Complete Checklist for Supplier Database Information

Before working with a supplier, and throughout your collaboration, you need reliable data to avoid disruptions, assess supplier risks, and ensure compliance.

From basic company details to financial health and ESG data, this checklist will guide you on what supplier information to track and why it matters.

Let’s start with the basics.

Did you know that B2B contact data decays as fast as 70.3% annually?

Imagine you urgently need to contact a supplier about a delayed shipment, but the only phone number you have is outdated.

Now, you’re scrambling to find the right contact while your production line is at risk of shutting down.

This is why keeping basic supplier information up to date is critical.

At a minimum, you should have:

Having accurate, easily accessible supplier information ensures quick communication, avoids delays, and prevents working with fraudulent suppliers.

If something goes wrong—a missing shipment, a pricing dispute, or a product recall—you don’t want to waste time figuring out who to call.

A supplier’s location affects more than just shipping costs.

It influences lead times, regulatory risks, and supply chain resilience.

So, if you don’t track where your suppliers operate, you could be caught off guard by trade restrictions, natural disasters, or geopolitical disruptions.

For example, a supplier might have its headquarters in Germany but manufacture products in China, with distribution centers in Mexico and Poland.

If new tariffs are imposed on Chinese exports or a factory shutdown occurs due to a local crisis, knowing these alternative locations gives you options.

In other words, you might be able to shift orders to a different facility and avoid costly delays.

John Dickson, former Chief Procurement Officer at AstraZeneca, explains this well:

Illustration: Veridion / Quote: Deloitte

In short, having multiple suppliers is one strategy, but working with suppliers that have multiple locations adds another layer of flexibility.

To make the most of this, you need accurate location data.

So, track not just headquarters, but all relevant sites—manufacturing plants, warehouses, and key distribution hubs to assess risks tied to specific locations.

You can do that easily with Veridion, our big data engine, as explained below:

Source: Veridion

Without this visibility, your supply chain could be more fragile than you realize.

It’s easy to assume product details are clear when working with suppliers—until an invoice arrives with unexpected charges or a shipment doesn’t meet quality standards.

Procurement teams need precise documentation of what each supplier provides, covering the product names, descriptions, and classifications:

Source: Veridion

Beyond that, you need data on pricing, minimum order quantities, return policies, as well as lead times for products.

Without these details, costly surprises become inevitable.

For example, a supplier might initially promise a 30-day lead time but extend it to 60 days after a contract is signed, throwing off your production schedules.

Or a bulk discount might apply only after a certain volume is reached—something you didn’t factor into budgeting.

A lack of transparency here can lead to price disputes, quality issues, and operational delays.

Tracking all product and service details from the start prevents misunderstandings, ensures supplier accountability, and protects your bottom line.

Because in procurement, small oversights can lead to big disruptions.

A supplier might seem reliable today, but without financial due diligence, you could be setting yourself up for serious risk.

Procurement teams often assume a supplier is financially stable without verifying key data—only to be caught off guard by sudden bankruptcies, price hikes, or shipment delays.

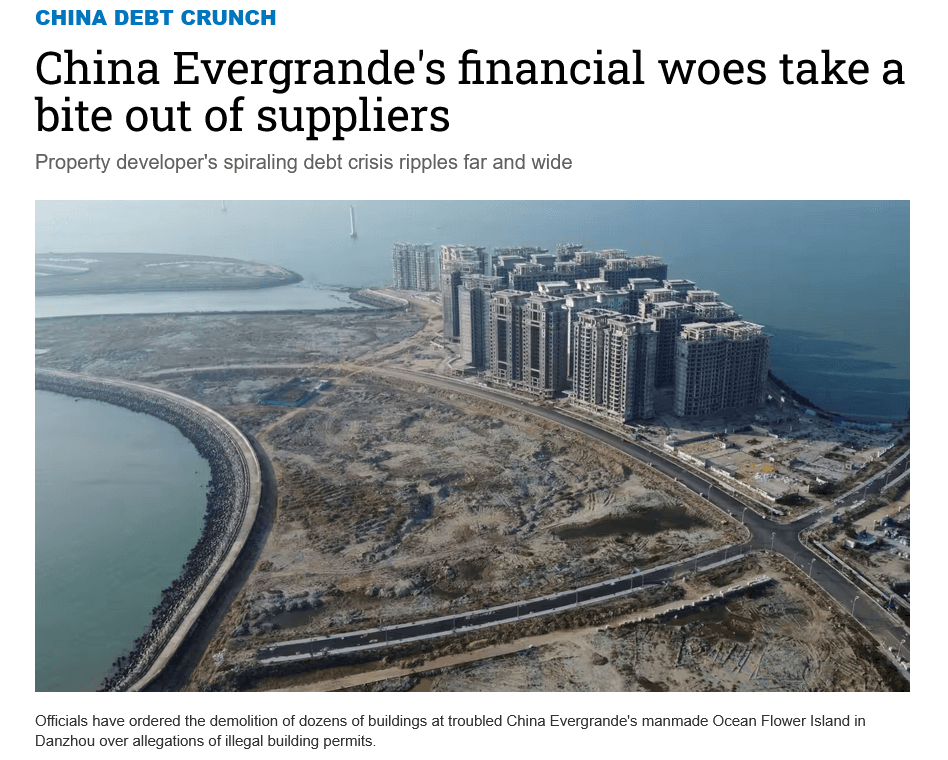

In 2021, the collapse of Evergrande, one of China’s largest real estate firms, left thousands of suppliers unpaid, forcing businesses to scramble for alternatives.

Source: Nikkei Asia

To avoid this, you need to track suppliers’ financial health before signing any contracts.

Payment terms matter—does the supplier demand upfront payments, or do they offer Net 30 or Net 60 terms?

Longer payment cycles can ease cash flow management, while strict prepayments can signal financial instability.

Credit history is another key factor to check.

Suppliers with frequent late payments or unresolved legal disputes may struggle to meet commitments.

Business credit agencies like Dun & Bradstreet, Experian, and Equifax provide supplier credit ratings and financial statements, such as balance sheets and cash flow reports, which reveal overall stability.

Source: Experian

And if the supplier is publicly traded, regulatory filings can provide further insights.

Financially unstable suppliers cut corners, delay shipments, and in the worst cases, shut down completely.

Knowing their financial position upfront protects your supply chain from avoidable disruptions, so make sure to include supplier financial data in your database.

Contracts aren’t just formalities—they define expectations, prevent misunderstandings, and protect your business from legal risks.

Without a signed supplier agreement, even minor disputes over pricing or service levels can escalate into costly conflicts.

Procurement teams should, therefore, ensure every supplier relationship starts with a formal agreement covering order terms, pricing structures, and service levels.

But contracts are only part of the legal picture.

NDAs are critical when sharing proprietary data, ensuring suppliers don’t disclose sensitive information to competitors.

While details of Apple’s contracts with its suppliers are largely unknown, court filings from its dispute with GT Advanced Technologies revealed that GT faced a $50 million penalty for leaking product information.

Source: 9to5Mac

This highlights how strict confidentiality clauses can be—and why suppliers must fully understand the legal implications before signing.

Moreover, terms and conditions of supply should clarify who is liable for delays, quality failures, or non-compliance—because without documented accountability, suppliers may not take responsibility when problems arise.

Intellectual property agreements are equally important, particularly if a supplier manufactures custom-designed components.

Without clear protections, nothing stops them from selling your designs to competitors.

And then there’s insurance—if a supplier’s faulty product causes financial or reputational damage, who absorbs the loss?

Without supplier insurance verification, the liability could fall on you.

Legal disputes are expensive, and gaps in documentation make them worse.

That’s why contracts and legal documents should be collected directly from suppliers, reviewed by your legal team, and stored in a centralized system where they can be accessed when needed.

Supplier compliance failures don’t just harm suppliers—they damage your business, expose you to fines, and put your supply chain at risk.

Tracking supplier certifications, insurance policies, and regulatory adherence is non-negotiable, especially in industries with strict oversight.

Boeing learned this the hard way in 2024.

Two of its suppliers allegedly replaced high-strength titanium and aluminum with substandard materials in the 787 Dreamliner.

Source: Financial Express

This violation of compliance standards triggered an industry-wide scandal, with potential legal consequences and regulatory scrutiny from the FAA and EASA, as one aviation legal expert explained:

“Boeing may face class action lawsuits if it’s proven that safety was compromised, not to mention the damage to its already fragile credibility.”

Procurement teams that don’t verify supplier compliance risk similar fallout.

If a supplier lacks necessary certifications—such as ISO quality standards, FDA approvals, or environmental permits—your business could unknowingly purchase non-compliant products, leading to recalls, legal liability, or customer trust issues.

Third-party verification platforms like EcoVadis or Achilles help validate compliance claims, while internal audits ensure suppliers meet evolving regulations.

However, compliance isn’t a one-time check—it requires ongoing monitoring.

Therefore, your database should include supplier certifications with expiration dates and automated alerts for re-verification.

Supplier performance directly impacts your operational efficiency, costs, and customer satisfaction.

A supplier that frequently misses deadlines, ships defective products, or struggles with responsiveness can cause production delays, increased returns, and costly disruptions.

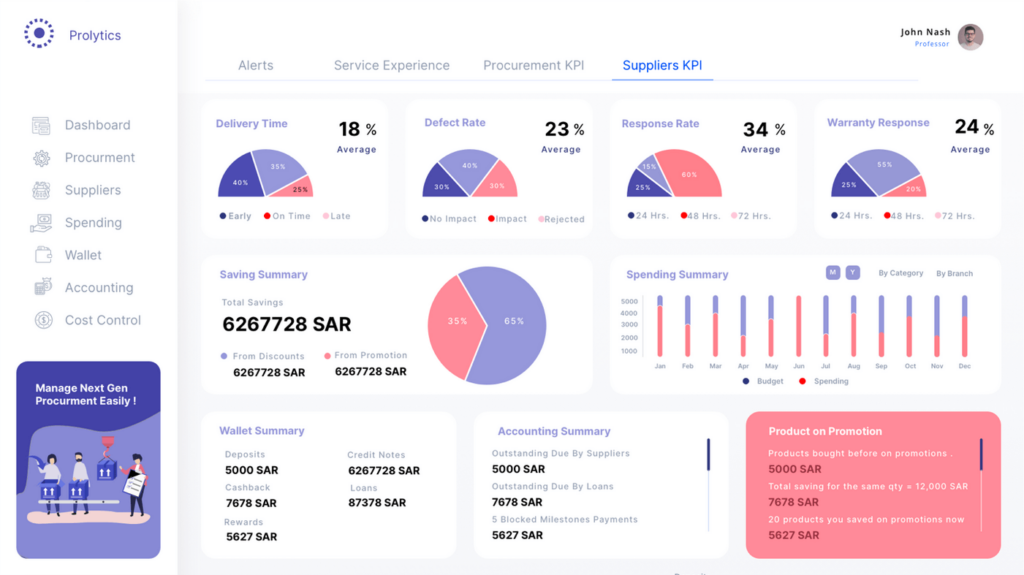

That’s why you should continuously track and evaluate supplier performance using key performance indicators (KPIs).

Some of the most critical ones include:

Monitoring these KPIs over time and having them stored in your supplier database will help you identify patterns and spot underperforming suppliers before they cause big problems.

The challenge, however, is collecting this data efficiently.

Yes, some metrics can be pulled from internal records—order histories, return logs, and incident reports.

But for a more comprehensive view, many procurement teams turn to supplier performance management systems.

These tools centralize performance data, providing real-time dashboards that track deliveries, quality issues, and service levels.

Source: Behance

Some platforms even integrate directly with enterprise resource planning (ERP) systems to automate data collection, ensuring procurement teams have accurate insights without manual tracking.

Additionally, third-party audits, customer feedback, and quality inspections all offer valuable external data points, verifying whether suppliers are meeting agreed standards.

Using these tools, you can automatically track supplier performance, identify trends, and flag underperforming vendors.

This helps ensure that your database reflects real-time insights, not outdated assumptions.

Every supplier relationship comes with risk.

Some are minor, like occasional late deliveries.

Others can be catastrophic, like a supplier going bankrupt, facing legal action, or being impacted by geopolitical instability.

If you don’t assess supplier risk upfront and monitor it over time, you could find yourself scrambling for alternatives when it’s already too late.

One major concern is geopolitical risk.

Suppliers operating in politically unstable regions may face sudden trade restrictions, factory shutdowns, or regulatory bans.

If you don’t track where your suppliers source materials and manufacture products, you could be blindsided by these disruptions.

Hidden subcontracting is another critical risk.

Some suppliers secretly outsource production to unapproved third parties, leading to quality issues, compliance violations, or ethical concerns.

Volkswagen experienced this firsthand when a sub-supplier used forced labor, causing U.S. customs to detain shipments, resulting in delays and reputational damage.

Source: VOA News

To stay ahead, procurement teams should use real-time risk monitoring tools that integrate with your supplier database to receive alerts on geopolitical events, financial instability, and compliance breaches.

The more proactive you are in managing supplier risks, the fewer disruptions you’ll face.

Environmental, social, and governance data on supplier activities is no longer optional to have in your supplier database.

Governments, investors, and consumers expect companies to track and enforce sustainability and ethical sourcing.

The US, for example, has banned most imports from China’s Xinjiang region unless companies prove their supply chains are free from forced labor.

Meanwhile, 76% of consumers say they would stop buying from companies that harm the environment or mistreat workers.

Illustration: Veridion / Data: PwC

The fast fashion industry, for instance, has been repeatedly exposed for ESG failures.

Zara, for instance, has faced backlash for sourcing from factories with poor labor conditions and excessive waste production.

To prevent such risks, companies need to track, including but not limited to:

But gathering ESG data is complex, requiring verification from multiple sources.

This is where Veridion, our data engine, simplifies the process.

Using AI and big data, Veridion continuously updates supplier profiles, covering over 120 million companies across 240+ countries.

It provides real-time insights into supplier sustainability efforts and labor practices.

Procurement teams can access detailed information on company activities, including net-zero targets, certifications, and adverse or controversial media coverage.

Here is Veridion’s comprehensive ESG taxonomy:

Source: Veridion

And ESG is just one piece of the puzzle.

Veridion helps track all supplier data categories we mentioned today, offering a comprehensive, always-current view of your supply base.

Yes, managing supplier information can be overwhelming, but with Veridion, it’s seamless.

A supplier database is more than a checklist—it’s the foundation of a resilient, risk-proof supply chain.

Outdated or incomplete information can lead to production delays, financial losses, and compliance violations.

But with the right data at your fingertips, you can make smarter decisions, avoid disruptions, and build stronger supplier relationships.

Manually tracking all these details is overwhelming—but you don’t have to do it alone.

Veridion simplifies supplier data management by providing continuously updated insights on millions of suppliers worldwide.

So, are you ready to take control of your supplier database?