5 Master Data Management Challenges to Overcome

Key Takeaways:

What if your biggest procurement risks aren’t rogue suppliers but your own data?

Fragmented records, inconsistent standards, and manual workflows are surprisingly common issues that plague organizations of all sizes.

These seemingly internal problems silently sabotage procurement performance, creating ripple effects that extend far beyond the procurement department.

When master data management falters, the consequences are immediate and far-reaching.

Strategic decisions become compromised by unreliable information, while operational bottlenecks emerge that impact your entire supply chain network.

This guide explores five critical challenges of master data management and provides actionable solutions to overcome them.

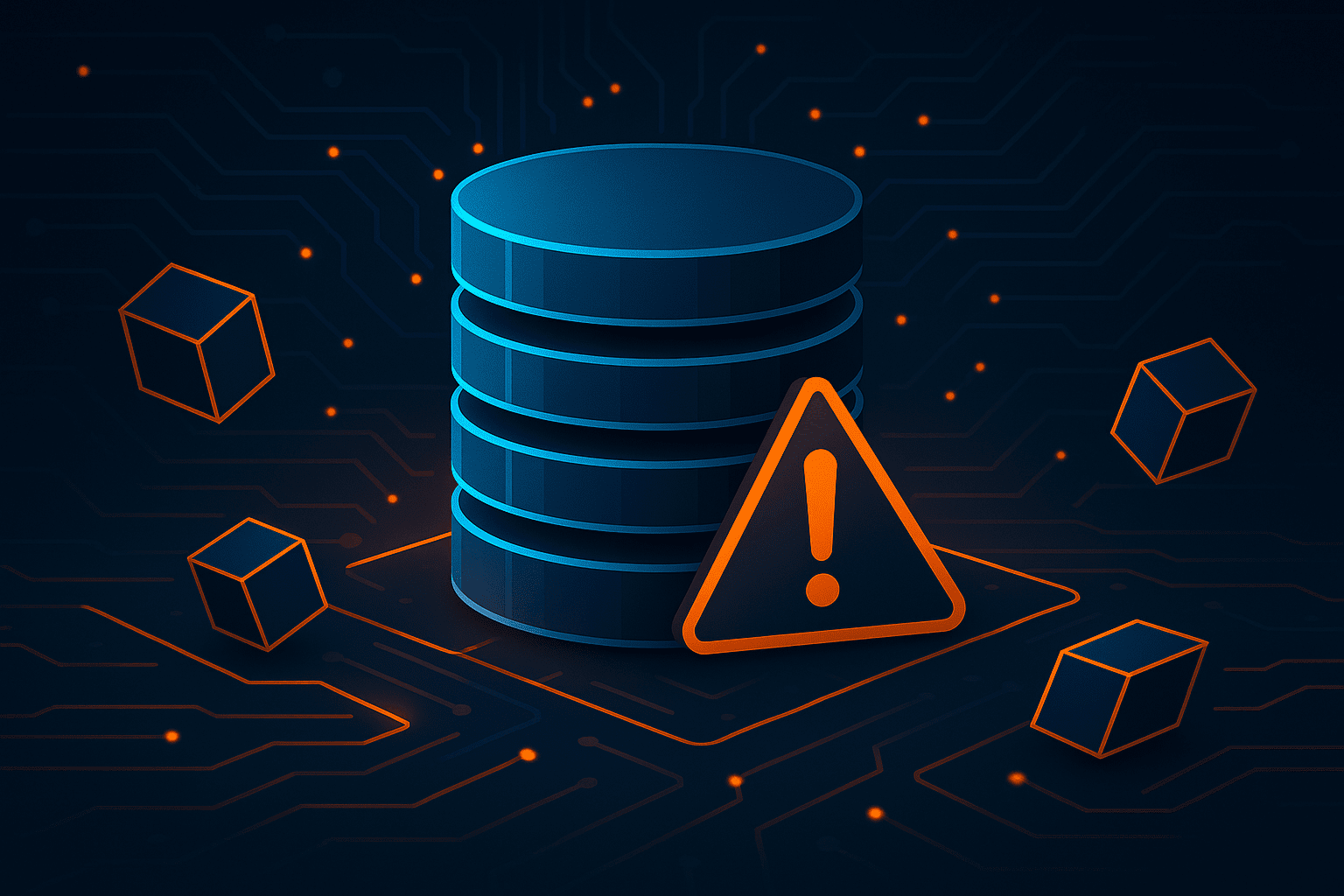

In many organizations, vendor data is stored independently across departments, with each maintaining its own supplier list.

This lack of alignment prevents data from being easily shared or accessed company-wide.

The result is disjointed records, duplicates, inconsistencies, and errors that ripple throughout your entire organization.

Source: Veridion

This fragmentation makes it nearly impossible to maintain a complete, accurate view of your vendor ecosystem.

And without that unified view, data-driven decision-making becomes a constant struggle, slowing down workflows and exposing your organization to unnecessary risk.

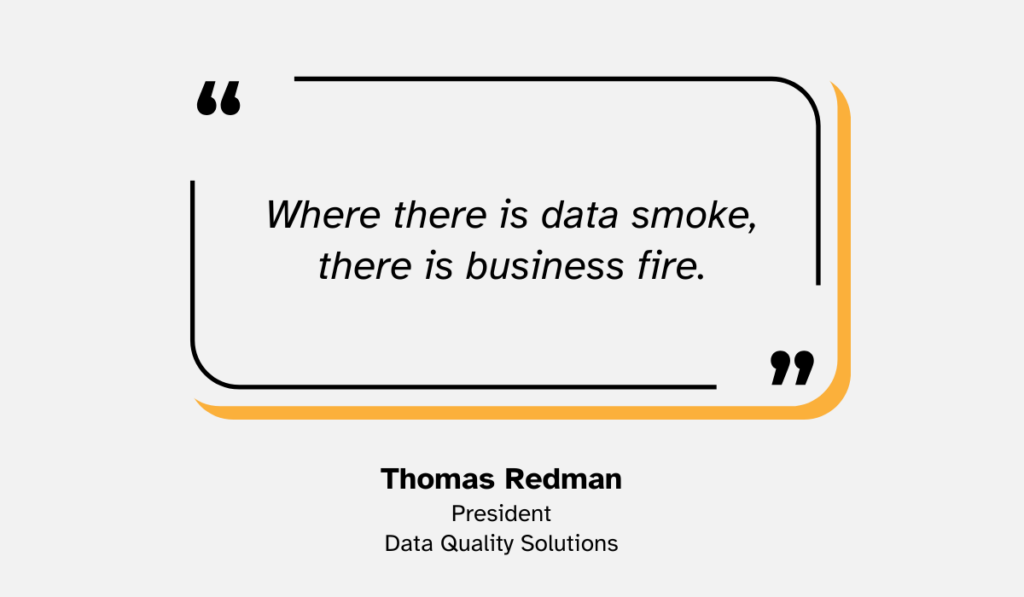

Data experts agree.

Thomas Redman, President of Data Quality Solutions, widely known as “the Data Doc,” warns that even minor signs of data fragmentation often point to deeper problems that can seriously disrupt business operations if not addressed early.

Illustration: Veridion / Data: Semarchy

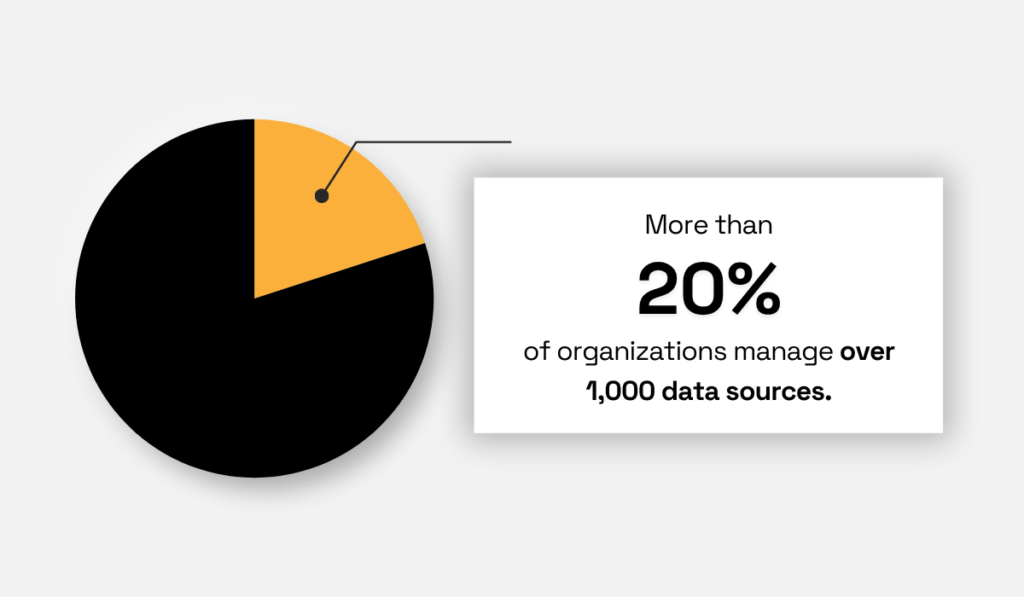

The scale of this challenge is significant.

One market survey found that the average organization manages 400 separate data sources, and more than 20% of organizations draw data from more than 1,000 sources.

Illustration: Veridion / Data: Matillion

With vendor data inevitably scattered across many of these siloed systems, achieving unified supplier insights becomes nearly impossible.

Add to that the complexity of handling a large number of third-party relationships in large enterprises, and the risk of data fragmentation skyrockets.

Even worse, 39% of organizations report having little to no formal data governance frameworks, which often leads to conflicting, unreliable data scattered across systems.

Similarly, many organizations juggle overlapping data across different systems, where the same supplier appears under different IDs in each department or system.

To overcome these silos, organizations need to focus on two key areas.

The first is to consolidate vendor data into one system.

That’s exactly what BAE Systems did. The aerospace and defense company harmonized its vendor onboarding processes by implementing a unified global platform.

Jerry Grable, Director of Supply Chain Technology, Data, and Risk, explains that instead of managing ten separate onboarding processes, the company now operates with a single, streamlined approach using one global form.

Illustration: Veridion / Data: HICX

This consolidation simplified onboarding while simultaneously improving operational efficiency and regulatory compliance.

BAE Systems’ platform now automatically collects updated documents when they expire, saving time and reducing manual follow-up.

With a single source of truth in place, you reduce errors, accelerate procurement cycles, and ensure every department works with the same clean data.

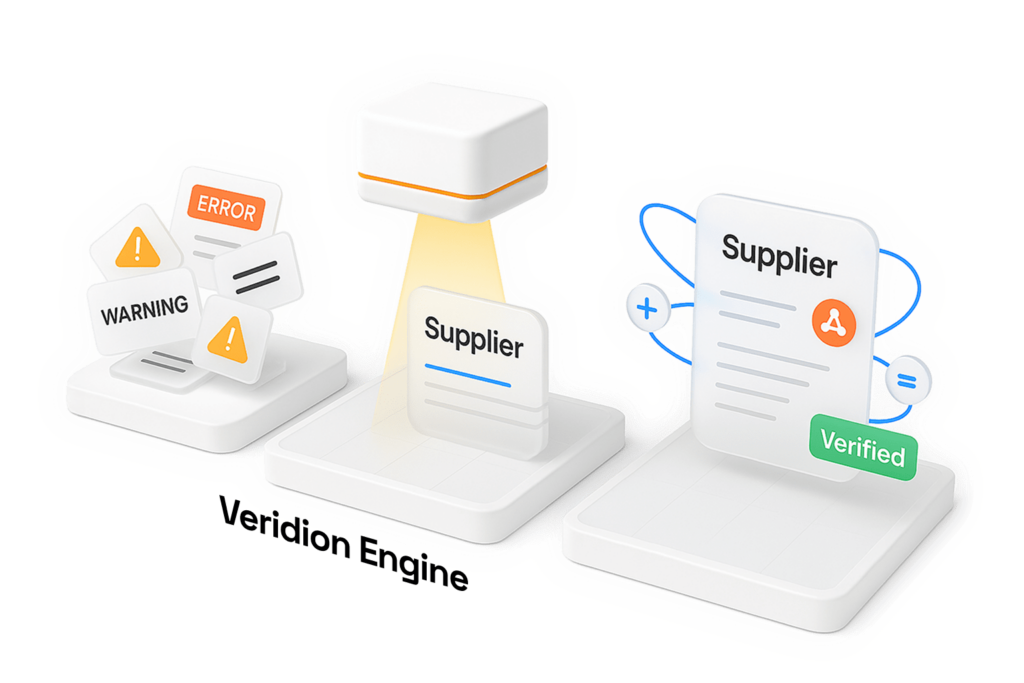

The next step in fixing siloed vendor data is implementing AI-powered master data management tools.

Modern MDM platforms such as Veridion can automatically unify siloed databases.

This means supplier updates, like a new address or ownership change, are reflected consistently across all systems, eliminating duplicate records and improving reliability.

Source: Veridion

In fact, more than 80% of organizations invested in AI in 2024, underscoring the role of AI in reducing manual errors.

Tackling silos is your first step toward clean, trustworthy vendor data. Once you centralize and integrate your systems, you can enforce consistent standards and governance.

From there, you’ll be ready to take in the next big challenge: weak governance practices.

Without strong data governance, even the best MDM tools can’t guarantee accurate vendor information.

Just look at Meta’s $1.3 billion fine for violating EU privacy laws. This is what weak governance can lead to.

Source: Google

You might have excellent software, but if no one owns the data or enforces data standards, quality will slip, and the costs will follow.

In the context of vendor data, the consequences may not always be regulatory fines, but they’re still significant.

Without clear ownership and strong data standards, inconsistent supplier records can lead to duplicated spend, missed compliance obligations, and operational inefficiencies.

Teams waste valuable time chasing down correct information instead of focusing on strategic tasks.

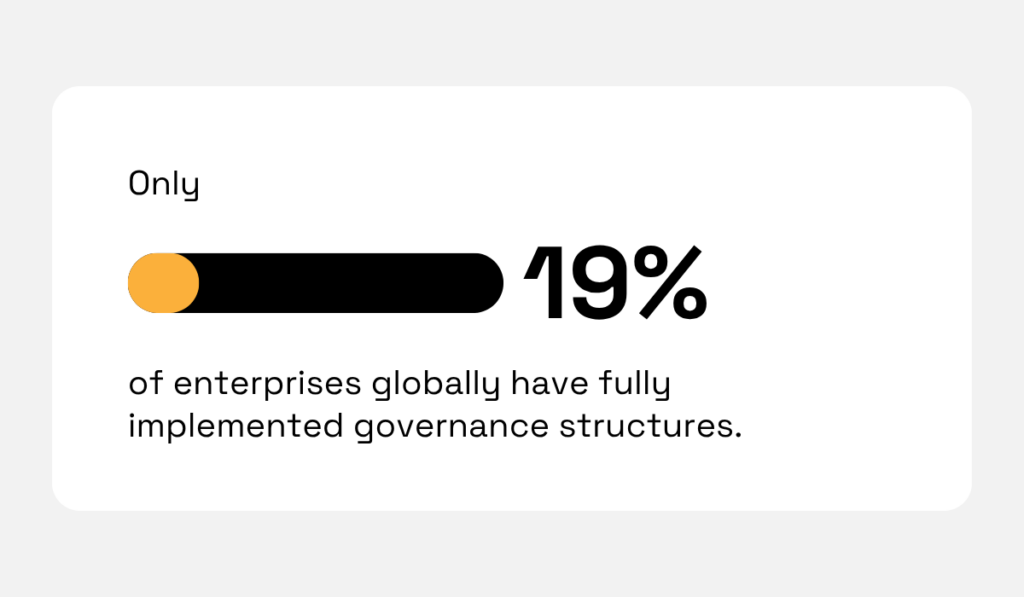

Unfortunately, that’s the reality for many companies.

According to TDWI, only 19% of enterprises globally report having fully implemented governance structures.

Illustration: Veridion / Data: TDWI

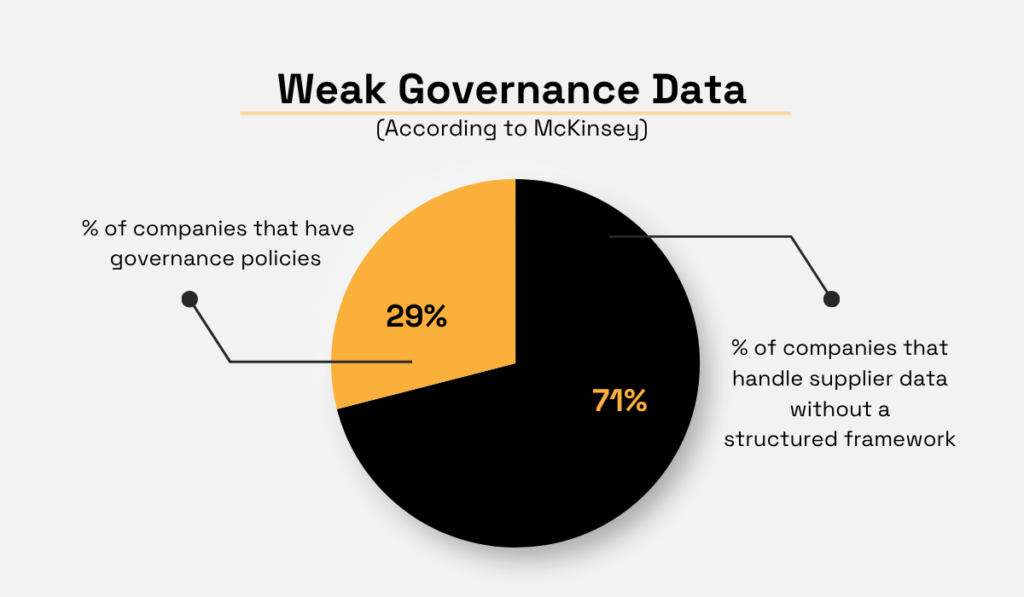

To make matters worse, a survey by McKinsey revealed that only 29% of companies have all the necessary governance roles and policies in place.

That means around 71% of companies manage supplier data without a structured framework for validation, ownership, and standardization.

Illustration: Veridion / Data: McKinsey

And that has consequences.

For example, different departments onboard vendors using inconsistent criteria, naming conventions, or data entry formats.

Without centralized oversight or clearly defined roles (like a master data manager or a data steward), no one enforces standards or catches errors early.

Naturally, this creates a fragmented, unreliable vendor database.

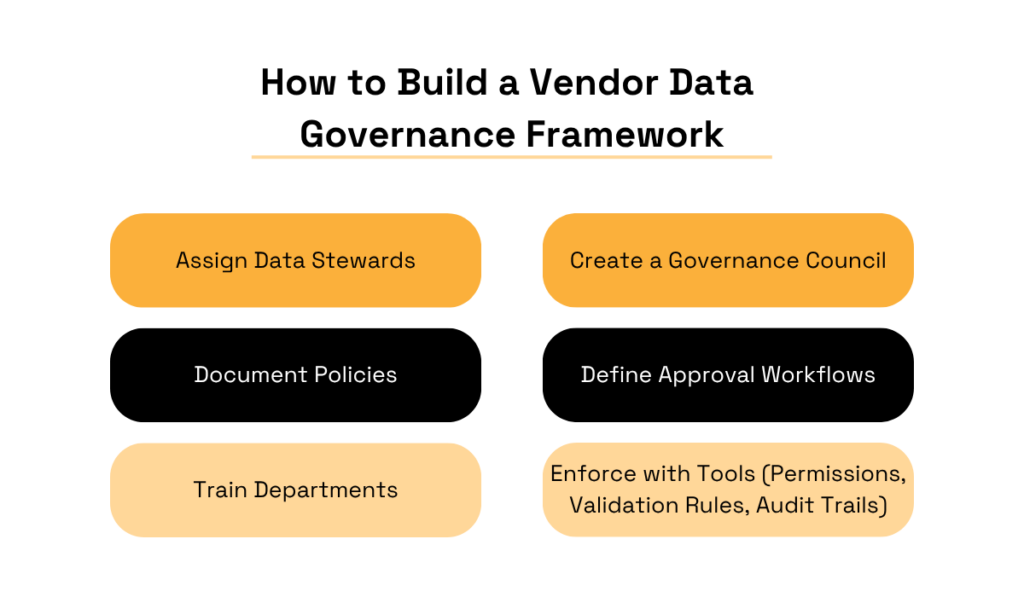

To solve this, you need a governance framework designed around your vendor data.

The visual below outlines a step-by-step framework for building it:

Source: Veridion

Start by assigning data stewards and creating a cross-functional governance council that includes both IT and business teams.

Their immediate focus should be on documenting policies clearly by:

Once these standards are established, train every department to follow the same protocols.

Since alignment begins with communication, ensure that everyone understands how to manage supplier data.

Finally, reinforce those standards with the right technology.

Specifically, use permissions to control access, audit trails to track changes, and validation rules to block bad data before it enters your system.

Once roles and rules are firmly in place, you’ll spend less time firefighting issues and more time making data-informed decisions.

Inaccurate or incomplete vendor records make every task harder.

You might have multiple addresses, outdated bank details, or misspelt company names in your system. These errors erode trust in your data.

Unfortunately, data quality issues are common.

77% of companies report significant challenges, and 91% say these problems negatively impact their performance.

Moreover, Gartner estimates that companies lose an average of $12.9 million per year due to bad data.

Illustration: Veridion / Data: Gartner & Datanami

Even simple gaps, like missing contact information or tax IDs, can delay payments and disrupt audits. Inconsistent product or service descriptions can lead to sourcing errors or mismatched orders.

And duplicate vendor entries distort performance metrics, making it difficult to evaluate spend efficiency or monitor contract compliance.

Beyond operational inefficiencies, poor data undermines strategic decision-making.

Procurement teams depend on clean, accurate data to track KPIs, analyze spending, and identify opportunities for cost savings or supplier consolidation.

Messy data leads to unreliable reports, skewed insights, and diminished stakeholder confidence.

But why is the data this poor?

Vendor data is constantly changing, from contact people to certifications and payment info.

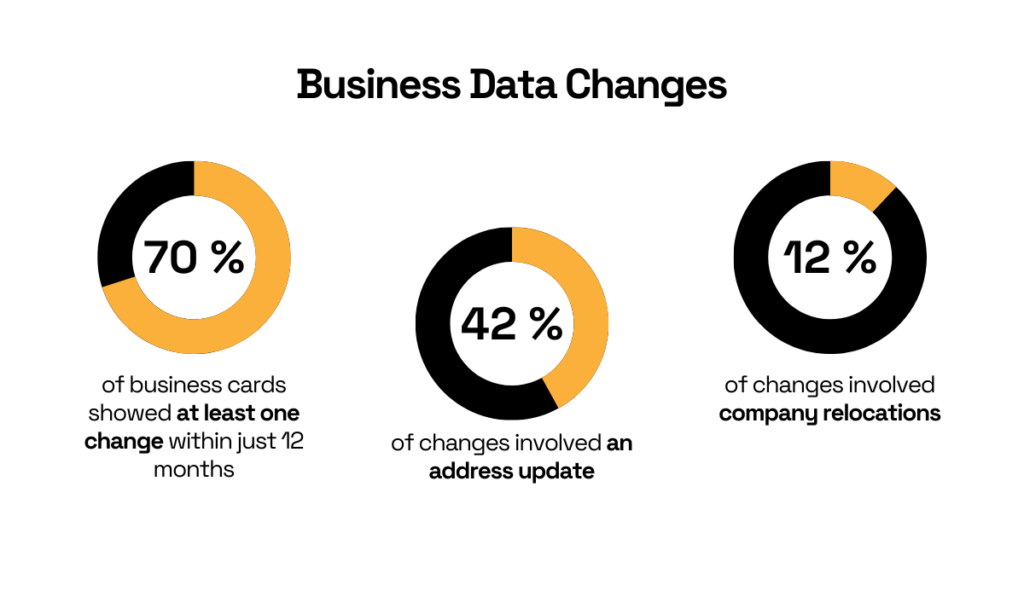

Research confirms this.

A study of 1,000 business cards found that over 70% contained changes within a year, with 42% showing address updates and 12% reflecting relocations.

Illustration: Veridion / Data: Industry Select

If that’s happening on business cards, it’s definitely happening in your vendor master. Without regular reviews, your supplier database quickly becomes outdated and error-prone.

To fix this, you must take a proactive approach.

Data audits should be a routine part of your vendor management process.

They involve cleansing and validating data across systems to identify and rectify gaps like:

This way, these flaws do not impact payments, contract negotiations, compliance, or core operations like sourcing, onboarding, and reporting.

After all, simply having a vendor on file isn’t enough if the data attached to them is incomplete.

This is also where you need to implement data enrichment, either manually (through outreach and internal records) or automatically (via third-party data providers like Veridion).

Source: Veridion

Veridion, for example, uses AI to pull structured data on millions of companies worldwide, helping procurement teams fill in missing information, verify business details, and eliminate guesswork.

For example, if a supplier lacks a VAT number, Veridion can source it from verified databases and enrich your records.

Source: Veridion

This capability illustrates automation’s power to overcome the flaws of manual processes.

Manual data entry breeds typos, erroneous naming, and duplicate supplier entries.

However, automation tools solve these core issues in two key ways:

By combining enrichment and automation, you reduce manual errors, cut cleanup time, and build a trusted vendor database.

Legacy software and disconnected systems can disrupt your MDM flow.

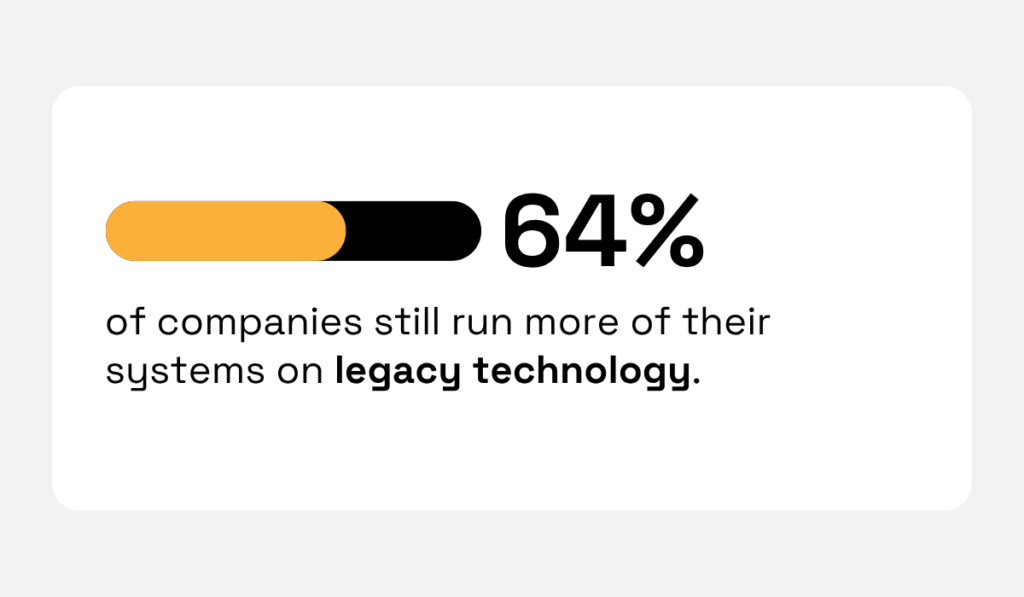

According to SnapLogic, 64% of organizations still run more of their systems on legacy technology, and 63% report that this technical debt is already degrading performance.

Illustration: Veridion / Data: Snaplogic

Imagine working with an old ERP, a custom database, and vendor records scattered across spreadsheets.

These systems often can’t “talk” (synchronize) to each other. So when you update a record (say, a supplier’s address), it doesn’t automatically reflect everywhere.

This lack of interoperability is a major technical barrier.

Each system may use different data formats, field names, or naming conventions.

For example, one platform might label a field as “Vendor Name,” another uses “Supplier,” and a third stores it as “Vendor/Supplier.”

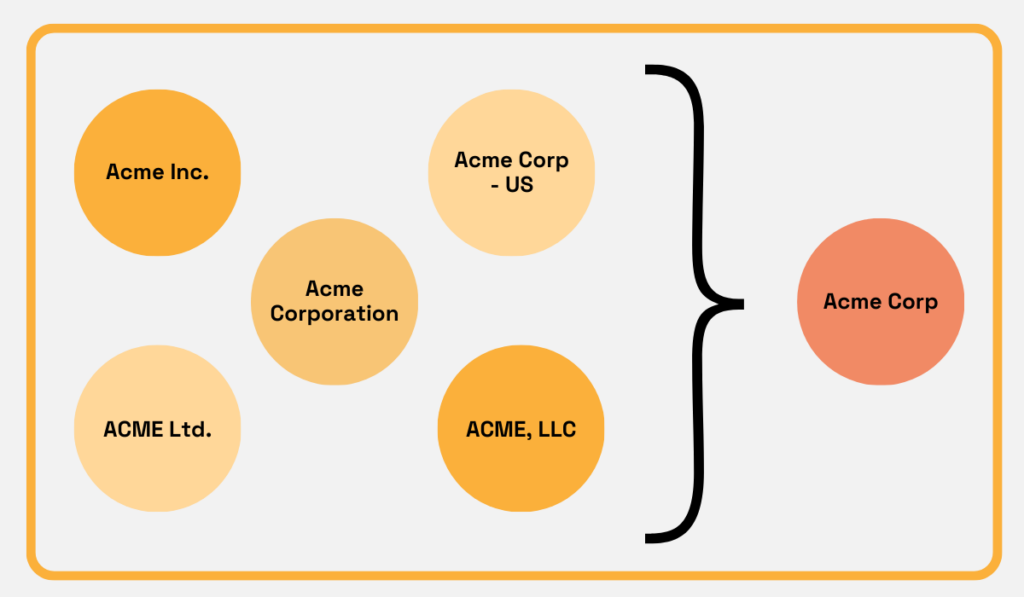

Even worse, suppliers can appear under different variations in each system, like “Acme Inc.,” “Acme Ltd,” “Acme Corp,” or “Acme US.”

Source: Veridion

Without standardized data structures, automated synchronization becomes virtually impossible.

Teams resort to manual data transfers or CSV file uploads—processes that are both time-consuming and prone to human error.

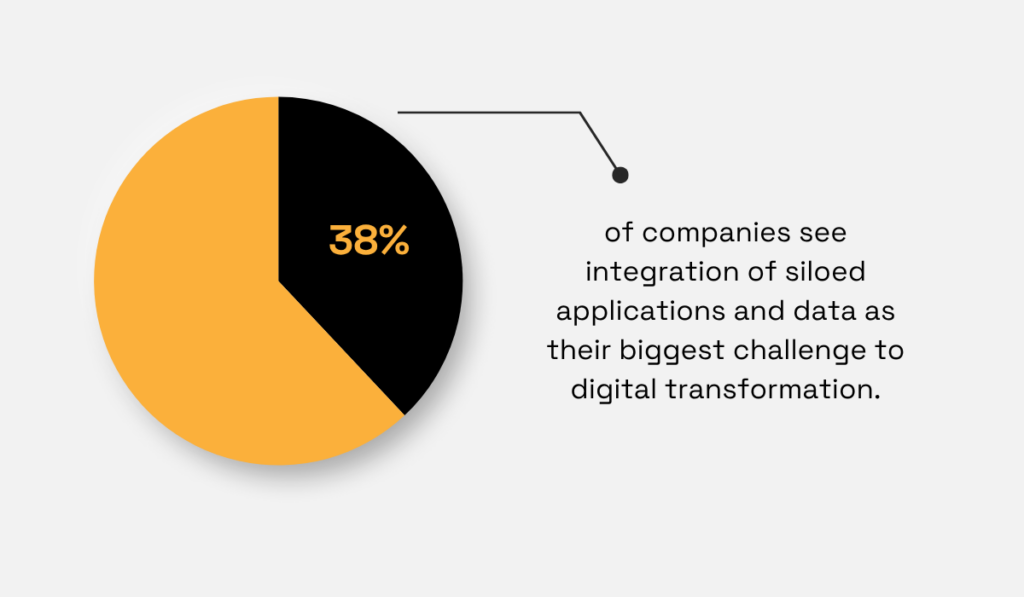

It’s no surprise that 38% of companies identify legacy-system data integration as their top digital transformation challenge.

Illustration: Veridion / Data: Elastic

To overcome this, start with middleware—software that connects disconnected systems and enables smooth data exchange.

Middleware pulls data from sources like ERPs, CRMs, and vendor portals, standardizes it, and routes it across systems without the need to rebuild your tech stack.

However, this is only half the battle.

You also need an MDM platform to centralize and enforce data consistency.

MDM tools create a single source of truth by standardizing vendor records, eliminating duplicates, and synchronizing changes across all platforms, automatically and in real-time.

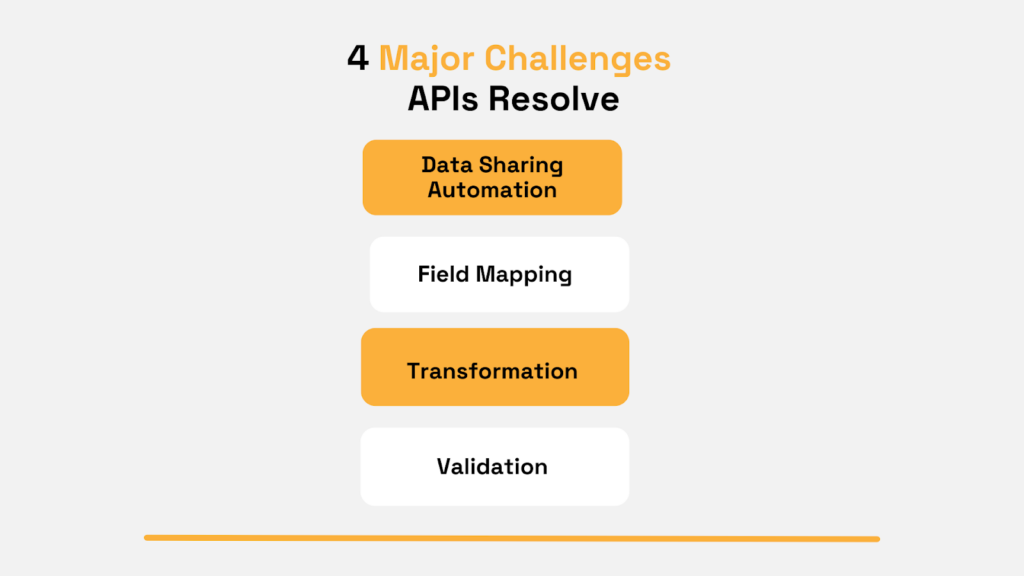

This setup requires an API-first approach.

Unlike manual uploads or file transfers, APIs automate data sharing, field mapping, transformation, and validation.

Source: Veridion

For instance, when a supplier updates their contact information in a portal, an API can instantly sync that change to your ERP and CRM.

This eliminates lag, prevents mismatches, and cuts down duplicate entries.

With this infrastructure in place, manual work drops dramatically.

Real-time synchronization ensures every team works from the same accurate vendor data, freeing up your time for strategy, not spreadsheets.

Manual processes remain the default approach for supplier data management in many organizations.

Procurement teams frequently spend hours copying information between spreadsheets, sending emails to suppliers for updates, or manually reviewing and approving individual data changes.

These workflows may seem manageable, but they are slow, error-prone, and increasingly unsustainable as vendor networks grow.

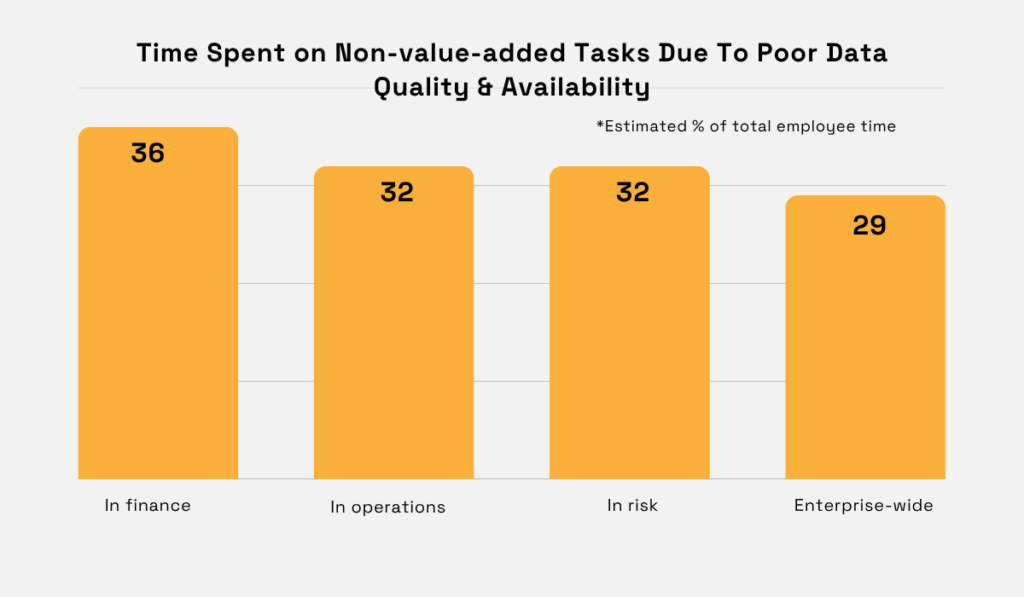

According to McKinsey, data professionals spend an average of 30% of their time on non-value-added manual tasks like correcting errors or seeking missing information.

Illustration: Veridion / Data: McKinsey

That’s time your procurement team could be using for strategic supplier sourcing, negotiations, or cost optimization.

Manual workarounds often exist because organizations lack a single, trusted source of supplier data.

When information is inconsistent or stored in disconnected systems, automated workflows break down, forcing teams to fall back on spreadsheets, emails, and phone calls.

This creates friction not only internally but also with suppliers, making collaboration more difficult.

To eliminate this reliance on manual processes, vendor data workflows must be digitized and governed by strong master data management practices.

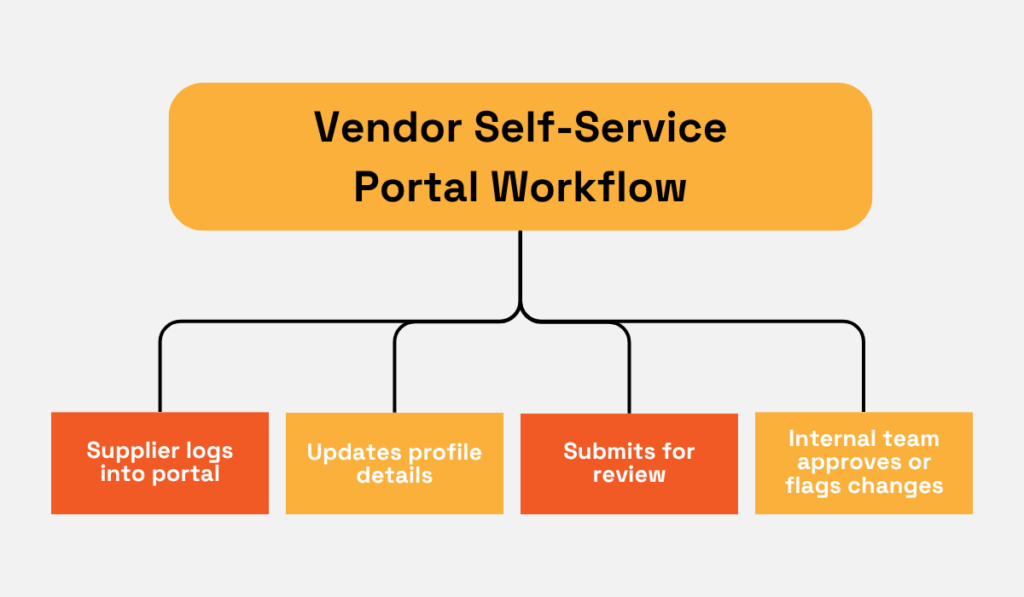

A key starting point is implementing vendor self-service portals, which let suppliers manage their own profiles.

By entering and updating their information directly, suppliers reduce the need for manual back-and-forth, while built-in access controls ensure that all changes go through internal approval before becoming part of your master data.

Source: Veridion

To ensure high-quality inputs from the start, these portals should include validation logic—rules that enforce required fields, standardized formats, and real-time verification against trusted databases.

For example, if a supplier enters an invalid tax ID or incomplete address, the system flags the issue before the data is saved.

However, ensuring accurate inputs is only part of the solution.

To truly move away from manual workflows, you need MDM software to centralize, standardize, and synchronize vendor data across platforms like your ERP, CRM, and procurement systems.

They also automate essential tasks like deduplication, field mapping, cleansing, and change tracking.

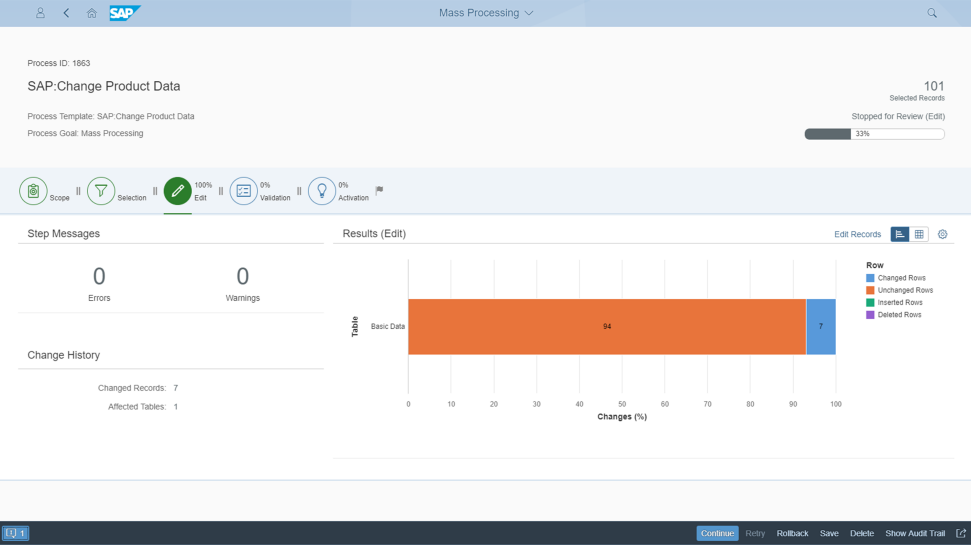

In cases where large-scale updates are needed, such as applying a new naming convention or correcting a formatting error across thousands of records, MDM tools provide specialized functionality.

For example, SAP Master Data Governance allows data stewards to perform bulk changes across supplier, customer, and product data using controlled, high-efficiency mass change processes.

Source: G2

This eliminates the need for risky, ad hoc edits while ensuring governance standards are enforced at scale.

Finally, with features like audit trails and role-based permissions, MDM ensures that every change is tracked and approved, supporting data quality, compliance, and accountability.

If you’re dealing with siloed systems, inconsistent records, or time-consuming manual processes, you’re not alone.

But you’re not stuck.

By centralizing vendor data, enforcing clear governance, integrating systems, and empowering teams and suppliers to maintain accuracy, you can break the cycle.

When your vendor data becomes clean, connected, and well-governed, your procurement function will transform from a tactical operation into a strategic business driver.