Find and Identify Reliable Suppliers: Our Guide

Key Takeaways:

A supplier with a fake certificate. A one-site factory stuck in a blackout. A sudden bankruptcy in your supply chain.

An organization that hasn’t yet dealt with this or similar scenarios is difficult to find, but in many cases, these risks can be avoided.

The trick is to find and identify reliable suppliers, and that’s exactly what’s explored in this practical guide.

Before engaging a supplier, it’s essential to confirm their legal status.

By verifying whether a company is properly registered and incorporated, you ensure that you’ll be working with a legitimate business entity capable of entering binding agreements.

Skipping this step could expose you to fraud, contract disputes, or abrupt supplier disappearances.

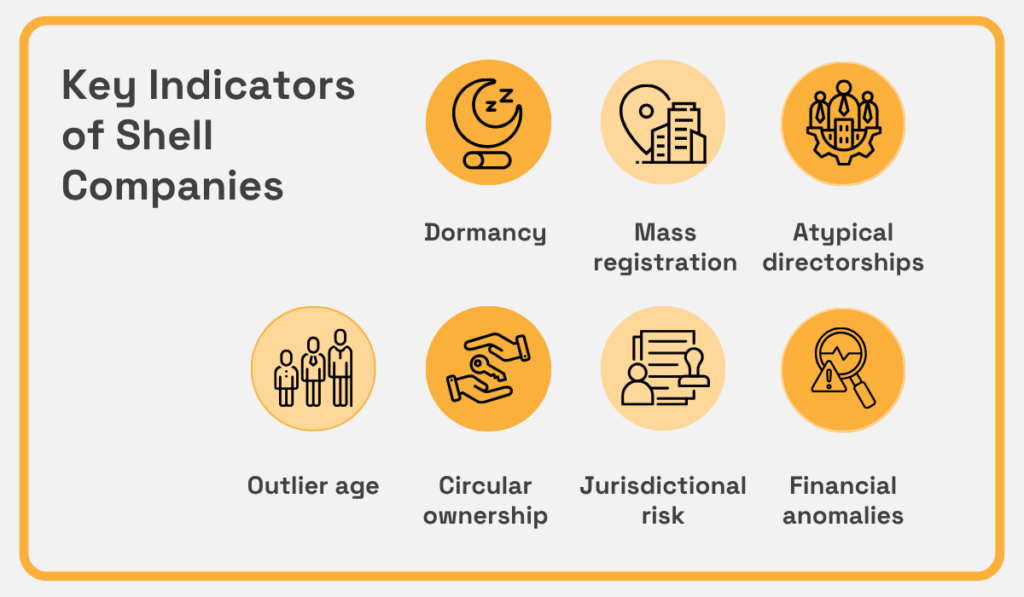

One of the most common risks is unknowingly dealing with a shell company: a business set up to appear operational but lacking any real activity.

Such entities often exist to obscure ownership or sidestep liabilities, but a closer look at the “business” typically reveals several warning signs and anomalies.

Source: Veridion

Of course, it doesn’t even have to be a shell company, but a recently re-registered business.

For instance, imagine entering a contract with a supplier whose business had quietly dissolved months earlier.

The supplier re-registered under a similar name but still has plenty of unpaid debts, exposing you to financial and legal complications in the future.

Moody’s Ted Datta explains that flagging these and similar warning signs on time means sidestepping regulatory issues, but also preserving your company’s reputation.

Illustration: Veridion / Quote: Fintech Magazine

Now, how do you do that?

You can start by consulting the supplier’s national business registry.

In the UK, this might be Companies House, in the US, the Secretary of State databases, and in the EU, platforms like the European Business Registry (EBR) shown below.

Source: EBR

If dealing with international suppliers, consider platforms like Troolio, which aggregate global business verification data.

Source: Troolio

You can also request copies of the supplier’s incorporation certificate and business license, check issue and expiry dates, and search for pending legal actions or bankruptcy filings using local court databases or designated services.

In the end, confirming legal status may feel routine, but it’s the first and simplest step of supplier risk management.

A supplier’s financial health directly affects their ability to deliver goods and services reliably, making it a common procurement risk.

Companies facing insolvency, unpaid taxes, or dwindling cash reserves are considered high-risk partners, as they’re more likely to cut corners on quality or simply fail to deliver.

In a recent example from Formula 1, Mercedes seemed to find itself in a tight spot after its sole engine supplier, Reaction Engines, went bankrupt.

Source: GP Blog

While Mercedes quickly lined up a replacement deal for 2026, things could’ve gone much worse had the collapse disrupted engine supplies for the rest of the 2025 season.

Supplier’s financial failures can halt production entirely, and the best safeguard against it is thoroughness.

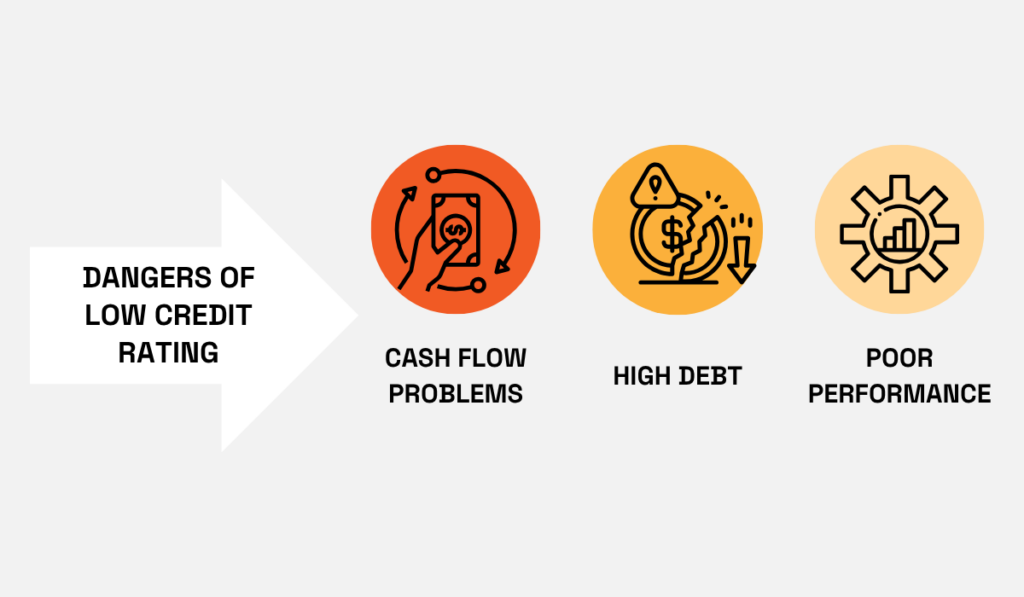

When conducting financial stability checks, start with the supplier’s credit rating.

It’s one of the clearest early indicators of cash flow problems, high debt levels, or operational instability.

Source: Veridion

Next, request audited financial statements for the past three years, reviewing solvency ratios, liquidity, and debt exposure. Public companies are required to publish this data, while private firms can often provide it under an NDA.

National tax services or platforms like Creditsafe can also help you check for unpaid taxes, liens, or bankruptcies.

However, don’t underestimate the value of references and word-of-mouth.

As entrepreneur David Hernandez notes, word travels fast, and a poor financial reputation is rarely a secret, especially in specialist industries.

Illustration: Veridion / Quote: LinkedIn

Finally, make sure to run regular financial health reviews for larger or business-critical suppliers.

Otherwise, their bad finances can quickly become your problem too.

Even a well-funded, legitimate supplier can become a serious liability if they can’t meet your volume and lead time requirements.

Competitive bidding tends to amplify these issues, with suppliers frequently overpromising production or service levels to win contracts.

The only possible outcome in these cases? Delivery failures and operational disruptions.

A clear example of this happened with the U.S. school bus contractor Zum in Howard County, Maryland, when mass bus shortages left students stranded and both parents and schools scrambling for a solution.

A 100+ page audit uncovered three core issues: chronic staff shortages, missed deadlines, and—most critically—the supplier’s overconfidence in their operational capacity:

Illustration: Veridion / Quote: WMAR 2 News

Now imagine what a similar breakdown would look like in a production context: incomplete orders, missed launch windows, stockouts, and eroded customer trust.

To avoid this, your procurement team needs more than supplier claims.

In other words, you need standardized, verifiable data on production capacity, facility count, and output limitations.

That means checking and ascertaining several things, including:

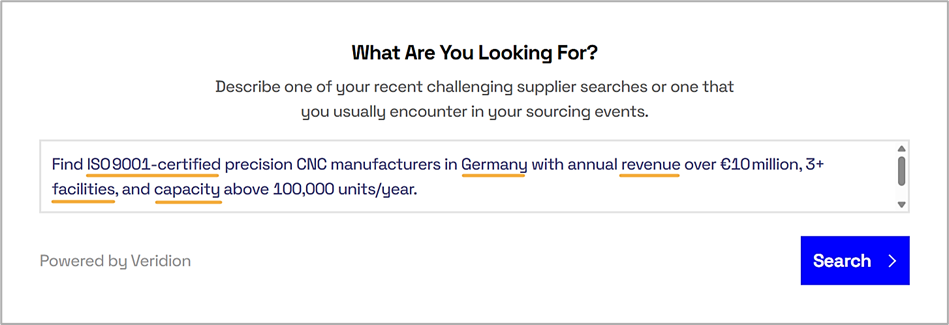

Platforms like Veridion simplify this by enabling you to filter suppliers by metrics such as facility count, number of employees, output capacity, and location.

Source: Veridion

That’s right: You can pose a single, natural language query and get integrated results instantly.

But regardless of whether you’re using advanced tools or more traditional methods, the most important thing is to quickly separate those who can deliver from those who can’t.

It’s not enough for suppliers to claim a production capacity of X units per month—you need to confirm whether their facilities can actually support those numbers.

Inadequate infrastructure and operational setup will inevitably impact your supplier’s ability to fulfill orders.

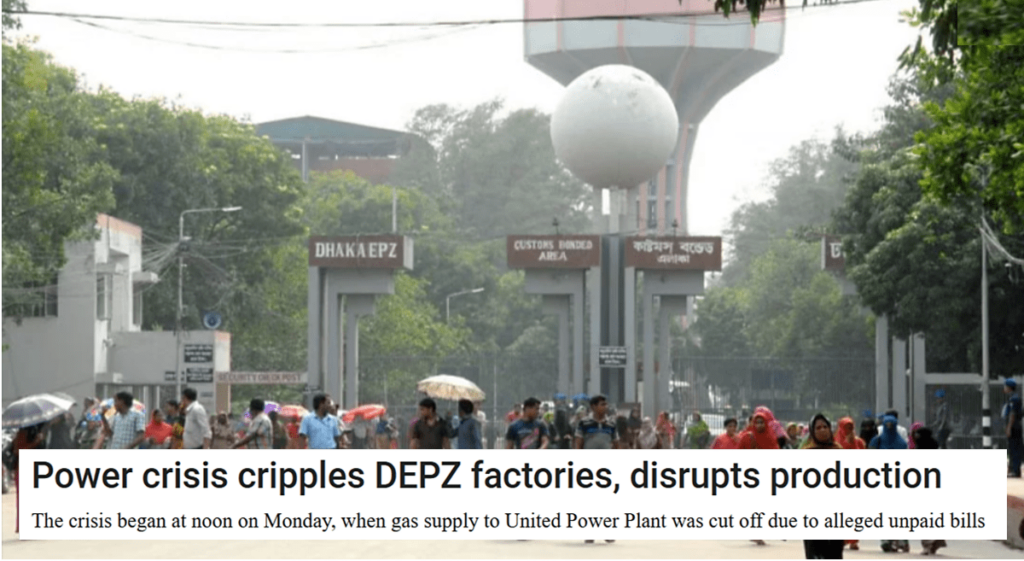

The 2024 power crisis in the Dhaka Export Processing Zone (DEPZ) is one telling example.

Extended regional outages, reportedly tied to longstanding grid instability but also unpaid electricity bills, forced multiple factories to halt production, creating severe supply chain bottlenecks.

Source: Dhaka Tribune

Regardless of the immediate cause, the incident exposed how vulnerable single-site operations without proper contingency plans can be.

And buyers who hadn’t reviewed power backup arrangements or demanded proof of installed generators quickly saw their supply chains grind to a halt.

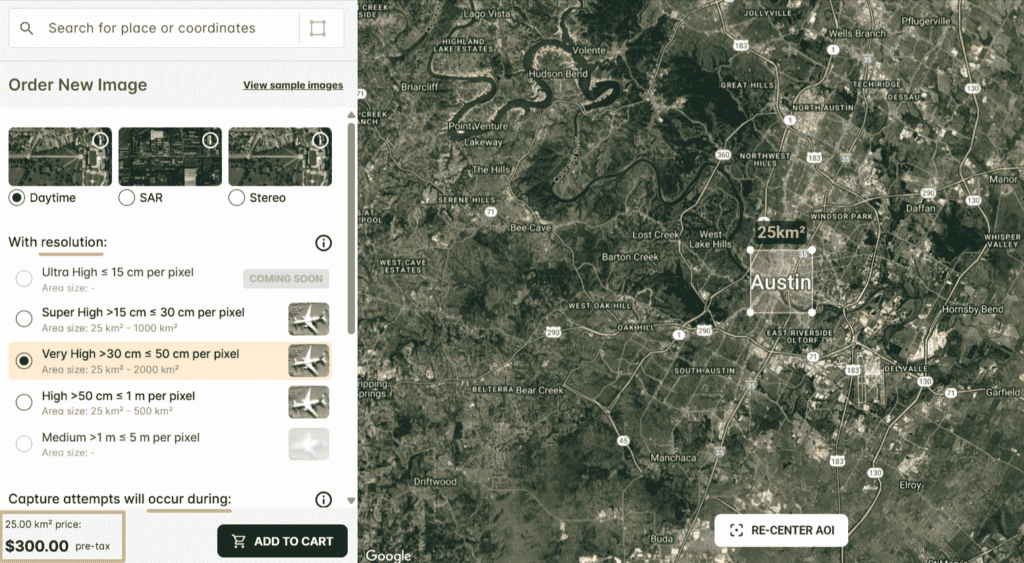

To avoid this, procurement teams should always request third-party audit reports, ask about power redundancy systems, and check the facility’s physical layout through satellite imagery services like SkyFi.

Source: SkyFi

While detailed, up-to-date commercial imagery is typically a paid option, free tools like Google Earth can still give useful early insight into factory size, location, and surrounding infrastructure.

Still, on-site factory visits remain one of the most effective ways to assess a supplier’s operational readiness.

When touring the facility, you can verify the extent of automation versus manual labor, especially around quality control processes.

As Steven Kirz, former managing director at Pace Harmon, points out, you should also use this opportunity to meet the proposed delivery team, not just executives.

Illustration: Veridion / Quote: ISM

After all, the team that’ll deliver your orders is in the best position to demonstrate how their facility can support your program and provide insight into key technologies.

Plus, you’re assessing both their capabilities and compatibility with your organization as a whole.

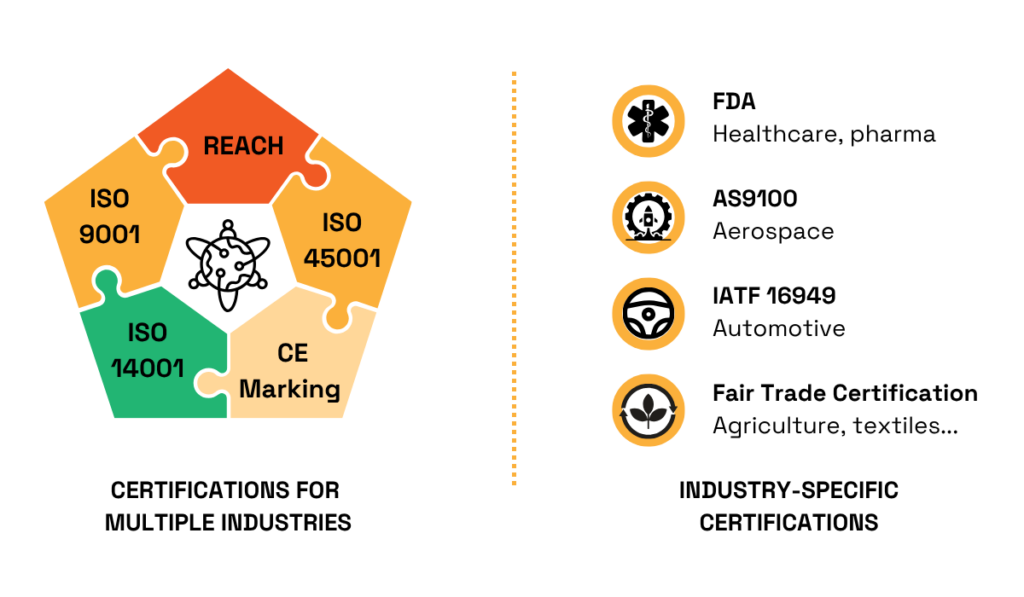

Valid, up-to-date certifications confirm that a supplier meets essential quality, safety, and regulatory standards, which makes them non-negotiable in supplier selection.

Depending on your industry, this might include broad frameworks, such as ISO 9001 for quality management systems, or sector-specific standards like AS9100 for the aerospace context.

Source: Veridion

Yet, suppliers skip or misrepresent certifications more often than you might think.

Sometimes it’s down to high costs or slow bureaucracy, but occasionally, they’ll falsely claim compliance.

Consider a scenario where a production department provides detailed technical specs for a new component but doesn’t specify mandatory certifications for selling in certain markets.

Procurement proceeds to select a technically capable supplier, and this new partner even invests in new equipment.

But by the time the first sample arrives, it becomes clear that the supplier doesn’t have the required certifications, forcing the company to either:

Both options are expensive and time-consuming, so how do you avoid this?

For starters, even a basic check using tools like IAF CertSearch can help verify accreditation status.

Source: IAF CertSearch

However, keep in mind that this is just one mechanism.

There’s a high chance you won’t find the certificate or certifying body there, and some suppliers may purposefully employ fraudulent tactics, using misleading links or fake certifications.

That’s why IKEA’s Stefano Bizioli Galli urges a meticulous approach, both during initial screenings and subsequent supplier audits.

Illustration: Veridion / Quote: IKEA

It’s this kind of continuous oversight that helps any business stay ahead of compliance risks and avoid costly surprises down the line, and it’s sure to benefit you as well.

Environmental, social, and governance (ESG) standards are a business-critical expectation in supplier selection.

Buyers now need to investigate everything from ethical sourcing practices and labor standards to environmental violations and community impact.

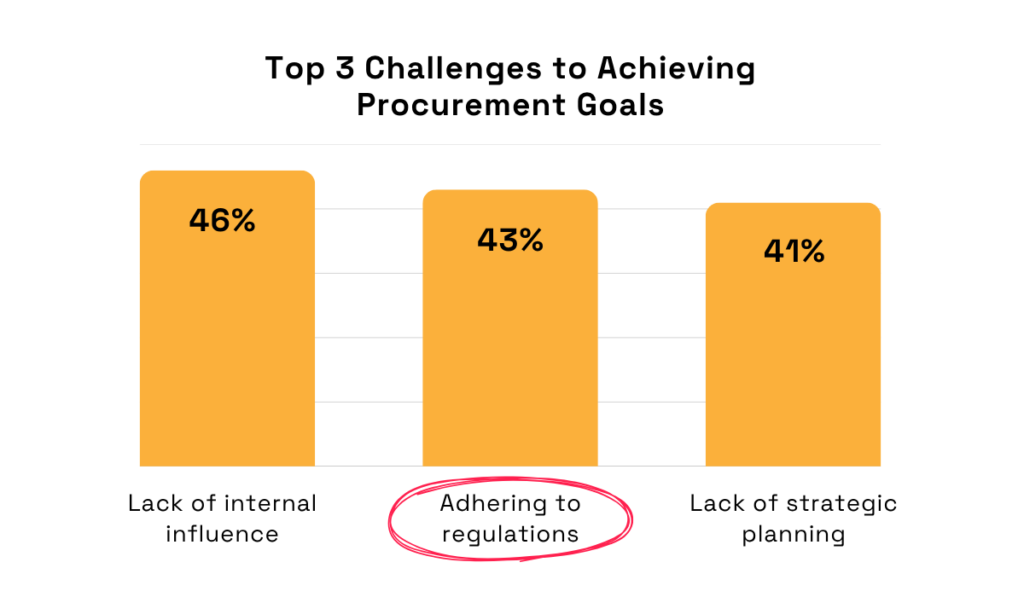

According to Procureability, 43% of professionals cite regulatory adherence as one of the top procurement issues preventing them from achieving goals.

Illustration: Veridion / Data: Procureability

And that figure doesn’t even cover the increasingly complex ESG reporting landscape.

As Stephen Tonks, Former Chief Supply Chain Officer at Fujikura Automotive Europe, explains:

“Eighty to ninety percent of regulations are Scope 3 focused, and it is down to procurement to collect the required data and present it to the rest of the organization”.

Even beyond emissions, tangled global supply chains complicate sourcing efforts and make it difficult to maintain transparency and standards throughout the partnership.

Following a PETA investigation into animal abuse in its supply chain, Gucci is facing a major reputational hit, as well as a major class-action lawsuit in the U.S.

Source: Forbes

Regardless of Gucci’s knowledge of these issues, it’s important to note that the problematic practices were documented among suppliers from the Asia-Pacific region, where labor and animal welfare regulations often differ from Western markets.

This regional disparity in ethical and environmental standards adds another layer of complexity for global procurement teams.

As Adam Brennan, Chief Sustainability & Communications Officer at Thai Union, points out, regional differences create inconsistent supply chain conditions and make it difficult for buyers to verify practices.

Illustration: Veridion / Quote: World Economic Forum

In other words, without standardized, transparent reporting mechanisms, these risks remain difficult to detect until the damage is already done.

That’s why Brennan and many other supply chain leaders advocate for scalable ESG monitoring tools capable of consolidating supplier data and flagging risk indicators early, no matter the region.

Ultimately, proactive oversight is a key element that separates resilient procurement strategies from reactive ones, protecting both operational continuity and brand reputation.

Even the most carefully constructed supplier selection process can quickly unravel if it’s built on outdated, incomplete, or unverifiable information.

In many organizations, procurement teams rely on patchy directories, static spreadsheets, or supplier-provided data that hasn’t been properly validated—a perfect storm with wide-reaching consequences.

Let’s say you’ve onboarded a supplier based on 2022 company records.

Production commitments were made, purchase orders issued, but what you don’t yet know is that by 2025, the supplier had changed ownership and quietly ceased key operations.

The moment all this comes to light is when the deadlines have already started slipping.

It’s a scenario procurement leaders know well and work to counter it.

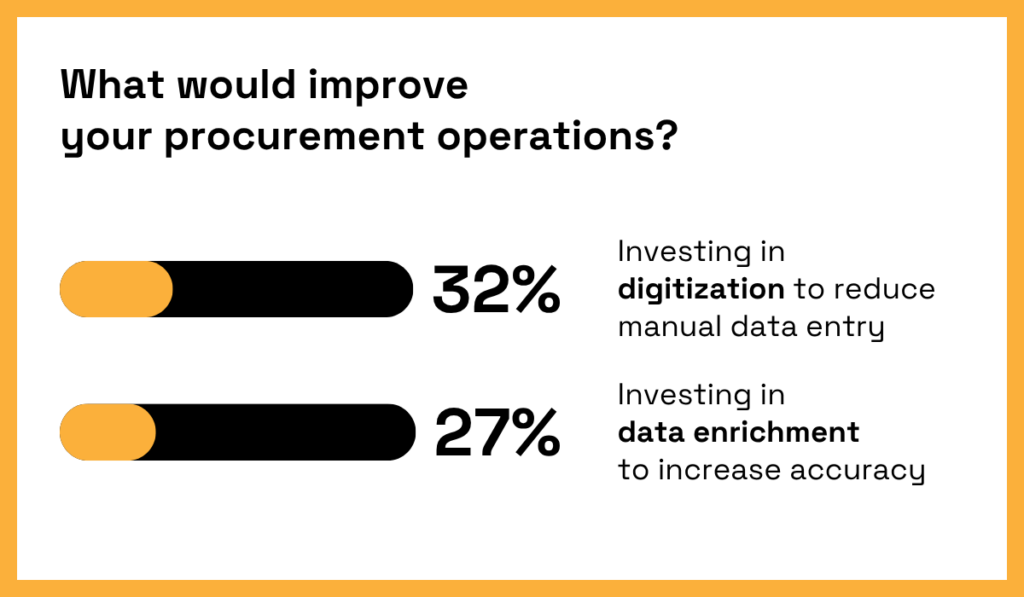

According to TealBook, procurement professionals cite digitization and data enrichment as the two most effective strategies for boosting procurement efficiency and resilience.

Illustration: Veridion / Data: TealBook

Automation and real-time supplier intelligence have become indispensable in modern procurement.

Technologies that automate data collection, such as AI-powered scraping tools and supplier onboarding platforms, are essential for reducing manual workload.

But while these tools address efficiency, they don’t automatically guarantee data accuracy or provide visibility beyond what suppliers choose to disclose.

To put it differently, automation still requires reliable, clean data that drives the best possible supplier decisions.

William Bagley, Chief Procurement Officer at Freddie Mac, agrees wholeheartedly, putting the role of data on par with processes and tools.

Illustration: Veridion / Quote: World Economic Forum

The real procurement advantage comes from combining automation with verified, external intelligence—and that’s where Veridion stands out.

Our AI-driven platform continuously aggregates, verifies, and updates supplier data from an expansive global network of nearly 130 million suppliers.

Source: Veridion

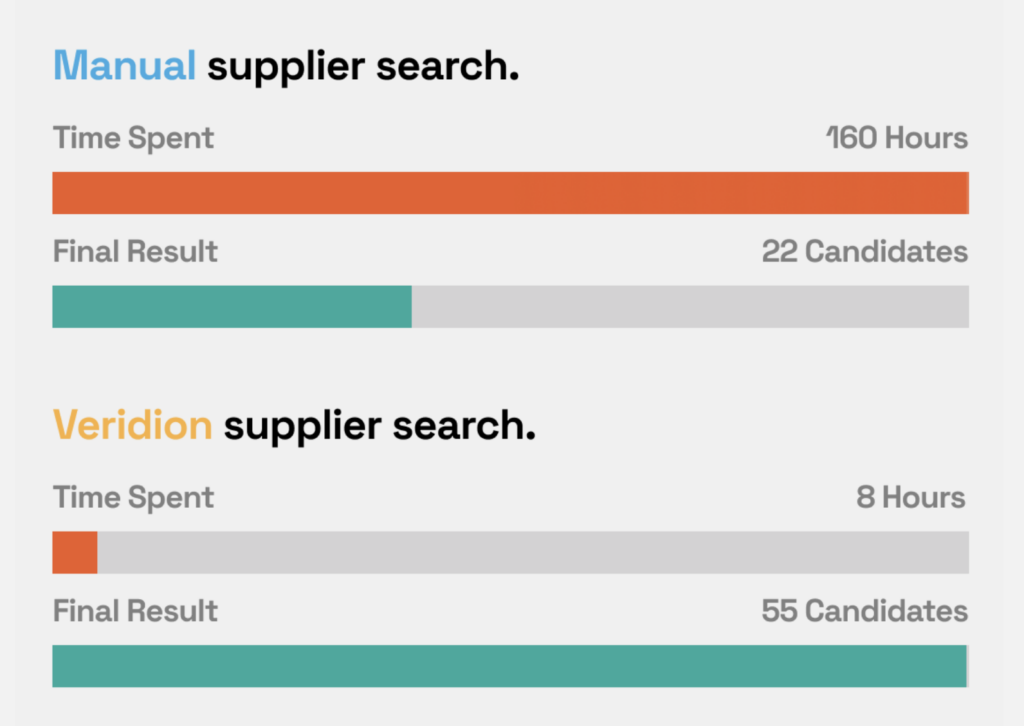

With Scout Supplier Discovery, you won’t have to spend hours digging through outdated directories or relying on self-reported figures—your procurement team can instantly access accurate, real-time profiles on suppliers worldwide.

Veridion’s platform allows you to filter candidates with precision, down to specific product categories, service capabilities, and compliance credentials.

Not only are you better equipped to identify ideal suppliers for your needs, but you can do so in a fraction of the usual time.

Source: Veridion

It’s faster, broader, deeper, and far more reliable.

Beyond discovery, extensive TPRM data and monitoring tools help you track supplier changes as they happen, ensuring your supplier data stays current and actionable.

While real-time supplier intelligence may not be essential for every organization, having accurate, up-to-date supplier data is crucial for transforming procurement from a reactive process into a proactive, strategic function.

The fastest way to lose control of your supply chain is by onboarding unreliable and noncompliant suppliers.

Rushing supplier selection without proper checks invites costly disruptions to your time, budget, and brand reputation.

On the other hand, conducting rigorous checks on legal standing, financial health, production capacity, and more shields your business from avoidable risks.

But here’s the bottom line: reliable data isn’t just valuable—it’s essential.

Want to stay one step ahead and safeguard your supply chain with confidence?

Then it’s time to harness advanced, tech-driven platforms and start prioritizing supplier intelligence.