5 Ways Active Supplier Management Benefits Companies

Key Takeaways:

What if your suppliers could be more than just vendors—what if they could be the key to unlocking growth, innovation, and resilience in your business?

In today’s unpredictable business landscape, with supply chain disruptions and compliance risks on the rise, companies can no longer afford to treat supplier relationships as mere transactions.

Effective supplier management has become essential, requiring a strategic approach that goes beyond the basics.

In this article, we’ll uncover the real value of strong supplier partnerships and explore how investing in supplier management can lead to tangible benefits.

Let’s dive into how turning your suppliers into strategic assets propels your business forward.

Wouldn’t it be great if your suppliers prioritized you above others?

Instead of being just another order in their system, your needs come first.

Your orders are getting fulfilled first during tight capacity, and you’re gaining early access to innovations, or even receiving better terms.

That’s the power of becoming a customer of choice—one your suppliers value so highly that they go the extra mile to support you.

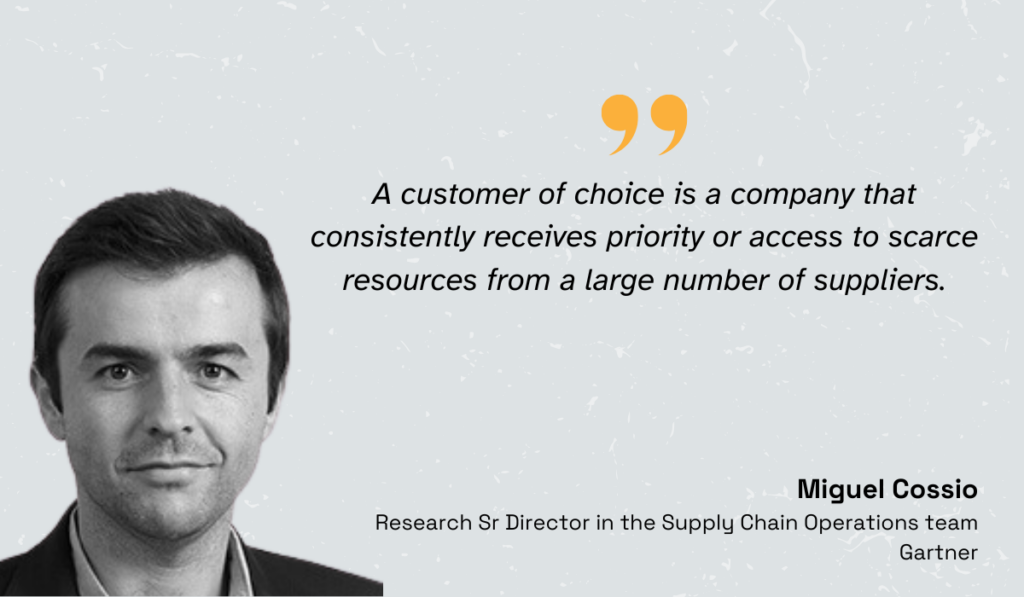

Miguel Cossio, a senior research director at Gartner, defines it well:

Illustration: Veridion / Quote: Supply Chain Brain

This concept has long been crucial in industries like transportation.

During peak seasons, supply chain disruptions, or market fluctuations, carriers often have to prioritize some shippers over others.

In those moments, being a customer or shipper of choice means securing priority access to transportation capacity, better rates, and more flexible service when it matters most.

However, this is no longer confined to transportation.

As Cossio notes, many organizations across different industries now realize the importance of supplier collaboration, with 88% reporting an increased focus on this area.

Illustration: Veridion / Data: Vizibl

Importantly, becoming a customer of choice doesn’t mean you need to pay more to suppliers to ensure that position, as Cossio further clarifies:

“It’s a misunderstanding where people think you need to pay more to become a customer of choice. The conversation about savings still needs to happen, but you need a more collaborative approach.”

Instead, it’s about fostering a mutually beneficial relationship.

This begins with active supplier management, which includes treating suppliers as partners, sharing forecasts, involving them in strategic planning, and aligning on mutual goals.

There are additional factors that will push your supplier to choose you as a customer of choice.

For example, timely payments are one simple but effective way to stand out.

Suppliers notice when their customers consistently pay on time, and it sends a clear message that you respect their time and resources.

They also notice when you don’t, which has some dire consequences, as this buyer explains:

Source: Reddit

Communication is equally vital.

Keeping suppliers informed about changes, challenges, or opportunities builds trust and demonstrates that you value the relationship.

Transparency, fairness, and a willingness to work through challenges together all contribute to being seen as a customer worth prioritizing.

A real-world example of this dynamic is the partnership between BMW and Peiker Acustic GmbH, a supplier of high-speed mobile internet technology for cars.

In 2012, BMW became the first automaker to introduce this feature, positioning itself as a leader in automotive innovation.

Source: BMW Group

BMW’s status as a customer of choice likely played a critical role in Peiker prioritizing this collaboration.

The result?

BMW gained access to cutting-edge technology, and Peiker elevated its reputation by working with a high-profile client.

As this example shows, being a customer of choice goes beyond receiving priority treatment.

It also opens doors to deeper collaboration, supply chain resilience, and innovations that give your company a competitive edge.

Let’s focus more on the latter.

Active supplier management drives innovation.

When you move beyond a transactional approach and focus on building trust and collaboration, suppliers are more likely to share their best ideas, new technologies, and innovative solutions with your organization.

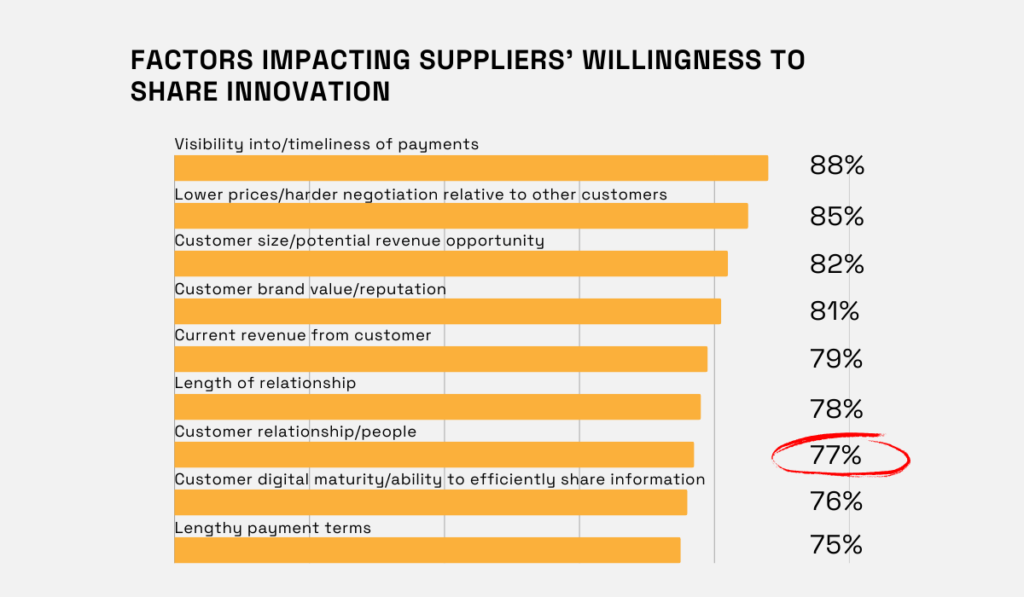

Research by Ivalua and Forrester confirms it.

Suppliers were surveyed on what influences their willingness to collaborate and share innovations with customers, and the results were clear.

Yes, visibility into payments and timeliness of payments were top factors.

However, the strength of the customer relationship also plays an important role, with 77% of decision-makers ranking it as a key factor impacting the supplier’s openness to innovation.

Illustration: Veridion / Data: Ivalua

And relationships are tightly connected with active supplier management.

What does this mean for procurement professionals?

If anything, this survey highlights the importance of fostering two-way trust with suppliers.

By prioritizing open communication and fairness you create an environment where suppliers feel comfortable taking risks and sharing their most valuable innovations with you.

And as you’ve maybe experienced firsthand, innovation leads to tangible results:

A standout example of supplier-driven innovation is the partnership between Pirelli, a global tire manufacturer, and VMI, a leader in tire production machinery.

VMI developed the UNIXX Belt Maker (and other UNIXX technologies), a groundbreaking system for producing steel belts used in tires.

Source: VMI Group

This technology revolutionized the process by:

Because of their close collaboration, Pirelli was able to refine its process control, aligning perfectly with its sustainability goals.

In a nutshell, this innovation reduced material waste, lowered production costs, and supported Pirelli’s commitment to environmental responsibility.

On the other hand, VMI benefitted from working with a high-profile partner, boosting its reputation in the industry, as well as winning a prestigious award.

Source: VMI Group on Facebook

The connection is clear: active supplier management can create an ecosystem where innovation thrives.

Suppliers are more likely to invest their resources into customers they trust, and the results can be transformative for both sides.

When suppliers are actively managed, compliance becomes more achievable.

It all comes down to accountability.

Those who know they’re being closely monitored are less likely to cut corners or deviate from established rules and expectations.

Active management keeps everyone on track, ensuring suppliers stick to the agreed contractual terms while also meeting broader regulations, industry standards, and ethical practices.

Think, for example, about Walmart’s approach.

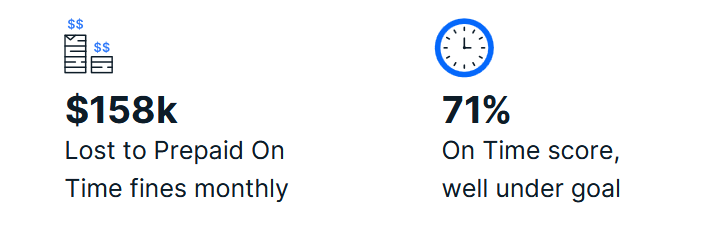

The company evaluates suppliers through performance metrics like its On-Time In-Full (OTIF) program.

Source: Redwood

Falling short of Walmart’s demanding 98% OTIF benchmark comes with steep consequences—suppliers face financial penalties of 3% of the cost of goods sold for non-compliance.

One supplier, for example, reported monthly losses of $158,000 because of these fines.

Source: SupplyPike

Knowing they couldn’t sustain such lossesΩ, they reworked their processes to improve performance and compliance.

If anything, this is proof that monitoring works.

When suppliers are held accountable, they make the effort to align with expectations.

But how do you actively manage suppliers and ensure they’re compliant?

There are several methods you can implement:

Visibility into suppliers is key for ensuring compliance, and this is where services like our Veridion come into play.

Veridion gives you access to detailed data on over 120 million suppliers worldwide.

You can find detailed compliance and risk information, firmographic data, and even ESG insights.

Source: Veridion

Plus, real-time notifications alert you to changes in supplier activities, helping you stay ahead of potential issues.

For your company, this kind of oversight translates to fewer regulatory headaches, smoother audits, and a more reliable supply chain.

It also means you’re less exposed to risks like reputational damage, operational delays, or financial penalties.

And let’s not forget the bigger picture—well-managed, compliant suppliers are more likely to align with your goals, whether it’s sustainability, ethical labor practices, or simply delivering on time.

In short, when you actively manage your suppliers, compliance stops being a constant worry.

It’s crystal clear that businesses need to be flexible to survive.

This agility helps companies quickly respond to market changes, adjust strategies, shift resources, and pivot operations to minimize negative impacts.

But where does this agility come from?

A big part of it comes from the way you manage your suppliers.

Strong, well-managed supplier relationships can make all the difference when you need to adapt to challenges or seize new opportunities.

Take the fashion industry during the COVID-19 pandemic as an example.

When lockdowns disrupted supply chains and demand plummeted, many fashion brands struggled.

Some reacted by canceling supplier orders to avoid having too much inventory, while others realized their suppliers could be key to staying ahead.

Source: Supply Chain Dive

Companies that partnered with so-called “super vendors” benefited greatly.

These suppliers, with factories spread across countries like China, Vietnam, and Bangladesh, were able to shift production between locations to work around lockdowns and border closures.

Naturally, by working closely with suppliers like these, brands could adjust quickly, ensuring products kept moving to meet customer demand.

A similar story can be seen in the tech industry.

During the global semiconductor shortage, many companies struggled to get the chips they needed for their products.

Apple, however, managed to avoid major disruptions.

Source: Reuters

Why?

Because of their strong, long-term partnership with TSMC, a key supplier of semiconductors.

Apple’s close collaboration made them a priority for TSMC, ensuring they got the chips they needed to keep their production on track.

But agility isn’t just about handling crises.

It also helps companies innovate and grow.

For example, if you’re launching a new product, flexible suppliers can quickly source materials, produce small batches for testing, and scale up production as demand increases.

Apple is an example of that, too.

Thanks to their supplier relationship, they were the first to adopt TSMC’s latest chip technology in 2021, showcasing how agility through supplier management can drive innovation.

Source: Reuters

The takeaway is simple: building and nurturing strong supplier relationships is key to achieving agility.

When you understand your suppliers’ strengths and challenges and work closely with them, you create a supply chain that can adapt to disruptions, embrace innovation, and keep your business thriving—no matter what obstacles arise.

Poorly managed suppliers can cause everything from small operational hiccups to catastrophic losses.

Here are some examples that prove that.

In 2013, Target faced one such disaster when hackers accessed their payment systems through a third-party vendor.

The breach compromised 40 million credit card numbers and cost Target $18.5 million in settlements, not to mention the reputational damage.

Source: Reuters

Stronger supplier management could have helped Target identify weaknesses in the vendor’s systems and avoid this costly outcome.

Another cautionary tale comes from Boeing’s 787 Dreamliner project.

In an attempt to cut costs, Boeing outsourced 70% of the aircraft’s design and manufacturing to over 50 suppliers, many of whom further outsourced their work.

Without proper oversight and communication, this web of suppliers led to delays, quality issues, and cost overruns totaling billions.

Boeing spent over $32 billion—far beyond the original $5.5 billion budget—and suffered devastating setbacks, including fatal plane crashes.

Several experts, including Dr. Christopher Tang from UCLA, highlight that Boeing’s lack of close supplier relationships was a key failure:

Illustration: Veridion / Quote: Industry Week

Beyond supplier risk management, active supplier management can save you money through joint value creation.

For example, collaborating with suppliers on innovation can lead to streamlined production processes, better product quality, and lower costs.

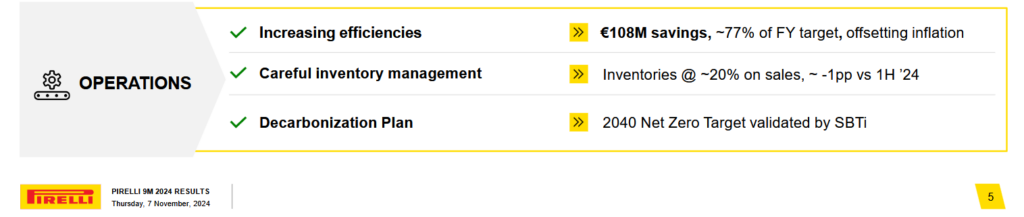

A great example is, once again, the partnership between Pirelli and VMI Group.

Their innovations ultimately cut Pirelli’s production costs and led to cost savings:

Source: Pirelli

All in all, every dollar saved through better communication, oversight, or process improvements is a dollar that can be reinvested into growing your business.

Active supplier management is the path to achieving these savings while building stronger, more reliable partnerships that benefit everyone involved.

In an increasingly competitive and unpredictable business landscape, the way you manage your suppliers can make or break your success.

By fostering trust, collaboration, and clear communication, you can become a customer of choice—earning priority treatment, access to innovations, and stronger supplier commitment.

Now is the time to take a closer look at your supplier relationships and implement strategies for active supplier management.

If you start today, you will reap these five benefits in no time.