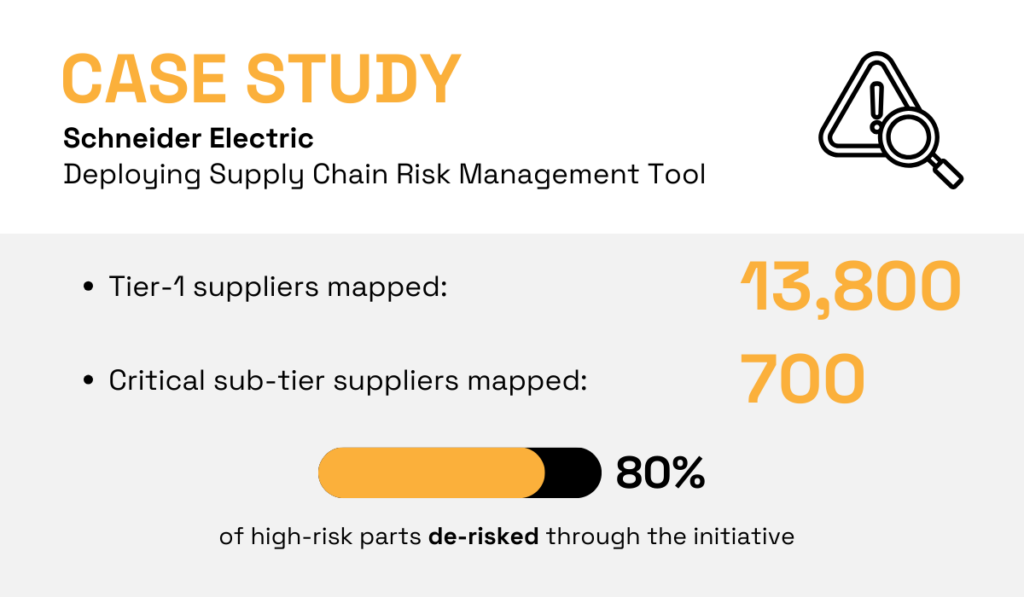

Take Schneider Electric for example. The energy management and automation giant has been consistently praised for its pioneering, resilient supply chain design.

Reliance on cutting-edge technology contributed to its success, as shown in a recent case study.

Schneider Electric leveraged a risk management tool to efficiently map risks related to nearly 14,000 Tier-1 suppliers, but also critical sub-tier suppliers.

Illustration: Veridion / Data: Procurement Leaders & GEP

By deploying its risk management tool of choice, the company gained actionable insights even on their sub-tier suppliers’ time-to-recover and time-to-survive, as well as potential revenue losses.

Veridion takes a slightly different, yet equally effective approach.

Supplier risk monitoring rests on real-time TPRM data.

Veridion’s supplier data is updated weekly making it the most accurate on the market.

Meanwhile, features like custom-made risk factors and real-time alerts enable you to instantly detect any concerning activity and prevent escalation.

Source: Veridion

Risk management aside, with global coverage and decision-grade company data, organizations have everything they need to ensure seamless SLM operations.

Don’t forget: although tools make things easier, risk assessments should be conducted regularly with or without them.

Supplier lifecycle management is undoubtedly complex, but it’s also grounded in several best practices that can quickly bring results.

With each practice we explored, you are one step closer to streamlining your processes and creating value overall.

Technology plays a pivotal role in their implementation, and across all SLM stages, paving the way for data-driven decision-making.

In simplest terms, adopting these practices is a surefire way to ensure resilience and growth, even in an increasingly competitive and dynamic global market.