7 Biggest Challenges of Global Procurement

Procurement might seem simple at first sight: identify the needs, choose suppliers, and receive goods.

However, the reality—particularly in global procurement—is much more complicated.

Sourcing from around the world presents unique challenges, such as grappling with complex logistics, supply chain disruptions aggravated by distance, managing currency fluctuations, and bridging cultural gaps.

Today, we’ll dive into these challenges and provide solutions to overcome the complexities of global procurement.

Let’s get started.

When you’re tasked with sourcing goods or services from suppliers scattered across the globe, managing the logistics behind it all can become quite a challenge.

Especially considering the different regulations and customs procedures each country has—from customs clearance to import duties and taxes, not to mention customs valuation, tariff classifications, and trade agreements.

And let’s not forget about the mountain of documents you have to deal with:

Source: Veridion

They all have to be accurate and compliant, and you have to have them readily available when needed.

If you don’t comply with these procedures, you risk delays, penalties, or even the seizure of goods.

Not exactly what you signed up for, right?

Mohamed Saeed, Procurement Manager at Add Link Group, brings up another layer of challenge—transportation infrastructure.

It varies in different countries, adding another hurdle to an already complex process:

“In many developing countries, roads, ports, and airports, may be inadequate or underdeveloped, making it challenging to transport goods efficiently.”

It’s no wonder, then, that developing countries often find themselves at the bottom of the list when it comes to logistics performance.

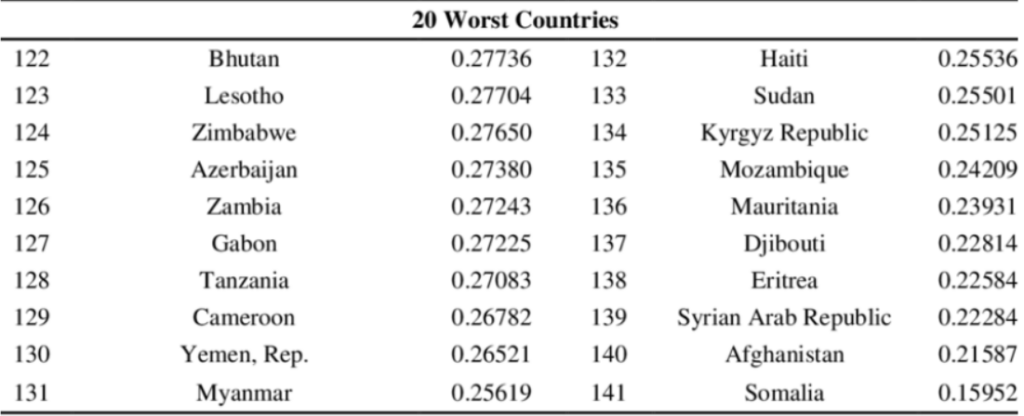

Source: Reserach Gate

And to make matters worse, these countries are also more prone to cargo theft.

Take South Africa, for example, which is one of the top countries affected by cargo theft, according to the 2020 Cargo Theft Report.

As evident, logistical complexities range from logistics procedures to transportation disruptions as well as theft.

So, how do you tackle these logistical nightmares head-on?

First and foremost, you must be aware of all the logistics procedures and all the documentation you need.

It’s essential to dot your i’s and cross your t’s to avoid any hiccups along the way.

Secondly, forge strong partnerships with reliable transportation and logistics providers who understand the complexities of international sourcing.

These partners should provide various transportation options that meet your needs, whether it’s sea, land, or rail transport.

Take KoçZer, for instance—they’re a Turkish global logistics provider offering just that.

Source: KoçZer

Collaborate closely with these partners to streamline processes, optimize routes, and navigate regulatory hurdles effectively.

And finally, leverage technology solutions to enhance visibility into logistics and transportation.

Implementing supply chain management software or tracking systems can give you real-time insights into the status of shipments and help identify potential issues before they escalate.

With the right strategies and partners by your side, you can conquer the logistical challenges of global procurement.

Geopolitical instability, natural disasters, trade disputes, and other unforeseen events can all disrupt supply chains and affect global procurement.

And the consequences can range from delays and material shortages to increased costs.

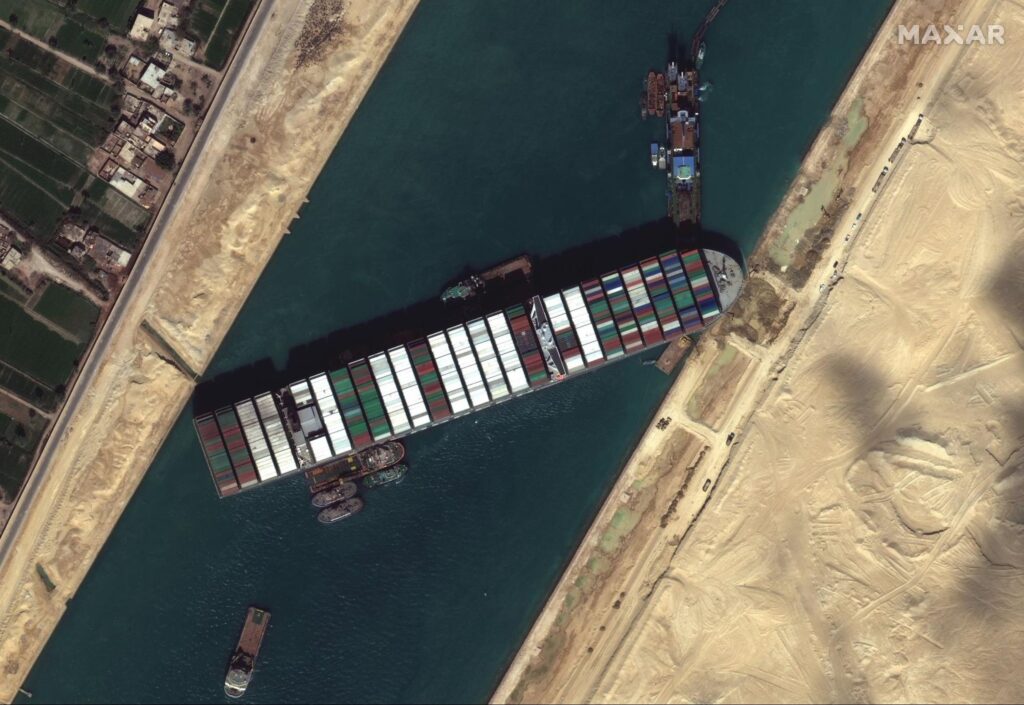

Recent years have seen various disruptions, ranging from more predictable, like labor issues at California ports and the Russia-Ukraine war, to the completely unexpected, such as the COVID-19 pandemic or the grounding of a container ship in the Suez Canal.

The impact of these disruptions on global procurement cannot be understated.

Take, for instance, the Suez Canal incident, which halted global trade at an estimated cost of $10 billion per day during the six days the ship remained stuck.

Source: CNBC

The ship stuck in the canal caused the rerouting of maritime traffic, which led to extended transportation times and increased expenses.

Naturally, this exacerbated delays in delivering goods to buyers and customers.

Not only that, but the blockage of the Suez Canal also disrupted the flow of approximately 1.5 million barrels of crude oil per day, which influenced global oil prices.

While many countries maintain ample oil reserves, Syria, which is embroiled in civil war, for example, faced fuel rationing due to delays in receiving a crucial tanker shipment from Iran.

The severity of these consequences shows just how important it is to have proactive measures in place to mitigate supply chain risks.

One vital solution is better supply chain visibility and agility.

By leveraging technologies like IoT sensors and fostering collaboration with partners, you can better anticipate and respond to disruptions.

In addition to improving visibility, implementing robust risk management strategies is essential:

Source: Veridion

This includes diversifying supplier sources geographically to reduce dependence on single suppliers or regions prone to disruptions and maintaining adequate inventory levels as a buffer against sudden supply shortages.

On top of that, establishing alternative transportation plans ensures flexibility in case of transportation disruptions, such as port closures or route blockages.

Finally, clear force majeure contract language provides legal protection in unforeseen circumstances.

These clauses outline specific events, such as natural disasters or political unrest, that may excuse parties from contractual obligations.

Such a contract will also help you navigate supply chain disruptions with more resilience.

And while supply chain disruptions are inevitable, proactive measures and strategic planning can minimize their impact and safeguard the continuity of global procurement operations.

One of the most critical challenges in global procurement is ensuring consistent product quality across diverse suppliers and regions.

While some suppliers prioritize durability, performance, and adherence to stringent quality controls, others may focus solely on cost-efficiency, risking products prone to malfunctions or defects.

This variability can stem from economic conditions, industry practices, and supplier capabilities, making it challenging for procurement professionals to identify and partner with reliable suppliers that meet their quality requirements.

On the other hand, collaborating with suppliers who do not prioritize quality, combined with poor quality control practices, can lead to a series of issues.

A prime example is the Samsung Galaxy Note 7 debacle in 2016 when their newest phones started exploding.

Source: NDZ

According to Samsung, the culprits were faulty batteries that lacked protective tape and had welding defects.

While the faulty batteries were, indeed, the supplier’s fault, Samsung’s management failure in quality control processes (as well as some design issues) also played a significant role.

If nothing else, this incident highlights the pressing need for stringent quality control and regular audits.

However, this challenge can be addressed at its root by sourcing reliable suppliers committed to delivering quality products.

You may wonder how to source such global suppliers.

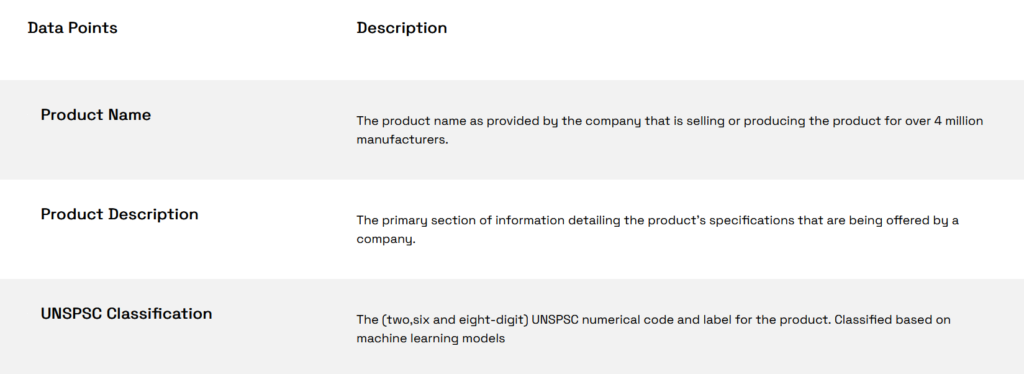

Take, for instance, our global supplier sourcing enabler, Veridion.

Through its complex search API, Veridion provides access to data on millions of global suppliers, including firmographic data and product specifications, in mere minutes.

Source: Veridion

By leveraging Veridion’s accurate and up-to-date data on suppliers, you can identify and partner with suppliers that prioritize quality, thereby minimizing quality-related risks in global procurement.

What’s more, Veridion’s granular control over confidence scores, custom-made risk factors, and real-time alerts keep you one step ahead in risk management.

Source: Veridion

Consider the advantage of receiving immediate alerts if a supplier’s product certification is revoked or quality rates plummet.

Equipped with such a tool, you’re always ahead in managing your suppliers and their quality.

To recap, while maintaining consistent product quality in global procurement may seem daunting, it’s all about choosing the most reliable suppliers who prioritize product quality.

And, of course, regularly controlling that they stay on track in delivering that quality.

However, navigating the landscape of global procurement isn’t just about finding the best suppliers.

It’s also about ensuring compliance with complex regulatory frameworks and trade barriers that vary from country to country.

Global procurement involves steering through a maze of regulations, tariffs, and import-export rules, all while tackling the challenges of protectionism—a practice aimed at shielding domestic industries from external competition by imposing tariffs on imports.

In this dynamic environment, staying informed about regulatory changes and trade agreements is essential for procurement teams.

You need to be proactive, constantly monitor updates that could impact your global procurement activities, and adapt your strategies accordingly.

It’s like being on a ship navigating through ever-changing waters.

However, doing this on your own is the real challenge.

To navigate these regulatory waters effectively, you should invest in training and hiring or consulting with experts versed in international regulations, compliance, and trade agreements.

Still, international trade laws are subjected to frequent revisions.

For instance, in 2024 alone, the EU introduced seven new regulations impacting European supply chains.

Illustration: Veridion / Data: Maersk

In light of this, relying solely on human supervision to stay updated is a daunting task.

That’s where robotic process automation (RPA) steps in as a technological ally.

By automating procurement processes and cross-referencing them against legal stipulations, RPA minimizes the risk of non-compliance that could lead to legal repercussions.

Here’s how it works:

The bots are programmed to extract relevant clauses related to regulatory compliance from the contracts.

Then, they cross-reference them against legal stipulations, such as labor laws and environmental regulations specific to each country.

If any discrepancies or violations are detected, the RPA bots flag them for review by the procurement team.

In essence, the challenge of regulatory compliance in global procurement is formidable but manageable with the right approach.

By staying informed, investing in expertise, and leveraging technological solutions, you can stay on top of regulatory requirements and ensure smooth sailing through global procurement waters.

Even though they are a natural part of the global economy, currency fluctuations are also a challenge in global procurement.

Consider this: you’re tasked with overseeing procurement operations, and suddenly, exchange rates shift.

Now, if you are not prepared, this can have severe consequences.

Exchange rate fluctuations can:

Overall, they can introduce volatility and uncertainty into global procurement processes.

That’s why it’s crucial to closely monitor exchange rates and implement strategies to mitigate associated risks.

One strategy is to use forward contracts.

With such contracts, you agree to purchase (or sell) a predetermined amount of currency at a fixed exchange rate on a future date.

Illustration: Veridion / Quote: Investopedia

This provides you with certainty and stability in your procurement costs, regardless of how the exchange rates may fluctuate in the meantime.

On the other hand, currency swaps involve exchanging one currency for another with a counterparty, typically at the spot rate, and then reversing the exchange at a specified future date.

This allows you to hedge against currency risk by swapping your exposure to one currency for exposure to another, potentially more stable currency.

And in case you are working with suppliers from a region or country with a high percentage of inflation or other disruptions, you can also include escape clauses in your contracts.

These clauses give you flexibility and allow you to renegotiate or terminate contracts in response to significant currency fluctuations or other unexpected events.

In summary, while currency fluctuations challenge global procurement, practical strategies such as forward contracts, currency hedging, and contract escape clauses help mitigate this risk.

Managing data security is paramount for global procurement operations, given the widespread sharing of sensitive information with suppliers and partners worldwide.

This raises significant concerns about data protection and confidentiality.

Procurement departments handle a plethora of sensitive data, from financial details like bank accounts and credit cards to personal information such as social security numbers, names, addresses, and phone numbers.

Additionally, company-sensitive data like bids, contracts, and other confidential documents are also at risk of exposure.

As highlighted by the Chartered Institute of Procurement & Supply, the repercussions of a cyberattack on procurement systems can be severe:

“Procurement professionals should care because a cyberattack could breach invoicing and purchase order systems, allowing the attack to control spending and disrupt business, which could cost money to recover from.”

Given the reliance on digital tools and interconnected supply chain networks, procurement organizations are increasingly vulnerable to cyber threats.

Hence, it is essential to implement robust cybersecurity measures, secure data transmission channels, and establish contractual agreements to safeguard confidential information and intellectual property rights.

Moreover, collaborating with logistics providers and suppliers that prioritize cybersecurity is equally important.

Suppliers, too, can inadvertently become the source of data breaches due to inadequate system security, malicious insiders, or mishandling of information by staff members.

That’s why it’s essential to hold them accountable for their cybersecurity practices through contractual agreements.

On the other hand, when it comes to logistic providers, a cyberattack on them means problems for you, too.

For example, Expeditors International of Washington Inc., a global logistics company, was hacked in February 2022.

Source: WSJ

The attack disrupted their operations, leading to significant delays and financial losses for both the company and its clients.

And this was not an isolated incident.

Just weeks before, hackers had hit two fuel logistics companies in Germany and firms based at ports in the Netherlands.

This warns us about the interconnected nature of data security risks across procurement, supplier networks, and logistics.

So, make sure to collaborate with vigilant partners and implement robust cybersecurity measures.

Only then can you mitigate these risks and uphold the integrity of sensitive information.

Interacting with suppliers, partners, and stakeholders from diverse cultural backgrounds and languages can be challenging.

Different cultural norms, communication styles, and languages create a melting pot of potential misunderstandings and misinterpretations.

What’s more, these factors are deeply ingrained and can’t simply be changed, adding more complexity to procurement processes.

Let’s say that your supplier misinterpreted a request, resulting in the delivery of the wrong components.

A seemingly minor miscommunication can snowball into a major issue impacting operations and relationships.

In global procurement, the consequences of this can be complex and include:

To tackle these challenges effectively, clear communication protocols must be in place to ensure accurate message conveyance and understanding among all parties.

These protocols may involve using translators or interpreters when language barriers exist, ensuring nothing is lost in translation.

Cultural sensitivity training is also invaluable, fostering awareness and understanding of diverse cultural norms and practices among procurement teams.

Moreover, technology can help you bridge cultural divides.

For example, communication platforms equipped with language support or translation tools facilitate seamless interaction, break down language barriers, and enable collaboration across borders.

And yes, cultural barriers can present formidable challenges in global procurement.

But they also offer opportunities for growth and learning.

By prioritizing effective communication, cultural sensitivity, and leveraging technology, you can overcome this challenge and nurture strong relationships with suppliers and partners from diverse cultural backgrounds.

In the end, it pays off more than you might think.

As we saw today, global procurement faces many challenges, from logistic complexities, supply chain disruptions, and regulatory requirements to cultural barriers and data privacy concerns.

However, with the right approach and effective strategies, all of these can be overcome and even turned into opportunities for growth.

Prioritizing strong supplier relationships, implementing robust risk management protocols, leveraging technology, and staying vigilant are essential components that will help you on this journey.

We hope the insights gained today will empower you to tackle and triumph over the challenges of global procurement.

Best of luck!