How to Improve Your Procurement Lead Time

In the realm of supply chain management, procurement lead times play a crucial role.

They ensure timely product delivery to customers and facilitate the smooth operation of your company by providing workers with everything they need.

With that in mind, in this article, we’ll explore six effective ways to enhance your procurement lead time.

From strengthening ties with existing suppliers to exploring new ones and embracing innovative strategies, these approaches promise to reshape your procurement landscape.

In this section, we’ll focus on how to enhance procurement lead times in situations where you have already selected your preferred supplier and are now negotiating their contract.

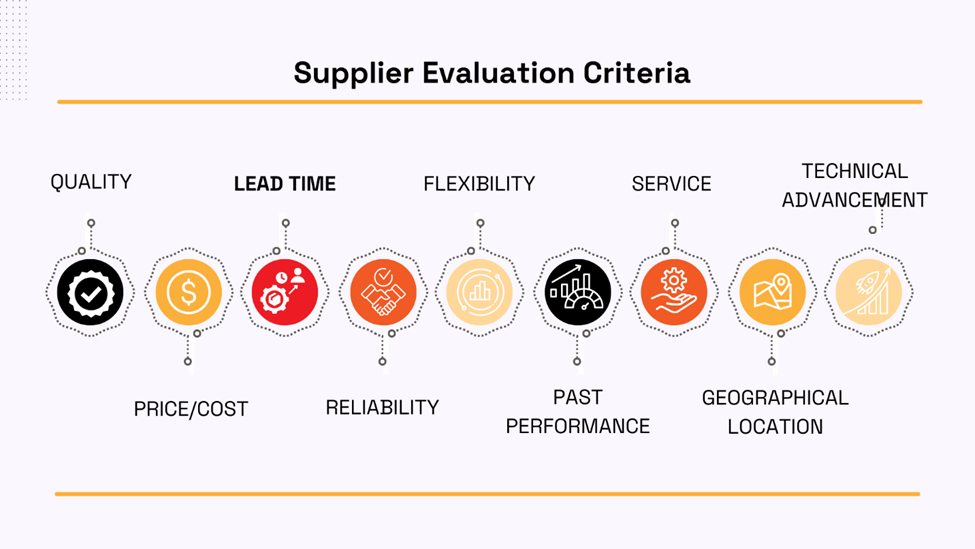

This implies that the chosen supplier underwent a rigorous evaluation based on various criteria, ensuring factors such as price, quality, and notably, lead time, were thoroughly assessed before making the selection.

Source: Veridion

Having completed this rigorous supplier evaluation process, you’ve now progressed to the critical stage of finalizing your future supplier’s contract.

During contract negotiations, integrating specific lead time provisions becomes a strategic move that can significantly impact the efficiency of your procurement process.

These lead time-related clauses should meticulously outline crucial details such as the expected lead time for each delivery of materials/components/products you’re sourcing from that supplier.

Clearly defining these timelines establishes a shared understanding between you and the supplier, ensuring alignment on delivery expectations.

Naturally, you should also specify that any damage to delivered supplies should be borne by the supplier.

Simultaneously, they should stipulate the same with their logistics service provider, if applicable.

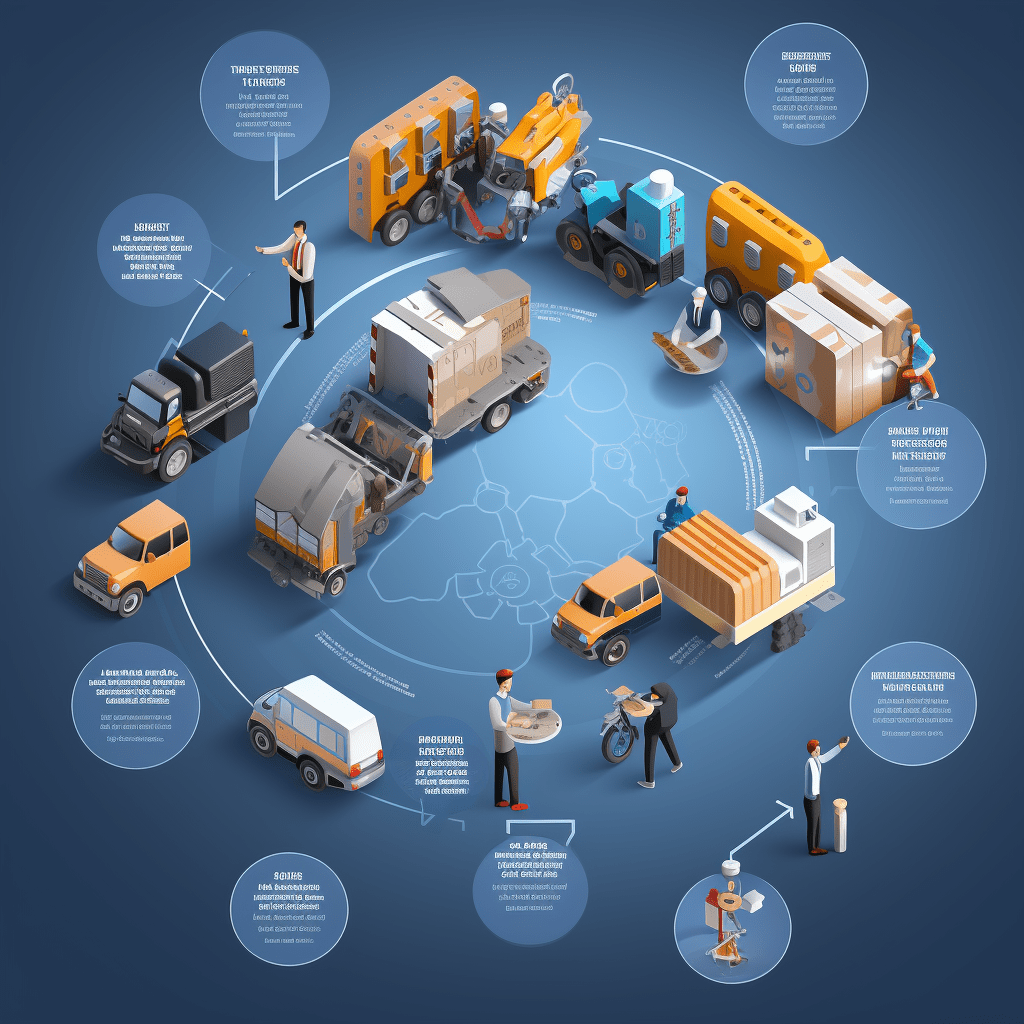

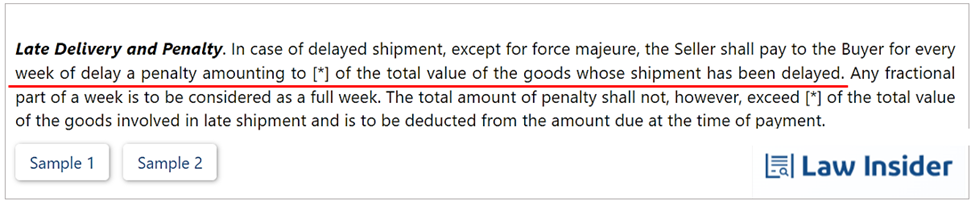

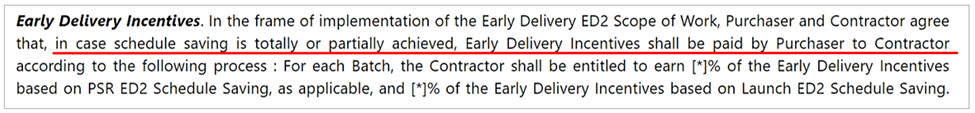

Another crucial element to consider is the establishment of penalties for late deliveries, as illustrated below:

Source: Law Insider

As you can see, this clause excludes force majeure events like natural disasters, pandemics, or other circumstances beyond the control of your supplier, ensuring a fair and practical approach to penalty enforcement.

That aside, similar penalty provisions in your supplier contracts can ensure adherence to agreed-upon procurement lead time.

Conversely, you can also consider incorporating incentives for early deliveries.

This proactive approach encourages suppliers to exceed expectations, resulting in a win-win situation.

Here’s an example:

Source: Law Insider

For suppliers, early delivery incentives don’t necessarily need to be monetary but can range from more favorable payment terms to priority consideration for future contracts.

Likewise, consider stipulating that the supplier must give advance notice of any proposed changes, whether because the prices of their raw materials increased, their stocks are depleted, or their supply chain is disrupted.

Overall, integrating these elements into your supplier contracts means that lead time expectations are clear, and a system of penalties and rewards is established, both of which can help you improve procurement lead times.

Knowing what your company’s procurement needs will be and sharing them with your suppliers can help them better prepare for your upcoming orders, allowing you to improve procurement lead times.

Of course, to share your demand forecasts, you first need to have them.

More specifically, demand forecasting is a pivotal aspect of effective supply chain management, particularly for large enterprises.

Accurate demand forecasts provide a glimpse into their future product demand based on historical data, market trends, and other influencing factors.

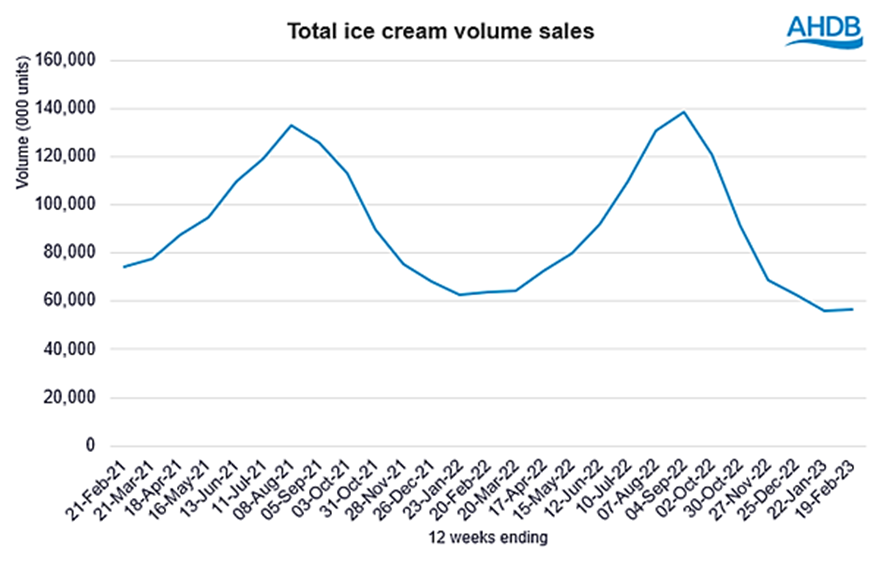

The ice cream industry exemplifies how seasonal variations impact demand, guiding manufacturers to manage stock levels and orders from suppliers accordingly.

Source: AHDB

Aware of this seasonality, ice cream manufacturers can strategically tailor production and stock levels to meet the fluctuating demand during scorching summer months.

If their demand forecasts are accurate, they can inform suppliers of their exact needs, thereby avoiding potential stockouts.

However, if their forecasts are off, there’s a risk of inadequate product availability or overstocking, emphasizing the importance of precision in demand forecasting.

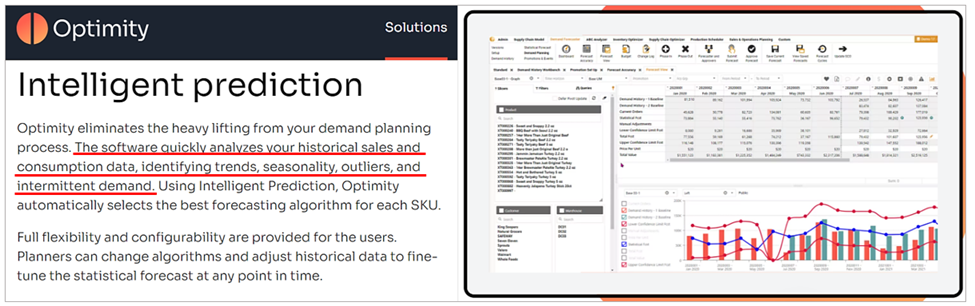

In today’s world, technology provides essential tools for replacing demand planning guesswork with data-driven demand plans.

Source: Optimity

As highlighted, such software tools take your historical sales data to make accurate future demand predictions.

Combined with procurement market intelligence, this allows you to share your company’s forecasted demand figures with suppliers, including expected fluctuations, seasonal variations, and any other relevant insights.

From there, you can engage in collaborative planning sessions with key suppliers, allowing them to provide specific insights and refine their own forecasting capabilities.

Moreover, you can consider introducing incentives for suppliers who demonstrate accuracy in aligning their production and lead times with your demand forecasts.

Overall, accurately forecasting your future demand and clearly communicating those forecasts to your suppliers can significantly improve procurement lead times.

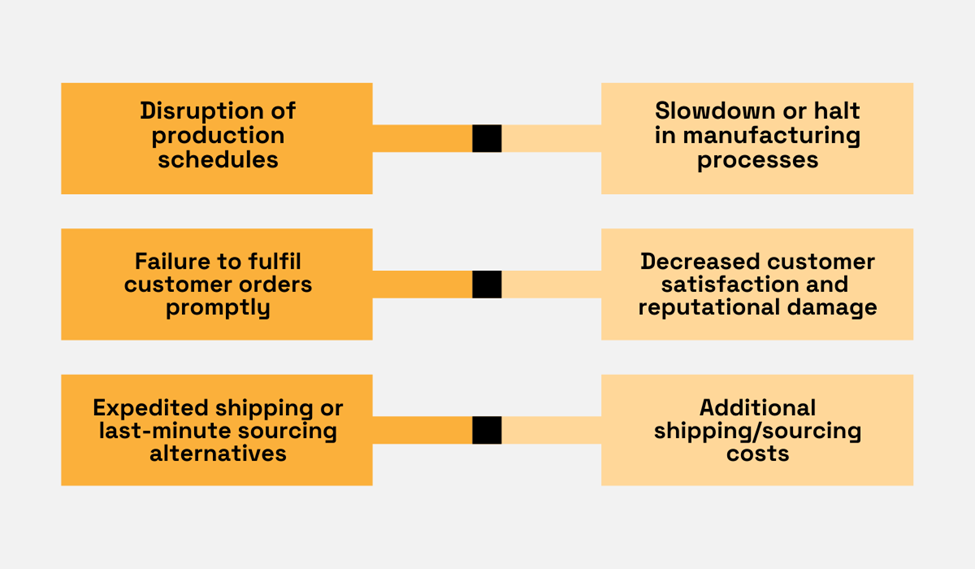

Efficient procurement relies on a network of dependable suppliers, so any glitches in this process caused by unreliable suppliers can create a ripple effect throughout your entire supply chain.

Consider a scenario where your supplier keeps failing to meet the agreed-upon lead time for the delivery of raw materials or product components your company needs for smooth operation.

As illustrated below, this can have a number of severe consequences:

Source: Veridion

Faced with these ramifications, it’s clear that unreliable suppliers can cause significant disruptions in your supply chain, leading to delays, stockouts, and potential damage to your company’s reputation.

Naturally, unreliability in suppliers can manifest in various forms beyond continuously extended lead times—from inconsistent product quality to communication breakdowns and financial instability.

In such cases, it becomes imperative to reassess your supplier relationships and, if necessary, find more reliable suppliers.

However, that can be a complex and time-consuming process, which is why many companies rather stick to their old suppliers despite the consequences.

This is where advanced supplier sourcing solutions like our Veridion can simplify and expedite the process of finding new, trustworthy suppliers.

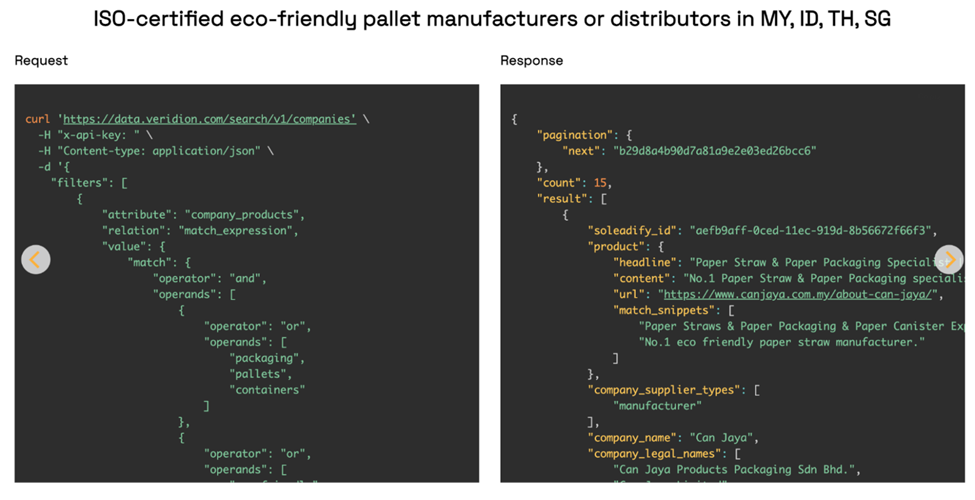

Source: Veridion

Simply put, Veridion provides an AI-curated, weekly updated, most comprehensive database of suppliers around the globe along with advanced search features (APIs).

By using these functions, you can find potential suppliers that meet your precise procurement needs in seconds instead of days, weeks, or even months.

Moreover, the search results come with confidence scores, allowing you to better evaluate the reliability of prospective suppliers according to any criteria you set.

As shown below, Veridion’s search is based on natural language input, meaning there’s no need for setting complex parameters to find suppliers that match your criteria.

Source: Veridion

With quick access to a diverse range of suppliers, each vetted for reliability and performance, you can streamline the identification and onboarding of trustworthy suppliers.

Overall, the ability to swiftly replace unreliable suppliers with credible alternatives offering more dependable procurement lead times can help you minimize disruptions and fortify the resilience of your supply chain.

Another way to reduce procurement lead times is to source from suppliers closer to you, as this significantly reduces the time (and risks) related to shipping from distant locations.

Although offshoring more affordable suppliers has been all the rage until a few years ago, this has significantly changed.

More precisely, the downsides of procuring goods from far-away destinations became painfully apparent for a number of reasons, such as:

Alongside natural disasters and geopolitical conflicts, these events have seriously impacted global supply chains, as discussed in many articles like the one by McKinsey shown below.

Source: McKinsey

Even without these disruptions, using suppliers who are closer to home (in your city, region, or a nearby country) can substantially improve your procurement lead times.

So, what can you do to find reliable nearshore suppliers?

As mentioned, you can easily discover them with Veridion by searching for those suppliers located in proximity to your company’s operations.

This will also help you conduct thorough market research on prospective suppliers, helping you mitigate any potential risks (including those related to your existing suppliers).

Source: Veridion

Once you’ve evaluated and short-listed potential suppliers, consider conducting on-site visits to assess their facilities and capabilities.

In addition to shorter lead times, using nearshore suppliers also:

In summary, nearshoring your procurement not only improves lead times but also brings about a range of operational benefits that contribute to the overall efficiency and robustness of your supply chain.

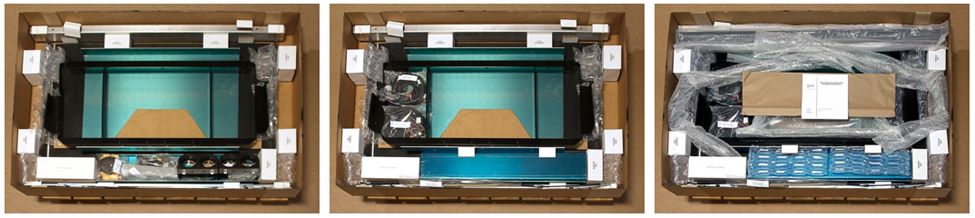

In terms of procurement lead times, kitting refers to your supplier bundling together the materials and components you’re sourcing from them into a single package (“kit”).

For instance, let’s say your company regularly sources electronic components, wires, and connectors from one supplier for your manufacturing processes.

Instead of receiving these items separately, each with its own shipping schedule, kitting allows you to receive them all together.

Source: Specialty Resources

Depending on your contractual arrangements, this bundling process can reduce shipping costs and expedite your inventory management processes, leading to shorter lead times between ordering supplies and using them to manufacture your company’s products.

However, even if your supplier doesn’t offer kitting services, you have the option to leverage it internally.

This involves grouping items at your warehouse after one or more suppliers deliver them.

While this may not impact your suppliers’ lead time, internal kitting can again reduce the time between placing an order and integrating delivered items into your production process.

All in all, leveraging product kitting is a practical way to enhance lead times and streamline your supply chain processes.

Preferably, this should be done by your supplier or, alternatively, it can be handled internally.

If you’re accustomed to placing substantial bulk orders from your supplier, believing it’s a cost-effective strategy, it might be time to reevaluate the impact this has on your procurement lead times and overall operational efficiency.

More precisely, it might turn out that smaller orders lead to faster deliveries, helping you improve lead times.

However, since every business has its nuances, you should first perform a total cost analysis, which serves as a valuable tool to identify the most efficient order fulfillment method for your organization.

Such analysis involves considering the multifaceted nature of your procurement costs, as illustrated below.

Source: Veridion

Understanding these submerged elements empowers you to make informed decisions, whether in favor of bulk purchase orders or smaller, more frequent shipments.

Moreover, the total cost analysis illuminates the intricacies of your procurement expenses, from hidden costs like order processing to inventory carrying, exposing complexities in decision-making.

The key lies in finding the optimal balance between order size and frequency to align with your unique business needs.

If the analysis shows that more frequent orders would improve not only your procurement lead times but also operational efficiency, consider transitioning towards this agile approach.

This can expedite shipments and also contribute to enhanced inventory turnover, crucial for navigating dynamic, fast-paced markets.

To recap, consider embracing a model of smaller, more frequent orders, as it can result in shorter lead times, enhanced inventory turnover, and increased operational agility.

It’s clear that optimizing your procurement lead times is essential for enhancing operational efficiency and maintaining a competitive edge in today’s dynamic business landscape.

From specifying lead times in supplier contracts and relying on reliable suppliers to embracing product kitting and more frequent orders, there are various strategies you can explore.

In doing so, advanced software solutions can provide invaluable support by streamlining demand forecasting, simplifying supplier sourcing, facilitating market research, and enabling data-driven decision-making.

By harnessing smart strategies and leveraging the power of technology, you can improve your procurement lead times, and unlock new levels of efficiency, agility, and resilience in your supply chain operations.