Global Procurement: Step-by-Step Guide

Global procurement opens doors to new opportunities and brings some great benefits.

However, this process demands careful planning, and specific steps must be taken to reap those benefits.

Today, we’ll take you through all the essential steps of embracing global procurement, from understanding your needs to securing reliable suppliers and drafting contracts.

Whether you’re a seasoned professional or new to the global procurement game, such a carefully planned approach to global procurement will help you transfer your procurement to the worldwide sphere—and do it with confidence.

Let’s get started.

Every procurement journey begins with recognizing the essential need for acquiring goods or services, whether they’re as mundane as office supplies or as critical as raw materials for production.

This principle holds true for global procurement as well, where the process starts with a deep dive into the needs of your procurement department and your organization as a whole.

So, before taking the plunge into global procurement, you must have a crystal-clear understanding of what your organization truly needs.

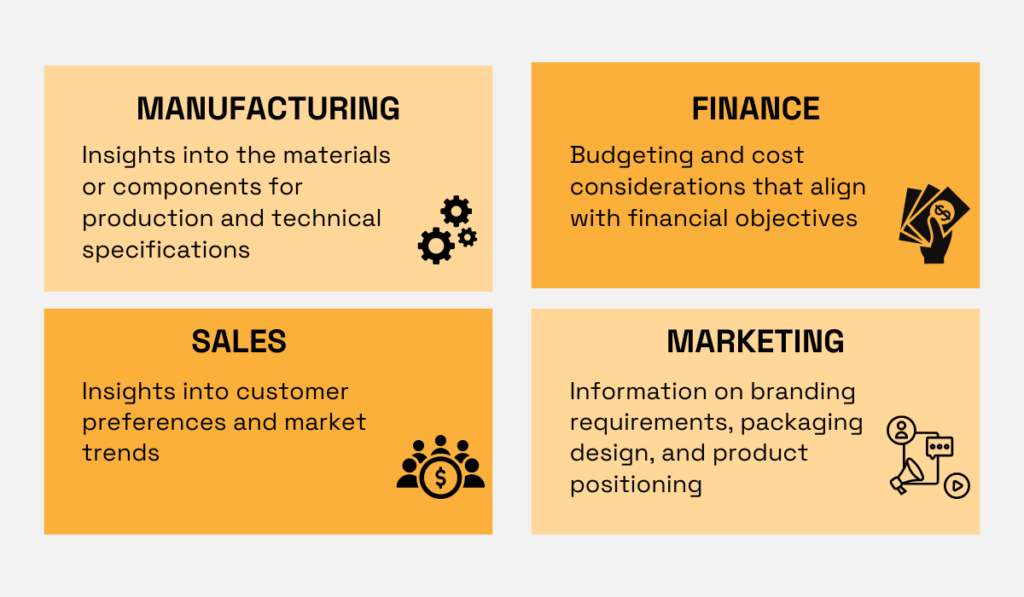

Naturally, this entails gathering insights from various departments, such as manufacturing, finance, sales, and marketing, as each department offers unique insights into the company’s procurement needs:

Source: Veridion

With the data gathered, you’ll identify several critical aspects:

Additionally, at this initial stage, it’s essential to assess the clearance requirements for imported goods.

Are there any special import restrictions, permits, licenses, standards, or regulations to adhere to?

When you have all this information ready, you can more easily search for suppliers who can provide you with just what you are looking for.

However, your organization’s needs might go beyond acquiring specific products or services.

For instance, management, procurement, and finance might collectively identify the need for more cost-effective products or services than those previously purchased.

Or, perhaps issues have arisen due to overreliance on suppliers from a single region, so there is a need to diversify supply chains.

Alternatively, maybe you want to expand your product range, requiring sourcing from new markets.

Source: Veridion

As you can see, organizational needs often branch out in various directions, so it’s important to be as thorough as possible at this stage.

The needs identified here will shape your entire global procurement process.

Finally, your organizational needs will direct you to which supplier market to research—which is your next step in global procurement.

Once you’ve identified your organization’s needs, it’s time to select the geographic regions or markets for sourcing goods or services.

This decision hinges on the requirements identified earlier.

For instance, if your priority is reducing supply chain risks, considering nearby markets through nearshoring might be beneficial.

A North American company could explore sourcing from Mexico or Canada to diversify its supplier base and reduce reliance on distant suppliers.

On the other hand, if cost reduction is the goal, researching markets with lower labor and raw material costs is crucial.

For instance, a clothing manufacturer might seek textiles from countries like Bangladesh or Vietnam.

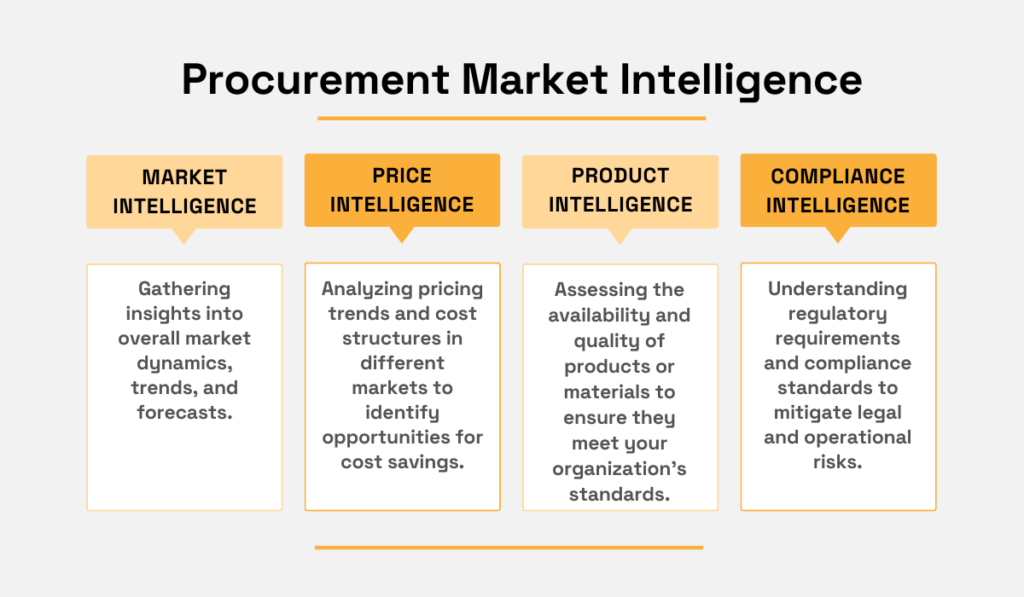

When choosing potential supplier markets, it is important to research the ins and outs of procurement market intelligence, including the following four components:

Source: Veridion

In addition to these factors, you should consider geopolitical stability, trade regulations, and logistical feasibility.

Also, don’t forget to assess available transportation modes and lead times for sourcing from these countries.

Only when you factor in all of the above can you identify potential risks and opportunities associated with different supplier markets.

Wondering where to access this market data?

Market research firms, government agencies, and big data platforms will be your go-to resources.

Government departments and agencies provide data on trade regulations, tariffs, and geopolitical stability.

Meanwhile, big data platforms offer insights into suppliers, market demands, and price fluctuations in real time.

Ultimately, the aim is to select supplier markets that strike the right balance between cost, quality, and reliability, aligning closely with your organization’s strategic objectives.

By assessing all relevant factors and leveraging available resources, you can establish a solid foundation for a successful global procurement strategy.

If the previous step was all about market intelligence, we now shift our attention to supplier intelligence.

In essence, this step entails gathering as much information as possible about potential suppliers from the decided-on markets.

Your task is clear: identify suppliers who can meet your procurement needs by assessing their capabilities, reputation, and reliability.

But before you dive into that, you need to gather information on potential suppliers.

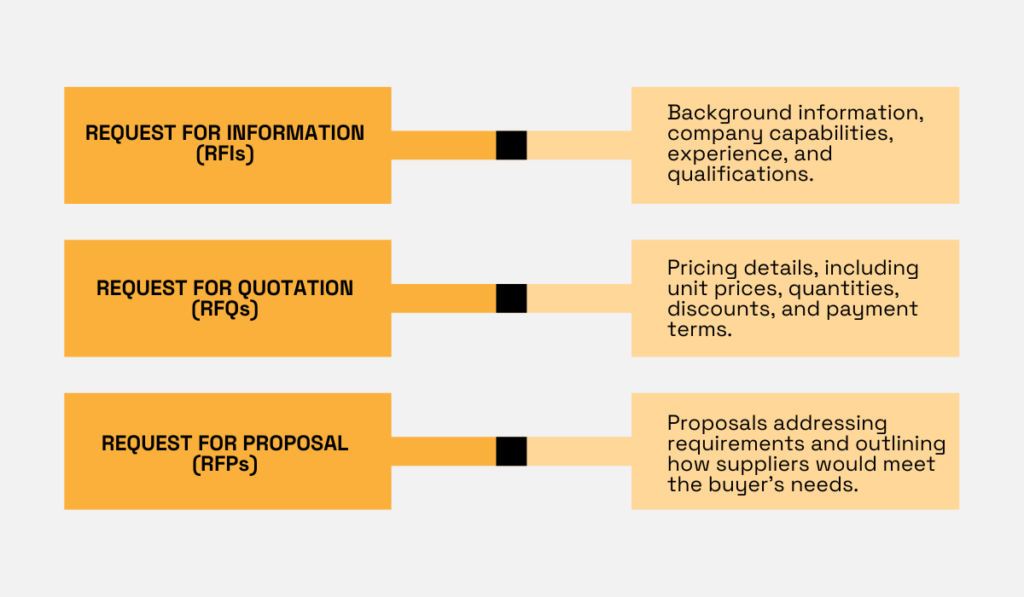

To do this, procurement teams often send out RFIs (requests for information) to suppliers.

RFIs ask for details about the company’s background, sought-after goods or services, product specifications, and other necessary information.

Alternatively, if your main focus is on collecting supplier pricing information (and you know the precise quantities and specifications of products you want to purchase), you can use RFQs (request for quotes).

RFQs solicit pricing details along with specifications, quantities, delivery requirements, payment terms, and evaluation criteria.

For more complex projects, you can turn to RFPs (requests for proposals).

RFPs prompt potential suppliers to provide detailed information and proposals on how they can fulfill your requirements.

Source: Veridion

However, collecting supplier information through these requests—and waiting for suppliers to respond—can be both time-consuming and resource-intensive.

This is where solutions leveraging AI and machine learning help reduce the time to gather supplier information.

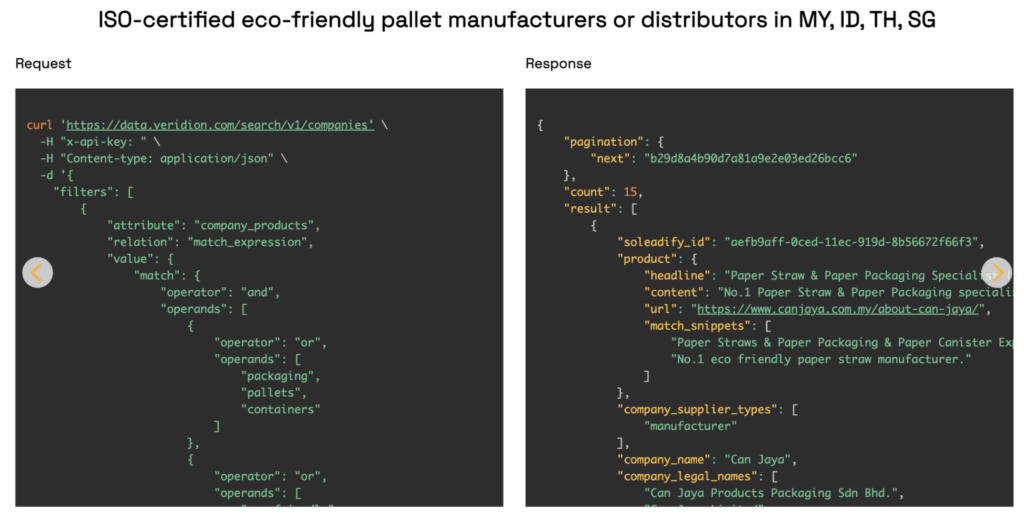

Our supplier sourcing enabler, Veridion, is one of those solutions.

Source: Veridion

Veridion has access to data on over 80 million global suppliers and more than 200 million products, covering everything from firmographic data to product specifications and ESG criteria.

But what sets Veridion apart is its ability to deliver up-to-date data in minutes through APIs, allowing users to input specific criteria and receive precise results.

For instance, if you need to procure pallets from South Asian countries and require manufacturers with ISO certification and sustainability practices, Veridion can provide you with a list of suitable manufacturers.

Source: Veridion

On top of that, Veridion ensures the freshness and accuracy of supplier data.

This ensures you get only the most accurate data on suppliers, unlike with RFIs, where suppliers may not always provide truthful information.

Having access to such quality data is crucial, as it enables informed decision-making when selecting the right suppliers to partner with.

In fact, we can confidently say that this step is the most important one in this guide.

The quality of your supplier data will ultimately determine your ability to select the right partners.

Let’s move on to making that decision.

Selecting the right suppliers is the next critical step in global procurement, and it’s where the rubber meets the road after collecting a wealth of data on potential partners.

At this point, you should compare potential suppliers based on the following key factors:

Let’s outline why each of these matters.

First and foremost, quality is non-negotiable, and there is not much to add here.

It’s the cornerstone of ensuring that the goods or services you procure meet your organization’s quality standards.

So, make sure to assess the quality of each supplier’s product.

Let’s move on to cost. While competitive pricing is attractive, it’s essential to balance it with long-term cost efficiency.

Sure, sourcing from the lowest bidder might seem like a win initially, but hidden costs or quality issues down the line could end up costing you more than you bargained for.

So, before choosing suppliers based on low costs, first reevaluate all the other criteria.

One of them is supplier reliability.

In fact, this is a key to maintaining seamless supply chain operations, especially when you source globally.

Timely deliveries, product consistency, and responsiveness to changes are all critical to consider.

Just imagine you source components for just-in-time manufacturing.

You need suppliers who can consistently deliver on schedule to keep production running smoothly. Otherwise, you risk production halts.

Compliance is another vital aspect to evaluate.

Suppliers must adhere to regulatory requirements and ethical standards to mitigate risks to your organization’s reputation.

Whether it’s food safety regulations or labor practices, ensuring compliance is also non-negotiable.

And let’s not forget capacity. Suppliers should be able to meet your organization’s demands, both now and in the future.

Whether it’s production capabilities or scalability, choose partners who can grow with you.

Once you’ve gathered all this data on your potential suppliers, it would be wise to create scorecards, evaluate each supplier against your criteria, and objectively compare them to identify the best solution.

And one more thing, don’t skip site visits—there’s no substitute for seeing suppliers’ operations firsthand.

In the end, selecting the right suppliers is the linchpin of building robust supply chains and driving organizational success.

So, take the time to evaluate suppliers thoroughly and choose wisely. Your procurement strategy—and your organization’s future—depends on it.

Now that you’ve identified the right suppliers, it’s time to roll up your sleeves and dive into negotiations.

This step involves discussing and finalizing various aspects of the agreement, including pricing, payment terms, delivery schedules, quality standards, and other contractual details.

Several factors come into play during these negotiations, each impacting the final terms and conditions:

| Volume of Purchase | The quantity of goods or services being procured can heavily influence pricing negotiations. Suppliers may offer discounts or preferential rates for larger orders to encourage bulk purchases. |

| Quality Standards | The desired level of quality set by your organization can also affect pricing discussions. Higher quality products or services often come with a premium price tag, reflecting superior craftsmanship or performance. |

| Transportation and Freight Costs | For imported goods, transportation and freight expenses can significantly impact the overall price. It’s crucial to clarify whether these costs are factored into the quoted price or if they’ll be billed separately. |

| Discounts for Prompt Payments | Some suppliers may offer discounts or incentives for accelerated payments, encouraging timely settlements and fostering a positive relationship. |

It’s important that you carefully weigh these considerations and negotiate terms that align with your organization’s objectives.

By putting effort—and skills—into negotiations, you can ensure that the procurement process meets your organization’s needs while maximizing value and minimizing risks.

Effective negotiation strategies can also pave the way for mutually beneficial agreements and long-term partnerships with suppliers.

After completing negotiations, the last step is to solidify the agreements by finalizing contracts.

Contracts are formal documents that outline the terms and conditions agreed upon between your organization and the selected suppliers.

You should ensure that contracts are comprehensive and that they cover all aspects of the sourcing relationship to avoid ambiguity and disputes.

This includes specifying details such as:

This document will make sure that all parties involved are clear on their rights, obligations, and expectations, which will minimize potential disputes and misunderstandings down the line.

Also, it’s essential for contracts to be legally sound, providing a framework for enforcement in case of disputes or breaches.

If that’s not the case, it could leave your organization vulnerable to legal risks and financial losses.

So, you should ensure that contracts comply with relevant laws and regulations governing procurement and contractual relationships.

Contracts should also include mechanisms for dispute resolution and contingency planning.

This means having procedures in place to address disagreements or unforeseen events, such as delays or quality issues, to prevent disruptions in the supply chain and maintain business continuity.

In summary, finalizing contracts is the last critical step in the global procurement process, ensuring that agreements reached during negotiations are documented and legally binding.

By creating comprehensive and enforceable contracts, you can minimize risks, foster stronger supplier relationships, and drive success in your global procurement endeavors.

And here you have it. With these six steps, global procurement doesn’t look so daunting, does it?

Let’s recap the steps.

First, identify your organization’s needs internally, then decide on the supplier market.

Next, collect supplier intelligence by using big data platforms that provide the most accurate and updated supplier data.

Then, carefully assess potential suppliers’ key metrics: quality, cost, reliability, compliance, and capacity, and based on this, select the right suppliers.

Finally, negotiate favorable terms and conditions, and finalize contracts to formalize agreements.

By diligently following the steps we outlined today, you can embark on your global sourcing with confidence.

Best of luck!