5 Global Procurement Trends to Know About

As global markets evolve, so does procurement, responding to supply chain disruptions and market shifts.

This includes diversifying supplier bases for resilience and nearshoring to enhance supply chain control and agility.

Additionally, the growing consumer focus on sustainability is driving businesses towards more sustainable procurement practices.

All these changes are catalyzing new trends in global procurement.

Today, we’ll explore five key trends that companies will have to grasp to stay ahead of the curve and effectively manage their procurement processes.

Let’s get started.

AI is a hot topic these days, and it’s no surprise that its influence extends to global procurement.

With its remarkable capabilities, artificial intelligence is revolutionizing how you approach procurement processes.

One of these capabilities is the one that allows you to analyze vast amounts of data quickly and accurately, which is particularly crucial for supplier discovery and sourcing efforts.

According to McKinsey, AI-powered solutions can reduce the time required to identify suitable suppliers by up to 90% or more.

Illustration: Veridion / Data: McKinsey

This efficiency gain, along with saving time and resources, is invaluable in today’s competitive landscape, where manual research methods fall short.

In fact, a survey by Capterra in 2022 revealed that 90% of small to midsize businesses plan to increase or maintain their investment in emerging technologies such as AI.

Illustration: Veridion / Data: Capterra

One AI-powered solution is Veridion, our supplier sourcing enabler that leverages AI and machine learning algorithms to scour the Internet for supplier data.

Veridion transforms raw data into actionable insights within minutes, providing businesses with a comprehensive and accurate database of global suppliers.

Source: Veridion

This data ranges from firmographic data, including supplier size and locations, to detailed information on product specifications and supplier ESG criteria.

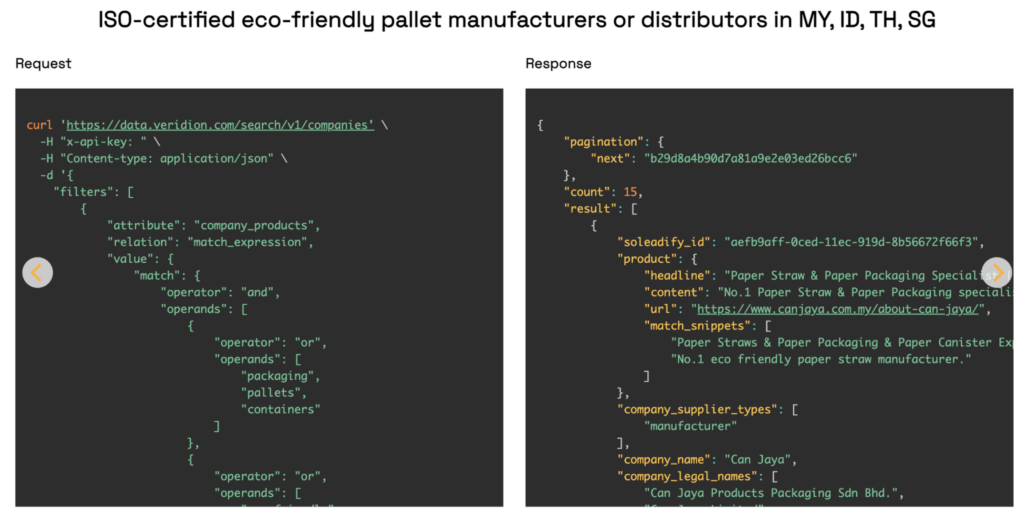

With access to this supplier information through Veridion search APIs, you can make informed decisions and streamline your supplier discovery and sourcing.

Source: Veridion

However, the benefits of AI-powered procurement data extend beyond this.

Through AI-powered analytics, you can gain valuable insights into supplier performance, market trends, and other procurement intelligence, as well as forecast demand more accurately.

For example, AI can analyze historical sales data, seasonality patterns, demographic trends, economic indicators, and even weather patterns or geopolitical events to generate forecasts.

This data-driven approach to procurement enables you to optimize your procurement strategies and mitigate procurement risks.

Overall, the reliance on AI-powered procurement data is driven by the need for efficiency, agility, and resilience in today’s procurement landscape, making it a trend that is bound to continue shaping the industry.

In today’s ever-changing supply chain landscape, businesses seek strategic responses to mitigate risks.

One such response gaining momentum is the diversification of procurement channels, and here’s why it matters.

When you diversify your supplier base across multiple countries, you’re not putting all your eggs in one basket.

This is crucial because it reduces your exposure to risks like geopolitical tensions, natural disasters, and economic instability in single regions.

For instance, imagine if your primary supplier region was hit by a devastating earthquake.

By diversifying your procurement channels, you can source materials from alternative suppliers in the unaffected areas, thereby minimizing—or, in this case, avoiding—supply chain disruptions and ensuring business continuity.

The significance of diversification is highlighted by a 2023 survey by QIMA, a global quality control and compliance service provider.

The survey found that 76% of respondents diversified their supplier geography in the past year alone, a notable increase from 50% in the previous year.

Illustration: Veridion / Data: QIMA

This indicates that more and more businesses are adapting to better handle supply chain disruptions and mitigate risks.

So, if you want to stay in the game, you must embrace this change, too.

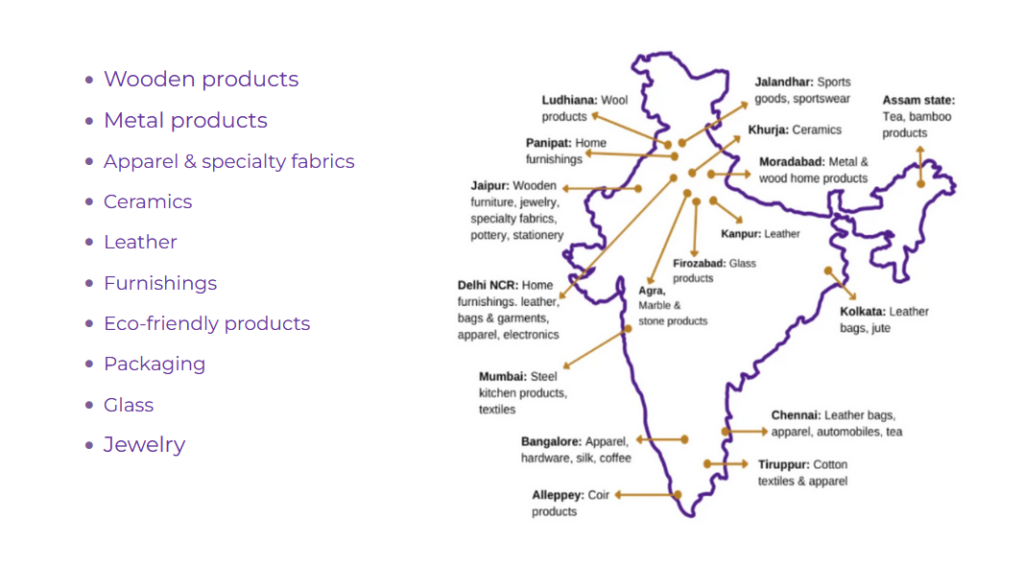

Amidst this trend towards diversification, it’s important to explain which countries are most affected.

Historically, China has been a popular choice for sourcing due to its well-established manufacturing infrastructure and competitive pricing.

However, events like the COVID-19 pandemic and geopolitical tensions between China and the US have exposed vulnerabilities in relying solely on China.

As a result, Vietnam and India have emerged as leading alternatives for diversified sourcing.

Equally favored by US- and EU-based brands (as per QIMA’s report), these countries offer promising options to diversify procurement channels.

They have low labor costs and offer a variety of natural materials, making them compelling and cost-effective regions.

Source: India Sourcing Network

However, despite this trend, China remains a key player in global supply chains, and businesses in Asia recognize its continued significance.

Still, the shift towards diversification is a response to the challenges of global procurement and supply chain disruptions.

By embracing this trend, you can ensure the continuity and resilience of your procurement operations.

Sustainability has shifted from a mere buzzword to a critical priority for individuals worldwide, significantly influencing both consumer behavior and business strategies.

A study conducted by GreenPrint, an environmental technology company, revealed that 78% of consumers prefer buying products labeled as environmentally friendly.

This statistic underscores the increasing significance of sustainability in purchasing decisions, compelling businesses to align with evolving consumer values.

Pete Davis, CEO and co-founder of GreenPrint, explains how this will affect businesses:

“Companies must build trust and loyalty by clearly demonstrating that they share environmental goals with their customers. Defending and preserving our planet is not only the right thing to do, it’s good business. Companies that are able to navigate the business of sustainability will be best positioned for future success.”

This sentiment resonates across various industries, from food and retail to manufacturing.

Businesses increasingly recognize the need to source materials responsibly, reduce carbon emissions, and minimize waste to uphold their environmental and ethical responsibilities.

However, to truly make an impact, companies need suppliers who share their commitment to sustainability.

Collaboration with like-minded suppliers who implement sustainable practices is, therefore, the key ingredient for becoming more sustainable.

Let’s see how companies are doing it.

Orsted, a Danish energy company, puts significant effort into reducing carbon emissions by investing in wind farms and encouraging its supply chain partners to adopt sustainable practices.

Source: Orsted

Across the pond, Seattle Chocolate Company works towards the same goal—becoming carbon neutral, caring more for the planet, and sourcing more ethically.

And they are great at it.

Seattle Chocolate Company is fully transparent about where they source their chocolate from (Peru and West Africa), but they also make sure that they do it ethically and conscientiously, as CEO and owner Jean Thompson explains:

“We work with farmers and the Rainforest Alliance to ensure that the farmers that we buy our cacao from are well compensated, as well as instructed and encouraged to follow good farming practices. Starting at the source is the most critical part of a responsible sustainability practice.”

Second, they work on reducing plastic use by collaborating with the only vendor in the world that produces compostable twist wraps they can use:

Illustration: Veridion / Quote: Green Matters

With its various sustainability practices, Seattle Chocolate Company tries to deliver positive impacts on society, nature, and climate.

As we can see, consumer demands for transparency and accountability continue to rise, which makes sustainability one of the most critical business imperatives.

But it’s not only about meeting consumers’ needs.

It’s about driving positive change, reducing carbon footprint, minimizing waste, preserving our planet, and supporting ethical work practices.

Working with suppliers should be more than just a business transaction, especially when procurement is transferred on a global scale.

Without trust and mutual respect, ensuring timely deliveries, maintaining quality standards, and surviving supply chain disruptions would hardly be possible.

So, it’s no surprise that strengthening supplier relationships and collaboration is a key trend in global procurement.

The benefits of nurturing these relationships extend to both sides.

For your company and procurement department, the advantages are clear:

On the supplier side, strong relationships bring stability and growth.

Suppliers feel reassured knowing they have a reliable partner, allowing them to plan for the future confidently.

What’s exciting is that building connections with customers opens doors to new opportunities and markets, driving business expansion, which is a win-win for everyone involved.

And when relationships benefit both sides, there’s a shared commitment to preserving and nurturing them.

Suppliers often go the extra mile to solve problems and minimize risks in these close-knit, mutually beneficial relationships, ensuring the partnership remains strong and intact.

Moreover, collaborating with the right partners can also propel suppliers toward sustainability.

A multinational consumer goods company, Unilever, takes this approach and ensures its suppliers grow alongside them.

Source: Unilever

As Unilever’s Chief Procurement Officer, Willem Uijen, points out:

“We encourage and support our suppliers on their own sustainability journeys and prioritize those who demonstrate shared values of respect and responsibility for people and planet by committing to our standards around responsible sourcing, sustainability, and human rights.”

This approach to suppliers not only strengthens relationships but also fosters a culture of sustainability throughout the supply chain, benefiting both parties and contributing to a more sustainable future.

In essence, prioritizing strong supplier relationships in global procurement is indispensable.

Only through robust partnerships, collaboration, and mutual trust can companies effectively navigate—and survive—the complexities of global supply chains.

Businesses are changing gears and moving towards nearshoring, especially after facing the disruptions caused by the COVID-19 pandemic and other recent supply chain hiccups.

But what exactly is nearshoring, and why is it gaining momentum?

Historically, companies have sourced suppliers from across the globe, often opting for low-cost manufacturing destinations such as China, as we explained earlier.

However, the pandemic showed the risks of relying on faraway suppliers, making procurement departments reassess global sourcing strategies.

In essence, nearshoring involves relocating manufacturing or sourcing operations closer to the company’s home country or primary market.

For example, Gap Inc., a worldwide clothing retailer, decided to embrace nearshoring to de-risk its supply chain after issues they had during the COVID-19 pandemic when one-third of Gap’s suppliers and production were located in Vietnam.

Former CEO Sonia Syngal explained the need for this in early 2022:

Illustration: Veridion / Quote: Supply Chain Dive

In fact, they plan to increase sourcing in Central America, investing $150 million by 2025.

The reason behind this is to strengthen their supply chain resilience and gain better control.

Let’s see how nearshoring makes this possible.

By sourcing from nearby countries, you can mitigate risks associated with long-distance transportation, border closures, and geopolitical tensions.

This proximity enables greater oversight and responsiveness, ensuring continuity of operations even in turbulent times.

On top of that, nearshoring encourages better communication and collaboration thanks to shared time zones and similar cultures.

This strengthens relationships with suppliers, boosts agility, and speeds up decision-making.

Geopolitical tensions, particularly between China and the US, have further fueled the shift to nearshoring.

And while these tensions alone may not have prompted such significant realignment of supply chains, the COVID-19 pandemic acted as a catalyst, Ashutosh Sharma, a research director at the market-research firm Forrester, points out:

Illustration: Veridion / Quote: Business Insider

In the US, businesses are increasingly turning to countries like Mexico for nearshoring opportunities.

Mexico’s proximity offers shorter lead times, reduced logistic costs, favorable trade agreements, and low labor costs, making it highly attractive.

Even Elon Musk plans to establish an assembly plant for Tesla in Monterrey, Mexico, capitalizing on these advantages.

Similarly, in Europe, the nearshoring trend is on the rise, with 55% of EU-based businesses increasing domestic or regional sourcing, according to QIMA’s report.

This trend reflects a broader shift towards localized supply chains, driven by the need to be more resilient and agile in an unpredictable global environment.

In the five trends we outlined today, we’re seeing a shift in global procurement driven by the necessity to be resilient and adaptable.

From supplier diversification and nearshoring tactics to fostering stronger supplier relationships, they all work towards one goal: ensuring smooth global procurement operations despite supply chain uncertainties.

As these trends become increasingly prevalent across industries and transform into standard global procurement practices, embracing them is essential for staying competitive.

So, now is the time to align your global procurement practices with these trends and secure your organization’s future!