The Ultimate Guide to Global Procurement

In today’s interconnected global economy, the procurement landscape has undergone a profound transformation.

More precisely, the advent of digital technologies and the emergence of complex supply chains spanning continents have exponentially expanded the scope and significance of procurement.

As businesses strive to remain competitive in this dynamic environment, the strategic adoption of global procurement has emerged as a cornerstone of success.

In this guide, we delve into the essence of global procurement, its pivotal role in driving organizational growth and resilience, and the strategic steps and pillars that underpin its implementation.

Global procurement, also known as global sourcing, is the strategic process of sourcing raw materials, goods, and services from suppliers located worldwide to meet the needs of an organization.

Unlike more traditional procurement, which typically focuses on local or regional suppliers, this type of procurement encompasses sourcing activities on a global scale, leveraging a network of suppliers across different countries and regions.

Source: Veridion

For instance, a company might be procuring electronic components from manufacturers in China for cost efficiency, while its products are assembled at its production facility in the USA.

Meanwhile, it might partner with research institutes in South Korea to outsource some of the services needed to develop new cutting-edge technology, leveraging the country’s expertise and innovation capabilities.

Simultaneously, the company could be sourcing packaging materials from suppliers in Europe to ensure high-quality packaging and compliance with industry standards.

This diversified approach allows the company to source essential components, streamline product innovations, and secure high-quality packaging materials from around the globe, optimizing its procurement performance and enhancing competitiveness.

This simple example underscores the importance of global procurement, which is the topic of our next section.

Global procurement plays a crucial role for companies looking to optimize their supply chains, reduce costs, mitigate risks, and expand their presence in the global marketplace.

That’s not surprising, considering that people were trading goods across the globe long before the advent of the internet and other technological advances, which revolutionized and supercharged this process.

More precisely, widespread online interconnectivity enabled companies to access resources and markets beyond their local boundaries, driving the need for strategic global procurement practices.

As articulated by procurement professional Sjoerd Goedhart, there are two main reasons why global procurement makes sense for companies:

Illustration: Veridion / Data: Procurement Tactics

It’s evident that global procurement offers significant advantages for companies, which only start with the two primary ones:

In essence, global procurement allows companies to procure resources and expertise that may not be available domestically, while also enabling them to reduce costs by sourcing from regions with competitive pricing.

Beyond these fundamental benefits, companies can leverage global procurement to:

For instance, by sourcing globally, companies can discover not only new suppliers but also new clients, thereby gaining access to new markets or customer segments.

Similarly, companies can elevate the quality of their products by procuring high-quality materials and components from specialized suppliers around the world.

Moreover, companies can diversify their sourcing locations and suppliers, reducing their dependence on a single region or supplier and increasing supply chain resilience.

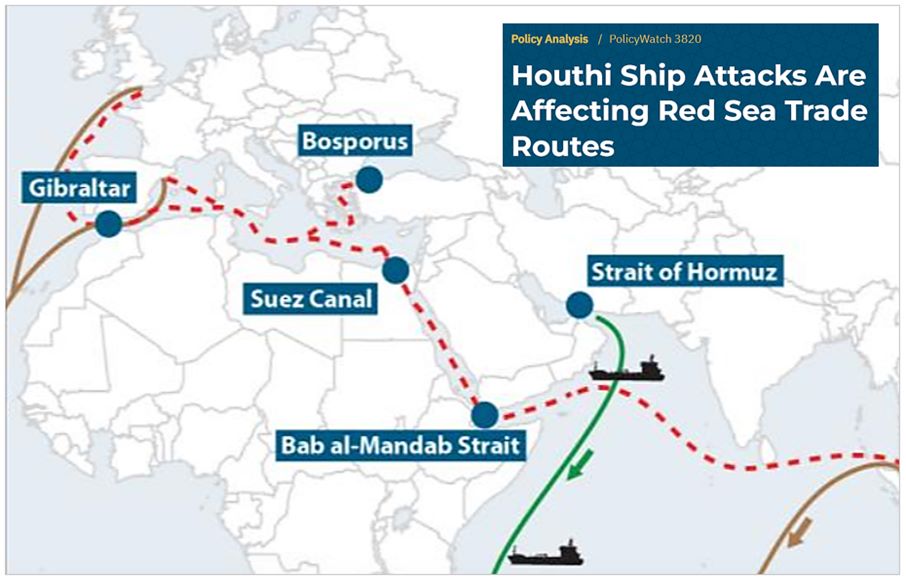

This diversification helps mitigate risks associated with suppliers’ own sourcing or financial issues, political instability or natural disasters in their countries, or disruptions on specific transport routes.

Source: Washington Institute

As fittingly illustrated, it should be acknowledged that all these advantages of global procurement also come with some inherent risks and challenges that must be carefully managed.

For example, companies may be faced with complex importing procedures, trade bans, quality control issues, hidden costs, or currency fluctuations, to name only a few.

To effectively navigate these challenges and capitalize on the benefits of global procurement, companies should implement strategic processes and utilize procurement automation tools.

In the following section, we’ll explore how these strategies and tools are applied throughout the five stages of global procurement.

Considering the importance of global procurement and the related complexities, risks, and challenges, it’s essential for companies to establish and follow a structured approach to their procurement processes.

Naturally, this approach overlaps with sourcing activities and checks applied to selecting any supplier, whether local or global.

That said, global procurement typically involves five key stages, each crucial for ensuring successful outcomes and mitigating risks.

Now, let’s see what they are.

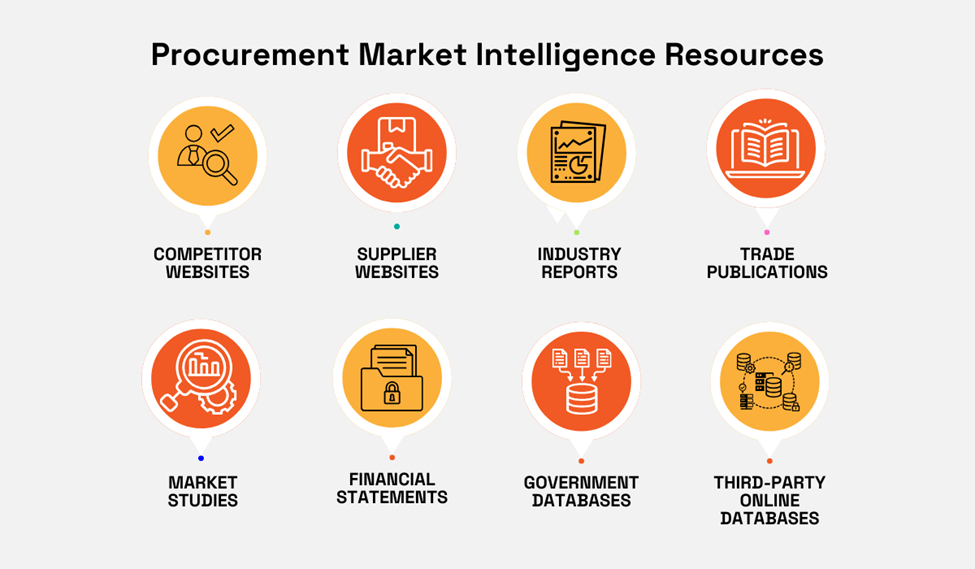

During the preliminary research stage, companies delve into extensive market analysis and supplier research to gather crucial information for informed decision-making.

For example, let’s consider a multinational corporation seeking to source raw materials globally for its manufacturing operations.

In this stage, the company would conduct thorough market research to identify potential suppliers of those raw materials, assess market trends, and understand regulatory requirements in different regions.

To do so, it can utilize various resources for gathering procurement market intelligence, as illustrated below.

Source: Veridion

After preliminary research, the company should have a comprehensive understanding of market and supplier landscapes around the world, enabling it to make informed decisions in the next stage of global procurement.

In this stage, companies rigorously assess potential suppliers and market conditions to ensure alignment with their procurement objectives.

This involves evaluating suppliers according to a range of criteria, from supplier capabilities and reliability to compliance with industry standards.

Simultaneously, companies analyze market dynamics, such as demand trends, competitive landscape, and regulatory factors, to identify opportunities and mitigate risks.

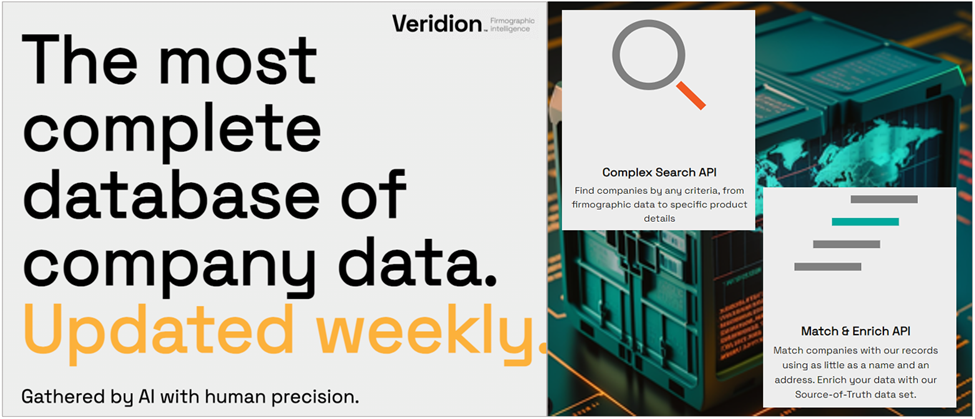

To do so quickly and efficiently, companies can leverage advanced supplier-sourcing tools like our Veridion.

Source: Veridion

By leveraging Veridion’s global supplier database with over 80 million companies and 200 million products and services in conjunction with its advanced search APIs, your team can save valuable time and resources.

More precisely, they can find potential suppliers that fit very specific procurement criteria in minutes instead of days or weeks.

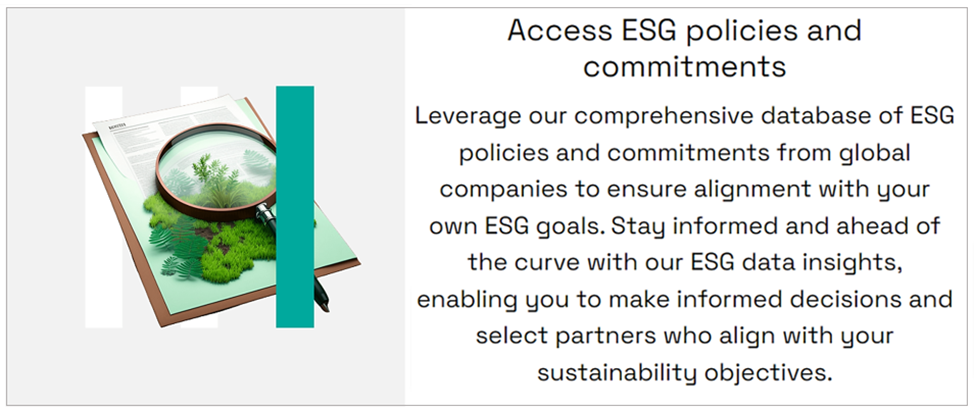

Likewise, they can use Veridion’s database to evaluate suppliers’ risk factors—such as the geographical locations of their facilities, track record, and reputation—as well as compliance with environmental, social, and governance (ESG) standards.

Source: Veridion

For instance, a company seeking to source electronic components globally might focus on potential suppliers’ production capacity, quality control measures, and adherence to ESG requirements.

Coupled with examining their local market environment, such as pricing trends, competitors, and geopolitical factors, companies can anticipate challenges and optimize their sourcing decisions.

This thorough evaluation process lays the foundation for selecting the most suitable suppliers to effectively fulfill your procurement needs.

Once suppliers and markets are evaluated, your procurement team can move to selecting the most suitable supplier based on your company’s specific requirements and criteria.

In this stage, supplier capabilities, performance history, pricing structures, and delivery terms are further scrutinized.

Then, the team can proceed to negotiate, draft the contract agreement, and establish a relationship with the chosen supplier.

The ultimate goal is to select suppliers that not only meet quality and reliability standards but also offer the most value and strategic advantages to the company’s supply chain.

During the implementation stage, the focus shifts to executing what was agreed with the selected supplier.

This involves finalizing their contract, establishing supply chain processes, and integrating suppliers seamlessly into the company’s operations.

For instance, this means defining order fulfillment procedures, delivery schedules (lead time), and quality control mechanisms.

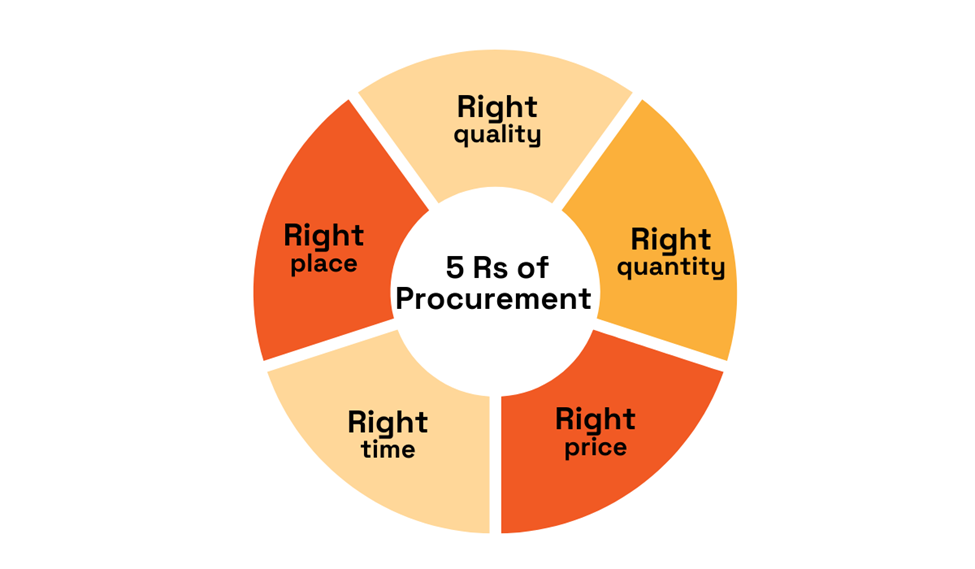

In essence, you want to ensure that the 5 Rs of procurement will be adhered to.

Source: Veridion

Additionally, you should establish clear communication channels and protocols (especially when dealing with overseas suppliers in different time zones) to ensure smooth coordination and collaboration throughout the procurement process.

Overall, a successful implementation stage will ensure that the procurement objectives are translated into actionable steps and that the necessary infrastructure is in place to support ongoing procurement activities.

After everything is put in place, the process of supplier performance monitoring should be implemented to ensure that procurement activities align with your company’s goals and standards.

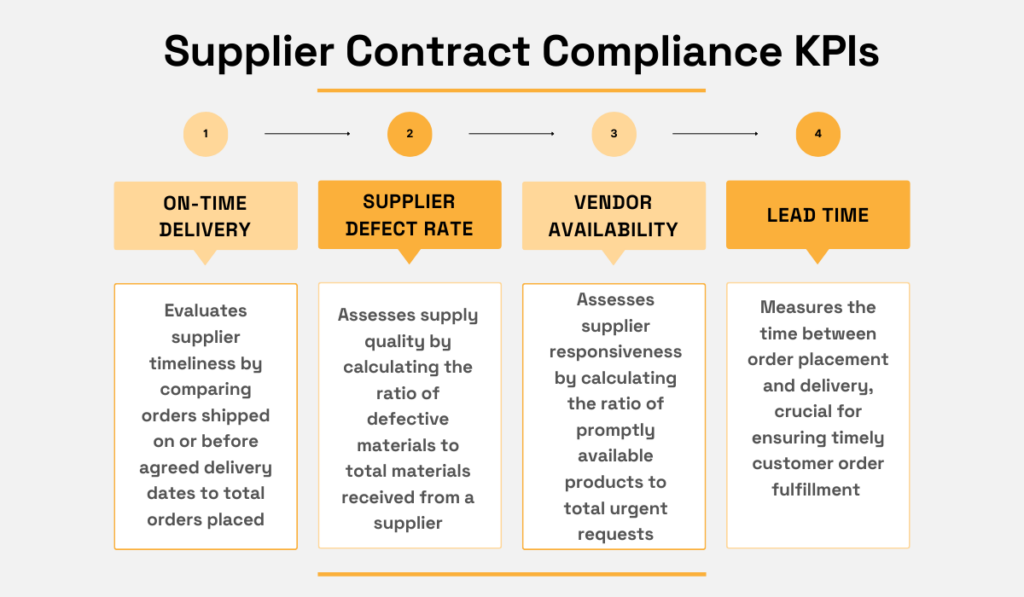

This involves continuously monitoring supplier performance by tracking key performance indicators (KPIs) such as delivery times, product quality, and compliance levels.

Here are a few KPIs typically used to monitor a supplier’s compliance with the agreed contract terms:

Source: Veridion

This ongoing process enables companies to identify and promptly address any issues or deviations that may arise, i.e., make necessary adjustments to optimize supplier performance and maintain competitiveness in their respective markets.

Each of the five described stages of global procurement is interconnected and critical for effectively and efficiently achieving your company’s objectives in the global marketplace.

Having covered what global procurement is, its importance, and key stages, let’s see what your organization needs for its sourcing efforts to be successful.

Naturally, the four pillars of global procurement described below largely overlap with resources used for more traditional local or regional procurement.

However, they may involve specific considerations, tools, and procedures aligned with the specific requirements of global procurement.

So, let’s explore how people, processes, technology, and supply chains should come together to achieve the best possible results in global procurement endeavors.

The success of global procurement relies heavily on the expertise, skills, and collaboration of people involved in the process.

This includes members of your procurement team, selected suppliers, and other stakeholders, such as logistics partners, market experts, and legal or financial advisors.

Moreover, your team of external experts should leverage their knowledge of cultural sensitivities and negotiation techniques specific to individual countries and markets.

Of course, effective communication, relationship-building, and cross-cultural understanding are essential for fostering strong supplier relationships and navigating international business environments.

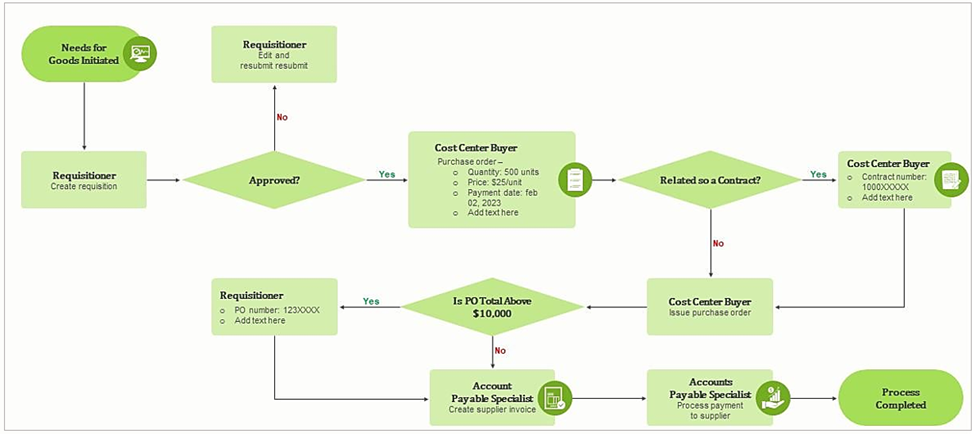

A well-defined and streamlined procurement process is crucial for ensuring consistency, efficiency, and compliance in global procurement activities.

This involves establishing clear procedures for supplier selection, contract negotiation, risk management, and performance monitoring.

Many companies establish a single procurement procedure that is followed for all purchases a company makes, like the example below.

Source: Slide Team

Moreover, standardizing processes across company departments and suppliers helps minimize errors, reduce cycle times, and improve overall procurement outcomes.

In addition to standardization, continuous process improvements are key to adapting to changing market conditions and driving procurement cost savings.

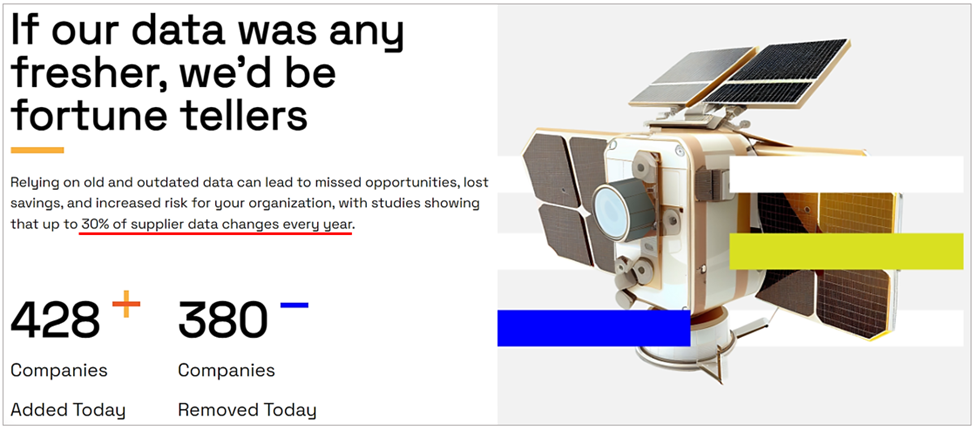

Technology plays a vital role in modern procurement by providing tools and platforms to automate, optimize, and streamline various procurement activities.

This includes procurement automation solutions like e-procurement systems, supplier relationship management software, analytics tools, and big data platforms that provide up-to-date supplier and market information.

Source: Veridion

Leveraging technology enables companies to enhance transparency, visibility, and control over their procurement processes, facilitating better decision-making and supplier collaboration.

Suffice it to say, utilizing procurement tools becomes even more important when sourcing globally.

The efficiencies and data-driven insights gained through technology can be further enhanced by ensuring integration between relevant enterprise systems.

Arising from the three above pillars and the five stages we covered, an efficient and resilient supply chain is essential for successful global procurement operations.

This involves establishing robust logistics networks, inventory management systems, and risk mitigation strategies to ensure the timely delivery of raw materials, components, and other supplies.

Source: Veridion

Collaboration with suppliers, freight forwarders, and third-party logistics providers helps companies optimize transportation routes, minimize lead times, and reduce supply chain disruptions.

Finally, integrating sustainability principles in procurement practices and monitoring supplier performance contribute to building a reliable, sustainable, and resilient global supply chain.

So, while exploring the definition, significance, key stages, and pillars of global procurement, we’ve underscored the critical role played by strategic processes, technological innovations, and collaborative efforts in this process.

As such, global procurement serves as a foundation for businesses seeking to enhance their supply chain efficiency, lower expenses, and extend their reach in the international market.

By embracing the right procurement tools and methods, companies can navigate the complexities of global procurement with confidence, ensuring sustainable growth and competitiveness in an increasingly interconnected world.