5 Benefits of Master Data Management for Your Supply Chain

Key Takeaways:

Supplier data is the backbone of modern supply chains.

But too often, it’s messy, duplicated, or incomplete.

That chaos leads to poor decisions, missed savings, and growing compliance risks.

Master Data Management fixes the problem by unifying and enriching supplier data across your organization.

In this article, we’ll explore five ways MDM transforms your supply chain, from boosting accuracy and compliance to cutting costs and improving supplier relationships.

When you look at large organizations, you’ll find they typically rely on multiple specialized systems, including procurement platforms, logistics management tools, financial software, and more.

The challenge with this setup?

Each department often maintains its own version of supplier information, creating disconnected data silos.

In fact, an Airtable and Forrester survey found that large enterprises use an average of 367 different software tools.

Illustration: Veridion / Data: Airtable

This leads to:

Add to that the 2.4 hours employees spend each day navigating piles of data spread across tools and spreadsheets, and decision-making inevitably slows down.

Illustration: Veridion / Data: Airtable

That figure comes from the same Airtable and Forrester survey, which shows just how much productivity these silos drain.

The longer teams are stuck reconciling records, the harder it is to react quickly when opportunities or risks appear.

All this combined hampers the organization’s efficiency, accuracy, and effectiveness, explains Venki Subramanian, former Senior Vice President of Product Management at Reltio:

Illustration: Veridion / Quote: CPO Strategy

The solution is to implement a single, reliable repository of supplier information.

Master Data Management (MDM) creates this unified view by consolidating data from all systems, providing the most accurate and up-to-date picture of suppliers and the entire supply chain.

With MDM, everyone in the organization works from the same trusted dataset.

This alignment solves multiple challenges at once:

The results speak for themselves.

One real-world example comes from a retail supplier and buyer of medical equipment.

With a growing customer base, expanding product lines, and a widening network of vendors and partners, the company struggled to get a complete view of core business entities and transactional data.

The result was slower product management cycles, delayed time to market, and inefficiencies across its supply chain.

By implementing an MDM platform following Fujitsu’s strategy, the company achieved full visibility across systems, which led to significant benefits across departments:

Illustration: Veridion / Data: Fujitsu

When supplier data lives in one place, your teams finally see the full picture and act on it faster.

One of the biggest wins you’ll see with MDM is dramatically improved data accuracy.

Why is this such an important benefit?

Well, because bad data holds companies back.

According to TealBook, as much as 82% of companies aren’t confident in the accuracy of their supplier data.

Illustration: Veridion / Data: Tealbook

When supplier information is wrong or outdated, teams waste time, overspend, and miss critical opportunities.

A common culprit is duplicate data records that multiply across every system in your organization.

Here’s what typically happens:

Suddenly, you’re looking at three separate supplier profiles for the same vendor, each with different contract terms and performance data.

These inconsistencies ripple across the organization, slowing procurement cycles, inflating logistics costs, and distorting spend analytics.

Research from Experian Data Quality shows just how damaging (and costly) inaccurate data can be to business operations:

Illustration: Veridion / Data: Econsultancy

While the numbers reflect company-wide challenges, the reality is that individual departments feel the pressure too.

Procurement, in particular, faces delays, missed savings, and unnecessary risks when supplier data isn’t reliable.

So, how do you make sure the data driving your supply chain is actually trustworthy?

The fix starts with having clean, up-to-date records.

But keeping data clean isn’t as simple as it sounds.

Manual updates take time and can easily let errors slip through.

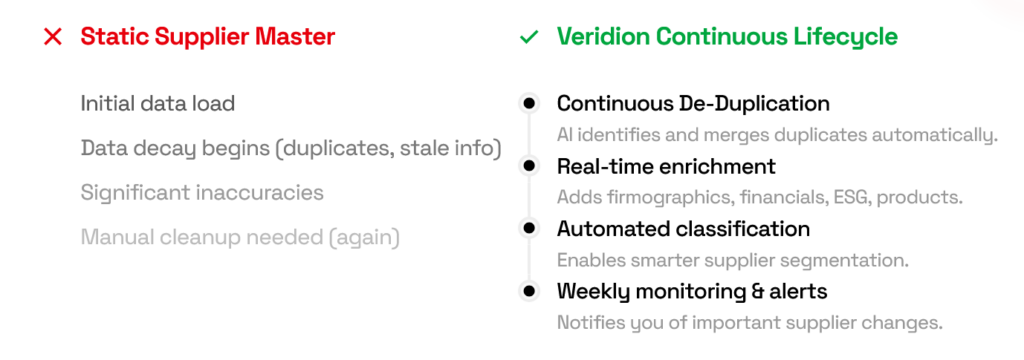

Our big data platform, Veridion, solves this by automatically enriching and validating supplier data with the help of AI and machine learning.

Source: Veridion

Veridion cross-checks and fills in gaps in key fields, such as:

This ensures that supplier profiles are always complete, consistent, and reliable.

The impact is immediate.

Procurement gains a clear view of supplier relationships when negotiating contracts.

Logistics reduced the risk of overpaying due to duplicate supplier entries. And finance can accurately track spend and performance metrics without reconciling fragmented records across systems.

With accurate data in place, companies can move faster, reduce friction, and maintain confidence in every part of the supply chain.

This is especially important for meeting today’s growing compliance demands.

Regulatory pressure keeps growing, and your compliance teams need accurate, complete supplier data to do their jobs.

One example is the Corporate Sustainability Reporting Directive (CSRD), which, since 2023, requires over 50,000 large companies to report on sustainability metrics, making reliable data more important than ever.

Think about ESG reporting alone.

You need comprehensive information across the three ESG pillars:

Navigating this complex data isn’t easy, especially when reporting frameworks and standards vary.

But gathering data isn’t enough for ESG compliance.

Data also needs to be accurate, consistent, and easy to verify.

Yet, data quality remains a top challenge. According to Deloitte, 57% of executives say poor data quality hinders their ESG efforts.

llustration: Veridion / Data: Deloitte

Inconsistent and incomplete supplier data makes it difficult to meet compliance requirements efficiently and accurately.

This is where MDM delivers a critical advantage.

It tracks and validates data across its entire lifecycle. It ensures every ESG metric, from Scope 1, 2, and 3 emissions to diversity stats, is reliable and aligned with reporting frameworks like GRI, SASB, and the EU Taxonomy.

With centralized, governed data, MDM makes it easier to:

The bottom line?

MDM keeps you in control.

It turns compliance from a last-minute scramble into a continuous, confident process, while protecting your reputation in an increasingly transparent market.

A lot can go wrong in a supply chain, and more often than not, the warning signs are buried in bad data.

Missing licenses, outdated certifications, inactive suppliers still marked as “active,” or overreliance on a single vendor in a disruption-prone region can all lead to costly problems.

These kinds of risks often fly under the radar when supplier data is scattered, incomplete, or simply outdated.

With MDM in place, procurement and supply chain leaders gain a centralized, real-time view of supplier performance, capabilities, and geographic spread.

This makes it easier to spot and act on risks before they escalate.

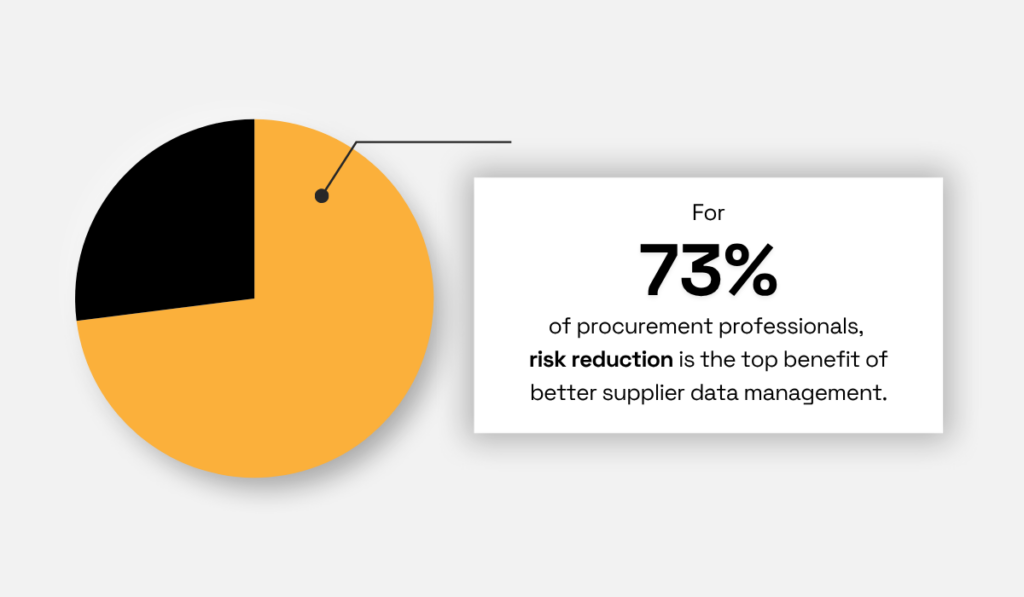

In fact, research shows that for 73% of procurement professionals, risk reduction is the top benefit of better supplier data management.

Illustration: Veridion / Data: HICX

As you can see below, MDM helps identify different types of supplier risk early on, from outdated licenses to inactive suppliers:

| Risk Type | MDM Detection |

|---|---|

| Outdated License | Flagged & Updated System |

| Single Vendor Dependency | Location Risk Alert Triggered |

| Compliance Gaps | Detected & Highlighted Early |

| Inactive Suppliers | Removed from Active Vendor List |

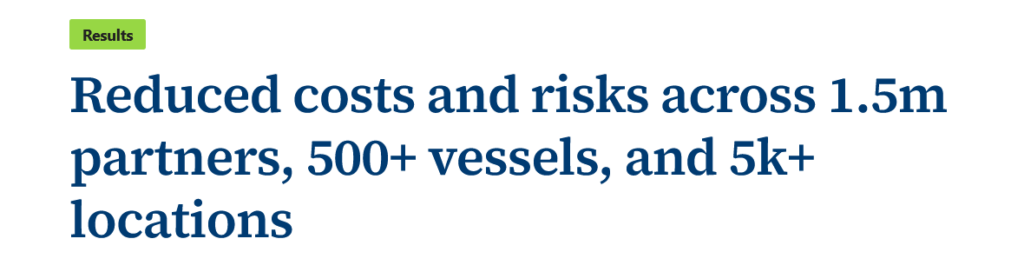

A real-world example comes from CMA CGM, a global leader in shipping and logistics.

Operating over 500 vessels and servicing 420 commercial ports worldwide, the company faces complex compliance requirements and high operational risk.

To modernize its workflows and strengthen compliance, CMA CGM built a centralized Intelligent Data Hub that integrated legacy and SAP systems, automated data validation, and unified partner, billing, and shipping data.

The results included reduced compliance risk across 1.5 million partners, lower costs for SAP rollouts, and improved partner satisfaction, all driven by stronger data governance.

Source: Semarchy

This kind of centralized visibility is exactly what turns MDM from a static database into a proactive risk management tool.

And when it’s paired with continuous data enrichment, it becomes a live early-warning system.

Platforms like Veridion strengthen MDM by updating supplier firmographics, financials, and ESG metrics in real time, auto-classifying vendors, and pushing alerts when something changes.

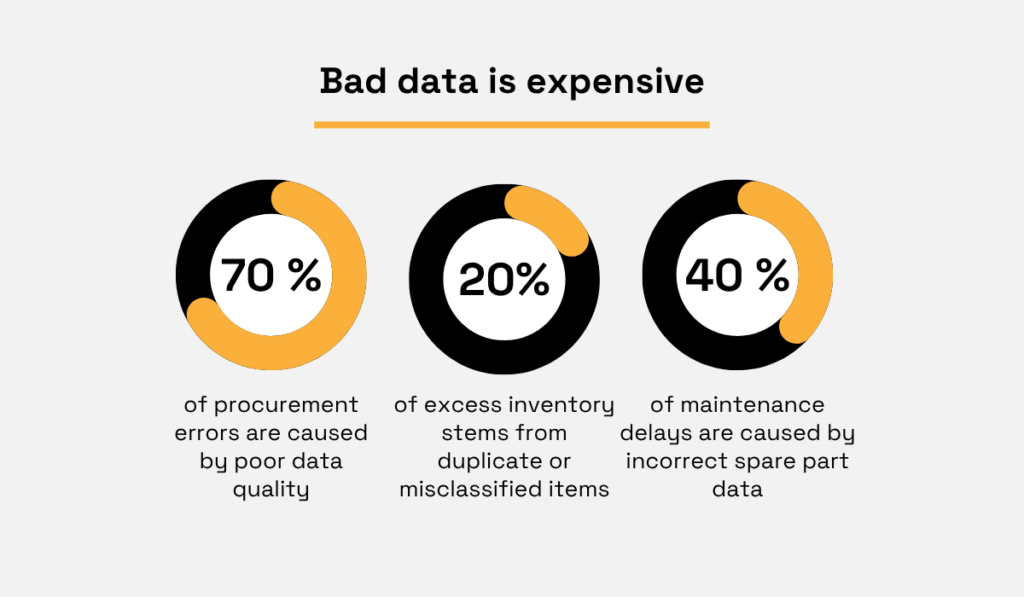

Bad supplier data is expensive.

Duplicates, inconsistencies, and missing info all lead to poor decisions, wasted time, and higher spend.

The link between poor data, poor decisions, and higher costs is measurable in every purchase order and supplier contract.

According to Coda, 70% of procurement errors are caused by poor data quality, leading to millions in losses from bad inventory and supplier decisions.

What starts in procurement quickly becomes an inventory problem, adding waste, delays, and extra costs.

More specifically, 15–20% of excess inventory stems from duplicate or misclassified items, while 40% of maintenance delays are tied to incorrect or missing spare part information.

Illustration: Veridion / Data: Coda

MDM changes that by giving companies a single, reliable view of their supplier data, leading to significant cost savings across the board.

For starters, clean data helps teams spot redundant vendors and unnecessary complexity in their supply base.

What does that mean?

MDM also improves visibility into spending.

With accurate, centralized data, procurement teams can identify patterns, spot inefficiencies, and uncover opportunities to renegotiate contracts or tap into discounts that were previously overlooked.

Think fewer mismatched part numbers, fewer incorrect orders, and less back-and-forth between departments.

And when your data is structured and consistent, reporting becomes more accurate.

This leads to better forecasting, smarter planning, and decisions rooted in facts instead of guesswork.

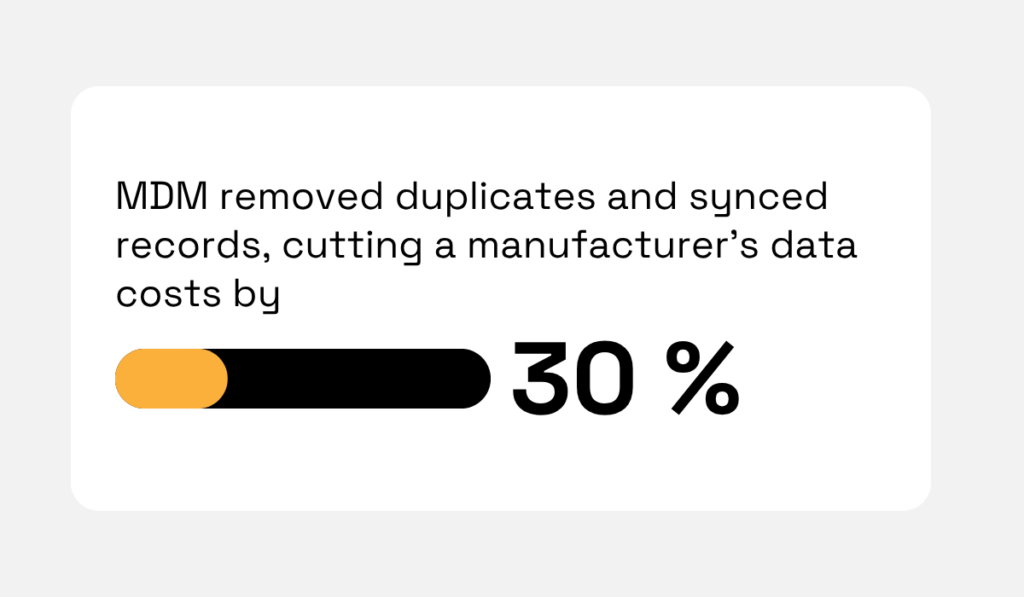

What happens when companies clean up their data?

The figure below shows how using MDM to fix and align records can significantly lower data management expenses.

Illustration: Veridion / Data: Coda

The real cost savings, however, come from implementing a proper MDM solution.

One of the clearest examples comes from AstraZeneca, which replaced 67 legacy MDM systems across 140+ countries with just three regional hubs.

By centralizing data on a single cloud-native platform, AstraZeneca saved £3.6 million annually in infrastructure and management costs, increased sales rep productivity tenfold, and reduced system complexity.

Source: Reltio

The shift also improved search speeds, streamlined customer communications, and enhanced consent management.

In the end, better data leads to better decisions, and with MDM, that means measurable savings.

Clean, well-organized data has a direct impact on a company’s profitability.

If you’re curious how procurement leaders are using accurate supplier data to unlock real savings, check our article on procurement cost savings.

Strong supply chains start with clean supplier data.

By bringing supplier information into one place, removing duplicates, and keeping data accurate, MDM builds a solid base for better decisions across your company.

Clean data means easier compliance and smoother operations, while unified supplier records give you better visibility and lower costs.

With automated tools backing it up, these benefits lead to smarter buying decisions and stronger supply chains.