6 Key Benefits of Global Procurement

Global procurement opens doors to vast opportunities beyond traditional sourcing boundaries.

Instead of a confined supplier pool, you now have access to the entire ocean, or, in other words, the global marketplace.

This shift brings numerous advantages, from discovering cost-effective alternatives and optimizing savings to stimulating innovation and diversifying your supply chain.

Today, we’ll explore six key benefits that embracing global procurement brings.

Stay with us, and let’s dive into the first benefit.

Procurement professionals like you are constantly on the lookout for cost-effective solutions without sacrificing quality.

And global procurement is your ticket to achieving just that.

By tapping into global markets and sourcing materials, products, or services worldwide—which global procurement essentially is—you can discover cost-effective alternatives and drive significant savings for your organization.

This advantage is particularly evident in regions with lower labor, materials, or production costs.

Let’s focus for a moment on lower labor costs.

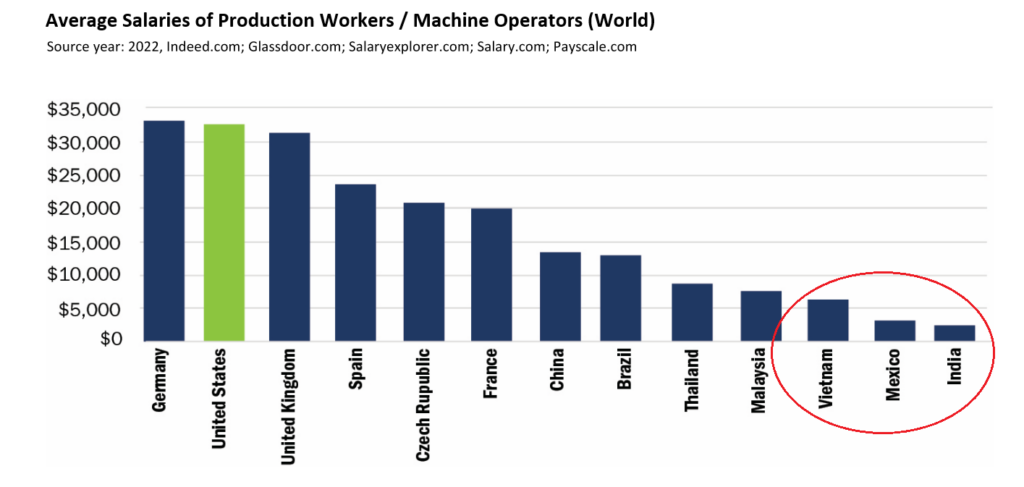

In 2022, research from the Reshoring Institute revealed that India, Mexico, and Vietnam are the countries with the lowest labor costs when it comes to manufacturing.

Source: Reshoring Institute

Due to that, Mexico, in particular, has emerged as a leader in reshoring manufacturing operations, as well as a viable option for global procurement.

Low labor costs and proximity to the United States make it an attractive location for businesses that want to source outside of the US but still seek to reduce transportation costs and lead times.

Moreover, Mexico has free trade agreements with the United States, Canada, and the European Union, which facilitates international trade and eliminates tariffs and trade barriers.

On top of that, Mexico’s well-developed manufacturing industry boasts a skilled workforce capable of producing high-quality goods, especially in sectors like automotive, aerospace, and electronics.

But Mexico is just one piece of the global map.

Sourcing from other countries enables cost savings, too. And not just in manufacturing.

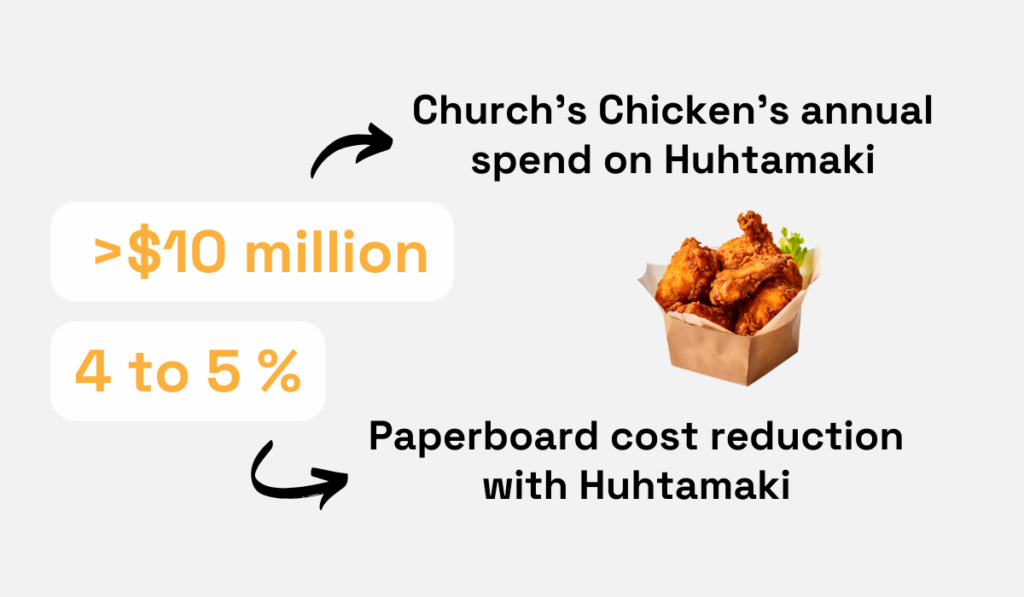

Church’s Chicken, an American fast-food chain, for example, slashed its packaging costs by leveraging global procurement.

So, besides just frying chicken, they are also frying up cost savings!

Christopher Ward, the company’s former Senior Vice President of Global Supply Chain, explained their shift from domestic sourcing to a global approach:

Illustration: Veridion / Quote: Inbound Logistics

This led them to collaborate with Huhtamaki, a global food packaging specialist from Finland, to source paperboard from across the pond.

Huhtamaki’s cost-effective production methods helped Church reduce paperboard costs by 4 to 5%, which is a significant feat considering their annual expenditure of over $10 million with the supplier.

Illustration: Veridion / Data: Inbound Logistics

But how is it possible that sourcing packaging from Europe is cheaper for businesses based in the US?

Well, despite transportation costs, sourcing packaging materials from Europe can be cost-effective due to various factors.

European suppliers often benefit from economies of scale, specialized expertise, and innovative production techniques that result in high-quality, competitively-priced materials.

For instance, Huhtamaki can offer affordable solutions because they make products using three different methods—paper, plastic, and molded fiber.

This wide range of products helps them meet their clients’ needs at a good price.

In summary, global procurement empowers you to tap into global markets where labor, material, and production costs are lower.

Ultimately, this translates into cost savings and higher profit margins for your business.

Global procurement offers businesses a key advantage: access to a broader pool of potential suppliers.

With a plethora of suppliers at your fingertips, you have the flexibility to compare options and select those that offer the highest value and most competitive pricing.

Moreover, increased access to suppliers fosters greater competition among them, which in turn can drive down costs and elevate product quality.

As suppliers vie for your business, they may offer improved terms, innovative solutions, and enhanced service levels to secure your partnership.

Source: Veridion

But the benefits don’t stop there.

When you have access to more potential suppliers, you can also work with more suppliers that are dispersed geographically.

Why does this matter?

Because working with more suppliers protects you from supply chain disruptions and makes you more resilient.

This is particularly crucial in today’s dynamic business environment, where unforeseen events can significantly impact supply chains.

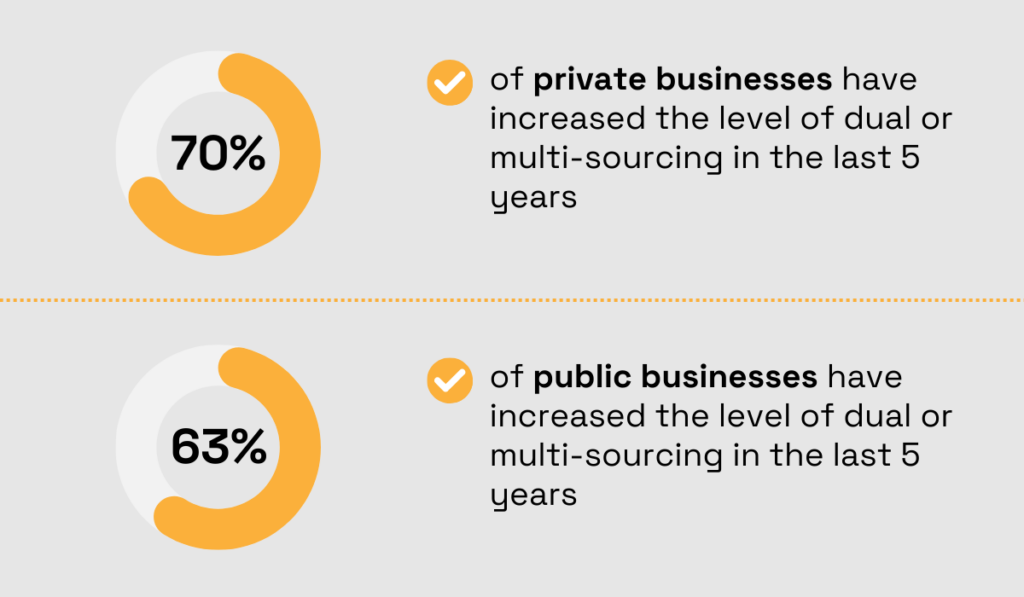

In fact, Deloitte’s survey from 2022 shows that organizations recognize this, given that as much as 70% of private and 63% of public businesses have increased the level of dual or multi-sourcing.

Illustration: Veridion / Data: Deloitte

This indicates a growing awareness of the need to mitigate supply risks by engaging with more than just one supplier.

John Dickson, Chief Procurement Officer at AstraZeneca, offers a valuable perspective on this matter:

“Dual sourcing is good procurement, but it is not always about having multiple suppliers per product. By engaging with supplier organizations with the capacity to support us across a network of local geographies, we ensure resilience is embedded in our supply chain to help us mitigate supply risks.”

He emphasizes that, while dual sourcing is advantageous, it’s also essential to collaborate with suppliers that are capable of supporting you across diverse local geographies to ensure resilience in the supply chain.

To recap, global procurement empowers businesses with access to diverse suppliers, which fosters competition, drives cost efficiencies, and fuels growth.

And last but not least, having access to more suppliers enables you to work with more of them, which makes you more resilient in the face of supply chain disruptions.

When it comes to innovation, global procurement puts the power in your hands.

By working with suppliers from different parts of the world, you have the chance to dive into a sea of fresh ideas, technologies, and processes.

Imagine you’re a manufacturing company, and you want to upgrade your production processes.

By engaging with suppliers from countries like China, renowned for their technological advancements, you can tap into state-of-the-art manufacturing equipment and automation systems.

These innovations, widely adopted in China but perhaps not yet available domestically, have the potential to revolutionize your operations, making them more efficient and streamlined.

Or, let’s take, for instance, Apple and their ever-growing success.

A key factor behind Apple’s groundbreaking products lies in their collaboration with global suppliers and their ability to innovate.

Among Apple’s suppliers is BOE Technology, a leading Chinese display panel manufacturer.

This company entered the market in 2003 and has since become the industry’s leader, primarily due to its commitment to technological innovation, as Si Da, the company’s Vice President and Chief Brand Officer, points out:

Illustration: Veridion / Quote: China Daily

In 2023 alone, they submitted over 90,000 new ideas for patents.

More than 90% of these were for new inventions, showing their commitment to creating innovative products or technologies.

To achieve this, the company invested more than 7% of its revenue into research and development (R&D) activities.

It’s crystal clear that when you source from such suppliers, you open opportunities for growth and innovation in your business.

Together, you can brainstorm ideas, co-create solutions, and push the boundaries of what’s possible.

Expanding your supplier network globally may initially raise concerns about maintaining consistent product quality.

It’s a valid worry, often echoed by procurement professionals like yourself.

However, the truth is, venturing into global sourcing can actually enhance the quality of your materials and goods.

But how does global procurement lead to better quality?

The visual below sums it up:

Source: Veridion

One key factor is the stringent quality control processes implemented by global suppliers.

Before their products even hit the market, these suppliers undergo rigorous checks and reviews, ensuring that every item meets the highest standards of quality.

This commitment to excellence translates into peace of mind for you, knowing that the products you source globally are held to the same high standards as those from domestic suppliers.

Moreover, global procurement opens doors to suppliers with specialized expertise and cutting-edge technology.

These suppliers often possess unique capabilities and innovative solutions that can elevate the quality of your products, as we explained earlier.

What’s more, by collaborating with such partners, you gain access to superior materials and goods that meet—and often exceed—your quality expectations.

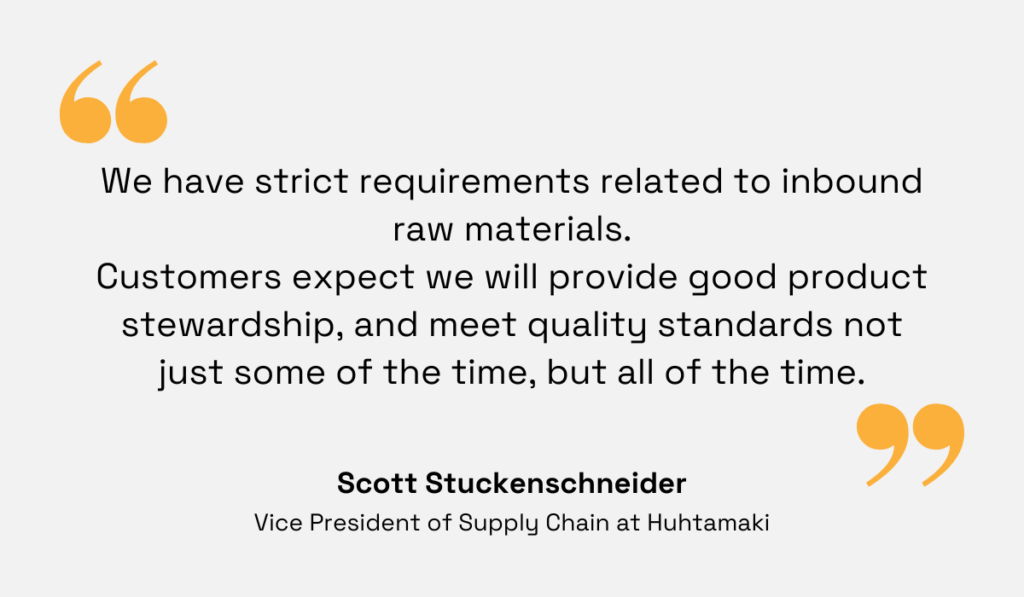

Remember Church’s Chicken, which opted to source paperboard packaging through Huhtamaki?

They, too, had concerns about the product quality.

However, their decision to source from Huhtamaki was driven by Huhtamaki’s reputation for delivering market-leading products rooted in a steadfast commitment to quality.

With strict requirements for inbound raw materials, Huhtamaki ensures that every product meets the highest standards of excellence, providing consistent quality assurance for Church’s Chicken and its customers.

Huhtamaki’s Vice President of Supply Chain, Scott Stuckenschneider, explains:

Illustration: Veridion / Quote: Inbound Logistics

So, global procurement isn’t just about expanding your supplier base—it’s also about getting better quality.

Tapping into global markets and collaborating with top-tier suppliers can help you access higher-quality materials and goods, and even set new standards for excellence in your industry.

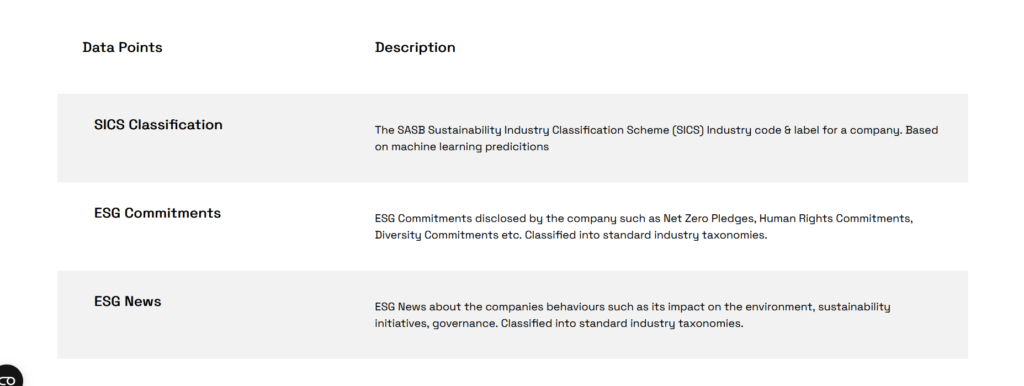

Global procurement can also help you make strategic decisions that drive long-term value for your organization.

One of those decisions is implementing sustainability practices in your procurement.

And today, sustainability is a cornerstone of corporate responsibility, brand reputation, and resilience.

Also, when you prioritize sustainability in your procurement strategy, you reduce your carbon footprint and contribute to a more ethical and socially responsible supply chain.

And while local sourcing may seem like the greener option due to shorter transportation distances, global sourcing can offer unique and often more extensive sustainability benefits.

For example, sourcing materials from regions with abundant renewable resources or advanced eco-friendly technologies can result in more sustainable production processes and lower environmental impact overall.

But how do you find suppliers that share your commitment to sustainability?

Veridion, our supplier sourcing platform, offers a solution.

Source: Veridion

Through Veridion’s search API, which can easily integrate into your systems, you can access a vast network of global suppliers and comprehensive data on their environmental, social, and governance (ESG) practices—as well as other real-time data.

Below, you can see which ESG data Veridion provides:

Source: Veridion

This resource empowers you to identify suppliers that align with your sustainability objectives and make informed decisions in supplier sourcing.

In a nutshell, global procurement enables you to integrate sustainability into your strategic decision-making processes, driving positive environmental and social impact while creating enduring value for your organization and stakeholders.

If, until now, we haven’t convinced you that you should procure globally, strategic sourcing and the sustainability factor should be that one defining benefit.

Have you ever found yourself grappling with supply shortages? What impact did that have on your business?

Did you experience production delays and couldn’t meet customer demand? Or have to incur additional costs to expedite shipments, find alternative suppliers, or implement rush production schedules?

All these are the negative effects of supply shortages.

Now, why do supply chain shortages happen in the first place?

The reasons are several:

All of these challenges become more pronounced—and more likely to affect you—when you rely on a single supplier or depend on suppliers primarily from a single region.

Gap Inc. experienced similar challenges due to the COVID-19 pandemic.

In 2021, with over 30% of Gap’s production taking place in Vietnam, the company faced inventory shortages when the country underwent a full lockdown for two and a half months.

Additionally, they had to spend $450 million in air freight expenses to mitigate shipping delays of that inventory that was available.

Could Gap Inc. have done something differently in keeping their supply in stock?

We can’t say for certain, as no one was truly prepared for the COVID-19 pandemic.

However, when looking back, global procurement does present itself as a strategic solution to the challenge of supply shortages due to unforeseen circumstances.

When you source globally, you reduce reliance on single suppliers or regions, thus mitigating the risk of supply shortage.

So, even if one region suffers from supply chain disruptions, the other may not.

This way, you mitigate the impact of localized disruptions or fluctuations in supply and avoid shortages.

This enables you to maintain consistent inventory levels, fulfill customer orders on time, and adapt to changing market conditions more effectively.

And as a matter of fact, Gap Inc. recognized this as a solution, too, as their then-CEO, Sonia Syngal, explained:

Illustration: Veridion / Quote: Supply Chain Dive

All in all, by sourcing globally, you can diversify your supplier base.

In turn, this helps you reduce supply shortages, as well as mitigate other supply chain disruptions more effectively.

Which makes it another great benefit of global procurement.

As you can see, global procurement opens many doors and brings various opportunities.

By expanding your supplier network globally, you gain access to a wider array of options, allowing you to identify cost-effective alternatives and choose the best partners for your needs.

In addition, collaborating with suppliers from different parts of the world brings fresh perspectives and innovative solutions to your business, fostering growth and competitiveness.

Finally, global procurement enables you to diversify your supplier base, build a more resilient supply chain, and mitigate risks of disruptions.

Overall, the advantages of global procurement are diverse and impactful.

If you want to reap these benefits in your procurement, our final piece of advice is this: start sourcing globally!